Acid liquor friction reducer and preparation method thereof

A technology of drag reducer and acid solution, which is applied in the direction of chemical instruments and methods, drilling compositions, etc. It can solve the problems of poor acid resistance, formation damage, temperature limitation of drag reducer, etc., and achieve temperature resistance and compatibility Good, prolonging the service life and reducing the pump pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1 acid liquid drag reducing agent BC-131

[0022] (1) Purification of acrylamide (AM) for use;

[0023] (2) Weigh the monomer 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in a beaker, add 70 ml of deionized water to dissolve, wherein the mass concentration of AMPS is 14.56%, and then add flake alkali to make the system pH adjusted to 9;

[0024] (3) Adding monomer acrylamide (AM) and long-chain cationic monomer (C) to the solution prepared in step (2) X DMAAC), the long-chain cationic monomer is a polyalkyldimethylallyl ammonium chloride cationic monomer, where X=14~20, the purchaser is Chengdu Baichun Petroleum Technology Co., Ltd., and the mass ratio of each monomer is AM:AMPS:C X DMAAC=1:1:0.06, then add deionized water to prepare an aqueous solution with a total monomer mass concentration of 30%;

[0025] (4) Add the monomer aqueous solution prepared in step (3) into the wide-mouthed bottle, shake well, and tightly cover the wid...

Embodiment 2

[0027] Example 2 Effect Evaluation

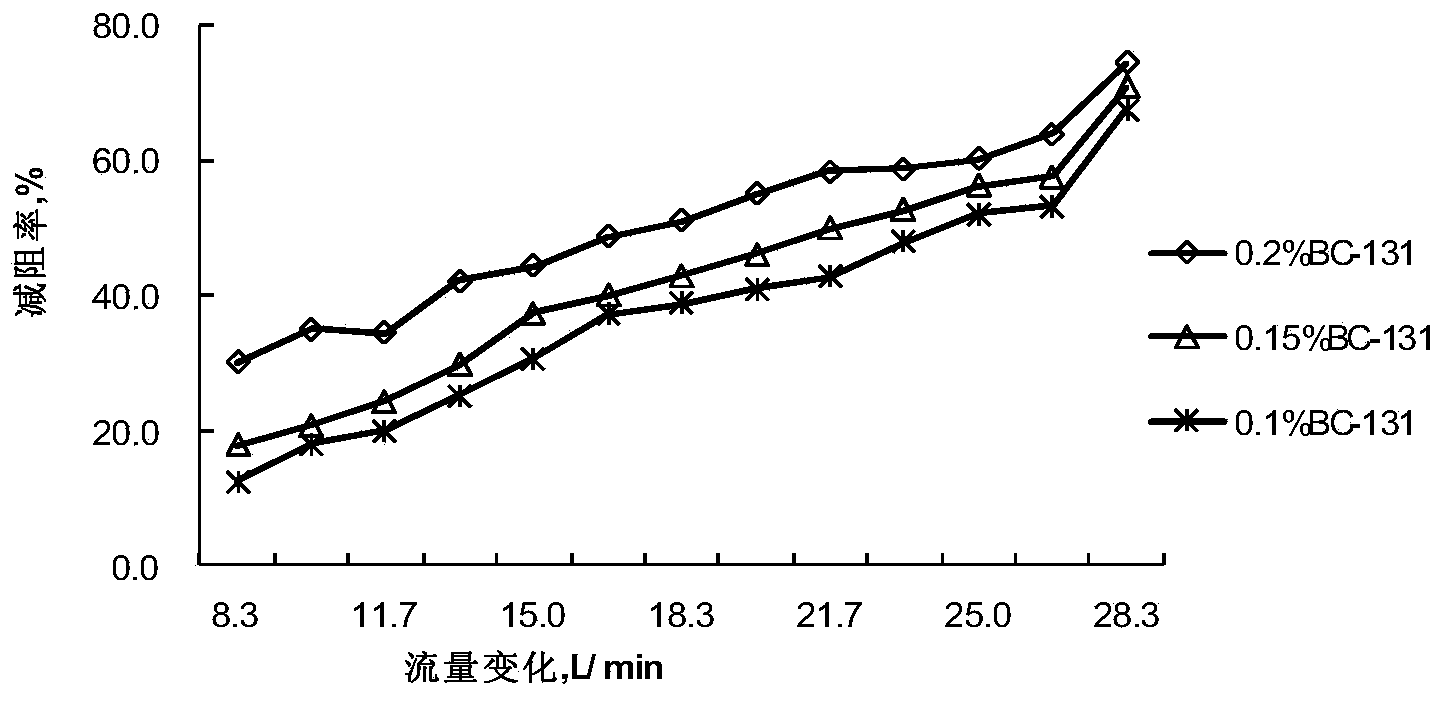

[0028] Use the flow loop friction test system to carry out the friction resistance test on the acid liquid drag reducer BC-131 prepared in Example 1, and compare it with the 12% (wt) blank acid, add it to the 12% (wt) acid The acid liquid drag reducer BC-131 prepared in Example 1 has a mass concentration of 0.1% (w / v). Select a 6mm pipeline for testing, record the frictional pressure drop after passing through the pipeline to calculate the drag reduction rate, and evaluate the drag reduction effect of the acid liquid drag reducer according to the size of the drag reduction rate. The relationship between the drag reduction rate and the flow rate is as follows: figure 1 , the maximum drag reduction rate can reach 65%.

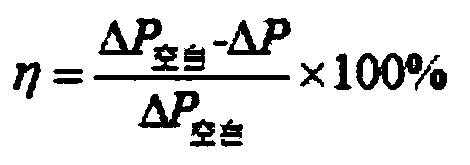

[0029] Drag reduction rate calculation:

[0030]

[0031] In the formula: η----drag reduction rate, %;

[0032] ΔP 空白 ----The pressure difference when the blank acid passes through the test pipeline, MPa;

[0033] ΔP--...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com