Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111results about How to "Good sand carrying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

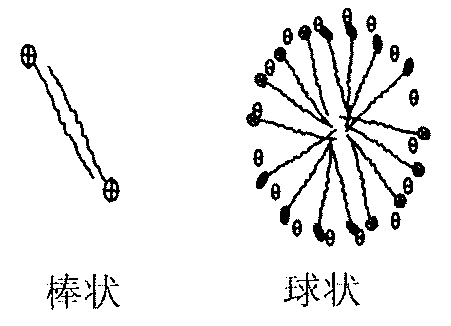

Acidic visco-elastic fluid, its preparation method and application thereof

InactiveCN102453481AGood sand carryingHigh viscoelasticityDrilling compositionFracturing fluidSURFACTANT BLEND

The invention relates to an acidic visco-elastic fluid, its preparation method and an application thereof. The fluid contains one or more cationic surfactants selected from a certain quaternary ammonium salt, a certain amine and a combination, one or more acids, one or more higher alcohols, one or more counter-ion salts, one or more corrosion inhibitors and water. The acidic visco-elastic fluid provided by the invention can be used for oilfield fracturing. On the application scene, each component is mixed and prepared into an aqueous solution of a certain mass percent; the aqueous solution isuniformly stirred and is punched together with a fracturing proppant into a well. The fracturing proppant in the fracturing fluid is uniformly dispersed and viscosity is broken completely.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

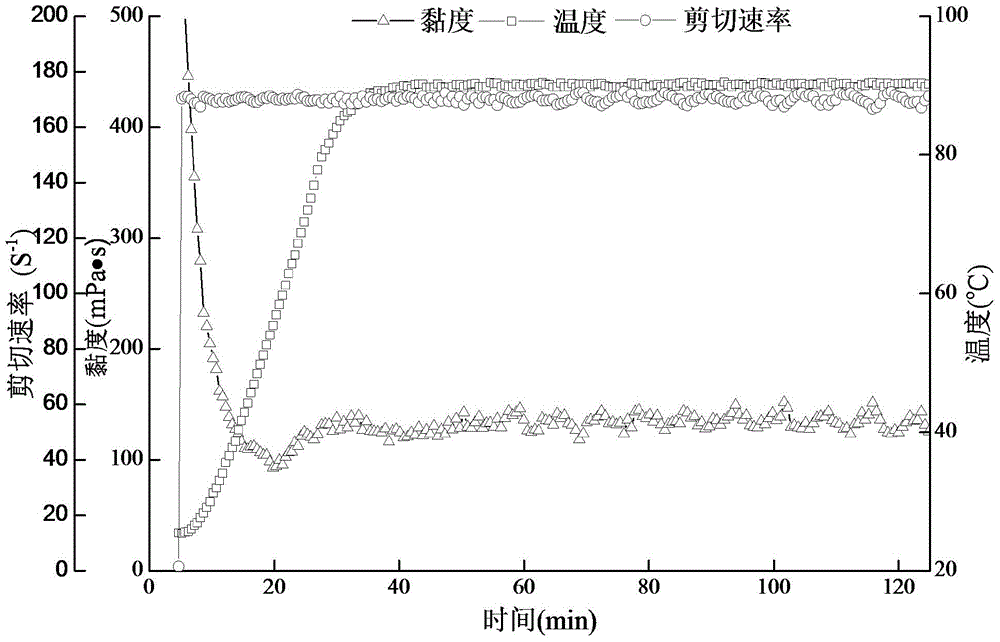

Acrylamide polymer thickener and preparation method thereof, and fracturing fluid

ActiveCN106146730AHigh temperature resistanceImprove high temperature resistanceDrilling compositionPolymer scienceFracturing fluid

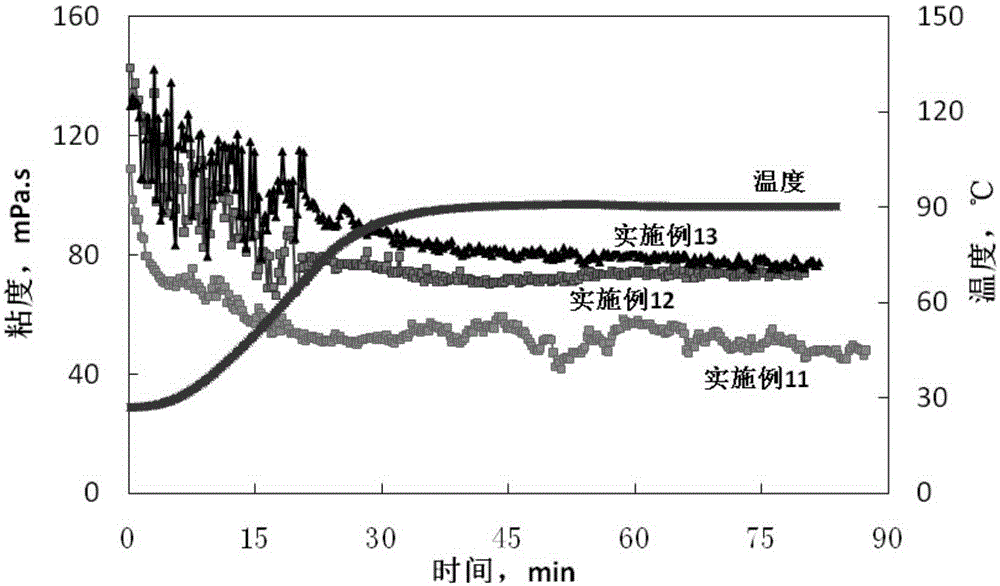

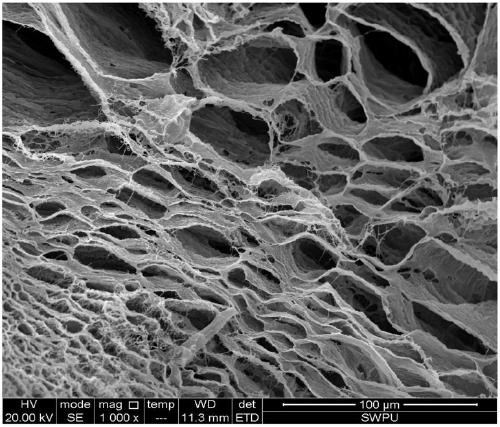

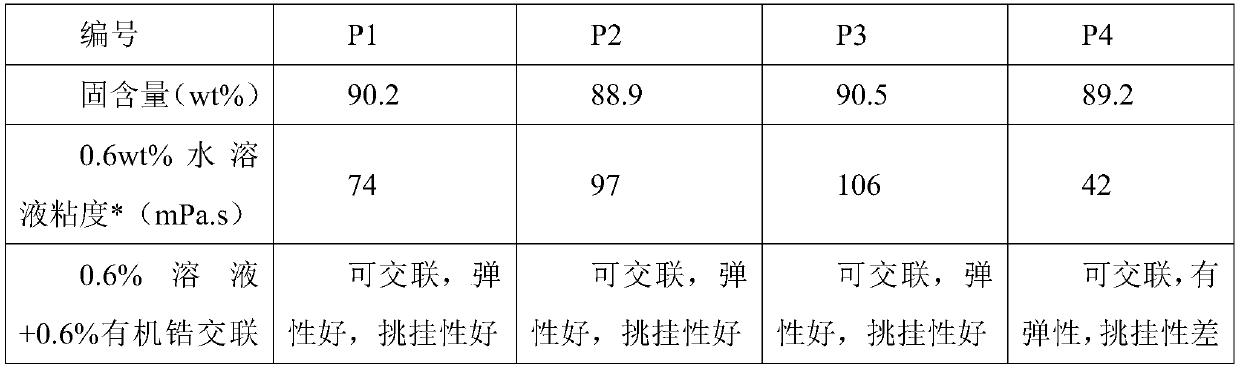

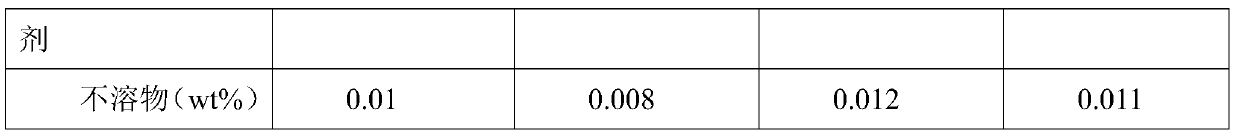

The invention provides an acrylamide polymer thickener and a preparation method thereof, and a fracturing fluid, wherein the acrylamide polymer thickener is composed of the components by the mass percentage: 20%-45% of a hydrophilic propenyl monomer, 4%-6% of a hydrophobic propenyl monomer, 1%-2% of an emulsifier, 0.2%-0.5% of an initiator, a latent crosslinking agent and the balance water, wherein the latent crosslinking agent accounts for 0.5%-1.8% of the total mass of the hydrophilic propenyl monomer and the hydrophobic propenyl monomer; the acrylamide polymer thickener provided by the invention solves the technical problems in the prior art that a polymer thickener has poor temperature resistance and salt tolerance and poor shearing stability, and the prepared acrylamide polymer thickener has high-temperature performance, and can effectively meet the requirements of on-site construction of slick water fracturing.

Owner:PETROCHINA CO LTD

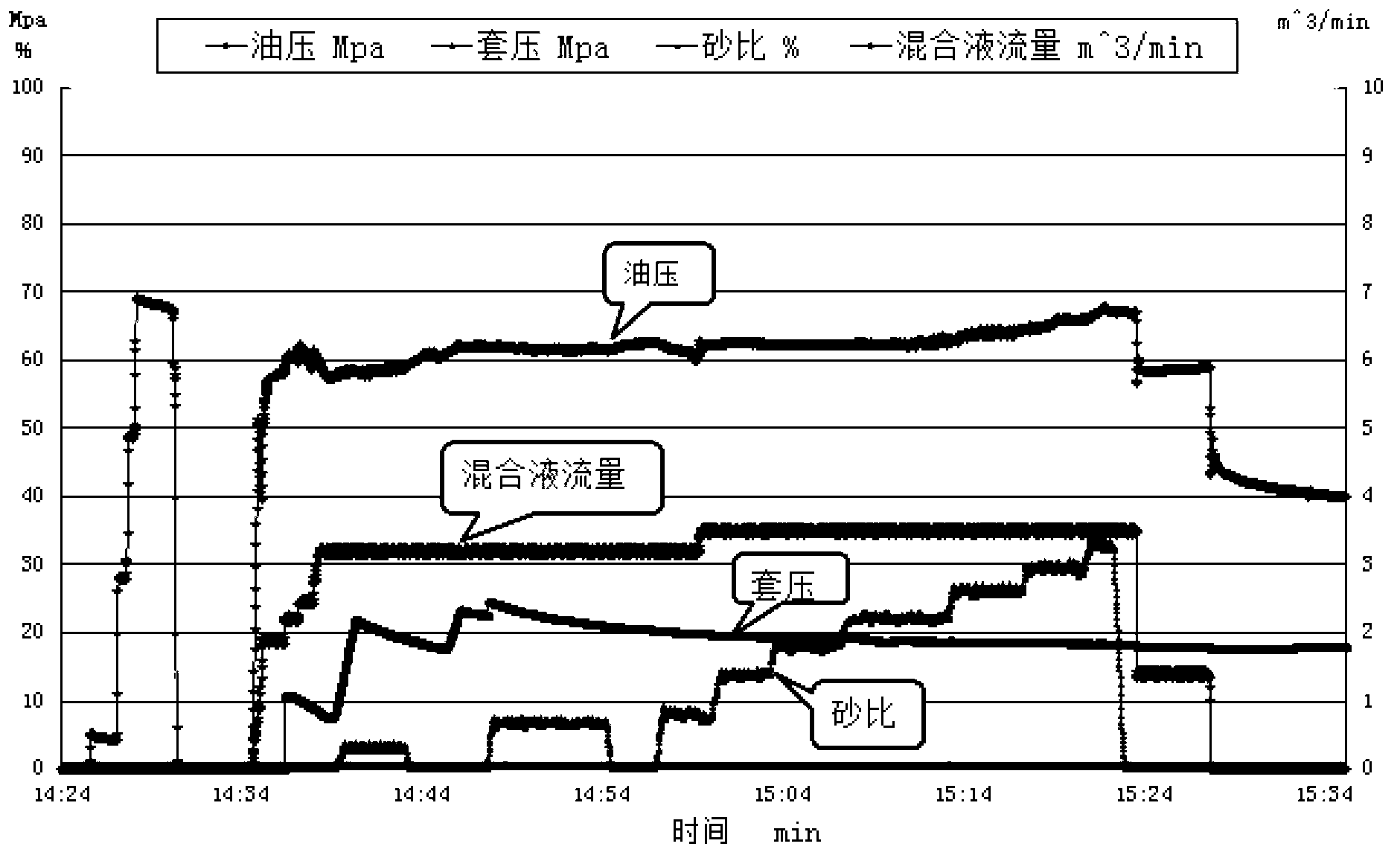

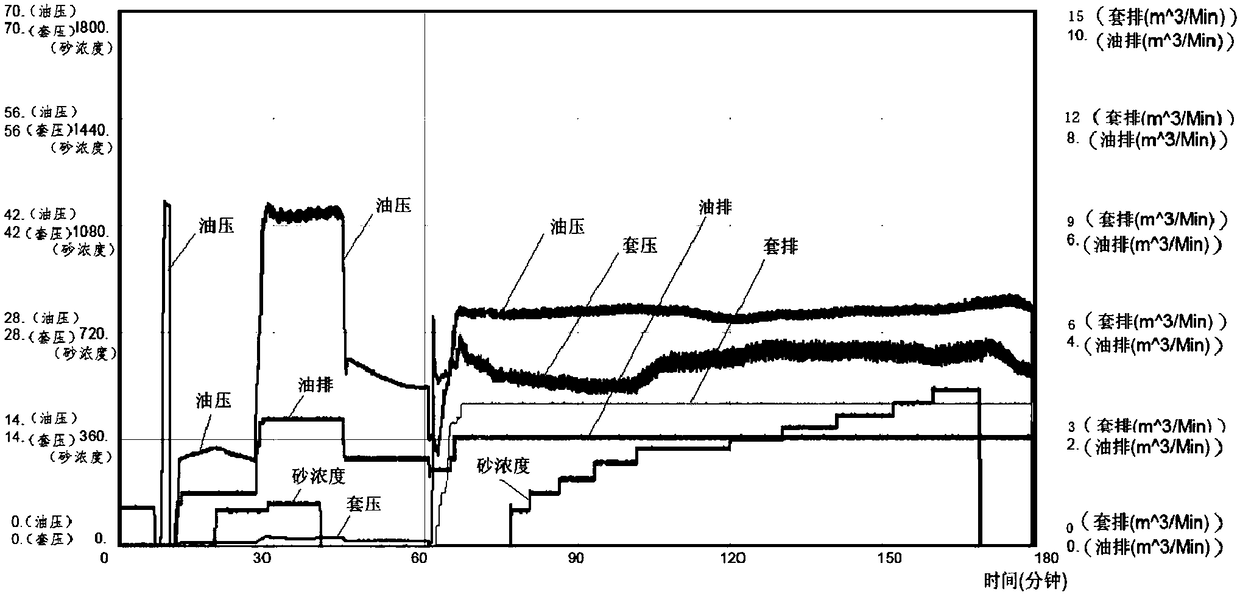

Preparation method and fracturing construction method of locally and continuously mixed clean fracturing fluid additive

ActiveCN102031102AGood sand carryingEasy to getFluid removalDrilling compositionFracturing fluidProcess engineering

The invention discloses a preparation method and a fracturing construction method of a locally and continuously mixed clean fracturing fluid additive. The invention is characterized in that the preparation of the locally and continuously mixed clean fracturing fluid additive comprises four steps, and the purposes of local and continuous mixing and continuous construction of the prepared clean fracturing fluid additive can be realized without preparation in a fluid preparation station or a well filed in advance. Thus, both the preparation method and the fracturing construction method of the locally and continuously mixed clean fracturing fluid additive are very simple and convenient.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Clean carbon dioxide foam fracturing fluid and preparation method thereof

ActiveCN104531129AFine foamImprove foam stabilityDrilling compositionPotassium persulfatePolymer science

The invention discloses clean carbon dioxide foam fracturing fluid and a preparation method thereof, and relates to the technical field of oilfield chemistry and fracturing production increase. The carbon dioxide foam fracturing fluid is mainly composed of a base solution, a foaming agent, a gel breaker and liquid carbon dioxide with the mass ratio being 100 to 0.15-0.45 to 0.02-0.08 to 100-900. The base solution is formed by 0.2%-0.55% of a thickening agent and water. The thickening agent is mainly formed by bisacrylamide, vinyl pyrrolidone, kation unsaturated monomer, anion unsaturated monomer, an initiator, sodium carbonate, an emulsifying agent and a hydrotropy agent. The foaming agent is mainly formed by hexadecyl dimethyl tertiary amine, dimethyl sulfate, caustic soda flakes, potassium persulfate and solvent. The clean carbon dioxide foam fracturing fluid has the advantages of being high in foam stability, high in temperature resistance and shear resistance, high in sand-carrying performance, wide in applicable temperature range, extremely low in residue content, high in backflow performance, and small in secondary damage to a reservoir after fracturing, thereby improving the fracturing effect and increasing the reservoir productivity.

