Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Good resistance reduction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

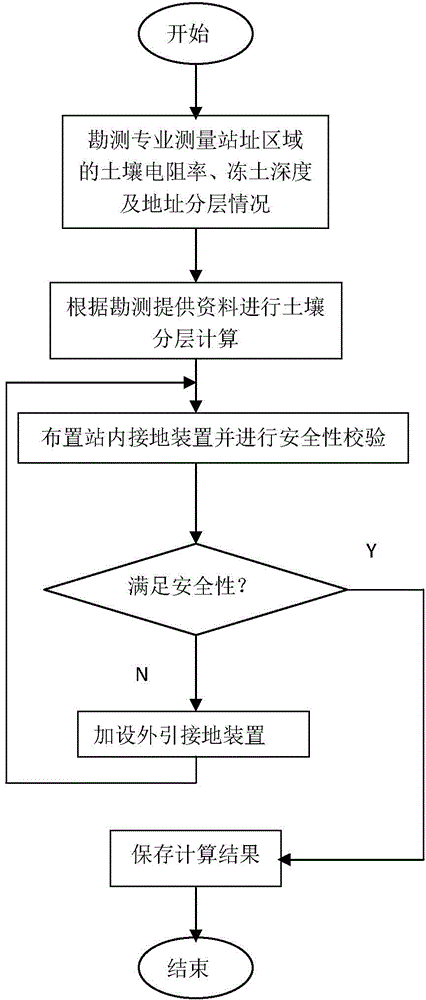

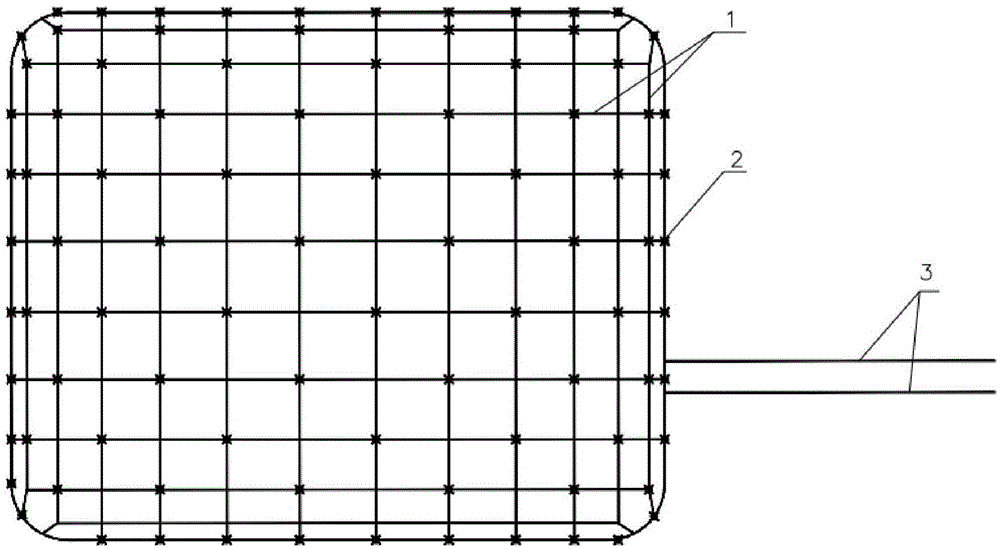

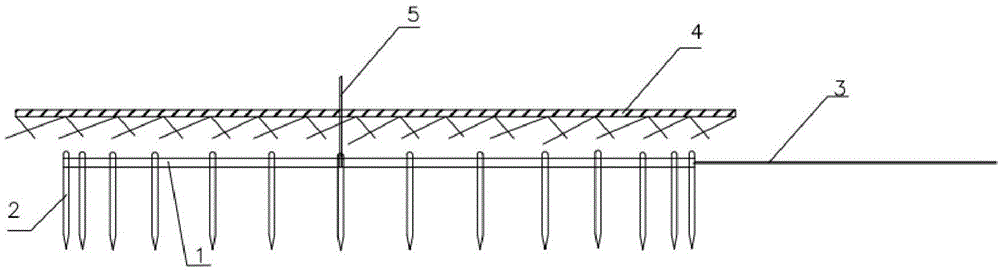

Construction method of resistance reduction and grounding device of transformer station

ActiveCN104901030ASolve problems that cannot meet technical requirementsMeet the needs of safe operationLine/current collector detailsConnection contact member materialSoil scienceSoil depth

The invention, which belongs to the technical field of the electrical power engineering, particularly relates to a construction method of a resistance reduction and grounding device of a transformer station. The method comprises: a surveyor measures a soil resistivity, a frozen soil depth, and a soil layering situation in a site area of a transformer station to obtain surveying data; a soil model is established according to the surveying data; on the basis of the soil model, a grounding device inside the station is designed in the site area of the transformer station; safety verification is carried out on the grounding device designed at the last step so as to obtain a verification result; if the verification result meets the requirement, a next step is executed; if the verification result does not meet the requirement, a grounding device is arranged externally outside the site area of the transformer station and safety verification is carried out; the verification result is stored; a construction drawing is drawn; and construction is carried out by organizing people. Under the circumstances that no extra collected land is increased, the construction method of the resistance reduction and grounding device of the transformer station is provided. The construction method has characteristics of obvious resistance reduction effect, simple structure, convenient construction, and low cost and the like.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD +1

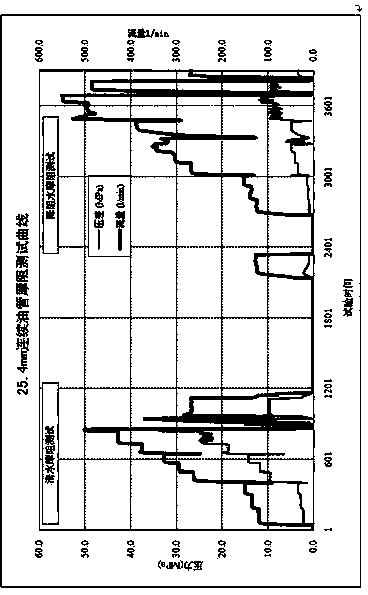

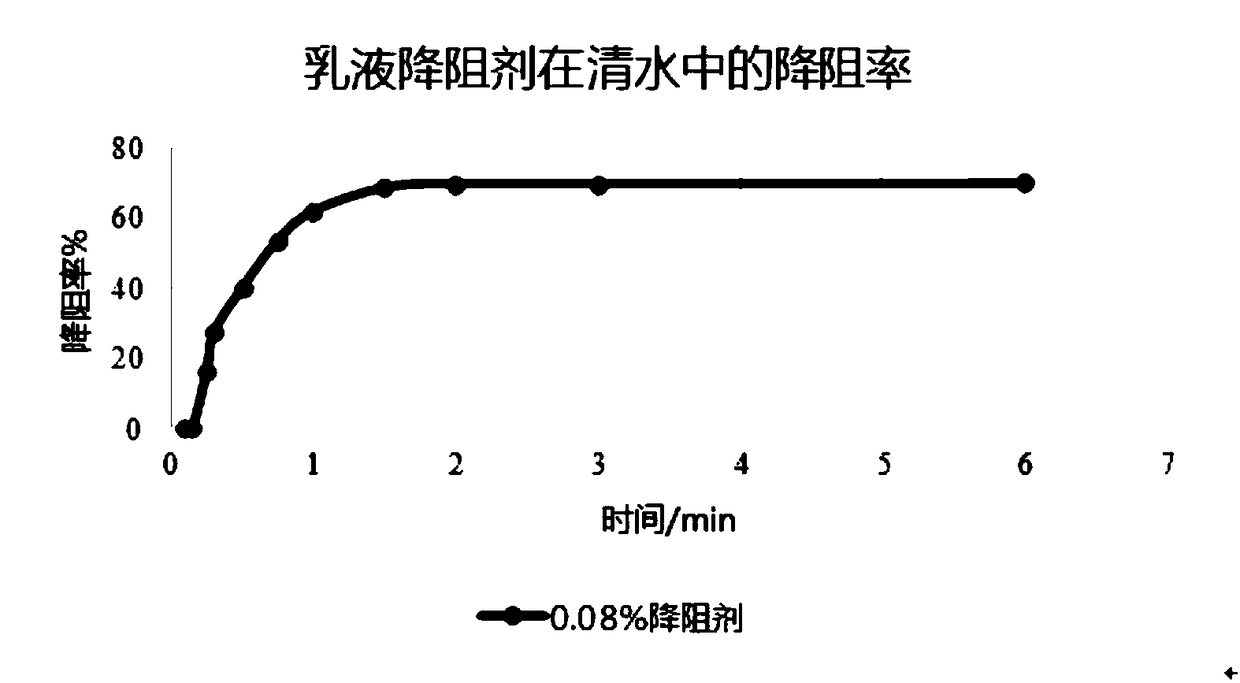

Inverse emulsion drag reduction agent for fracturing shale gas by using quick water and preparation method thereof

ActiveCN103881693AImprove structural stabilityGood drag reduction effectDrilling compositionFracturing fluidSodium hydrogen sulphite

