High-temperature-resistant thickening agent for fracturing fluid, and preparation method and application thereof

A thickening agent and anti-high temperature technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of affecting oil recovery efficiency, ineffective application, and affecting the performance of fracturing fluid, so as to increase the physical exchange rate. Joint point, easy operation and use, good solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

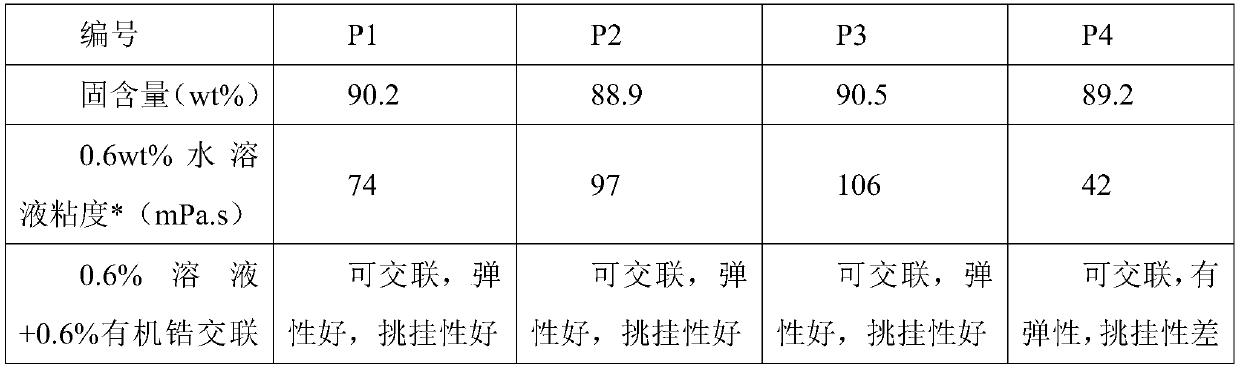

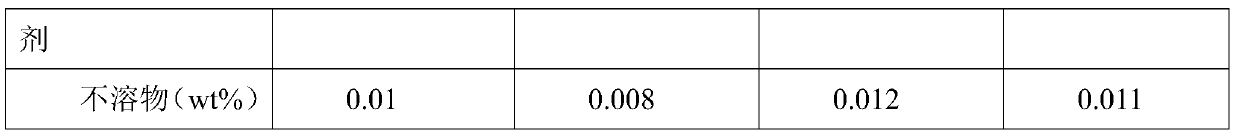

Embodiment 1

[0030] The present invention is a kind of anti-high temperature thickener for fracturing fluid and its preparation method and application, comprising selecting AM, NVP, sodium acrylate and diacetone acrylamide as comonomers, and the molar feeding ratio of the four monomers is AM:NVP : sodium acrylate: diacetone acrylamide = 1:0.05:0.03:0.05. First, the monomer is added into water and stirred until it is completely dissolved, and an aqueous solution system with a monomer concentration of 20 wt % is prepared. Then add the molecular weight regulator isopropanol, the addition accounts for 0.002% of the total mass of the monomers. Adjust the pH value of the system to 6.8, adjust the initiation temperature to 24°C, add initiator hydrogen peroxide and ferrous sulfate (each accounting for 0.02% of the total monomer mass) to initiate polymerization, and the solution begins to become viscous; continue the reaction when the reaction system reaches the highest temperature After 2h, a pol...

Embodiment 2

[0032] Select AM, NVCL, sodium styrene sulfonate and nonyl alcohol polyoxyethylene ether (12) acrylate as comonomers, and the feeding ratio of the four monomers is AM: NVCL: sodium styrene sulfonate: nonyl alcohol polyoxyethylene Oxyethylene ether (12) acrylate = 1:0.03:0.01:0.06. Firstly, the monomer is added into water and stirred until it is completely dissolved, and an aqueous solution system with a monomer concentration of 27% by weight is prepared. Then add the molecular weight regulator isopropanol, the addition accounts for 0.001% of the total mass of the monomers. Adjust the pH value of the system to 7.2, adjust the initiation temperature to 18°C, add initiators ammonium persulfate and sodium bisulfite (each accounting for 0.014% of the total monomer mass) to initiate polymerization, and the solution begins to become viscous; when the reaction system reaches the highest temperature Afterwards, the reaction was continued for 1 h to obtain a polymer gel, and the reacti...

Embodiment 3

[0034] Select AM, sodium 2-acrylamide-2-methylpropanesulfonate, sodium acrylate and dimethylaminoethyl methacrylate as comonomers, and the feeding ratio of the four monomers is AM: 2-acrylamide-2- Sodium methylpropanesulfonate: sodium acrylate: dimethylaminoethyl methacrylate=1:0.02:0.02:0.08. First, the monomer is added into water and stirred until it is completely dissolved to prepare an aqueous solution system with a monomer concentration of 25 wt%. Then add the molecular weight regulator isopropanol, the addition accounts for 0.001% of the total mass of the monomers. Adjust the pH value of the system to 7.5, adjust the initiation temperature to 10° C., add initiators 2,5-dihexylbishydroperoxide and sodium bisulfite (each accounting for 0.011% of the total monomer mass) to initiate polymerization, and the solution begins to become viscous; When the reaction system was raised to the highest temperature, the reaction was continued for 1.5 h to obtain a polymer gel, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com