Owner:CHENGDU BAICHUN PETROLEUM TECH

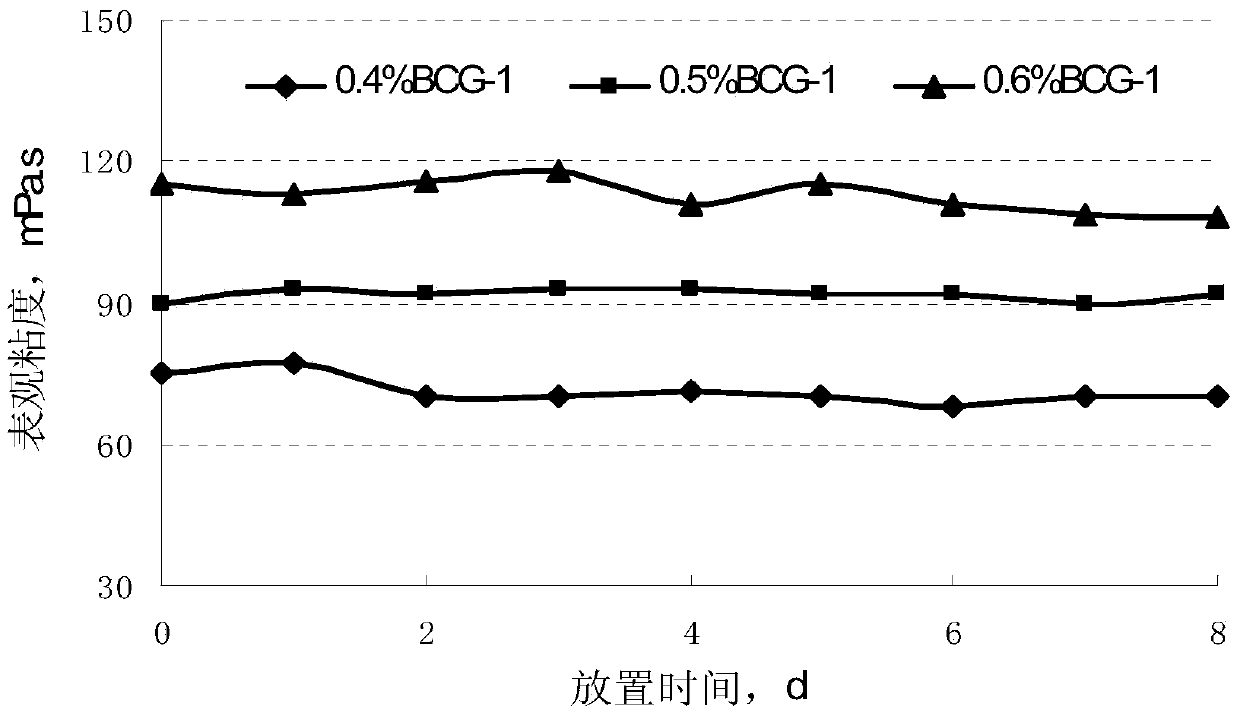

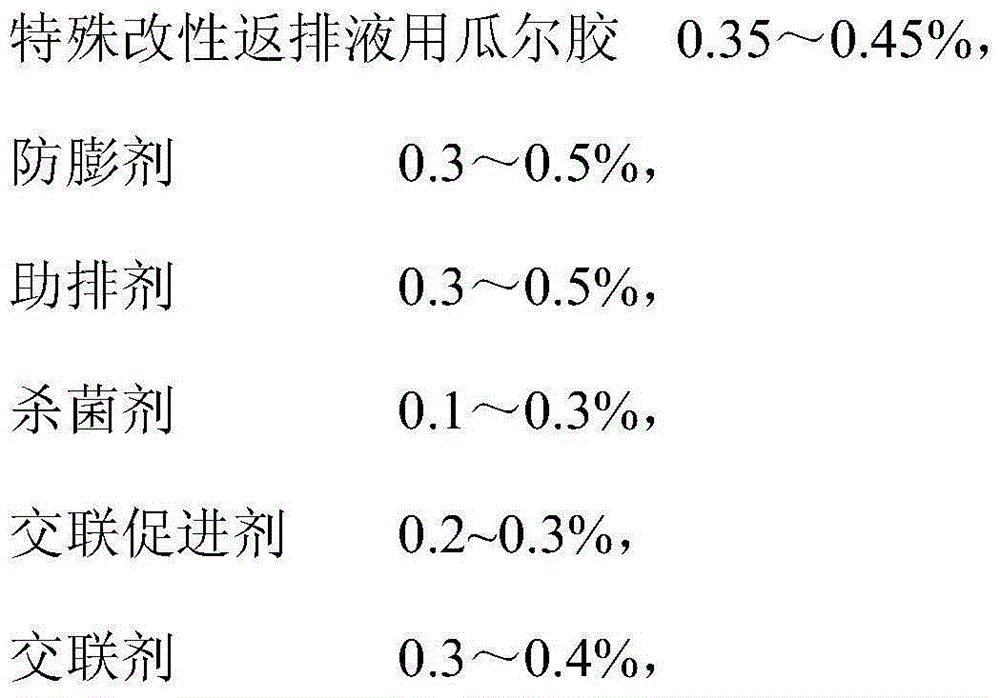

Formula and preparation method suitable for preparing fracturing fluid from continental facies shale gas well fracturing flow-back fluid treatment water

InactiveCN104610954ASolve the problem of large water consumptionConserve waterDrilling compositionSoil scienceFracturing fluid

The invention discloses a formula and a preparation method suitable for preparing fracturing fluid from continental facies shale gas well fracturing flow-back fluid treatment water, belonging to the technical field of oilfield chemistry. The formula for preparing the fracturing fluid from the continental facies shale gas well fracturing flow-back fluid treatment water is provided aiming at the deficiencies existing in the prior art. The formula consists of base fluid and a cross-linking agent, wherein the cross-linking agent is an anti-temperature mineralization-degree-resistant cross-linking agent, and the formula comprises 0.4%-0.6% of cross-linking agent and the balance of base fluid; the base fluid consists of the following components in percentage by mass: 0.4%-0.45% percent of hydroxypropylguar gum, 0.3%-0.5% of gas well clean up additive, 1%-2% of stabilizer, 0.1%-0.15% of bactericide, 0.1%-0.2% of modifier, 0.03%-0.05% of antisludging agent, 0.6%-0.8% of gel breaker and the balance of the continental facies shale gas well fracturing flow-back fluid treatment water. The cyclic utilization of the continental facies shale gas well fracturing flow-back fluid treatment water is realized through the formula of the fracturing fluid, and the prepared fracturing fluid has good sand-carrying property.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Fracturing fluid prepared by recovery waste water of crude oil and preparation method of fracturing fluid

ActiveCN103074049AAlleviate needsSolve processing problemsDrilling compositionCross-linkFracturing fluid

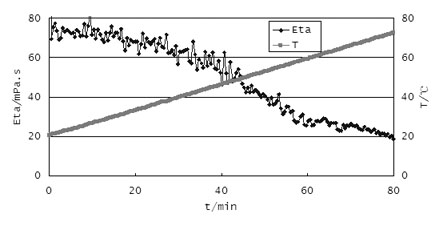

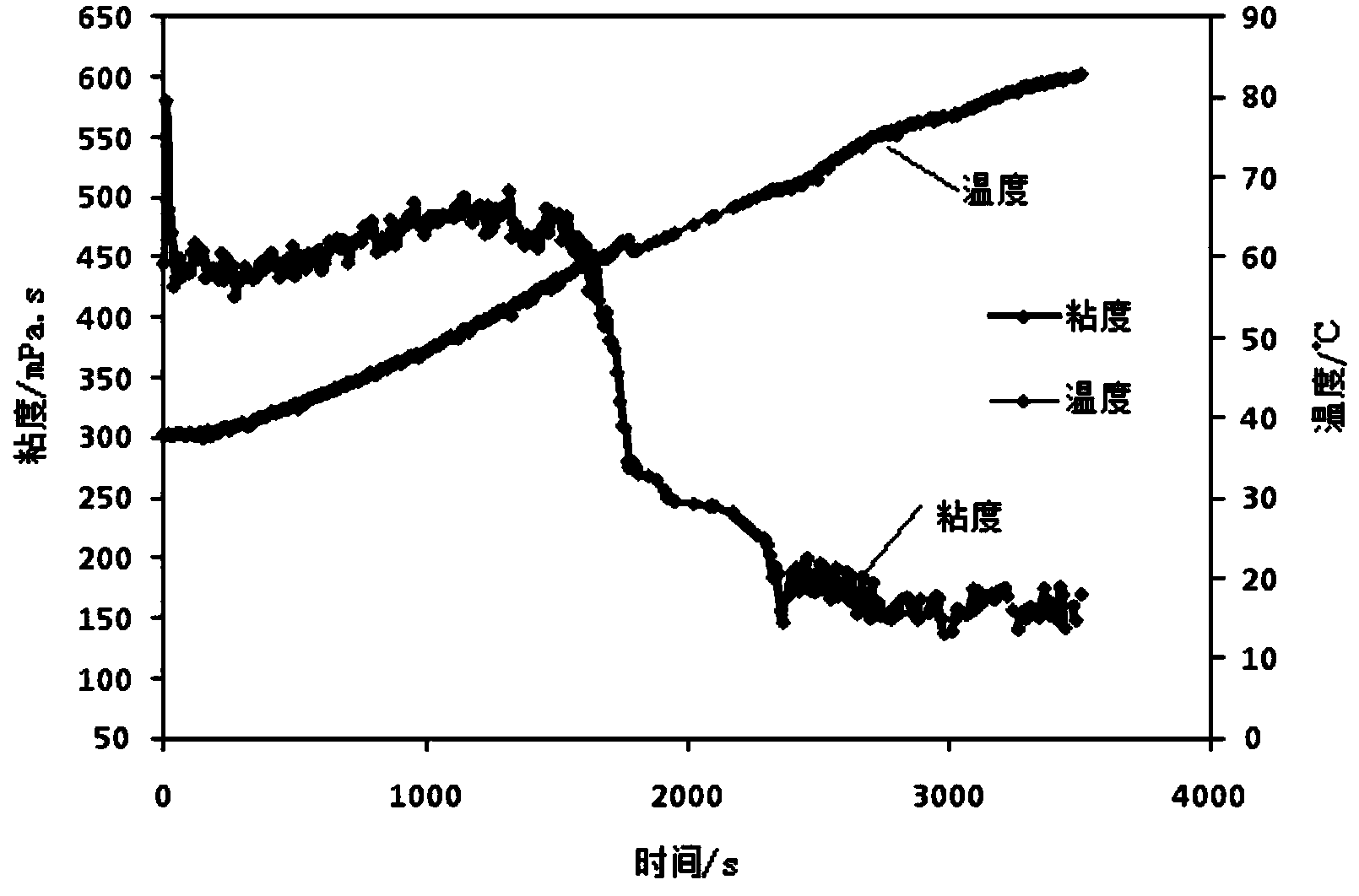

The invention discloses an association polymer fracturing fluid prepared by recovery waste water of crude oil. The fracturing fluid comprises the following components: 0.2-1.4wt% of thickening agent, 0.01-0.1wt% of thickening assistant, 0.05-0.1% of metal ion stabilizing agent, 0.02-0.05wt% of water block preventive, 0.05-0.2wt% of high-temperature stabilizing agent, 1-2wt% of clay stabilizing agent and the balance of the recovery waste water of the crude oil. Compared with the prior art, the fracturing fluid has the benefits that the fracturing fluid system adopts an association polymer as a primary thickening agent, no cross-linking agent is used, structural viscosity is formed by the synergetic effect of the association polymer and an ampholytic surfactant, and the fracturing fluid has the characteristics of temperature resistance, good salt tolerance, shear resistance, bacterial corrosion resistance and low friction, and has a good solid carrying behavior when the viscosity is greater than 20mPa*s.

Owner:CHENGDU BAICHUN PETROLEUM TECH +1

Supercritical carbon dioxide based fracturing liquid system and application thereof

ActiveCN103540308AViscosity value adjustableGood sand carryingFluid removalDrilling compositionEnvironmental resistanceAdhesive

The invention relates to a supercritical carbon dioxide based fracturing liquid system and application thereof. The fracturing liquid system comprises the following components: 0.1%-5% of adhesive, 0.3%-6.5% of conditioner and the rest of supercritical carbon dioxide. The supercritical carbon dioxide based fracturing liquid system provided by the invention can be used for oil field fracturing. In an application field, all components are mixed in certain mass percentage, and a propping agent is pumped into a stratum together with the mixture. The fracturing liquid system provided by the invention has the characteristics of good sand-carrying properties, easy backflow, no residues and no water phase, completely eliminates water-lock and water-sensitive damages, effectively reduces the viscosity of crude oil, inhibits clay swelling, improves the reservoir permeability, greatly saves water resources and can reach the purpose of efficient, environment-friendly and green construction.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid and preparation method thereof

ActiveCN104178102AHigh apparent viscosityImprove structural strengthDrilling compositionCross-linkPolymer science

The invention discloses a cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid and a preparation method thereof. The preparation method comprises the following steps of (1) preparing a thickener for the fracturing fluid; (2) preparing a cross-linking agent for the fracturing fluid; (3) preparing a gel breaker for the fracturing fluid and (4) preparing the cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid. The fracturing fluid prepared by adopting the preparation method has the characteristics of excellent viscoelasticity, temperature resistance and shear resistance, sand-carrying performance and wide applicable temperature range; the fracturing fluid can well meet the requirement on the fracturing construction, and the content of the residue is very low; after the fracturing, the secondary harm to a reservoir is small and thus the fracturing effect is improved and the production capacity of the reservoir is increased.

Owner:CHENGDU BAICHUN PETROLEUM TECH

Low-cost water-based clean fracturing fluid and gel breaking fluid used for fracturing

The invention provides a water-based clean fracturing fluid for fracturing. The fracturing fluid is formed by a small canonic antiswelling agent, organic sodium salt, a cationic surface active agent and water, wherein the concentration of the small canonic antiswelling agent is 0.4 percent by mass, the concentration of the organic sodium salt is 0.06 to 0.18 percent by mass, the concentration of the cationic surface active agent is 0.2 to 0.6 percent by mass, the mass ratio of the cationic surface active agent and the organic sodium salt is 1:0.3, the organic sodium salt is sodium salicylate, and the cationic surface active agent is any one or the mixture of 16-18 alkyl-3-methylammonium chloride. The invention can well solve the pollution problem of the fracturing fluid to the coal bed, simultaneously improve the sand-carrying performance of the fracturing fluid greatly, the price thereof is only 1.5 to 2.0 times of active water fracturing fluid and is far lower than that of guargum fracturing fluid and common clean fracturing fluid.

Owner:CHINA UNITED COALBED METHANE NAT ENGRES CENT

Acidic water repellent associated matter fracturing fluid

ActiveCN102206484ALess residueGood anti-expansion effectDrilling compositionDemulsifierSalt resistance

The invention relates to acidic water repellent associated matter fracturing fluid. The fracturing fluid consists of crosslinked fluid and original fluid, wherein the crosslinked fluid comprise the following components in percentage by weight: 0.2 to 0.5 percent of acidic crosslinked agent, 0.01 to 0.035 percent of crosslinked regulator A, 0.02 to 0.3 percent of crosslinked regulator B, 0.02 to 0.2 percent of gelbreaker and the balance of water; and the original fluid comprises the following components in percentage by weight: 0.3 to 0.7 percent of FS-927 polymer, 1 to 4 percent of potassium chloride, 0.5 to 1.5 percent of MJ-1 high-temperature discharge aiding agent, 0 to 2.5 percent of JTY-100 fluid loss agent, 1 percent of PR-1 demulsifier, 0 to 0.02 percent of temperature stabilizer and the balance of water. The fracturing fluid has the advantages of high crosslinking delaying performance, temperature resistance, salt resistance and shearing resistance, high sand carrying capacity, small damages to stratum, low friction resistance, low residue amount and good expansion preventing effect, can easily break gel and flow back, and breaks through the traditional concept that retarded crosslinking polymer fracturing fluid has temperature resistance and sheering resistance which can be realized at the temperature of not more than 100 DEG C.