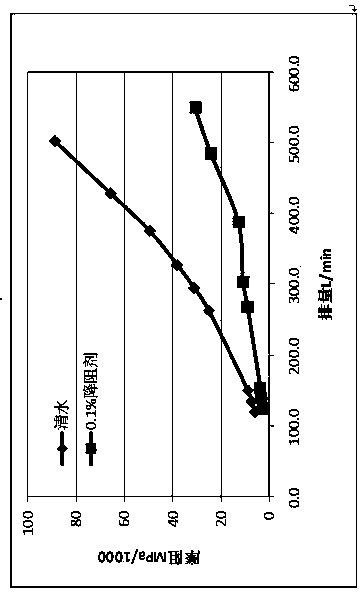

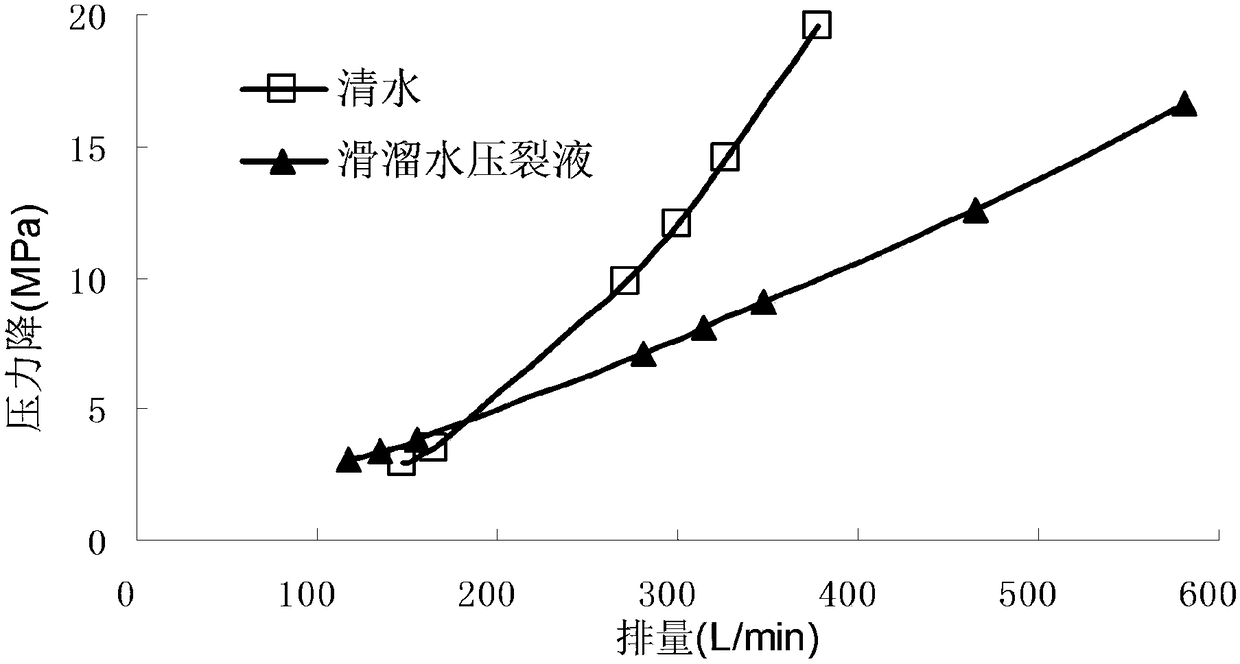

The invention discloses an inverse emulsion drag reduction agent for fracturing a shale gas by using quick water and a preparation method thereof, and relates to the technical field of petroleum engineering. The inverse emulsion drag reduction agent is a macromolecular water soluble polymer which is prepared from acrylamide, sodium acrylate and dodecyl methacrylate copolymerized in an inverse emulsion, and azo diisobutyl hydrochloride and sodium hydrogen sulfite as complex initiation systems. A long-chain hydrophobic monomer is introduced into the drag reduction agent, so that the shear resistance of the drag reduction agent in a high displacement pump injection process is improved, meanwhile, the drag reduction agent is prepared from the inverse emulsion in a polymerization manner, the product is a liquor and instant, the liquor demands of a continuous mixed construction technology for fracturing the shale gas are met, the dosage for field use is 0.06-0.8% of mass of clean water, and the drag reduction rate can be up to 73%.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Long-acting antiseptic resistance-reducing agent

ActiveCN101882477AIncrease stickinessCompact structureConductive materialNon-conductive material with dispersed conductive materialSodium BentoniteEngineering

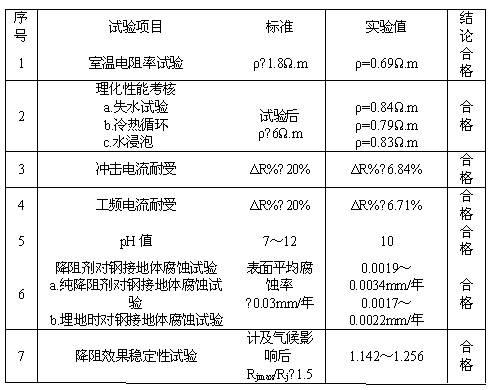

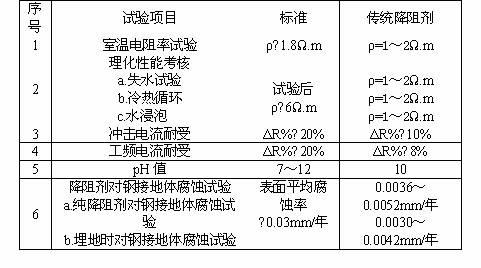

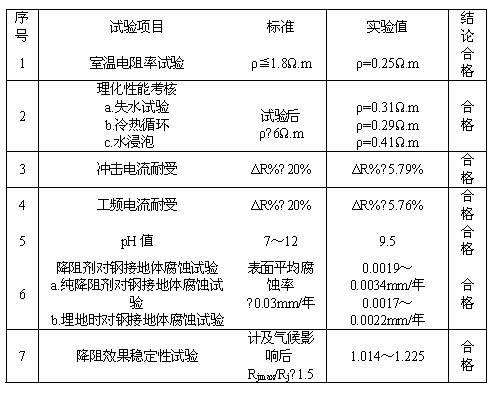

The invention relates to a long-acting antiseptic resistance-reducing agent for protecting a grounding device to normally run. The resistance-reducing agent is formed by mixing 35-70 percent by weight of bentonite and 30-65 percent by weight of petroleum coke. The resistance-reducing agent has the advantages of higher viscosity, compact structure, less influence by climatic factor due to difficult loss along with rain water on the basis of sufficient permeability, long-acting performance, obvious resistance-reducing effect, good antiseptic effect, no toxic element and no pollution to the environment.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

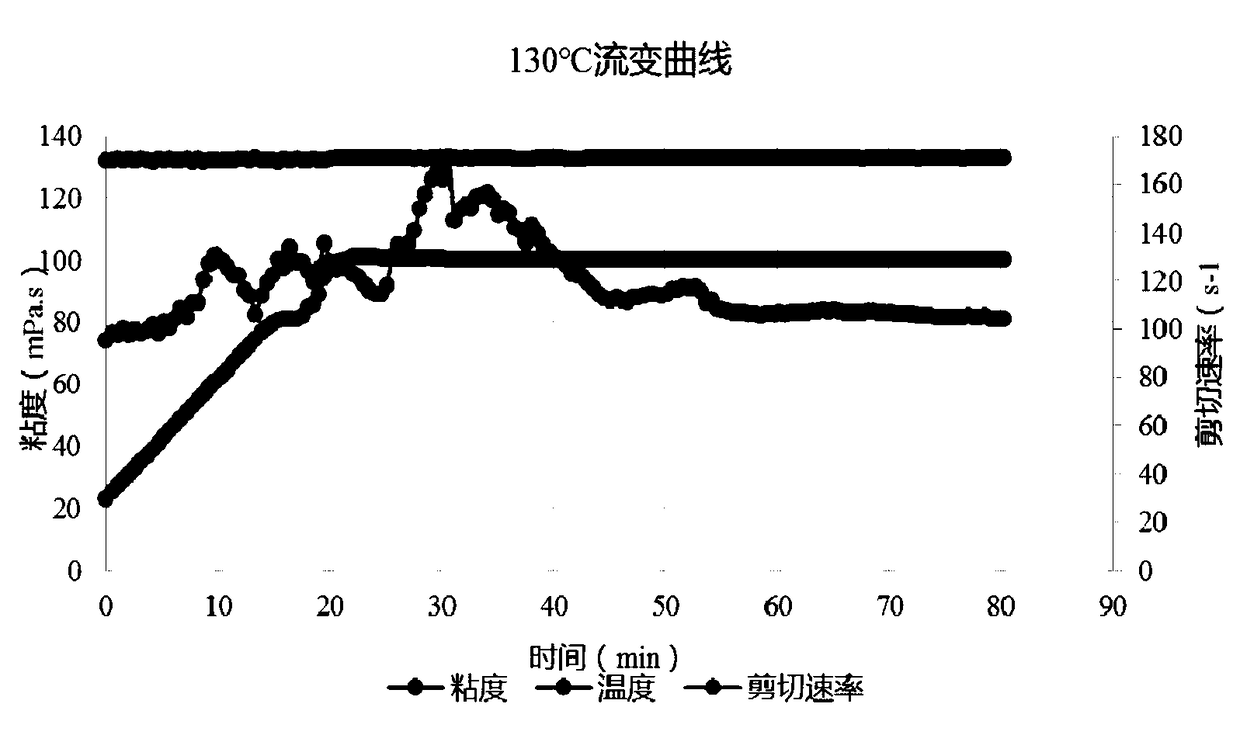

Inverse-phase micro-emulsion polymer fracturing fluid system with online construction function

ActiveCN108559479AGood resistance reduction effectEasy to reuseDrilling compositionMethacrylatePolymer science

The invention discloses an inverse-phase micro-emulsion polymer fracturing fluid system with an online construction function. The inverse-phase micro-emulsion polymer fracturing fluid system comprisesinstant dissolving emulsion thickening agents, functional auxiliaries, a clay stabilizer and fluid preparation water. The instant dissolving emulsion thickening agents are inverse-phase micro-emulsion polymers, and inverse-phase micro-emulsion polymerization is carried out on raw materials including acrylamide, acrylic acid, strong-hydrophilicity monomers, a functional monomer A, a functional monomer B, pH (potential of hydrogen) regulators, solubilizers, composite emulsifiers, oil solvents, initiators and deionized water to obtain the instant dissolving emulsion thickening agents; the functional monomer A is methyl methacrylate or ethyl methacrylate or a mixture of the methyl methacrylate and the ethyl methacrylate; the functional monomer B is vinylphosphonic acid or vinyl sulfonic acid;the functional auxiliaries are non-ionic surfactants; the clay stabilizer is potassium chloride, and the fluid preparation water is clear water or high-mineralization water or treated stratum flow-back fluid. The inverse-phase micro-emulsion polymer fracturing fluid system has the advantages that the inverse-phase micro-emulsion polymer fracturing fluid system is high in dispersing and swelling speed and can be prepared in a batch manner or can be continuously mixed, 'online construction' requirements even can be completely met by the inverse-phase micro-emulsion polymer fracturing fluid system, processes for constructing the inverse-phase micro-emulsion polymer fracturing fluid system are simple, and the fracturing cost can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

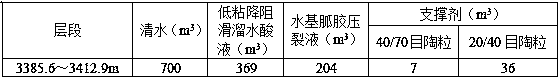

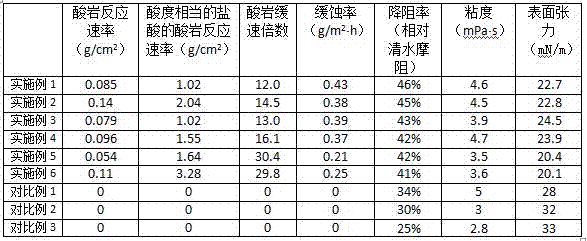

Method for volume acid-fracturing reformation of seam net of carbonate reservoir

InactiveCN107216866AGood resistance reduction effectImprove responseFluid removalDrilling compositionWater basedSodium ascorbate

The invention provides a method for volume acid-fracturing reformation of a seam net of a carbonate reservoir. The method specifically comprises the following steps: (1) injecting low-viscose resistance-reducing sliding acid liquor, performing plunger injection for at least three times and performing volume fracturing reformation of the seam net; (2) injecting a water-based sand-carrying fracturing fluid and forming sand-filling cracks in length not less than 120 meters on the two sides of a well shaft; (3) injecting a displacement fluid, closing the well and then draining the liquid, wherein the low-viscose resistance-reducing sliding acid liquor is composed of 5-20% of acid, 1-3% of alkyl quaternary ammonium salt, 0.5-2% of sodium ascorbate, 0.1-0.5% of emulsion corrosion inhibitor, 0.5-1% of citric acid, 1-3% of discharge aiding agent and the balance of water; the emulsion corrosion inhibitor is selected from any one of polypropylene glycol emulsion, polyvinylpyrrolidone emulsion, acrylamide and 2-crylic acid-2-methallyl sulfonate copolymer emulsion; and the acid is selected from hydrochloric acid, formic acid, acetic acid or bionic acid. The method is simple in construction, the flow conductivity of the seam net is high and the yield-increasing effect is excellent.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

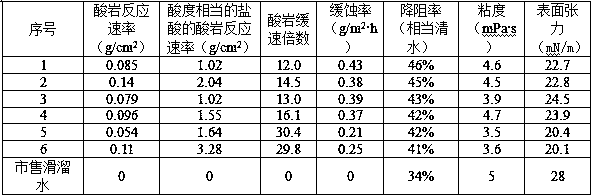

Low-viscidity drag-reduction slick water acid liquid for carbonate reservoir bed

InactiveCN107216867ASlow reaction rateAvoid the danger of deformationFluid removalDrilling compositionSodium ascorbateReaction rate

The invention provides a low-viscidity drag-reduction slick water acid liquid for a carbonate reservoir bed, which contains the following raw materials in percentage by weight: 5-20% of an acid, 1-3% of an alkyl quaternary ammonium salt, 0.5-2% of sodium ascorbate, 0.1-0.5% of an emulsion corrosion retarder, 0.5-1% of citric acid, 1-3% of a discharge aiding agent, and the balance of water, wherein the emulsion corrosion retarder is any one of polypropylene emulsion, polyvinylpyrrolidone emulsion and 2-acrylamido-2-methylpropanesulfonic acid-acrylic acid copolymer emulsion; the acid is any one of hydrochloric acid, formic acid, acetic acid or a bionic acid. The low-viscidity drag-reduction slick water acid liquid provided by the invention has low acid-rock reaction rate and good drag-reduction effect, and can reduce fracture acidizing construction wellhead pressure, so that the slot volume crack wall surface suffers from uniform acid corrosion all along, and the crack system around a well casing is more developed, which is helpful for yield increase. The low-viscidity drag-reduction slick water acid liquid has good corrosion inhibition effect, and can realize on-site large displacement construction.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

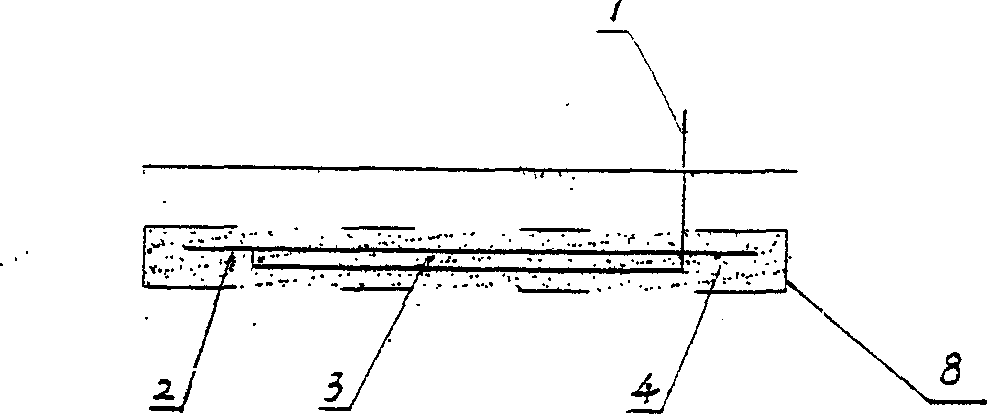

Novel grounded resistance-reducing agent and novel grounded resistance-reducing module

InactiveCN101841086APrevent penetrationPrevent oxidation and corrosionOrganic fertilisersCarbon-silicon compound conductorsAdhesiveConductive materials

The invention provides a novel grounded resistance-reducing agent and a novel grounded resistance-reducing module, which are characterized in that a non-metallic conductive material in the novel grounded resistance-reducing agent and the novel grounded resistance-reducing module is microcrystalline graphite. The novel grounded resistance-reducing agent mainly comprises the non-metallic conductive material namely the microcrystalline graphite and an alkaline gelling material; and the novel grounded resistance-reducing module mainly comprises the non-metallic conductive material namely the microcrystalline graphite, an adhesive and a metal component. An attached drawing is an abridged general view of the novel grounded resistance-reducing module, wherein 1 is a resistance-reducing module, and 2 is an extended part of the metal component. The novel grounded resistance-reducing agent and the novel grounded resistance-reducing module have low electrical resistivity, are long-acting, stable, nontoxic and harmless, can be suitable for meeting requirements on long-acting ground protection of an electrical appliance and a building under the conditions of various atrocious climates and various geologic environments, have low production costs, are simple and convenient to implement, have abundant raw material sources, and are ideal grounded conducting materials.

Owner:任涤权

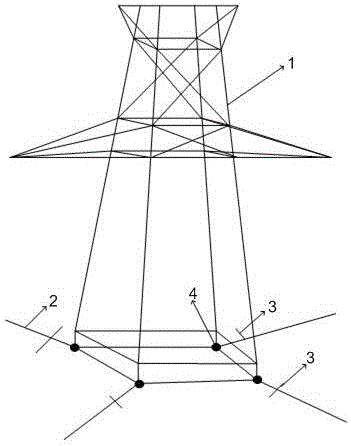

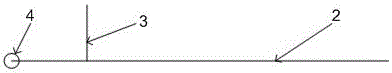

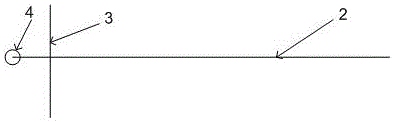

Device and method for reducing grounding resistance of grounding grid

InactiveCN106451030AEasy breakdownGood resistance reduction effectCoupling device engaging/disengagingGrounding gridElectrical resistance and conductance

The invention discloses a device for reducing grounding resistance of grounding grid. The device comprises at least one horizontal grounding conductor which is fixed at the bottom of the tower. The horizontal grounding conductor is provided with at least one spark thorn conductor which is fixed between the middle part of the horizontal grounding conductor and the impingement current injection point of the horizontal grounding conductor. By setting the spark thron conductor at the front middle of the impingement current injection point near the horizontal grounding conductor, a large part of the current flow of the injection point will flow to the spark thorn conductor, so that the equivalent radius of the spark effect of the spark conductor is enlarged, the soil is more prone to breakdown, and the spark effect is very significant, which, at the same time, has a great influence on the current distribution of the horizontal grounding conductor, so that the resistance value of the grounding resistance is reduced, and the resistance reduction effect is remarkable.

Owner:DATONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +1

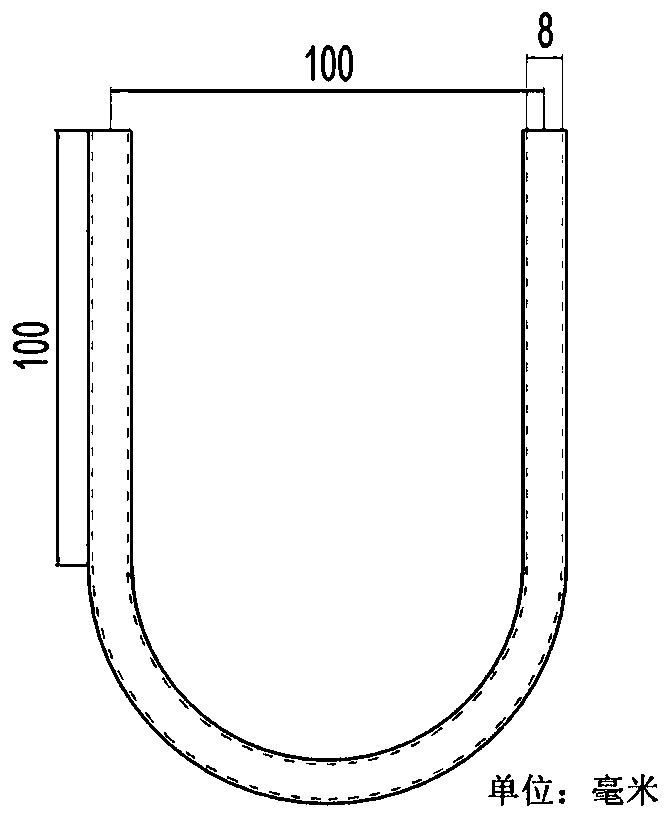

Preparation method of super-wetting coating on inner surface of U-shaped titanium tube

PendingCN110552042AImprove hydrophobicitySimple preparation processSurface reaction electrolytic coatingTio2 nanotubeTitanium

The invention relates to the field of preparation of an inner surface coating and fluid resistance reduction of a special-shaped tube, in particular to a preparation method of a super-wetting (super-hydrophilic or super-hydrophobic) coating suitable for the inner surface of a U-shaped titanium tube. When the special-shaped tube is used for transferring fluid, the fluid generates a large pressure loss in the bent portion. The super-hydrophobic coating is prepared on the inner surface of the special-shaped tube, so that resistance and energy loss are obviously reduced, and the purpose of reducing the resistance during fluid transmission is achieved. A titanium oxide nanotube array coating is uniformly prepared on the inner surface of the U-shaped titanium tube by taking the U-shaped titaniumtube as a raw material and adopting a coaxial anodic oxidation method suitable for the U-shaped tube, so that the purpose of modifying the super-wetting coating on the inner surface of the U-shaped titanium tube is achieved. The preparation method has the advantages of being simple to operate, wide in application range, high in practicability, low in cost and the like, and can be widely applied to the fields of fluid resistance reduction of the special-shaped tube and the like.

Owner:CHONGQING UNIV

Corrosion-resistant and resistance-reduction conductive concrete for acid soil areas

ActiveCN104556856AImprove conductivityImprove anti-corrosion performanceSolid waste managementSuccinic acidSolvent

The invention relates to the field of conductive concrete and particularly relates to corrosion-resistant and resistance-reduction conductive concrete for acid soil areas. The corrosion-resistant and resistance-reduction conductive concrete is prepared from the following raw materials: cement, polyaniline and a filler, wherein the polyaniline is composed of the following components in parts by weight: 20-40 parts of aniline, 5-15 parts of acidic catalyst, 30-40 parts of oxidant and 3-20 parts of solvent; the filler is one or more of sand, stone, fly ash and grey stone; the acidic catalyst is one or more of hydrochloric acid, phosphoric acid, picric acid, dodecylbenzene sulfonic acid, dinonylnaphthalenesulfonic acid sol and succinic acid dioctyl phthalate sulfonic acid; the oxidant is one or more of persulfate ammonium, potassium dichromate, hydrogen peroxide, potassium iodate and potassium permanganate; the solvent is one or more of water, ethanol and ethyl acetate; when applied to a transmission line grounding grid, the conductive concrete provided by the invention can be used for not only reducing the grounding resistance, but also improving the corrosion resistance of a grounding electrode, especially in an acidic corrosive soil environment.