Owner:PETROCHINA CO LTD

Fracturing fluid

ActiveCN103666437AGood sand carryingGood temperature and shear resistanceDrilling compositionCarrying capacityFracturing fluid

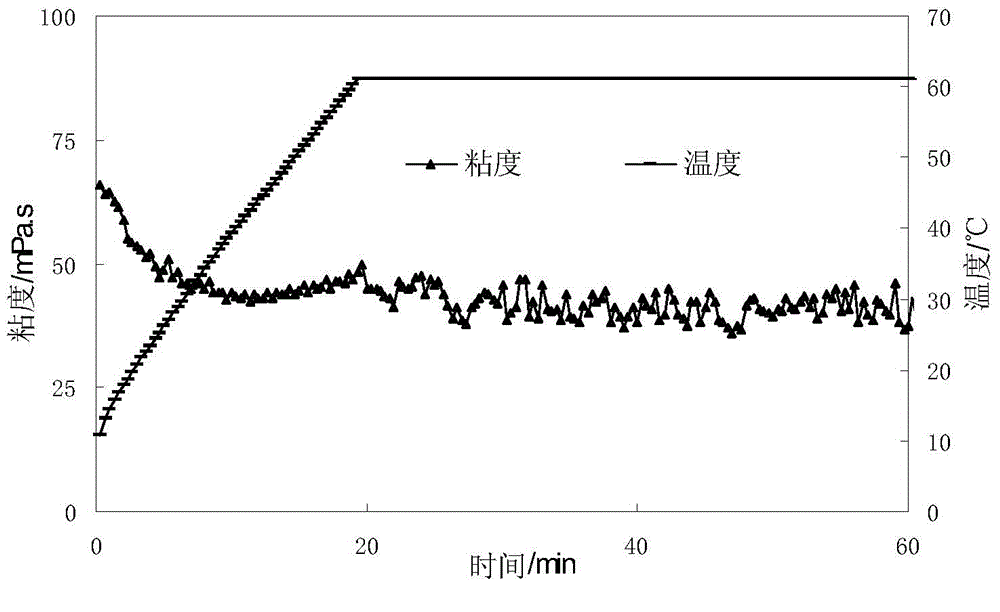

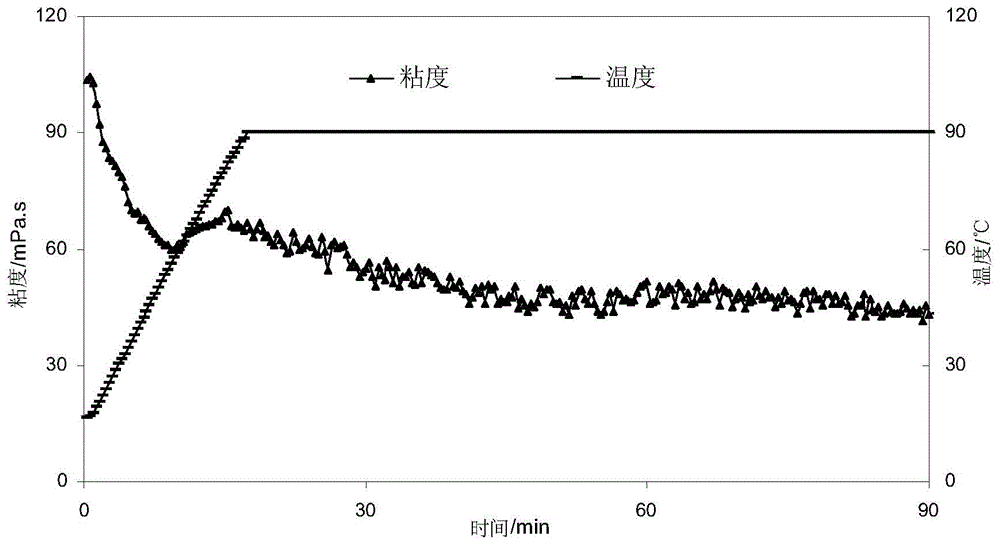

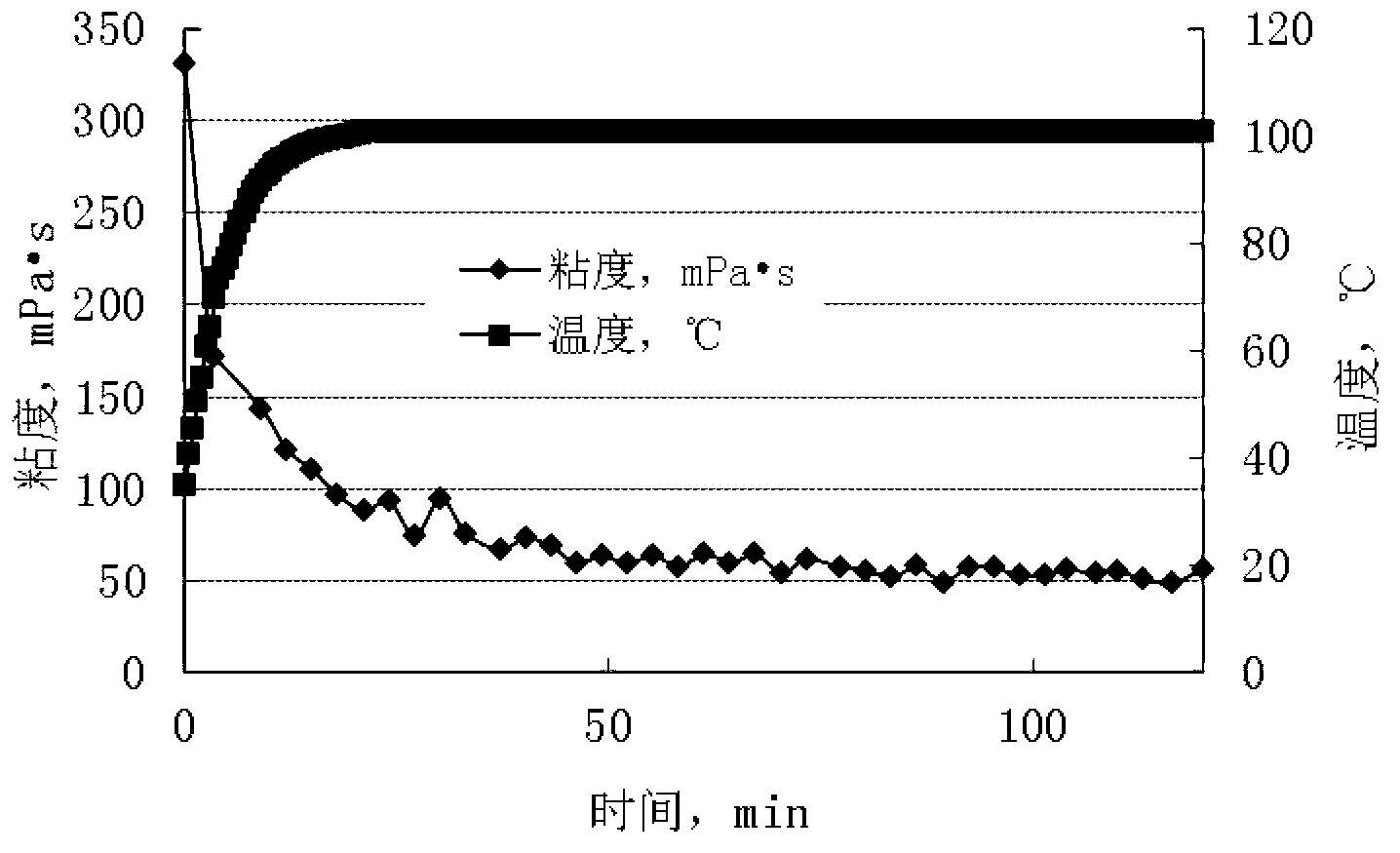

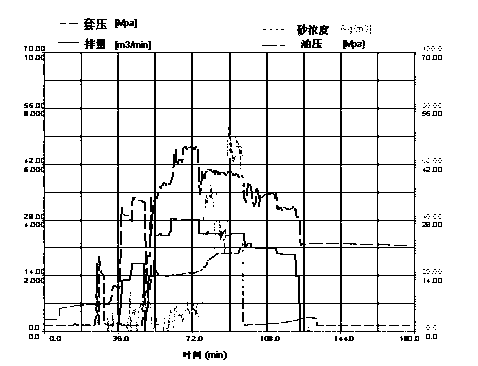

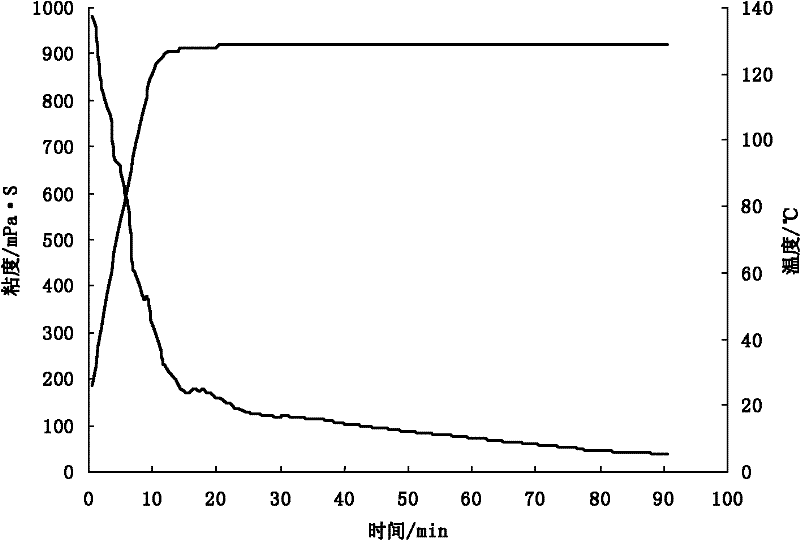

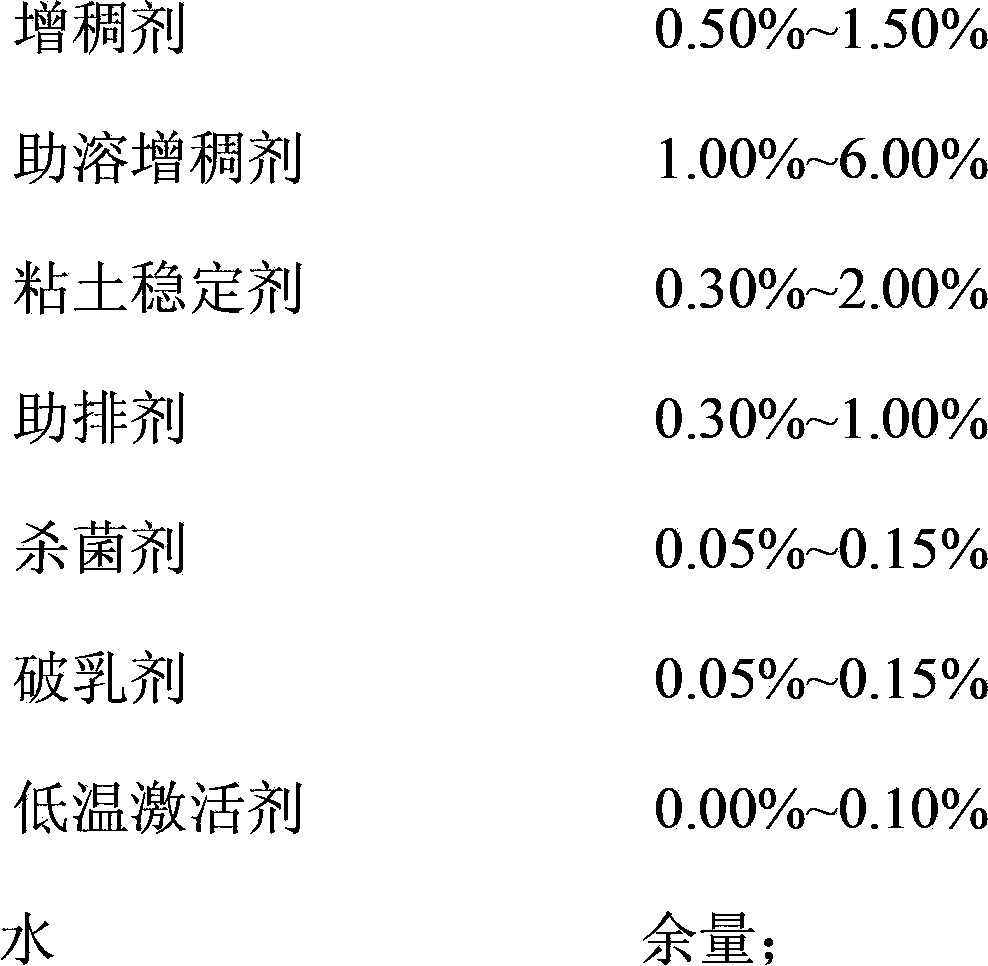

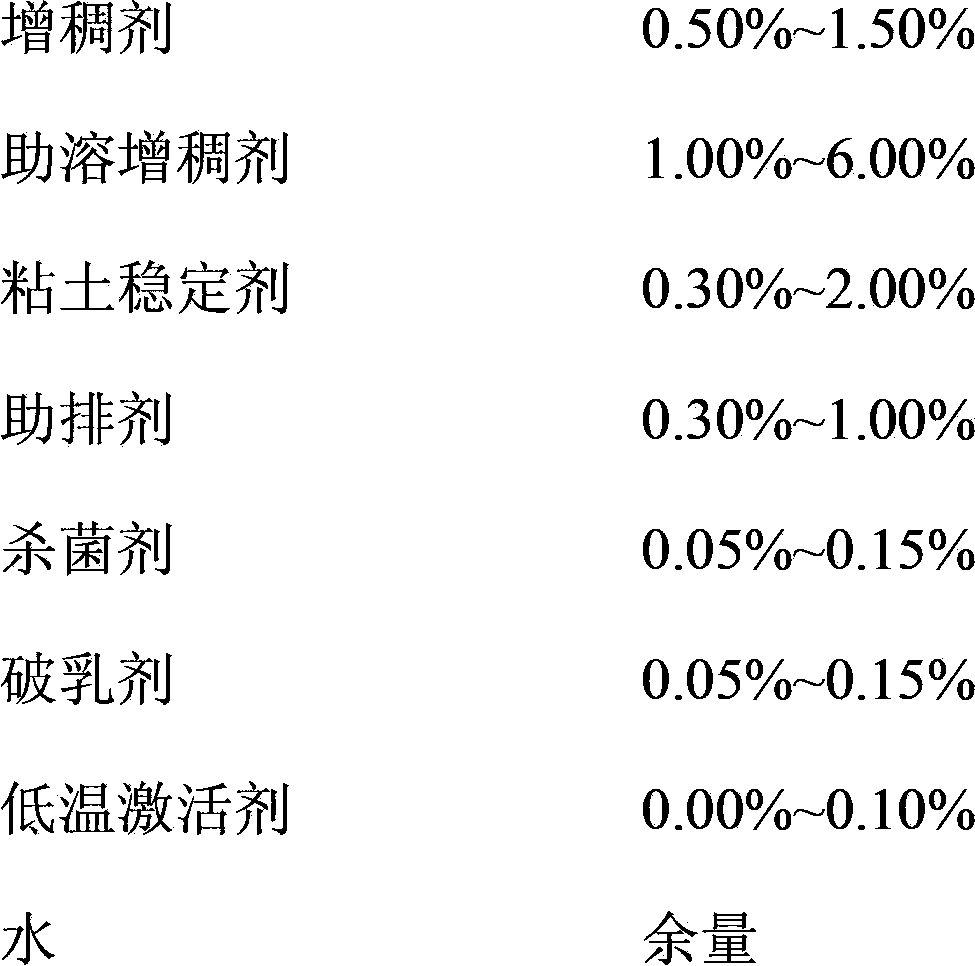

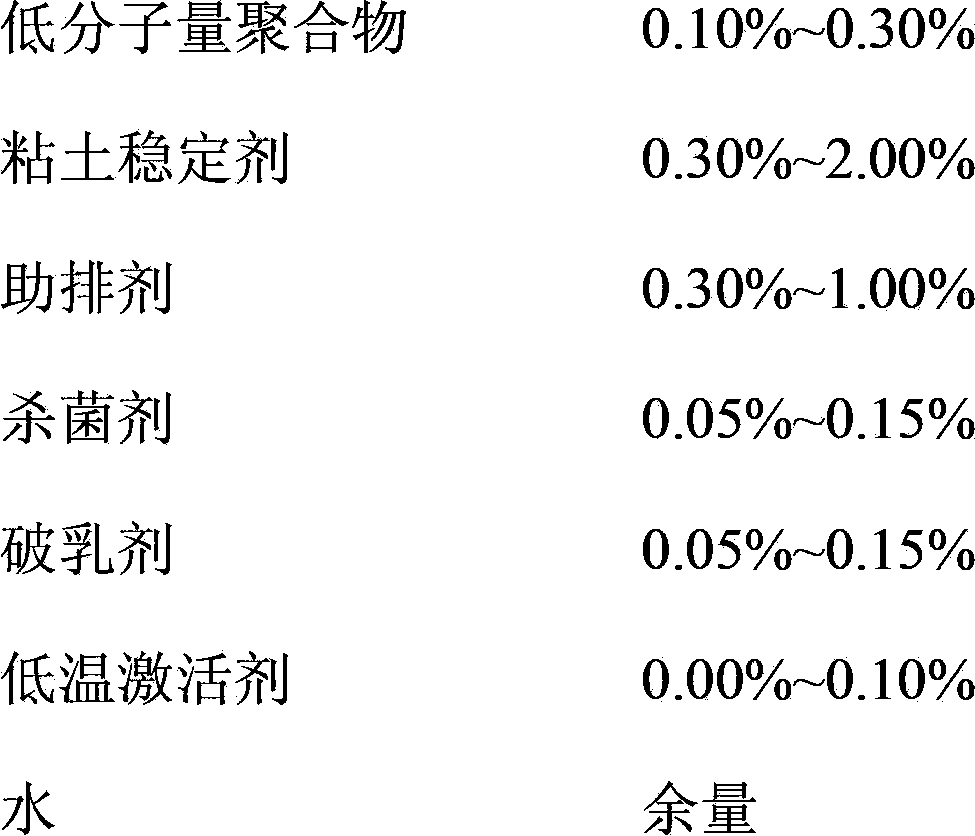

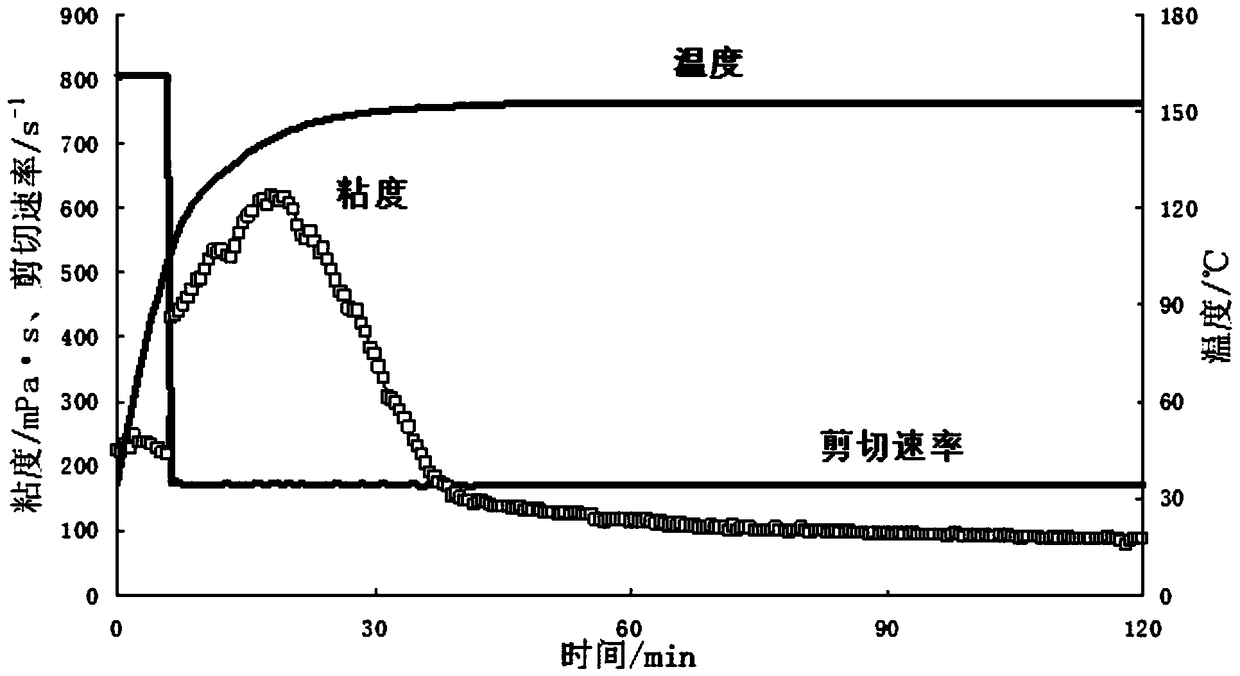

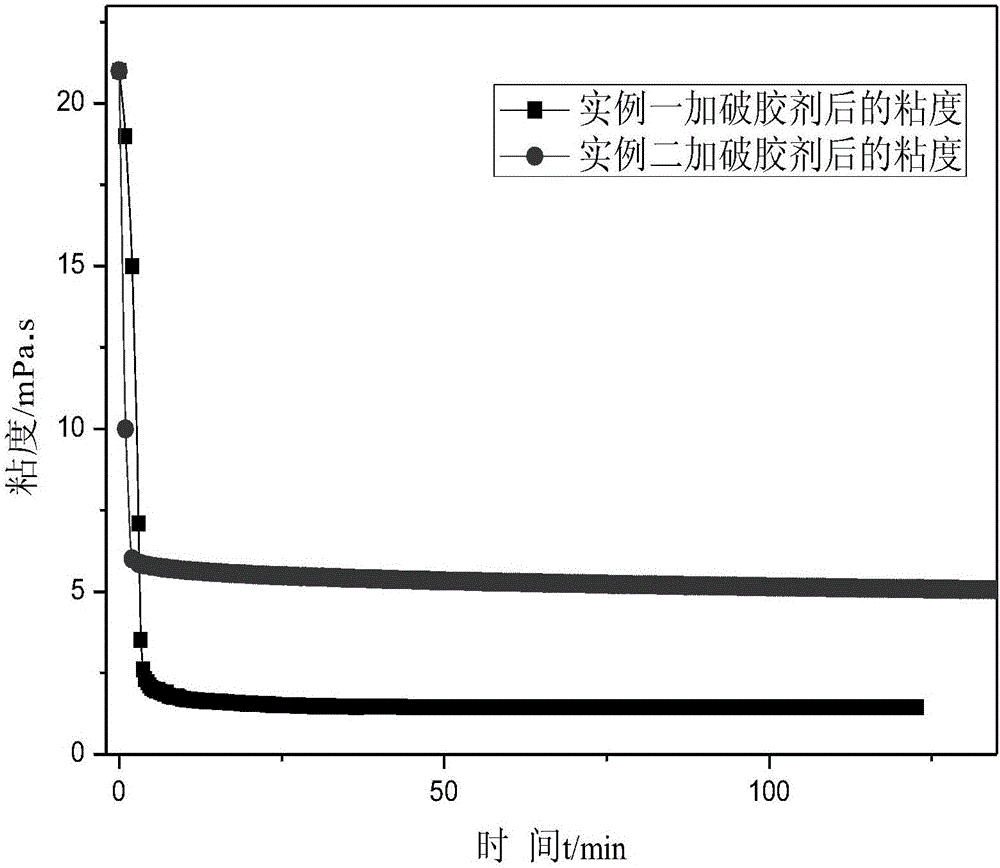

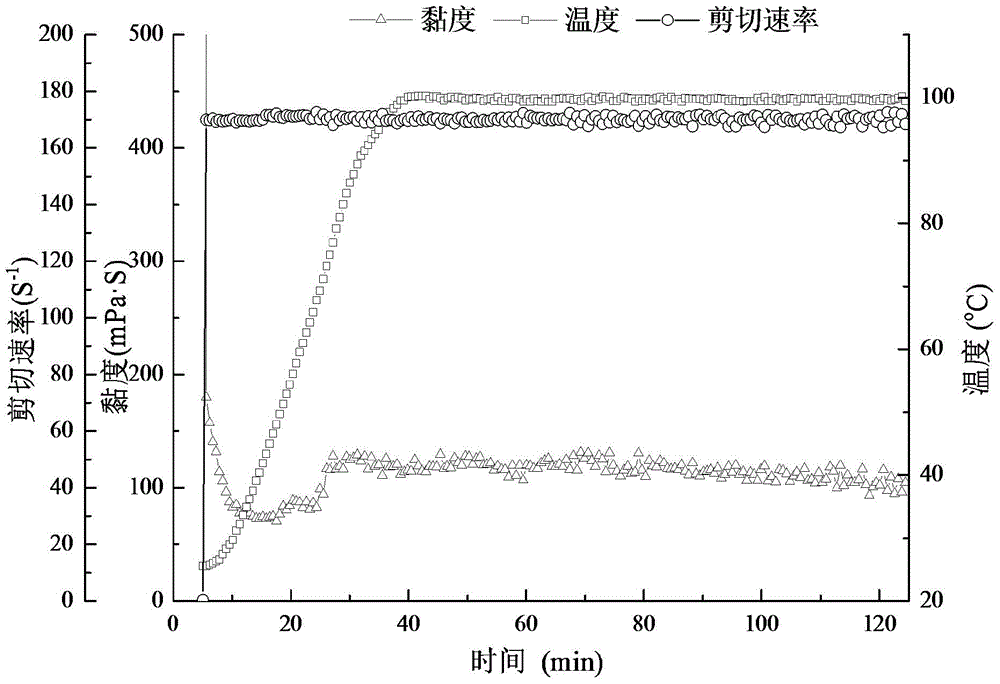

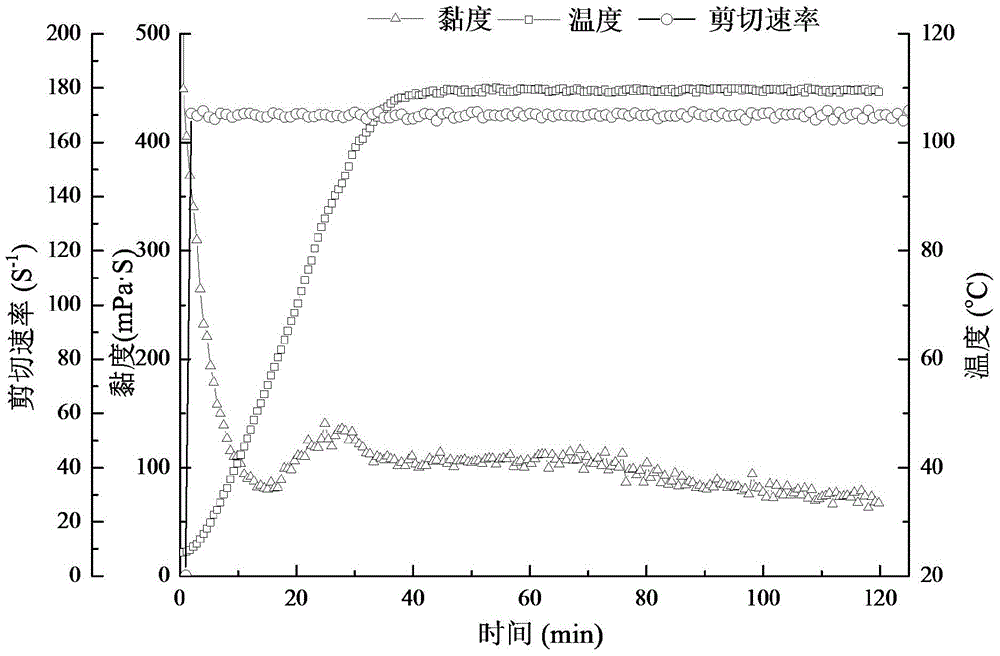

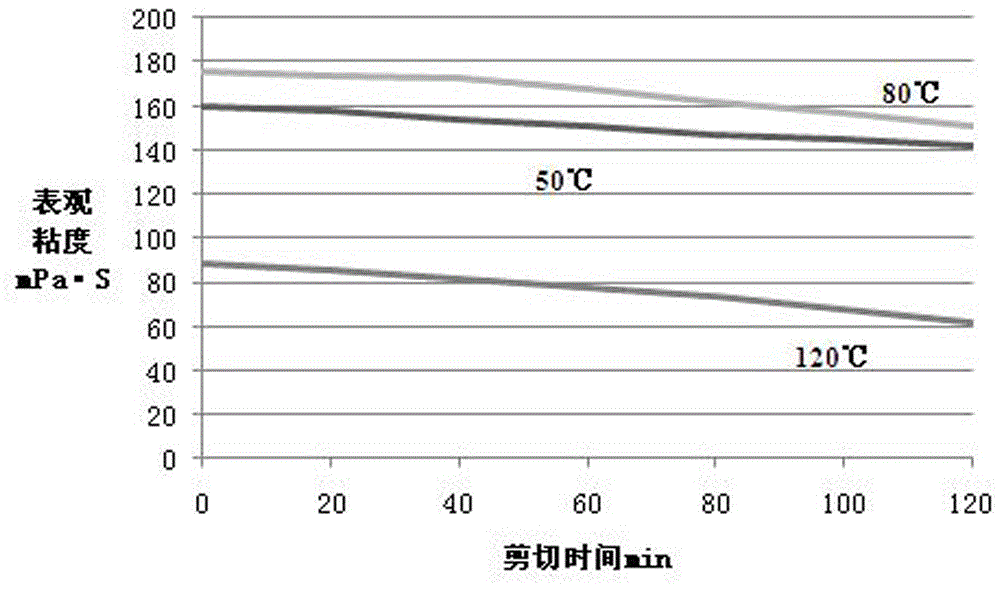

The invention relates to a fracturing fluid which comprises a base fluid A and a base fluid B, wherein the base fluid A is prepared from a thickening agent, a hydrotropy thickening agent, a clay stabilizer, a discharge aiding agent, a sterilizing agent, a demulsifying agent, a low-temperature activator and water; the base fluid B is prepared from a low-molecular weight polymer, the clay stabilizer, the discharge aiding agent, the sterilizing agent, the demulsifying agent, the low-temperature activator and the water. When fracturing construction is carried out, the base fluid A and the base fluid B are mixed in proportion, the low-molecular weight polymer and a thickening agent molecule are mutually wound in a stirring process to form a certain space reticular structure for effective thickening, and the hydrotropy thickening agent compresses a winding structure through electric repulsion so that a gel is further thickened and forms good solid carrying capacity; the shearing