Owner:NANCHONG POWER SUPPLY COMPANY STATE GRID SICHUANELECTRIC POWER +1

Solid grounding resistance-reducing agent and method for preparing the same

InactiveCN1542079AGood resistance reductionImprove conductivityOther chemical processesSodium BentoniteGrounding resistance

The present invention relates to low-resistivity earthing agent, and is especially one kind of solid low-resistivity earthing agent with flyash as main material and its preparation process. The solid low-resistivity earthing agent is prepared with flyash as well as additives including bentonite, graphite and hydrated lime and through mixing. Using flyash as main material can reduce environmental pollution and lower cost. The solid low-resistivity earthing agent is superior to available marketable similar product and has resistivity not higher than 0.5 ohm.m, no toxicity, no pollution, no corrosion, compact structure and stable performance. The solid low-resistivity earthing agent may be used widely in work earthing and protecting earthing of various electric apparatus, building, etc.

Owner:许国进

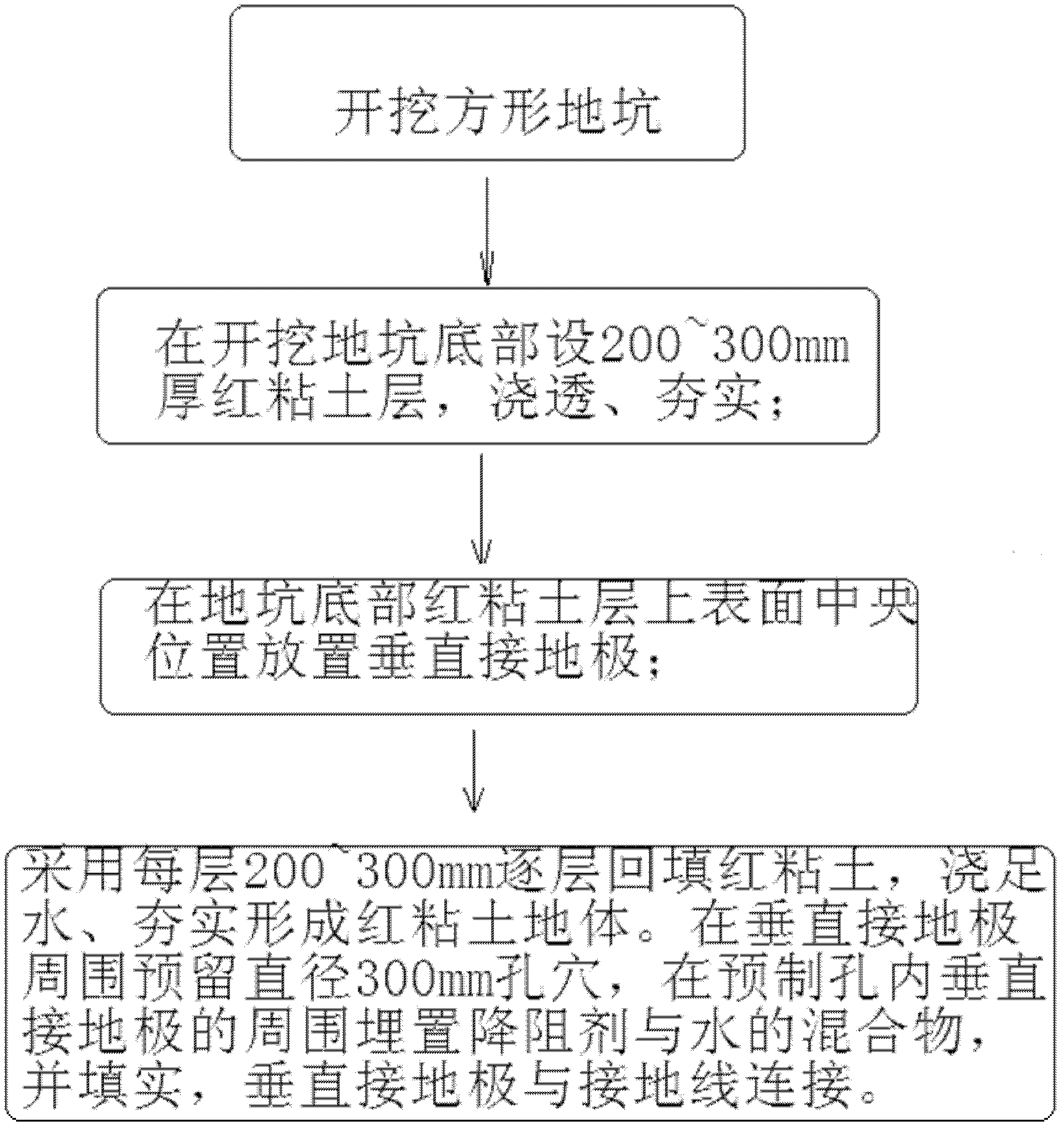

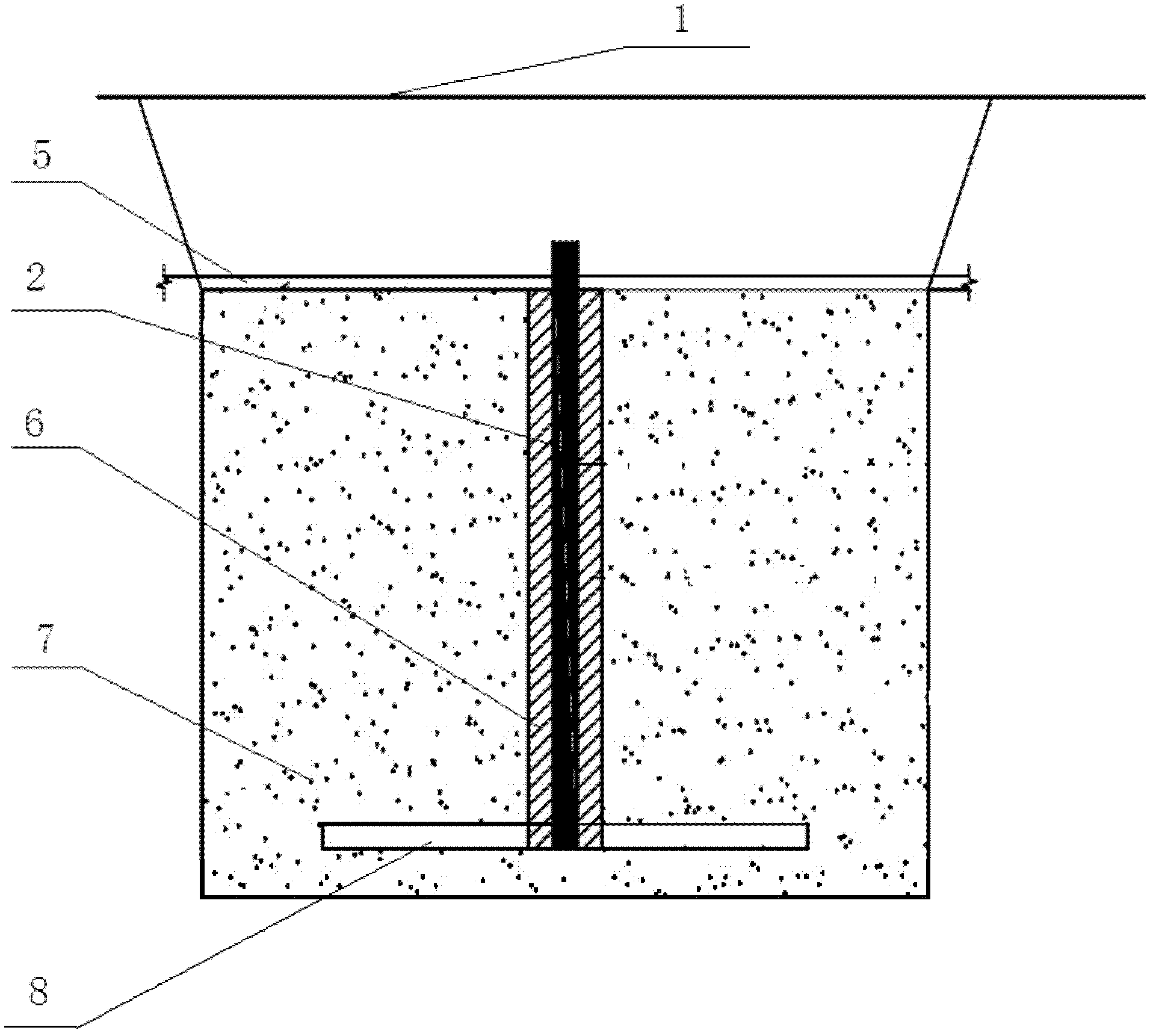

Grounding resistance reduction process method for sand/gravel area

ActiveCN102437437ASimple patented processEasy constructionLine/current collector detailsConnection contact member materialElectrical resistance and conductanceEngineering

The invention discloses a grounding resistance reduction process method for a sand / gravel area, which comprises: establishing a pit on a construction site based on the characteristic of good water retention capability of red clay, setting up a vertical grounding electrode in the pit, laying mixture of a resistance reduction agent and water around the grounding electrode, filling red clay around the vertical grounding electrode with the laid mixture of the resistance reduction agent and the water for forming a red clay body, making the vertical grounding electrode connected with a grounding wire, pouring the red clay body layer by layer with water, and compacting the red clay body layer by layer. The invention has the beneficial effects that: the cost is low; and the process is simple; and the effect of resistance reduction is best and stable and reliable in a long time, and the method can be applied in any project with requirements for the grounding resistance.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

Graphite composite resistance-reduction cloth production process

InactiveCN104376921AAvoiding the disadvantages of corroding metal grounding bodiesExtended service lifeCable/conductor manufactureConnection contact member materialElectricityYarn

The invention belongs to the technical field of lightning protection and grounding for electric power, railways, telecommunications, factories and mines, high-rise buildings and the like, and particularly relates to a graphite composite resistance-reduction cloth production process. The graphite composite resistance-reduction cloth production process comprises the following steps that expansible graphite with the carbon content being 99.5 percent or more is selected and high-temperature expansion is conducted at 1000 DEG C, so that graphite worms are obtained; the surface of special fiber is evenly immersed with an adhesive; the special fiber is evenly laid between an upper layer of electricity-conducting low-resistance graphite coiled material and a lower layer of electricity-conducting low-resistance graphite coiled material; the composite electricity-conducting low-resistance graphite coiled materials are cut into electricity-conducting low-resistance graphite belts; the electricity-conducting low-resistance graphite belts are made into electricity-conducting low-resistance graphite yarn through a twisting machine in a unidirectional twisting mode; the graphite composite resistance-reduction cloth is woven by a braiding machine through the electricity-conducting low-resistance graphite yarn formed in a twisted mode. The graphite composite resistance-reduction cloth production process is simple, controllable in production cost and capable of bringing convenience to large-scale production, application and popularization.

Owner:河南盛煌电力设备有限公司

Resistance reduction agent for oil well fracturing and preparation method of resistance reduction agent

InactiveCN105238383ARaw materials are easy to getSimple processDrilling compositionSolubilityHydrophilic monomer

The invention provides a resistance reduction agent for oil well fracturing. The resistance reduction agent for oil well fracturing comprises components A and components B., and the ratio of the components A to the components B is 20:80. The components A comprise 25-37.5 parts of acrylamide, 5-50 parts of hydrophilic monomers, 2.5-10 parts of sodium hydroxide, 1.25 parts of persulfate and 150.25-215.25 parts of water. The components B comprise 450-880 parts of hydrophobic monomers, 100-400 parts of spans, 10-100 parts of alkylphenol ethoxylates and 10-50 parts of alcohol amine salt type anionic fluorocarbon surfactants. Raw materials of the resistance reduction agent are easy to obtain, the preparation technology is simple, water solubility is good, friction resistance is reduced by more than 60%, the interface tension is below 10-2 mN / m after gel breaking, when the resistance reduction agent is used, fast flowback can be achieved while no discharge adding agent needs to be added, and wide application prospects are achieved.

Owner:西安长庆化工集团有限公司

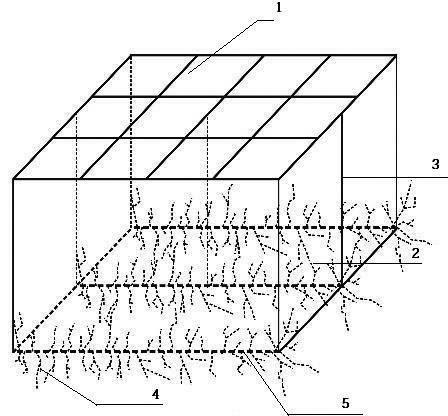

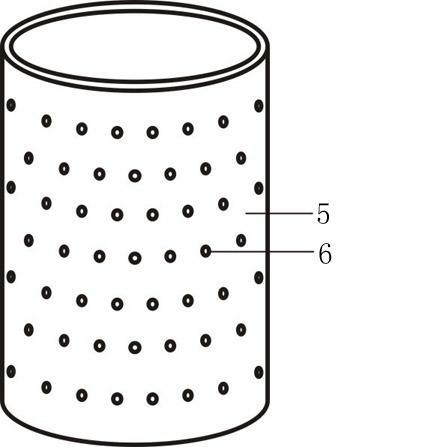

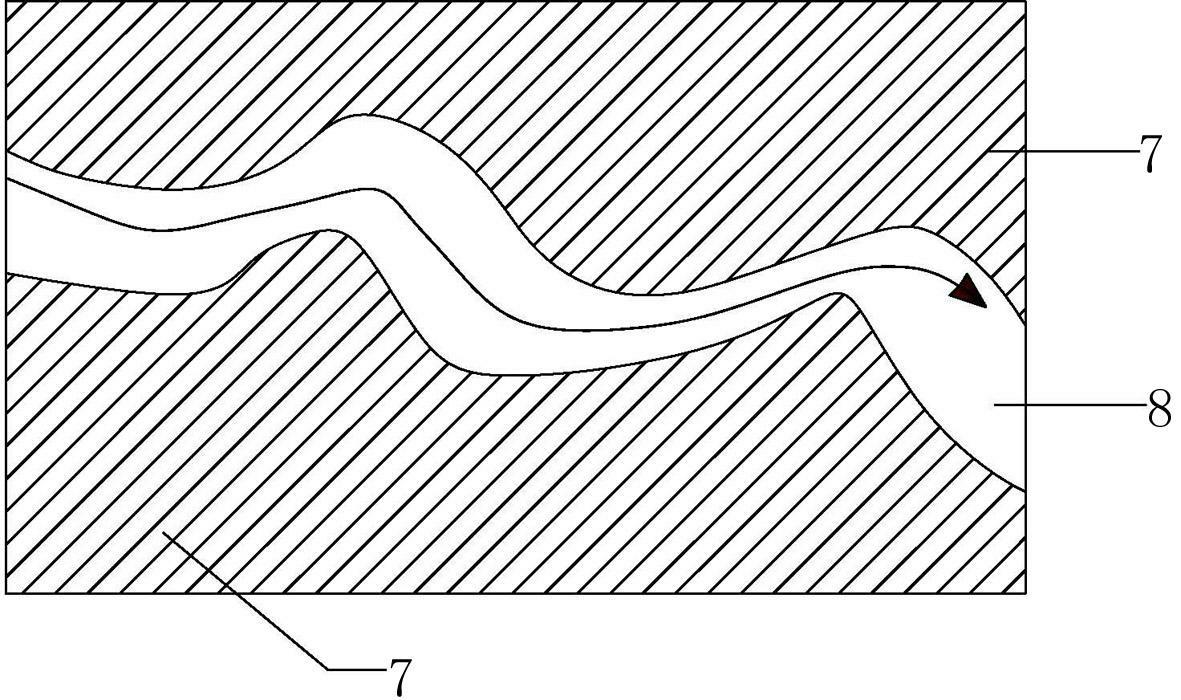

Soil non-excavation grounding resistance reduction method

InactiveCN102610935ADoes not affect damageWill not affect trafficLine/current collector detailsConnection contact member materialEngineeringHigh pressure

The invention relates to a soil non-excavation grounding resistance reduction method, in particular to a non-excavation project resistance reduction technology. The soil non-excavation grounding resistance reduction method is characterized in that two layers of horizontal resistance reduction ground screens are arranged on the grounding soil; one layer of the horizontal resistance reduction ground screen is arranged on the soil surface to form a surface ground screen, and the other layer is located in the underground soil layer with the soil resistance smaller than 300 ohm meters to form an underground ground screen; the surface ground screen is steel fabric; the underground ground screen is formed by spraying a resistance reducing agent into the soil through holes formed on the pipes laid by a directional drilling non-excavation pipe laying method so as to bind with the soil; and the surface ground screen is connected with the underground ground screen through a vertical grounding connection wire. The non-excavation resistance reduction method provided by the invention does not affect the traffic nor destroy the environment, and has the advantages of short construction period, low comprehensive cost, significant resistance reduction effect, and high social and economic value.

Owner:云南省昆明农业气象试验站 +1

Antifouling paint

InactiveCN103173085AAdd supportReal sea toxin rate control is reasonable and stableAntifouling/underwater paintsPaints with biocidesToxic materialReduced properties

The invention discloses an antifouling paint which is characterized by comprising the following components by weight percent: 30% to 50% of drag-reducing polymer without containing stannum, 20% to 40% of toxic materials, 2% to 5% of auxiliary base materials, 5% to 10% of pigments, 10% to 20% of solvent and 4% to 7% of an addition agent. The antifouling paint is low in toxic content and can not damage the marine environment. When the antifouling paint is matched with an anti-rusting paint, the good physical property of a ship body is achieved. A paint film formed by the antifouling paint is smooth and flat, good in drag-reducing property and uniform in abrasive corrosion rate and realizes energy conservation and consumption reduction.

Owner:NINGBO SANLI NEW MATERIALS

Graphene resistance-reducing agent for fracturing fluid

InactiveCN106085385AReduce frictionGood resistance reduction effectDrilling compositionPhosphateFiltration

The invention discloses a graphene resistance-reducing agent for a fracturing fluid. The graphene resistance-reducing agent comprises the following raw materials by weight: 1 to 50 parts of graphene, 5 to 60 parts of a surfactant and 1 to 60 parts of a wetting agent, wherein the surfactant is a nonionic surfactant or anionic surfactant and is one or more selected from a group consisting of alkylphenol polyoxyethylene ether, stearyl alcohol polyoxyethylene polyoxypropylene ether, polyether phosphate, dodecylbenzene sulfonic acid and fatty alcohol ether sodium sulfate-AES. The graphene resistance-reducing agent has the advantages of good resistance-reducing performance, few components, small filtration loss, high viscosity, environment friendliness and good compatibility; through addition of graphene or modified graphene, a lubrication coefficient can be effectively decreased, frictional resistance between the fracturing fluid and a crack wall is lowered and filtration loss is reduced; thus, construction pressure in the process of fracture is reduced, and the graphene resistance-reducing agent is applicable to large-scale large-discharge volume fracture technology. The graphene or modified graphene resistance-reducing agent has good compatibility with a reservoir in the process of fracture and acidification, does not contain mineral oil and poses no pollution to the reservoir and environment.

Owner:CARBORN TIME TECH CO LTD

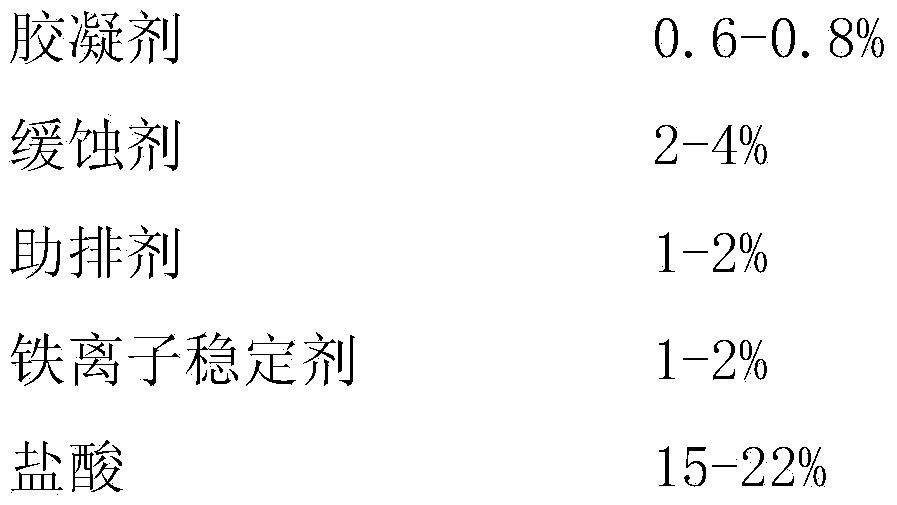

Gelled-acid acid liquor applicable to high-temperature carbonatite acidification

InactiveCN103923633AEasy to prepareGood resistance reduction effectDrilling compositionFiltrationMass-Volume Percentage

The invention discloses gelled-acid acid liquor applicable to high-temperature carbonatite acidification. The gelled-acid acid liquor comprises 0.6%-0.8% by mass volume of gelling agent, 2%-4% by volume of corrosion inhibitor, 1%-2% by volume of discharge aiding agent, 1%-2% by volume of iron ion stabilizer, 15%-22% by volume of hydrochloric acid and the balance of water. The gelled-acid acid liquor disclosed by the invention can be applied to high-temperature carbonatite acidification construction, is high temperature-resistant and salt-resistant, has good retardance, de-filtration, perforating and resistance reducing performances, and can effectively relieve secondary damage to achieve a deep acidification process. The gelled-acid acid liquor system is stable in performance, simple to prepare, convenient to construct and capable of being effectively applied to high-temperature carbonatite acidification modification construction.