is carried out at 50 DEG C and 170S-1,3.5MPa for 60 minutes, the viscosity is more than 50 mPa.s, an oxidized type gel breaker is added according to the proportion of 0.01%-0.20% in a wedge shape, the gel can be thoroughly broken within 2 hours, and the viscosity of gel breaking liquid is less than 5 mPa.s.

Owner:PETROCHINA CO LTD

Self heat-generating and gas-generating clean fracturing fluid

InactiveCN102952535ALess harmfulImprove seepage capacityDrilling compositionPolymer scienceFiltration

The invention relates to a self heat-generating and gas-generating clean fracturing fluid comprising the raw materials of, by mass: 0.2-0.5% of a thickening agent, 2-4% of a structural enhancer, 2-15% of a heat generating agent A, 2-10% of a heat generating agent B, 2% of a structural enhancer solvent, 1-5% of a heat generating catalyst, 0.1-1% of a cleanup additive, 0.05-1.0% of a gel breaker, 0.05-0.15% of a broken plastic additive, and balance of water. The fracturing fluid has good temperature resistance, good shearing resistance, and sand-carrying property. The fluid can automatically generate heat and gas, such that the fracturing fluid is foamed in stratum. The fluid has low filtration loss. Gel breaking can be carried out with conventional persulfate and stratum oil, gas, and water dual gel breaking manner. Quick flow-back after pressure can be realized, and low-pressure oil and gas well self-spraying flow-back effect can be greatly improved. No residue and low harm is caused. The fracturing fluid can be used in fracturing modification of middle-shallow-stratum high-pour-point oil, crude oil with high viscosity, and low-pressure low-permeability oil and gas reservoirs.