Owner:CNPC BOHAI DRILLING ENG

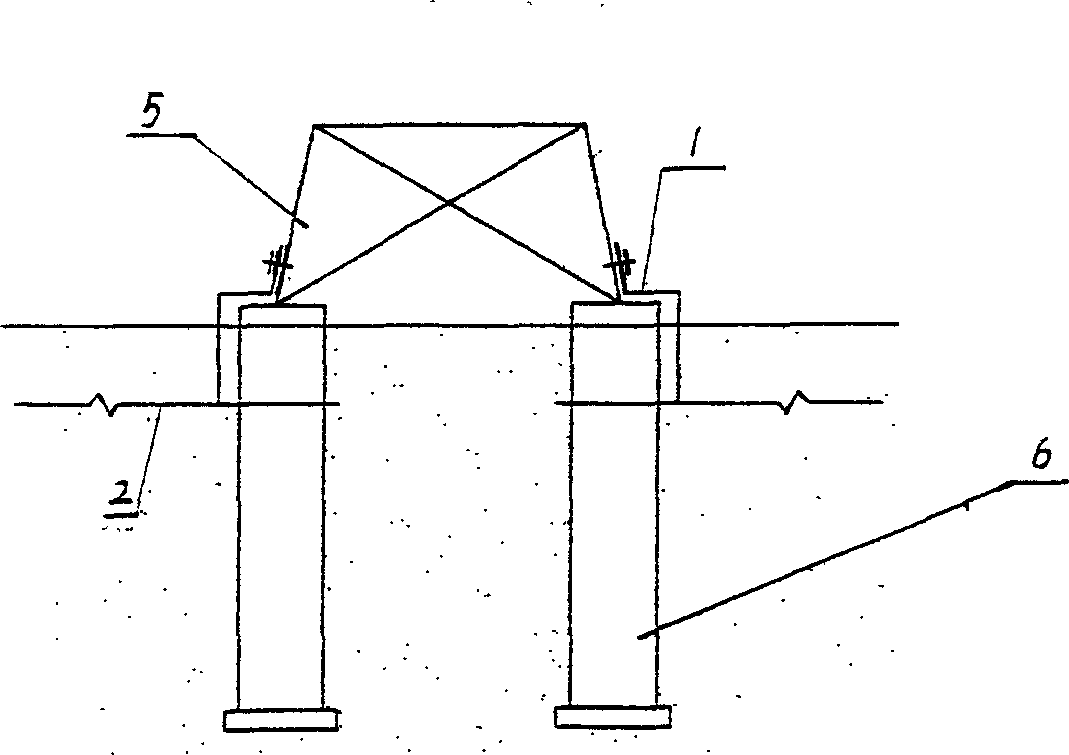

Electrochemical earthing body

The present invention relates to anticorrosion and resistance lowering technology for earthing body, and is especially one electrochemical earthing body. The electrochemical earthing body has earthing body connected to the lead-down wire, magnesium alloy belt anode connected to and embedded with the earthing body, and resistance lowering agent around the earthing body and the belt anode. The electrochemical earthing body of the present invention integrates traditional earthing mode, resistance lowering agent technology and anode protecting principle, and has low resistance, long effectiveness, no corrosion and other features. The electrochemical earthing body of the present invention has the basic construction mode the same as traditional mode and is suitable for engineering requirement.

Owner:马春兰 +5

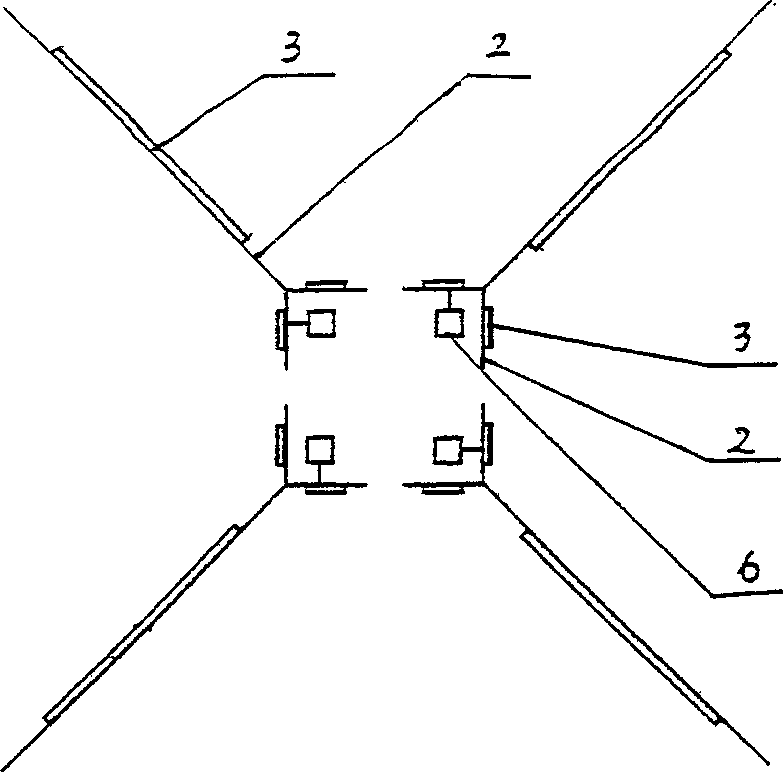

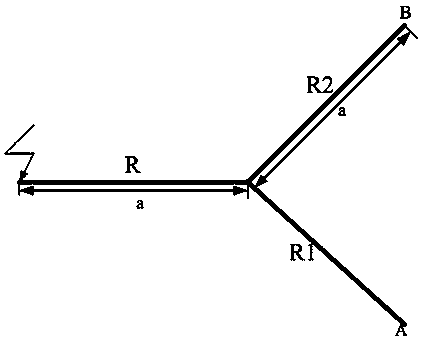

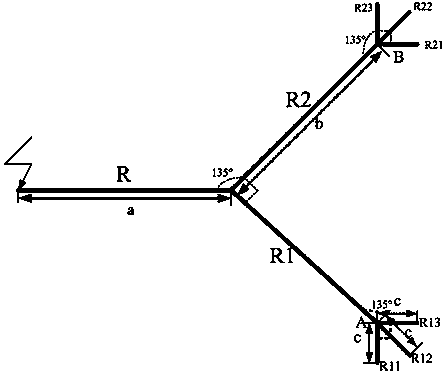

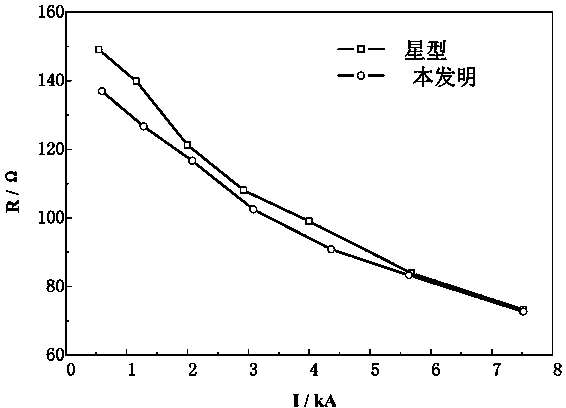

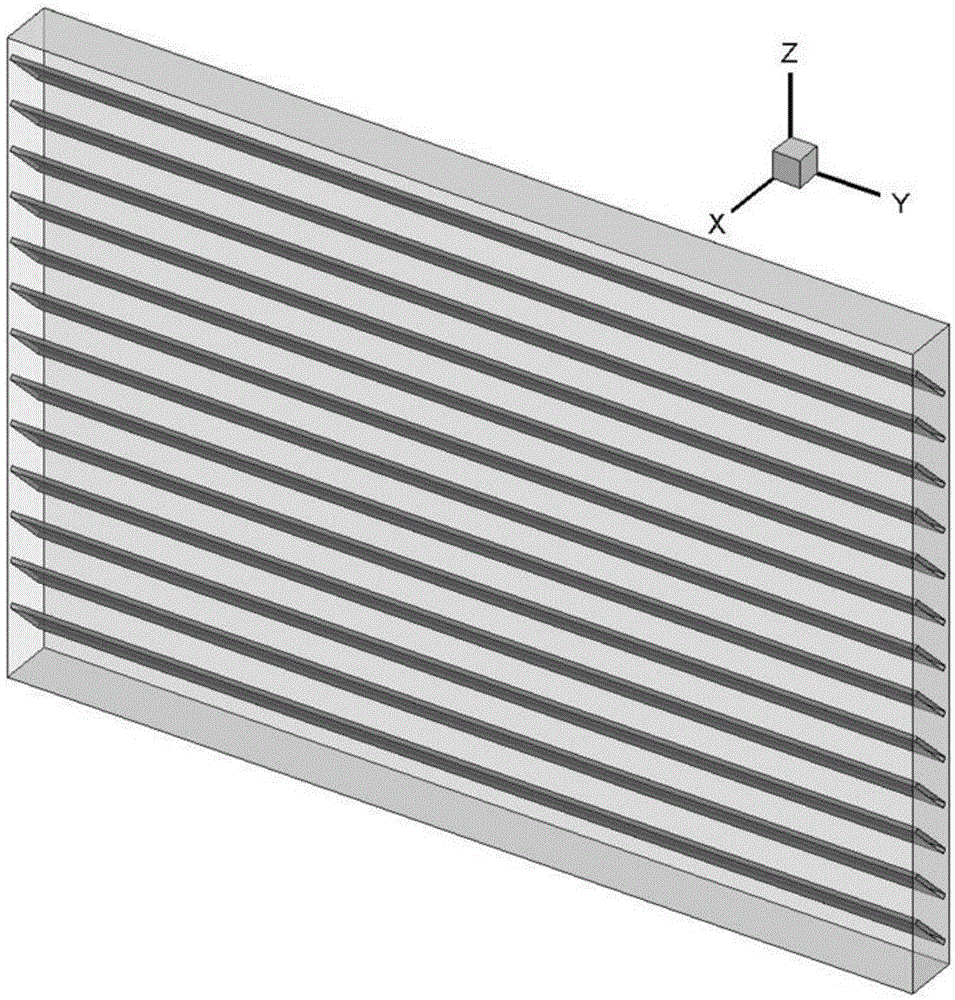

Multi-current scattering arm star-shaped grounding electrode topological structure

ActiveCN103457045AImproved impact characteristicsReduce the impact ground resistance valueConnection contact member materialElectrical resistance and conductanceElectric power system

The invention belongs to the field of electric system grounding for lightening protection, and relates to a multi-current scattering arm star-shaped grounding electrode topological structure. The multi-current scattering arm star-shaped grounding electrode topological structure is specifically suitable for a grounding electrode in a pole tower earth screen. A novel grounding electrode arrangement form is designed so that an impact grounding resistance value under a high earth resistivity can be reduced. According to the arrangement form, current scattering channels, in the grounding electrode, of a lightning current are increased, namely, each radiation branch of the star-shaped grounding electrode is additionally provided with at least one bifurcate current scattering arm, one end of each bifurcate current scattering arm is connected with the tail end of the corresponding radiation branch, the other end of each bifurcate current scattering arm extends in the radial direction, therefore, the better current scattering effect can be achieved, the impact performance of a grounding body is effectively improved, and the impact grounding resistance value of the grounding electrode is reduced. The structure is easy to manufacture and install, construction difficulty caused by the fact that the grounding electrode is lengthened blindly is avoided, a very good resistance reducing effect can be achieved, the performance is superior, and the structure is economical and reasonable.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID +1

High resistivity soil environmental protection grounding resistance reducing agent preparation method

ActiveCN106941028ACompact structureSufficiently permeableLine/current collector detailsCable/conductor manufactureEnvironmental resistanceRare earth

The invention discloses a high resistivity soil environmental protection grounding resistance reducing agent preparation method, and belongs to the grounding material preparation technical field; the method comprises the following steps: reacting lanthana with a nitric acid solution so as to prepare a mixed solution; crushing graphene, heating and expanding same, and Alkaline etching so as to allow the graphene to form a porous structure; importing a resin group on the graphene, allowing the graphene to nest in a bacteria cellulose network structure formed by microbes, and the bacteria cellulose has very strong water reserving ability, thus increasing the grounding body equivalent sectional area and the contact area with the soil; loading organic rare earth and graphene surface resin group into the graphene pores, and mixing with an auxiliary agent so as to obtain the grounding resistance reducing agent. The prepared resistance reducing agent has moisture absorbing ability, is low in resistivity, good in long-acting stability, lossless, and cannot corrode the grounding body, thus providing better resistance reducing effect, and providing wide application prospect.