Owner:PETROCHINA CO LTD

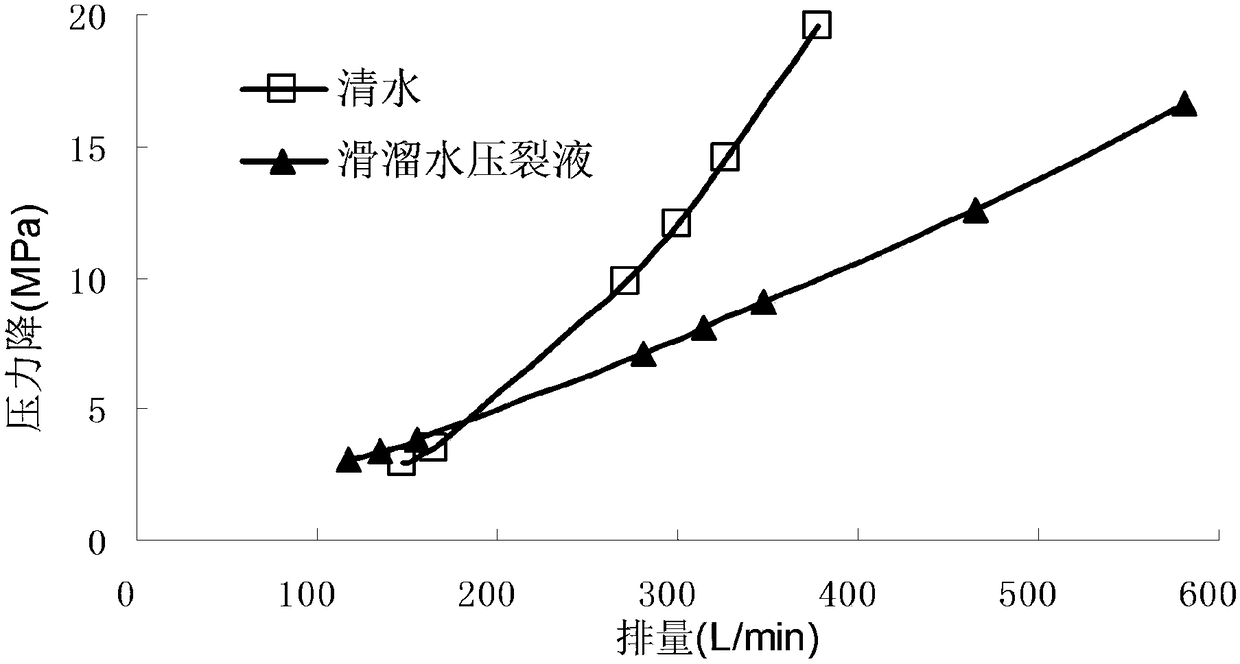

Emulsion type drag reduction thickener used for oil and gas well fracturing, and preparation method thereof

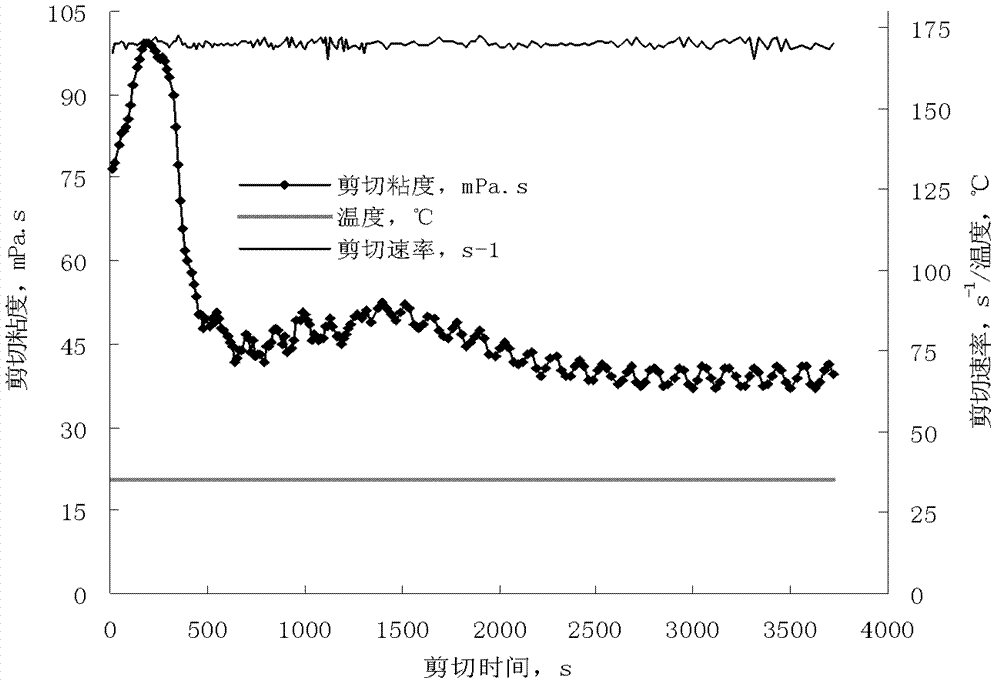

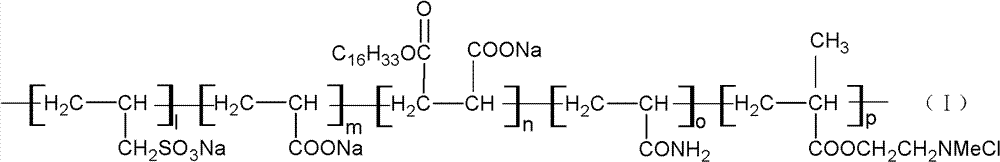

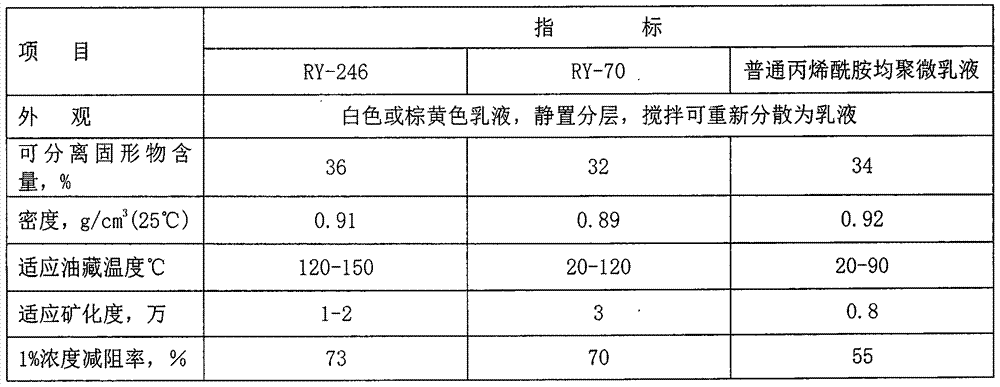

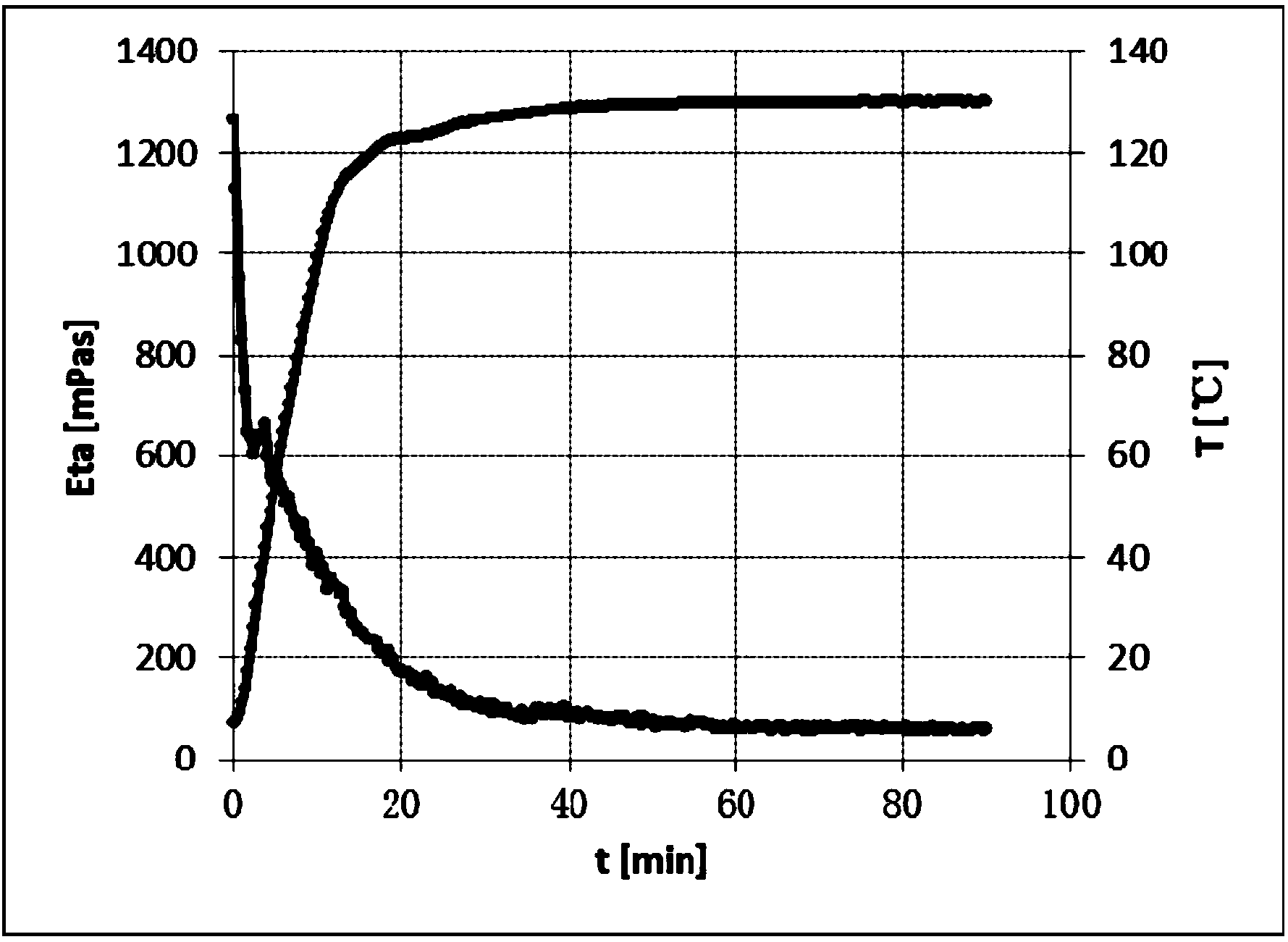

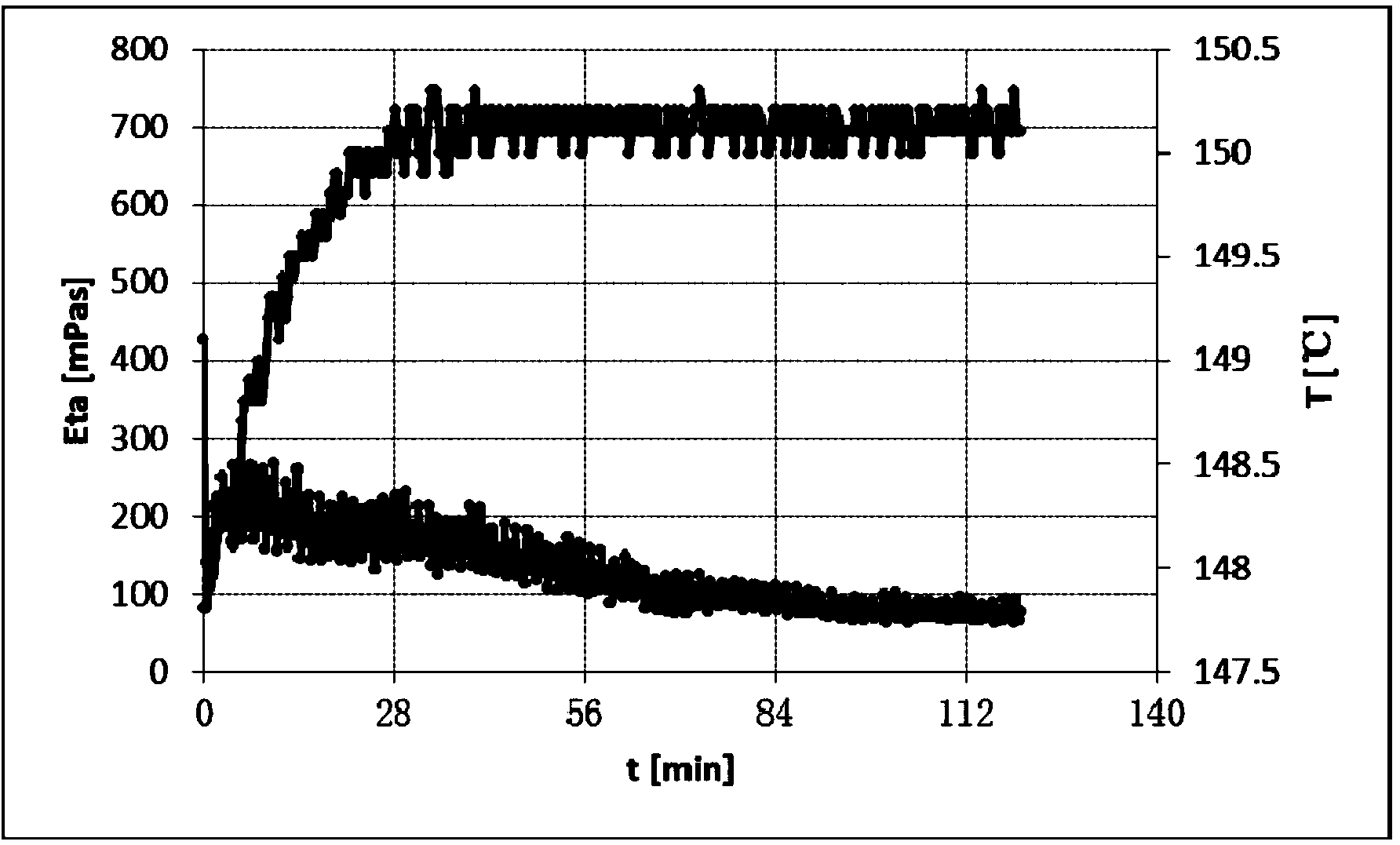

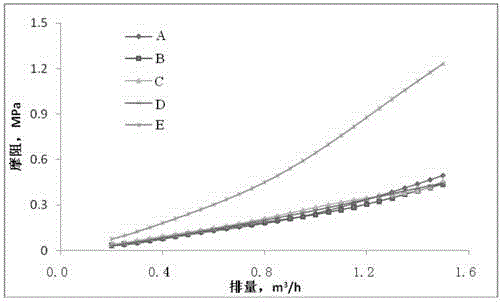

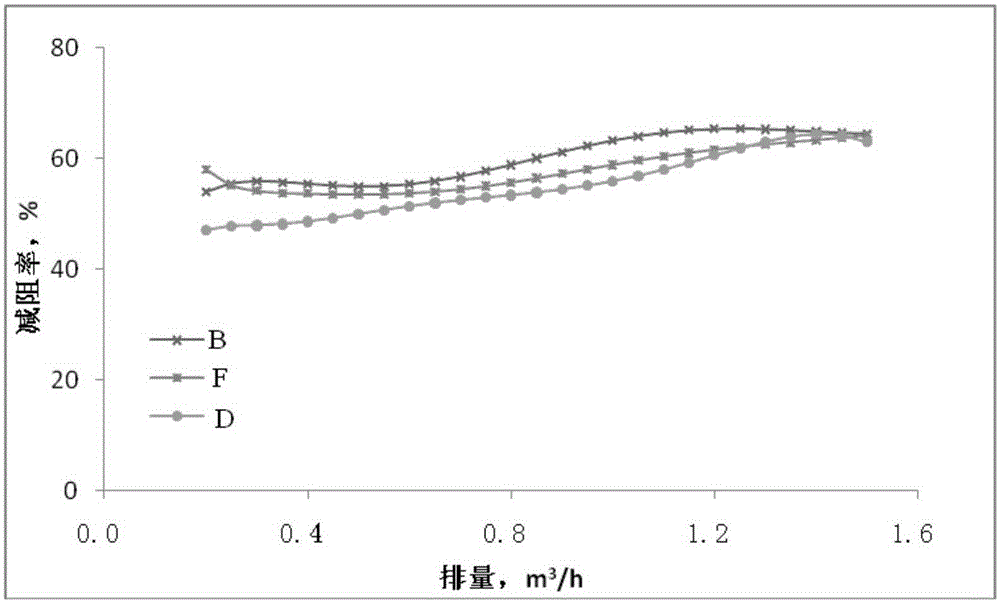

InactiveCN106939159AImprove performanceSimple processDrilling compositionPotassium persulfateReduction rate

The invention discloses a preparation method of an emulsion type drag reduction thickener used for a fracturing fluid. The method comprises the following steps: weighing raw materials comprising acrylamide, functional monomers, span80, potassium persulfate, cyclohexane, OP-10 and deionized water; stirring and mixing a dispersant and cyclohexane in a polymerization monomer; and carrying out initiation and polymerization to form the emulsion type drag reduction thickener. Compared with the prior art, the method has disclosed in the invention the advantages of simple process and environmental protection; and the emulsion type drag reduction thickener has stable performances, the highest reservoir temperature can reach 150 DEG C, the drag reduction rate is 70% or above, and the above one product solves two problems of a drag reduction stage and a sand carrying stage.