Owner:CHANGZHOU UNIV

Ion grounding electrode filling material

InactiveCN101887765AGood resistance reduction effectLower resistanceNon-conductive material with dispersed conductive materialConnection contact member materialSodium BentoniteFilling materials

The invention provides an ion grounding electrode filling material which is characterized by comprising the following raw materials in percentages by weight: 55% of graphite, 20% of bentonite, 5% of conductive powder, 3% of lime and 17% of alum. The ion grounding electrode filling material has good resistance reducing effect, low resistance and longer service time and better stability.

Owner:长沙市雷立行电子科技有限公司

Preparation method of salt-tolerant soluble drag reducer

InactiveCN107698708AGood resistance reduction effectImprove salt toleranceDrilling compositionEmulsion polymerizationNitrogen

The invention discloses a preparation method of a salt-tolerant soluble drag reducer. The preparation method comprises the following steps: (1) dissolving sorbitan mo-nooleate in white oil, performingpreparation to form a continuous phase; (2) sequentially dissolving acrylic acid, 2-acrylamido-2-methylpropane sulfonic acid, acrylamide and sorbitan mo-nooleate polyoxyethylene ether in deionized water, adjusting the pH value of a system to be 7.5-9 by a sodium hydroxide adjusting system, and performing preparation to form a dispersion phase; and (3) in a mixing state, dripping the dispersion phase into the continuous phase, after finish of dripping, pumping in nitrogen, then adding an initiator, and performing a thermostatic reaction at 30-40 DEG C. The polymer drag reducer prepared throughinverse emulsion polymerization is good in drag reducing effect, excellent in salt tolerance and high in dissolution speed, restrictions of low dissolution speed, high adding amount and low drag reducing rate are broken through, and significance is achieved on lowering the fracturing construction cost and saving fresh water resource.

Owner:SHAANXI SHENGMAI PETROLEUM

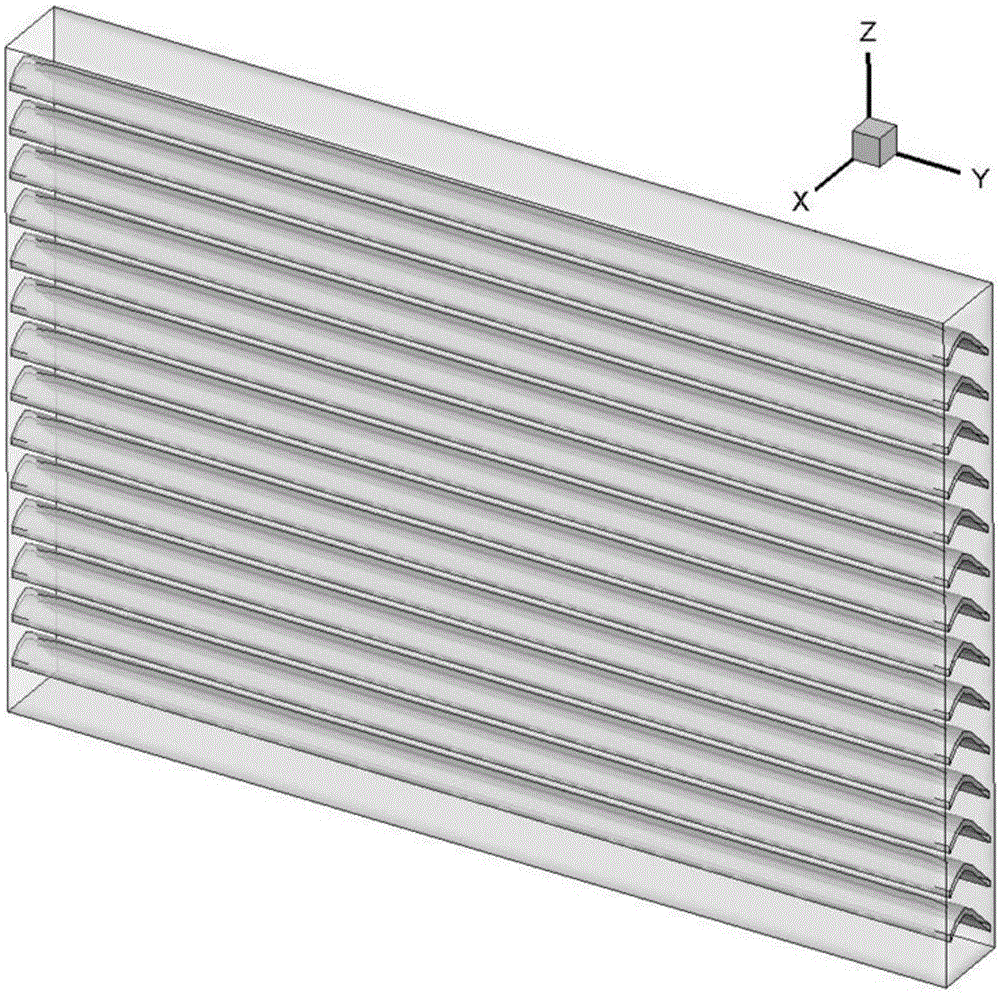

Air inlet diversion type blade blind window for ship

InactiveCN105625913ASmooth correction flowOptimize the regional flow fieldDoor/window protective devicesVentilation arrangementWindow shutterPulp and paper industry

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

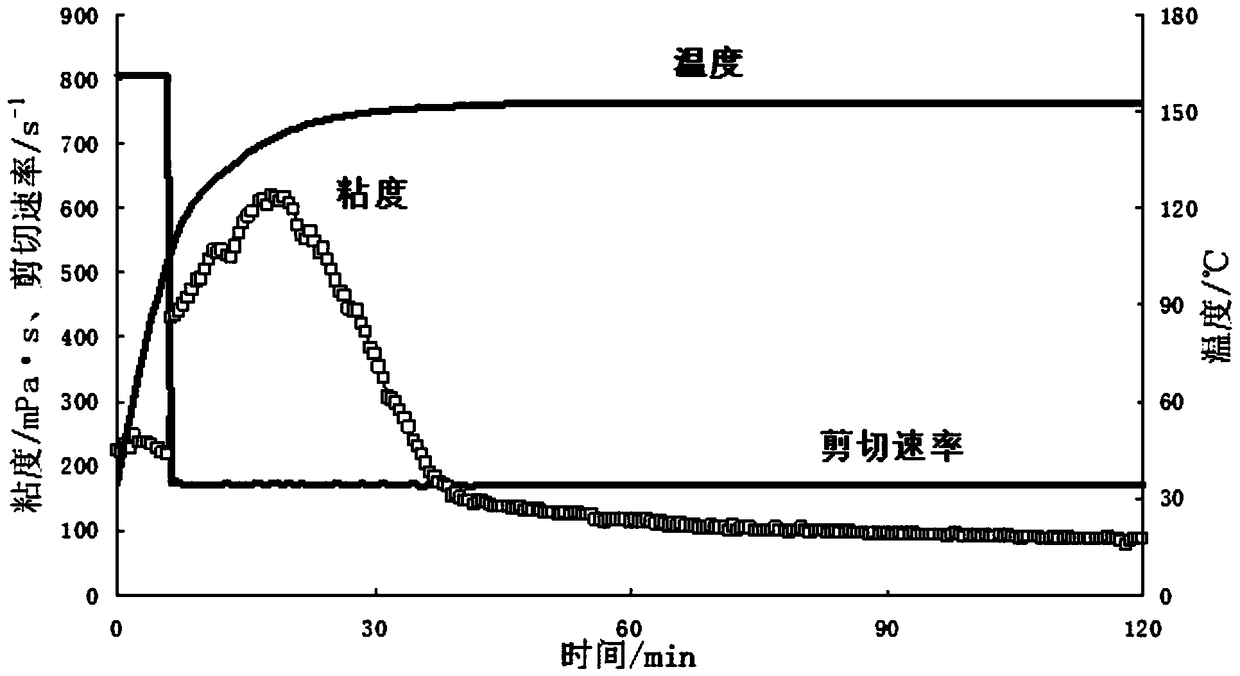

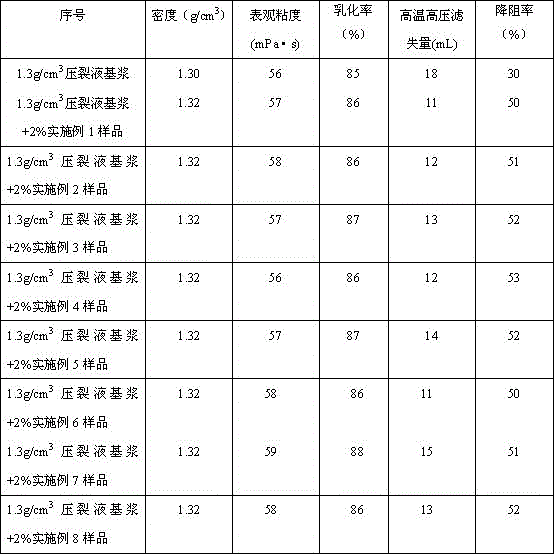

Integrated composite emulsion type clean fracturing fluid capable of being blended on line and preparation method thereof

The invention provides an integrated composite emulsion type clean fracturing fluid capable of being blended on line and a preparation method thereof. A low-concentration emulsion thickening agent which has good resistance reduction performance and cross-linked rubber which is formed by cross-linking of a high-concentration emulsion thickening agent and has good sand-carrying performance are utilized for preparing the integrated composite emulsion type clean fracturing fluid capable of being blended on line. The system is characterized in that the low-concentration emulsion thickening agent isadopted to prepare slick water, the high-concentration emulsion thickening agent is adopted to prepare linear rubber, and the linear rubber is combined with a cross-linking agent to form the cross-linked rubber, thereby realizing multi-purpose effects of one emulsion thickening agent. Compared with the existing composite fracturing fluid, the integrated composite emulsion type clean fracturing fluid system capable of being blended on line, provided by the invention, has the advantages that the formula is simple, the types of additives are few, continuous blending can be realized under the condition that the fluid does not need to be prepared in advance during construction, the quantity of on-site fluid storage tank groups is reduced, and fluid preparation processes can be simplified and alot of cost can be saved during fracturing construction. Other properties of the system are not weaker than those of existing other products.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

Preparation method of water purifying material

InactiveCN106335939ALarge specific surface areaImprove adsorption capacityWater/sewage treatment by substance additionWater/sewage treatment using germicide/oligodynamic-processWater qualityToxic material

The invention relates to a preparation method of a water purifying material. The preparation method of the water purifying material comprises the following steps: (1) mixing an inorganic adsorbing material and high molecular polymeric masterbatch according a ratio of 1: 4 to 1: 5 in a twin-screw extruder at the temperature of 160-180 DEG C, repeatedly extruding, and mixing for three times to obtain water purifying material masterbatch; (2) spinning the water purifying material masterbatch obtained in the step (1) into a nanofiber membrane by using a molten electrostatic spinning machine, and sterilizing to obtain the water purifying material provided by the invention, wherein the inorganic adsorbing material comprises the following raw materials in parts by weight: 12-16 parts of active carbon, 13-15 parts of attapulgite, 8-12 parts of nano titanium dioxide, 6-8 parts of stalactite and 6-9 parts of tourmaline. The water purifying material provided by the invention has controllable size and thickness and very good resistance reduction, can adsorb impurities and certain toxic substances in water very well, and has an effect of purifying water; treated water is weakly alkaline and facilitates acid and alkali balance and nutritional balance of a human body.

Owner:孙冠州

Preparation method for special resistance reducing agent for lightning protection grounding engineering

InactiveCN107017476AGood resistance reduction effectImprove conductivityLine/current collector detailsNon-conductive material with dispersed conductive materialFiberPolyvinyl alcohol

The invention discloses a preparation method of a special resistance-reducing agent for lightning protection and grounding engineering, and belongs to the technical field of resistance-reducing agents. In the present invention, rice husks are firstly buried in the soil to degrade the rice husks, and then under alkaline conditions, the lignin components are dissolved and removed, and then butyl phthalate is used as raw material, polyvinyl alcohol and dodecylbenzenesulfonic acid Sodium is used as a template. Under the condition of oil bath, butyl phthalate is hydrolyzed, and the hydrolyzed product is evenly dispersed in rice husk powder. The nano-titanium dioxide produced by hydrolysis is used as a catalyst to further degrade the rice husk fiber, and then carbonized. Ultra-fine carbonized rice husk fiber, followed by acrylamide as a monomer, combined with carbonized rice husk fiber as a filler, and finally mixed with cement to obtain a special drag-reducing agent for lightning protection and grounding projects. The resistance reducing agent obtained by the invention can effectively protect the grounding body and avoid corrosion of the grounding body during use, has excellent electrical conductivity and good lightning protection effect, and effectively solves the problem that the traditional resistance reducing agent is easy to corrode the metal of the grounding body and is easy to fail.

Owner:宁波高新区远创科技有限公司

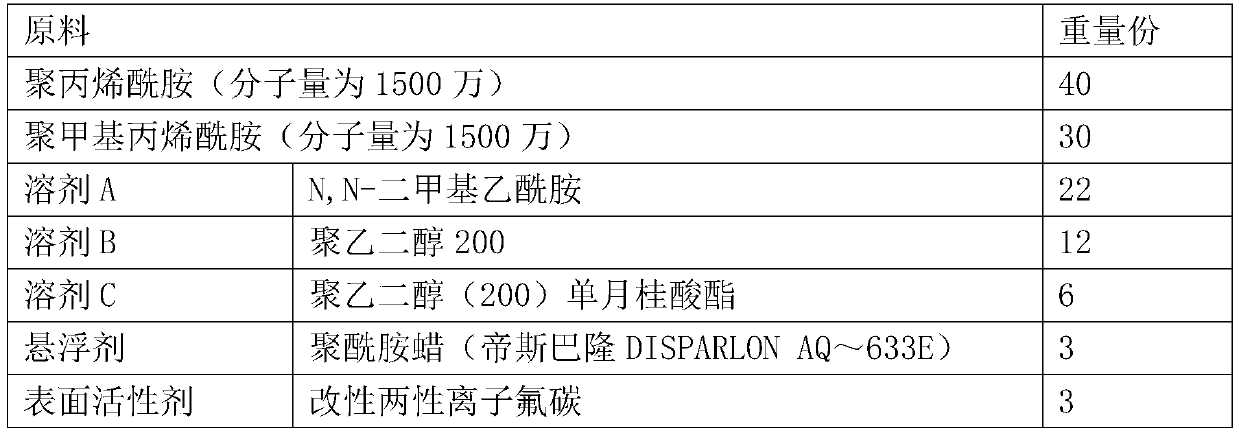

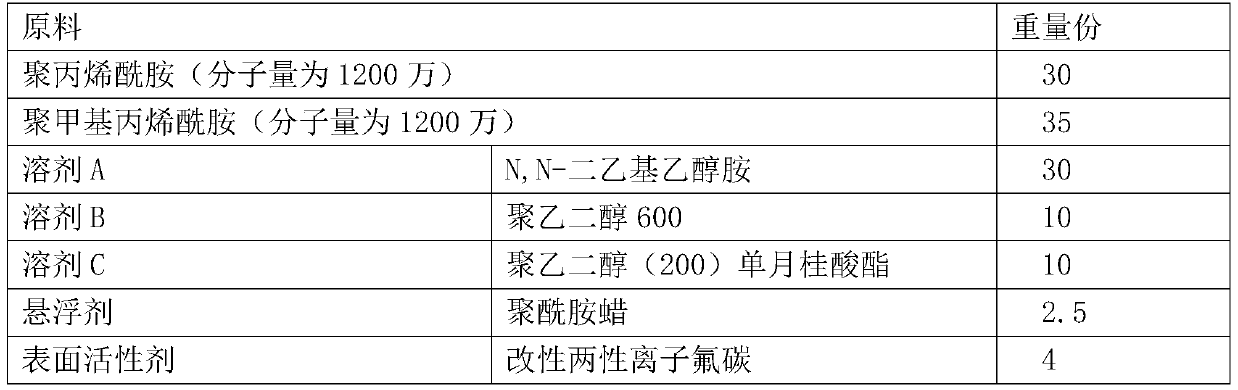

High-content water-based resistance reducing agent and preparation method thereof

ActiveCN111394085AEliminates slow dissolutionEliminate oil phase damage problemsFluid removalDrilling compositionMethacrylamideSolvent

The invention provides a high-content water-based resistance reducing agent and a preparation method thereof, and solves the technical problems in the prior art that a powder resistance reducing agentis low in hydration speed, oily residues exist after gel breaking of an oily suspension resistance reducing system, environmental friendliness is not achieved and the powder content of a water-basedresistance reducing suspension system is low. The preparation comprises the following raw materials in parts by weight: 20-50 parts of polyacrylamide; 20-40 parts of polymethacrylamide; 22-66 parts ofa solvent A; 4-12 parts of a solvent B; 6-18 parts of a solvent C; 1-3 parts of a suspending agent; and 3-6 parts of a surfactant, wherein the solvent A is alkyl amides; the solvent B is polyethyleneglycol; and the solvent C is polyhydric alcohol or polyhydric alcohol esters. The high-content water-based resistance reducing agent not only has the characteristics of high hydration speed, high powder content and good storage stability, but also can realize integrated operation and online blending.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD +1

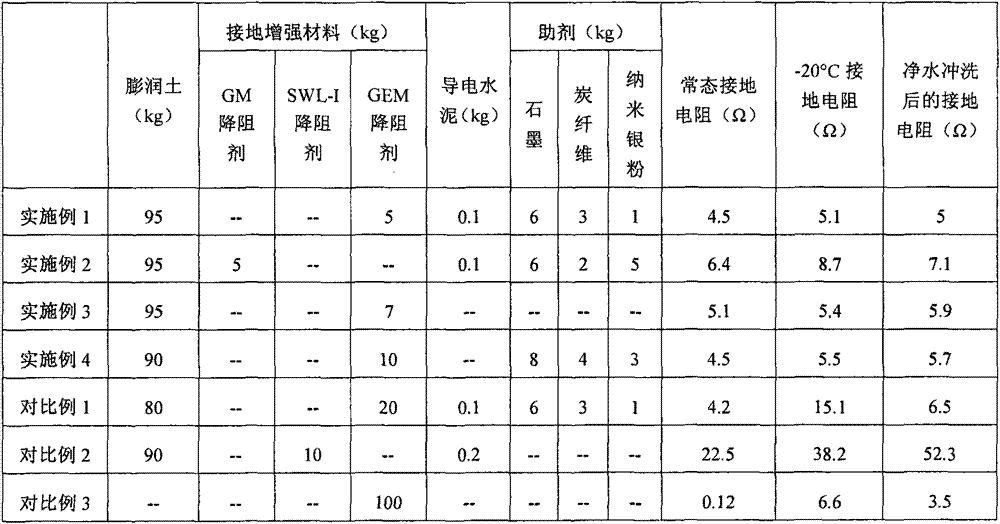

Resistance-reducing composition and application to soil thereof

ActiveCN103198872APrevent moisture lossExtended service lifeConductive materialConnection contact member materialReducing capacityOhm

The invention provides a resistance-reducing composition and application to soil thereof. The resistance-reducing composition comprises, by weight, 90-95 parts of bentonite, and 5-10 parts of grounding reinforcing materials with specific resistance of 0.1-0.15 ohm meter. According to the technical scheme, after the bentonite and the grounding reinforcing materials with the specific resistance of 0.1-0.15 ohm meter are mixed, resistance-reducing capacities of the bentonite are optimized by utilizing the low specific resistance of the grounding reinforcing materials, water-retaining properties of the bentonite are utilized at the same time so that the low specific resistance of the grounding reinforcing materials and superiorities of long-term effectiveness are brought into full play and geometric dimensions of a grounding electrode are further increased, and therefore the grounding resistance is lowered. As the grounding reinforcing materials and the bentonite are mixed for being used, the use amount of the grounding reinforcing materials of high cost is reduced.

Owner:STATE GRID CORP OF CHINA +2

Slick water suitable for field continuous mixing, and preparation method therefor

InactiveCN105018065AHigh swelling rateGood resistance reduction effectDrilling compositionFracturing fluidEnvironmental engineering

The present invention relates to the technical field of slick water, and is slick water suitable for field continuous mixing, and a preparation method therefor. The slick water suitable for field continuous mixing has the following raw materials in parts by weight: 0.6-1 parts of a resistance reducing agent, 6-10 parts of a multifunctional synergist, and 990-994 parts of water. The slick water suitable for field continuous mixing provided by the present invention are dramatically increased in the swelling ratio and the resistance reducing ratio when compared with the existing slick water. The slick water suitable for field continuous mixing provided by the present invention is good in resistance reducing effect, thorough in gel breaking, and superior to a common fracturing fluid in all indicators of the flowback liquid after gel breaking, meets the production requirements of field continuous mixing, reduces the construction pressure and ensures safe construction.

Owner:CNPC XIBU DRILLING ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com