Owner:北京希涛技术开发有限公司

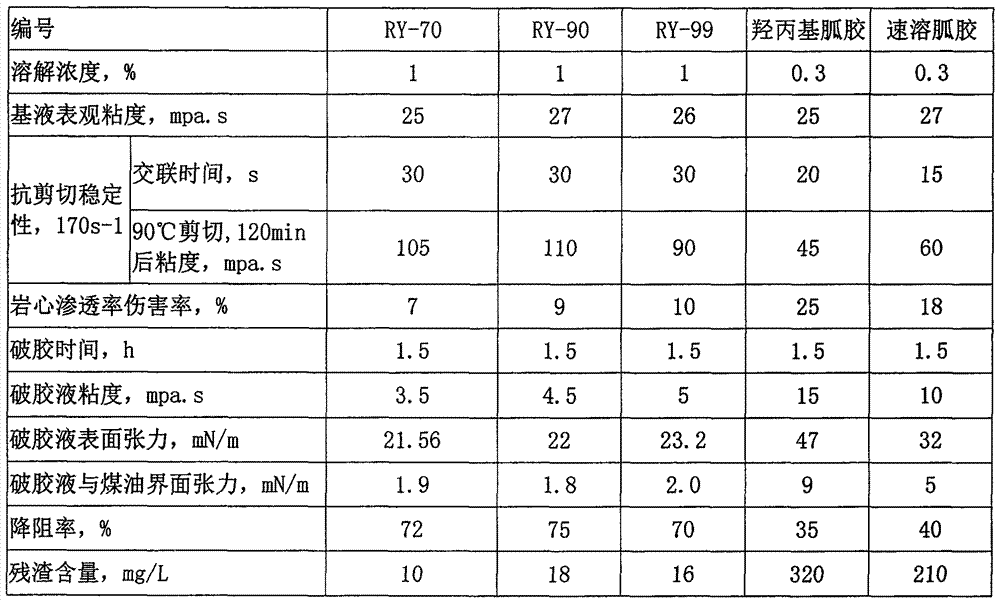

Fracturing fluid prepared by utilizing fracturing flow-back fluid and preparation method thereof

InactiveCN105131932ACompletely broken glueAchieve recyclingDrilling compositionPolymer scienceFracturing fluid

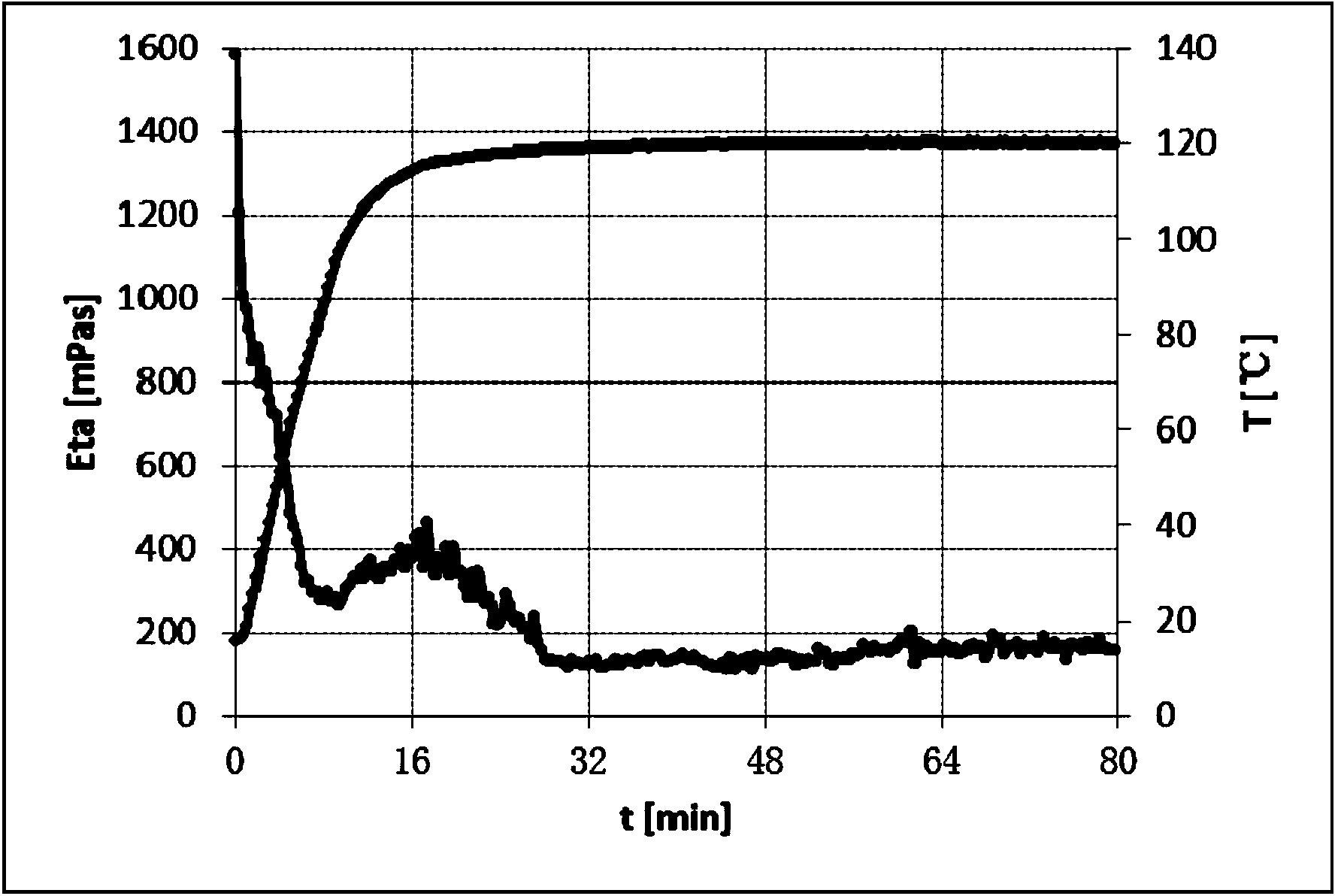

The invention provides a fracturing fluid prepared by utilizing a fracturing flow-back fluid and a preparation method thereof. The fracturing flow-back fluid is not processed or subjected to simple processing and then is directly used to prepare the fracturing fluid. The fracturing fluid is composed of a thickening agent and other auxiliary agents, and employs a crosslinking agent compatible with a guar gum thickening agent used for the flow-back fluid and a crosslinking promoter. The formula crosslinking time 1-3 min is adjustable, the temperature resistance is 120 DEG C or more, and the system frictional resistance is reduced by 20% or more compared with a common hydroxypropyl guar gum fracturing liquid. The fracturing liquid preparation method realizes cyclic utilization of the fracturing flow-back fluid, and the prepared fracturing liquid possesses good performances.

Owner:昆山京昆油田化学科技有限公司

Inverse-phase micro-emulsion polymer fracturing fluid system with online construction function

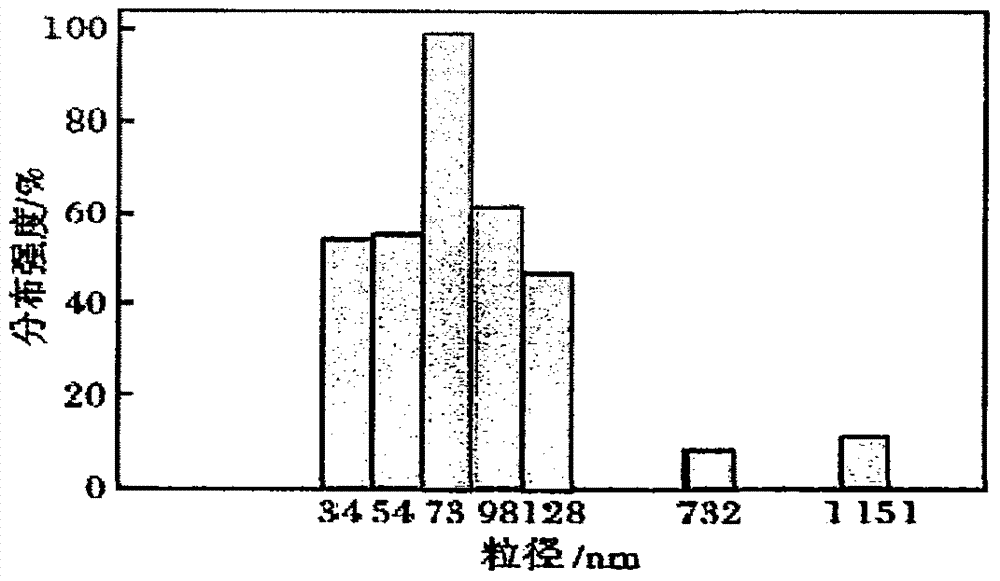

ActiveCN108559479AGood resistance reduction effectEasy to reuseDrilling compositionMethacrylatePolymer science

The invention discloses an inverse-phase micro-emulsion polymer fracturing fluid system with an online construction function. The inverse-phase micro-emulsion polymer fracturing fluid system comprisesinstant dissolving emulsion thickening agents, functional auxiliaries, a clay stabilizer and fluid preparation water. The instant dissolving emulsion thickening agents are inverse-phase micro-emulsion polymers, and inverse-phase micro-emulsion polymerization is carried out on raw materials including acrylamide, acrylic acid, strong-hydrophilicity monomers, a functional monomer A, a functional monomer B, pH (potential of hydrogen) regulators, solubilizers, composite emulsifiers, oil solvents, initiators and deionized water to obtain the instant dissolving emulsion thickening agents; the functional monomer A is methyl methacrylate or ethyl methacrylate or a mixture of the methyl methacrylate and the ethyl methacrylate; the functional monomer B is vinylphosphonic acid or vinyl sulfonic acid;the functional auxiliaries are non-ionic surfactants; the clay stabilizer is potassium chloride, and the fluid preparation water is clear water or high-mineralization water or treated stratum flow-back fluid. The inverse-phase micro-emulsion polymer fracturing fluid system has the advantages that the inverse-phase micro-emulsion polymer fracturing fluid system is high in dispersing and swelling speed and can be prepared in a batch manner or can be continuously mixed, 'online construction' requirements even can be completely met by the inverse-phase micro-emulsion polymer fracturing fluid system, processes for constructing the inverse-phase micro-emulsion polymer fracturing fluid system are simple, and the fracturing cost can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

Preparation and application of anionic clean fracturing liquid and gel breaker thereof

InactiveCN106566521AGood effectGood sand carryingFluid removalDrilling compositionFracturing fluidSURFACTANT BLEND

The invention relates to the technical field of oil filed fracturing, and specifically relates to an anionic clean fracturing liquid, which is composed of 0.5 to 10% of anionic surfactant, 5 to 20% of counter-ion salts, and the balance being water. The provided clean fracturing liquid preserves all advantages of conventional clean fracturing liquids. The species of additives can be reduced and the requirements on liquid blending equipment can be lowered by using the clean fracturing liquid. The fracturing liquid can be used in oil fields with a high mineralization degree. The gel breaking time can be well controlled by using a gel breaker and the cost is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

Organic aluminum-zirconium crosslinking agent and preparation method thereof, and low-molecular polymer fracturing fluid

InactiveCN104371699AImprove high temperature resistanceFacilitate cross-linkingDrilling compositionSolubilityFracturing fluid

The invention discloses an organic aluminum-zirconium crosslinking agent and a preparation method thereof, and a low-molecular polymer fracturing fluid. The crosslinking agent is prepared by reacting the following raw materials in parts by weight: 15-25 parts of zirconium salt, 15-25 parts of aluminum salt, 150-250 parts of polyalcohol, 75-85 parts of organic acid, 15-25 parts of gluconate and 55-65 parts of water. The organic aluminum-zirconium crosslinking agent has excellent high temperature resistance, and has favorable crosslinking effect under the conditions of high temperature and high salinity. The organic aluminum-zirconium crosslinking agent is stable under the condition of low pH value, can implement acid crosslinking, and ensures the normal proceeding of the acid fracturing. The organic aluminum-zirconium crosslinking agent has favorable compatibility with polymers and high crosslinking capacity; and the fracturing fluid formed by compounding the organic aluminum-zirconium crosslinking agent with polymers has the advantages of stable gel, excellent solid carrying capacity, excellent viscosity breaking performance and excellent shearing resistance under high-temperature conditions. The organic aluminum-zirconium crosslinking agent has the characteristics of high solubility, no pollution and low damage degree to the reservoir, and has wide application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional composite fracturing liquid system

ActiveCN105219372AStrong shear resistanceSimple recipeDrilling compositionHigh concentrationOrganic synthesis

The invention provides a multifunctional composite fracturing liquid system. The multifunctional composite fracturing liquid system comprises resistance reduction water and high-viscosity sand carrying liquid, wherein the resistance reduction water comprises 0.02 to 0.15 percent by weight of the resistance reduction agent; the high-viscosity sand carrying liquid comprises 0.2 to 0.75 percent by weight of a thickening agent; the resistance reduction agent and the thickening agent are identical aggregation polymer and are natural modified aggregation polymer and / or organic synthetic aggregation polymer. The low-concentration aggregation polymer having good resistance reduction performance and the high-concentration aggregation polymer having good sand carrying performance are used for forming the multifunctional composite fracturing liquid system; compared with the existing composite fracturing liquid system, the multifunctional composite fracturing liquid system has characteristics of fewer types of additives, simple formula and simple preparation process; meanwhile, the system has good resistance reduction performance, shear resistance and sand carrying performance; return liquid of the system can be reused after being treated in a way such as flocculating, precipitating and filtering, and the utilization rate of water for fracturing is increased.

Owner:SICHUAN GUANGYA POLYMER CHEM

High-temperature-resistant full-suspension low-damage fracturing fluid and preparation method thereof

The invention discloses a high-temperature-resistant full-suspension low-damage fracturing fluid, which comprises the following components in percentage by weight: 0.3-0.5% of a low-damage thickeningagent, 0.1-0.4% of a multifunctional stabilizer, 0.1-0.3% of a regulator, 0.4-0.8% of a suspension synergist and the balance of clear water or saline water; the preparation method of the fracturing fluid comprises the following steps of: 1, adding the low-damage thickening agent, the multifunctional stabilizer and the regulator into clear water or saline water under a stirring condition, uniformlystirring, and swelling for 2 to 4 hours to obtain fracturing fluid base liquid; 2, fully mixing the fracturing fluid base liquid and the suspension synergist to form the full suspension fracturing fluid with excellent sand carrying performance and temperature resistance under the combined action of physical crosslinking and chemical crosslinking. The fracturing fluid is superstrong structure fluid formed by carrying out physical crosslinking and chemical crosslinking on acrylamide polymer and suspension synergist together, and the temperature resistance can reach 150 DEG C; the sand carryingperformance is excellent, the strong spatial structure can completely suspend a proppant, and the influence of temperature is small.

Owner:SOUTHWEST PETROLEUM UNIV +2

High-temperature-resistant thickening agent for fracturing fluid, and preparation method and application thereof

InactiveCN111019042AExcellent high temperature resistance and salt resistanceGood solubilityDrilling compositionFunctional monomerMaterials science

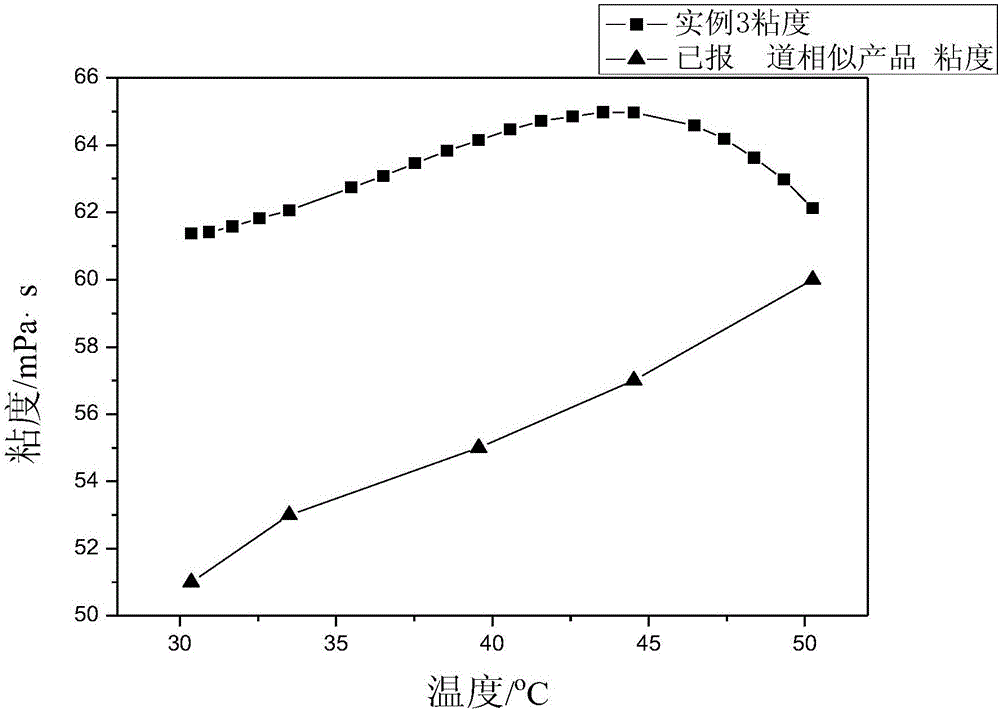

The invention discloses a high-temperature-resistant thickening agent for a fracturing fluid, and a preparation method and an application thereof. The high-temperature-resistant thickening agent for the fracturing fluid and is characterized in that the thickening agent comprises acrylamide, a salt-resistant functional monomer and a temperature-sensitive functional monomer free radical; and the molar ratio of the acrylamide to the salt-resistant functional monomer to the temperature-sensitive functional monomer is 1:(0.01-0.08):(0.05-0.15). A temperature-sensitive unit and a salt-resistant unitare introduced into an acrylamide molecular chain in a solution copolymerization mode, so that the copolymer is endowed with excellent high-temperature resistance and salt resistance and also has good solubility, viscoelasticity and sand carrying property.

Owner:四川盛年同缔实业有限公司

Guar gum cleaning fracturing fluid with micro residue and weak damage

InactiveCN106905948AUse low concentrationReduce harmDrilling compositionPolymer scienceSulfate radicals

The invention relates to guar gum cleaning fracturing fluid with micro residue and weak damage. The guar gum cleaning fracturing fluid with micro residue and weak damage is composed of base liquid, a cross-linking agent and a gel breaker, the base liquid is composed of hydroxypropyl guar gum, a cleanup additive, an anti-swelling stabilizing agent, a fracturing bactericide, a fracturing de-emulsifier, a scale inhibitor and water. According to the invention, a guar gum multinucleated cross-linking agent with low amount is used, delay crosslinking effect is strong, guar gum concentration is greatly reduced, glue breaking residue amount is reduced, a multifunctional scale inhibitor is cooperated for preventing fouling generated by water used for fracturing liquid and stratum water, a selective polymer fracturing catalyst capable of thoroughly breaking glue and no generating sulfate radical is selected, liquid viscosity and residue content are reduced, the surface tension of the gel breaker after gel is broken is lower, the gel breaker is easily discharged, the formed guar gum multinucleated cross-linking agent has good temperature and shearing sustainability, and excellent proppant carrying capacity.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Crosslinking agent system, low-concentration polymer crosslinked fracturing fluid and preparation methods of crosslinking agent system and low-concentration polymer crosslinked fracturing fluid

InactiveCN108179008AImprove efficacyLower seepage capacity of the groundDrilling compositionPolymer scienceFracturing fluid

The invention provides a crosslinking agent system, a low-concentration polymer crosslinked fracturing fluid and preparation methods of the crosslinking agent system and the low-concentration polymercrosslinked fracturing fluid. The low-concentration polymer crosslinked fracturing fluid has both high viscoelasticity of the existing polymer fracturing fluid and low damage of a clean fracturing fluid. The economical efficiency of the fracturing fluid is improved by means of low concentration, and accordingly, the low-concentration polymer crosslinked fracturing fluid is more popular with oilfields on the premise of cost decreasing, benefit increasing and reservoir protecting. A prepared base fluid has the viscosity range of 10-24 mPa.s, and is easy to prepare and pump. Delayed crosslinkingtime is 30-120 s, gel can be formed after crosslinking, viscosity is enhanced three times or more, sand carrying is facilitated, and a supporting agent can be delivered to the far end of a fracture. Therefore, the low-concentration polymer crosslinked fracturing fluid inherits various advantages of the traditional fracturing fluid, and further, the sand carrying capability and fracture conductivity of the fracturing fluid can be improved effectively.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

Low-damage and ultralow-concentration guar gum fracturing fluid system, preparation method and application of guar gum fracturing fluid system

ActiveCN106085404AReduce concentrationReduced shear resistanceDrilling compositionCarrying capacityHeat resistance

The invention discloses a low-damage and ultralow-concentration guar gum fracturing fluid system, a preparation method and an application of the guar gum fracturing fluid system and belongs to the technical field of reservoir reforming for oil-gas field development. In order to solve the problems that the existing conventional fracturing fluid systems hardly give attention to the lowering of concentration of a thickener, the prolonging of crosslinking time, the improving of gel strength and gelout capability and being environmentally friendly, a SITAR-11 powerful delayed crosslinker is selected, so that formed gel is endowed with a relatively high delayed crosslinking effect while heat resistance, shearing resistance and solid carrying capacity for the formed gel are guaranteed, and the concentration of the thickener is greatly lowered; and on one hand, the reduction of cost and the increase of economic benefit are facilitated, and on the other hand, the amount of gelout residues is reduced after the concentration of the thickener is lowered. Further, FANTA-05 and FANTA-06fracturing gelout enzymes, which are thorough in gelout and controllable in gelout time, and a ZITHE-34 efficient discharge aiding agent are added in a matched manner, so that the fracturing fluid system, which has a delayed crosslinking effect, is high in heat resistance and salt tolerance, excellent in solid carrying behavior, controllable in gelout time and thorough in gelout and is green, environmentally friendly and efficient, can be formed.

Owner:CHINA PETROLEUM & CHEM CORP +1

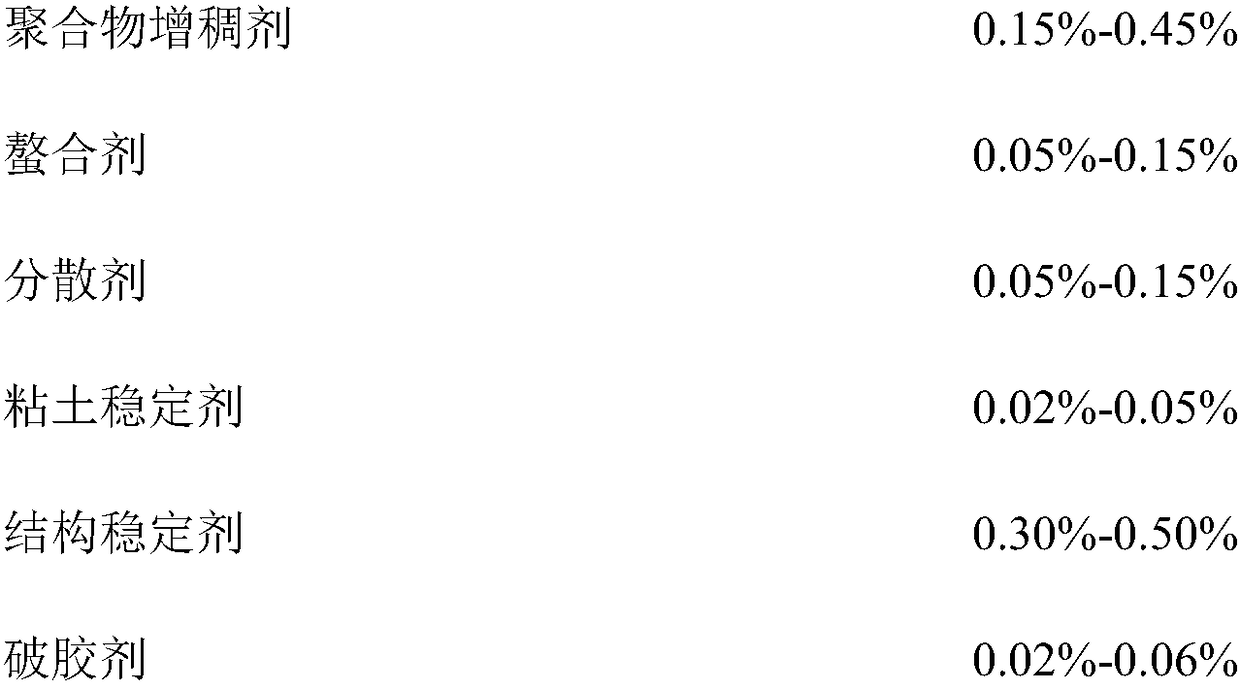

Slickwater fracturing fluid suitable for being used at hypersalinity condition

InactiveCN108559477AGood drag reduction performanceSimple processDrilling compositionSalt resistanceStabilizing Agents

Provided is a slickwater fracturing fluid suitable for being used at a hypersalinity condition. The slickwater fracturing fluid is prepared from, by mass, 0.15-0.45% of polymer viscosifier, 0.05%-0.15% of chelating agent, 0.05%-0.15% of dispersing agent, 0.02%-0.05% of clay stabilizer, 0.30%-0.50% of structure stabilizer, 0.02%-0.06% of gel breaker and the balance water. The slickwater fracturingfluid has the advantages of being low in viscosity, friction and cost and easy to recycle, easily flowing back and the like; the problems are mainly solved that at the hypersalinity condition, polymers are poor in salt resistance and sand-carrying stability and does not easily disperse; the problem can also be solved that vegetable glue fracturing fluid easily rots; after being filtered, flow-backliquid can be further directly recycled, and requirements of large-scale fracturing construction of compact oil-gas reservoirs can be effectively met.

Owner:PETROCHINA CO LTD

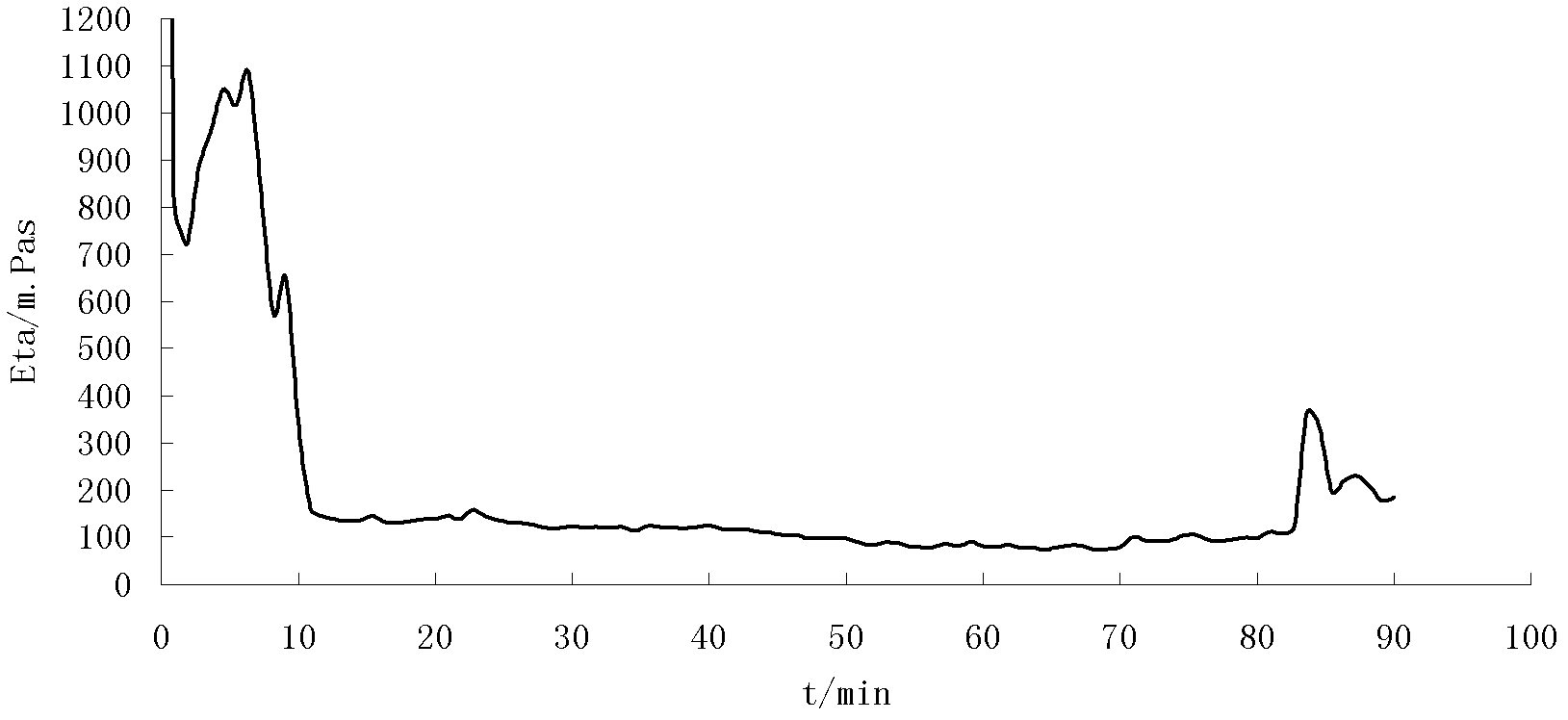

High-density fracturing fluid capable of slowing crosslinking and resisting high temperature

ActiveCN103254885AGood temperature and shear resistanceIncrease pressureDrilling compositionCross-linkPolymer science

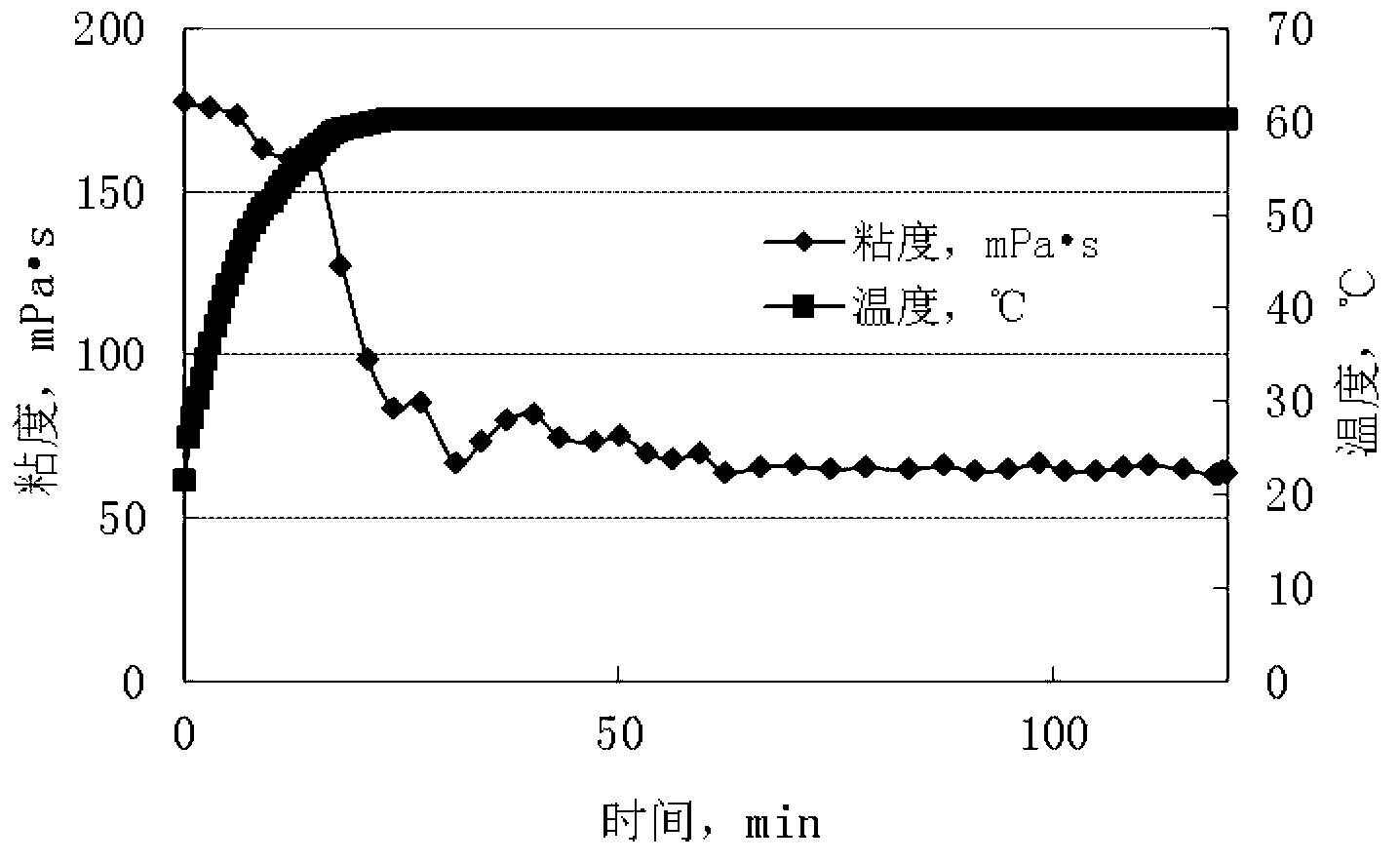

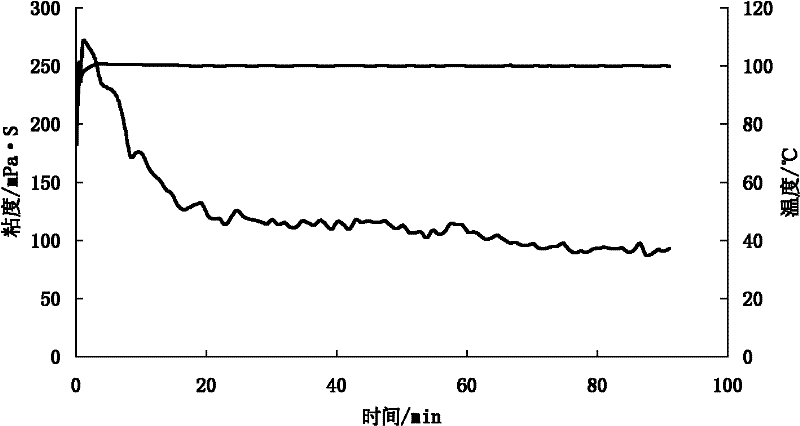

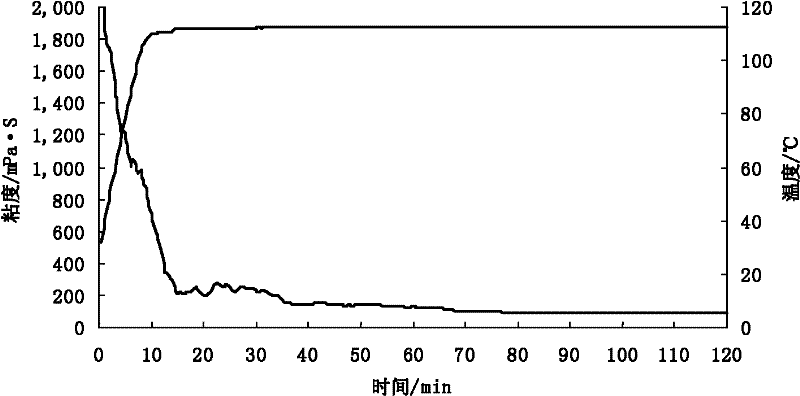

The invention relates to a high-density fracturing fluid capable of slowing crosslinking and resisting high temperature. The fracturing fluid is composed of a stock solution and a crosslinking liquid with a volume ratio of 10 : 1, wherein the stock solution comprises, by weight percent, 0.5-0.65 % of hydroxypropyl guar gum, 8-45 % of a weighting agent A, 6-30 % of a weighting agent B, 0.5-2 % of a ZJ-07 cleanup additive, 0.01-0.04 % of a pH-value conditioning agent A, and the balance being water; the crosslinking liquid comprises, by weight percent, 0.5-3 % of a cross-linking agent YGB, 1-2 % of a cross-linking agent HT, 0.1-0.4 % of a pH-value conditioning agent B, 0-0.35 % of a gel breaker and the balance being water. The fracturing fluid is good in temperature-resistance and shearing-resistance performances, wherein the temperature-resistance performance is up to 145 DEG C, and a viscosity is still more than 120 Pa*S after the liquid is sheared for 90 minutes under 145 DEG C and 170 S<-1>.

Owner:PETROCHINA CO LTD

Boron cross-linking agent for fracturing fluid and preparation method thereof and ultralow hydroxypropylguar gum concentration fracturing fluid prepared from boron cross-linking agent

InactiveCN105754574AIncreased cross-linking sitesSmall sizeDrilling compositionCross-linkPolymer science

The invention relates to a boron cross-linking agent for a fracturing fluid in the technical field of oil-gas field development and an ultralow hydroxypropylguar gum concentration fracturing fluid prepared from the boron cross-linking agent. The cross-linking agent comprises the following ingredients (by weight): 20-30 parts of an amide compound, 40-60 parts of water, 50-100 parts of glycol, 13-25 parts of boric acid, 20-30 parts of n-butanol and 30-40 parts of an aldehyde compound. The ultralow hydroxypropylguar gum concentration fracturing fluid contains (by volume): 98.6-98.9 parts of a hydroxypropylguar gum aqueous solution and 0.6-0.9 part of the boron cross-linking agent for a fracturing fluid. By the use of the cross-linking agent and under the precondition of guaranteeing performance of the fracturing fluid, hydroxypropylguar gum concentration can be reduced by more than 30%, thus lowering costs of the fracturing fluid and decreasing damage to the bottom layer.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anhydrous fracturing fluid suitable for shale gas and preparation method of anhydrous fracturing fluid

The invention belongs to the technical field of petrochemical engineering, and particularly relates to an anhydrous fracturing fluid suitable for shale gas and a preparation method of the anhydrous fracturing fluid. The anhydrous fracturing fluid suitable for shale gas is prepared from the following raw materials in percentage by mass: 0.5-2% of a crosslinking agent, 2-6% of a complex iron activator and the balance of a low carbon hydrocarbon; in a pressure vessel with a pressure of 0.8-3.0 MPa, the crosslinking agent is added into the low carbon hydrocarbon to be uniformly mixed, the complex iron activator is added to be stirred for 2-5 min, so that the anhydrous fracturing fluid suitable for shale gas is obtained; and the low carbon hydrocarbon is one or a mixture of more of propane, butane, n-hexane, n-heptane and kerosene. The anhydrous fracturing fluid suitable for shale gas easily flows back, has a good sand-carrying property, does not harm reservoirs, and can satisfy the needs of fracturing reconstruction of shale oil and gas and strong water-sensitive compact oil and gas reservoirs. A synthetic method is simple, and the content of an effective component dialkyl phosphate in a product is high, thereby facilitating the industrialization production of the anhydrous fracturing fluid.

Owner:SOUTHWEST PETROLEUM UNIV

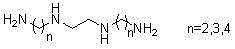

Clean fracturing fluid for oil fields and preparation method thereof

ActiveCN105820805AImprove performanceLow temperature resistanceDrilling compositionOrganic acidFracturing fluid

The invention discloses clean fracturing fluid for oil fields and a preparation method thereof, belonging to the technical field of oil production engineering in the petroleum industry. The clean fracturing fluid can be obtained by synthesizing a gemini surfactant by using organic acids, an N,N-dimethylamino compound, an N,N'-diaminoalkylethylenediamine compound and halohydrin as raw materials and then stirring a water solution of the gemini surfactant and an ammonium chloride solution according to a certain proportion. Compared with traditional fracturing fluid, the clean fracturing fluid has good temperature and shear resistance and good sand-carrying property, dispenses with gel breakers and reverse discharge and is convenient to use.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

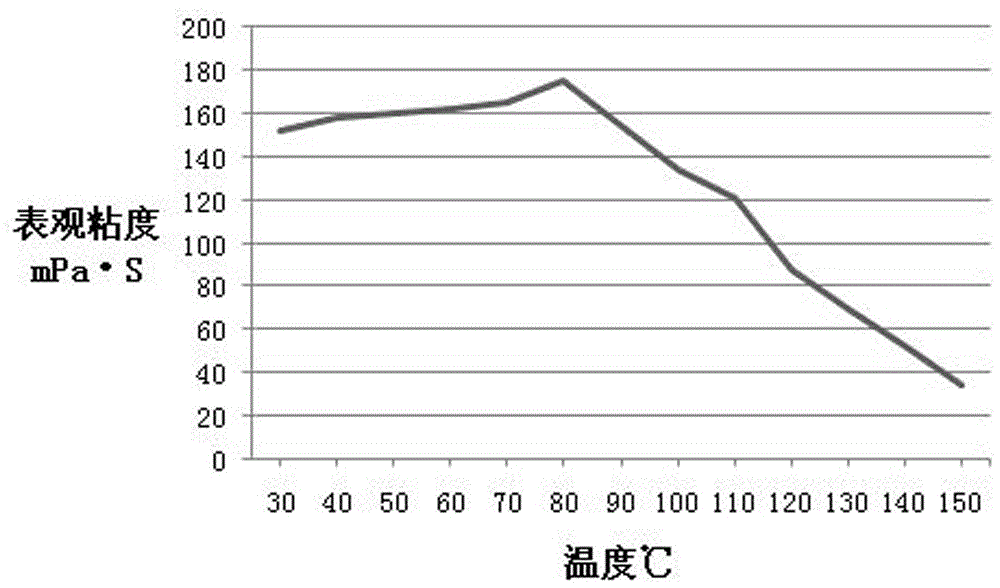

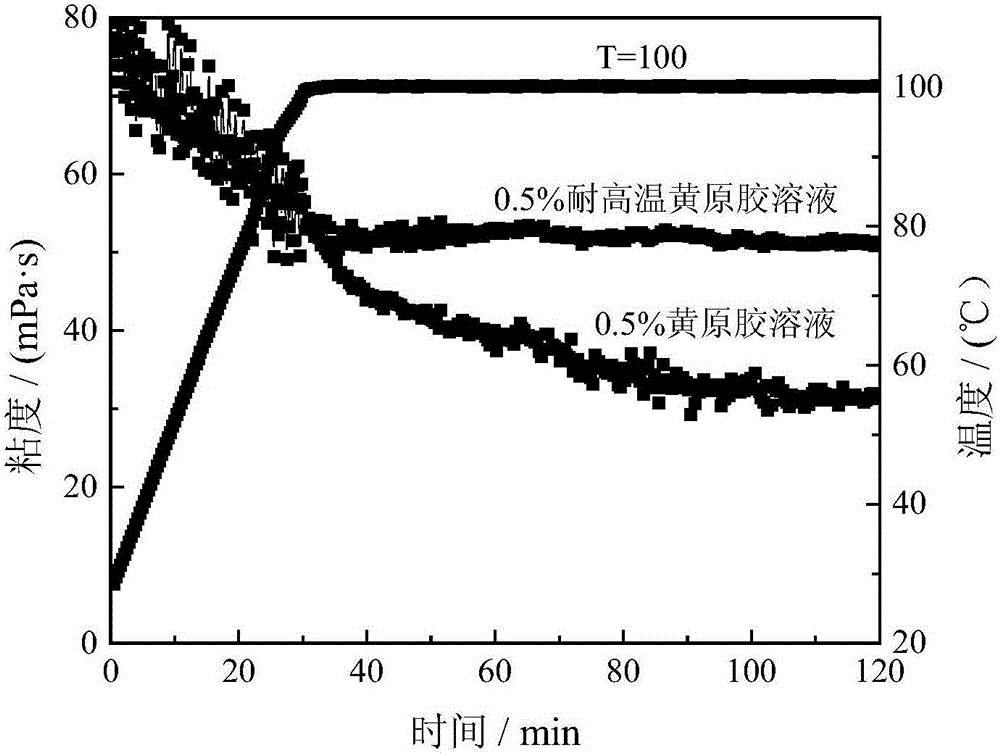

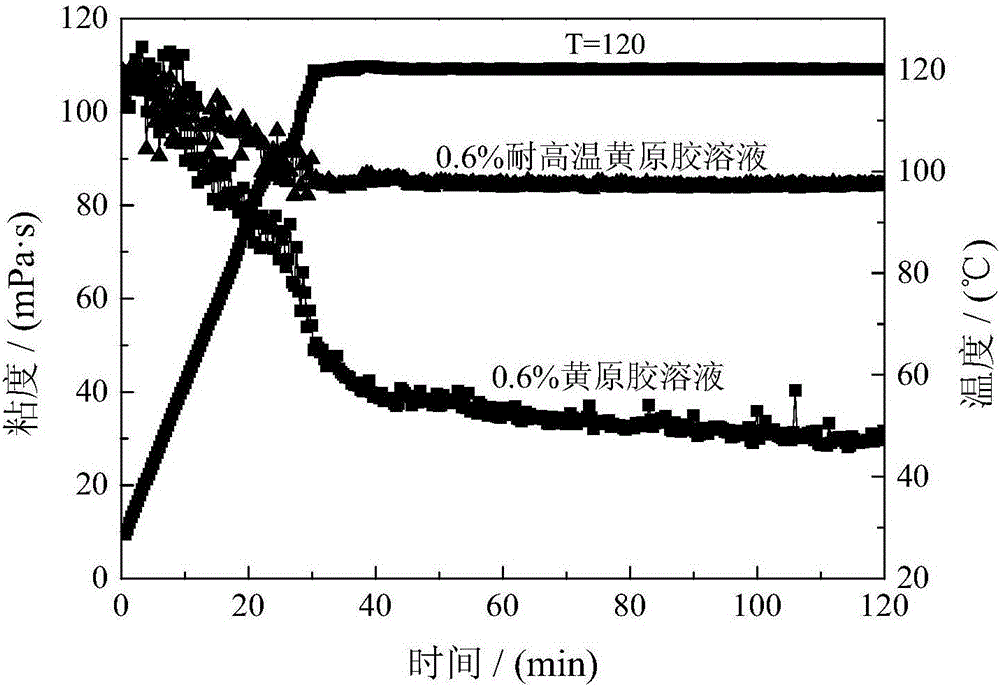

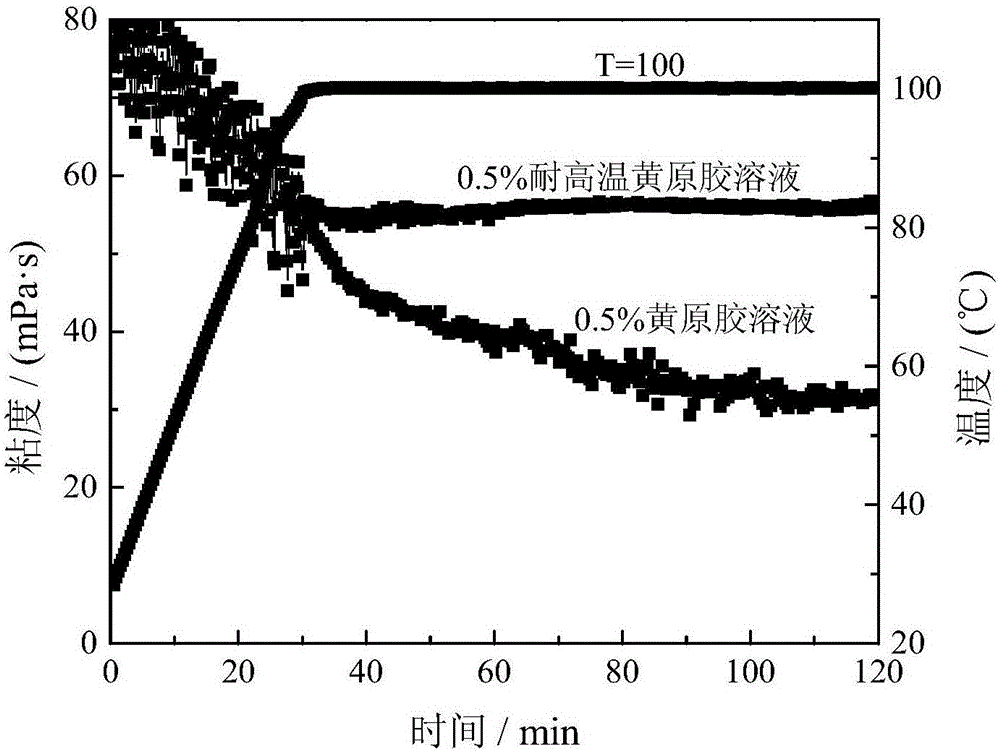

High-temperature-resistant xanthan gum fracturing fluid and preparation method thereof

InactiveCN106800924AGood sand carryingImprove temperature and shear resistanceDrilling compositionFracturing fluidChloride

The invention provides a high-temperature-resistant xanthan gum fracturing fluid and a preparation method thereof. The fracturing fluid comprises the following components in parts by weight: 0.4-0.6 part of xanthan gum, 0.2-2 parts of temperature stabilizer and 1.0-3.0 parts of other auxiliary additives. The temperature stabilizer (composed of calcium chloride, potassium formate and the like) is added to promote the transformation of the xanthan gum structure to the double spiral structure, thereby enhancing the temperature resistance and shear resistance; and thus, the xanthan gum still has favorable solid-carrying behavior under the conditions of high temperature and high shear.

Owner:PETROCHINA CO LTD

Clean high-temperature water-base fracturing fluid

InactiveCN107674668AViscoelasticImprove temperature resistanceDrilling compositionWater basedCross-link

The invention provides clean high-temperature water-base fracturing fluid. The clean high-temperature water-base fracturing fluid comprises components including, by weight, 0.5%-6% of clay stabilizers, 2%-6% of accelerators, 0.01%-0.1% of bactericides, 0.6%-3.0% of alcohol with a low molecular weight, 0.4%-2% of zwitterionic surfactants, 0%-0.5% of polysaccharide compounds and the balance water. The components are mixed with one another to obtain the clean high-temperature water-base fracturing fluid. The clean high-temperature water-base fracturing fluid has the advantages that as proved by indoor evaluation, the temperature resistance of the clean high-temperature water-base fracturing fluid can reach 150 DEG C at least, and accordingly the clean high-temperature water-base fracturing fluid is superior to general clean fracturing fluid systems; the dosage of betaine is 0.4%-2% (a weight ratio) and is far lower than the dosage (2%-5%) of amphoteric surfactants in formulas for conventional fracturing fluid; the clean high-temperature water-base fracturing fluid is convenient to use and operate, excellent in sand suspension ability and superior to common cross-link guar gum and quaternary ammonium salt systems, and cross-link can be omitted.

Owner:河北中大永迪生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com