Preparation method of carbon nano tube/ thermoplastic polyurethane photoresponse intelligent driving material

A thermoplastic polyurethane and carbon nanotube technology, which is applied in the preparation of carbon nanotube/thermoplastic polyurethane light-responsive intelligent driving materials, and in the field of carbon nanotube/thermoplastic polyurethane composite materials, can solve the problems of no light driving and weak light absorption. , to achieve the effect of being conducive to large-scale production and wide application, simple process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

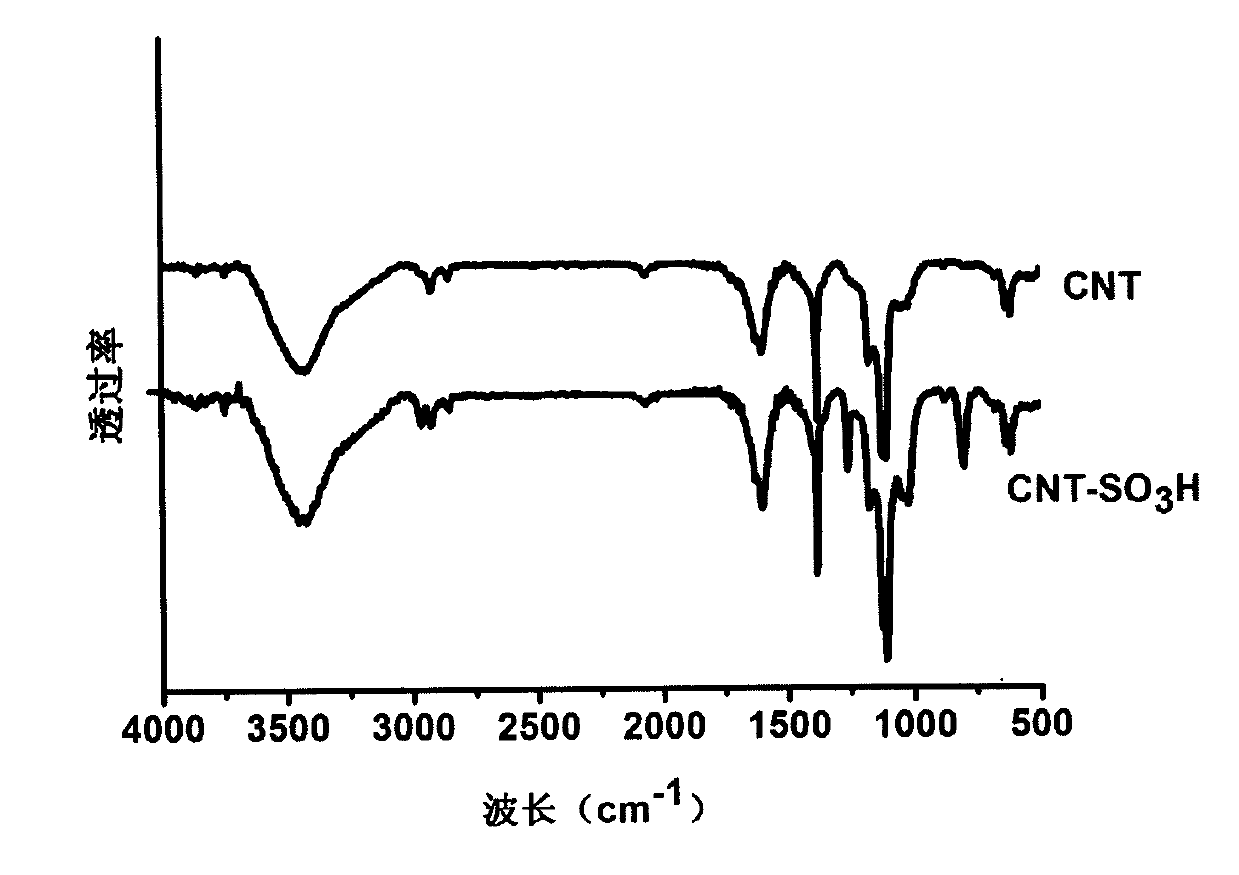

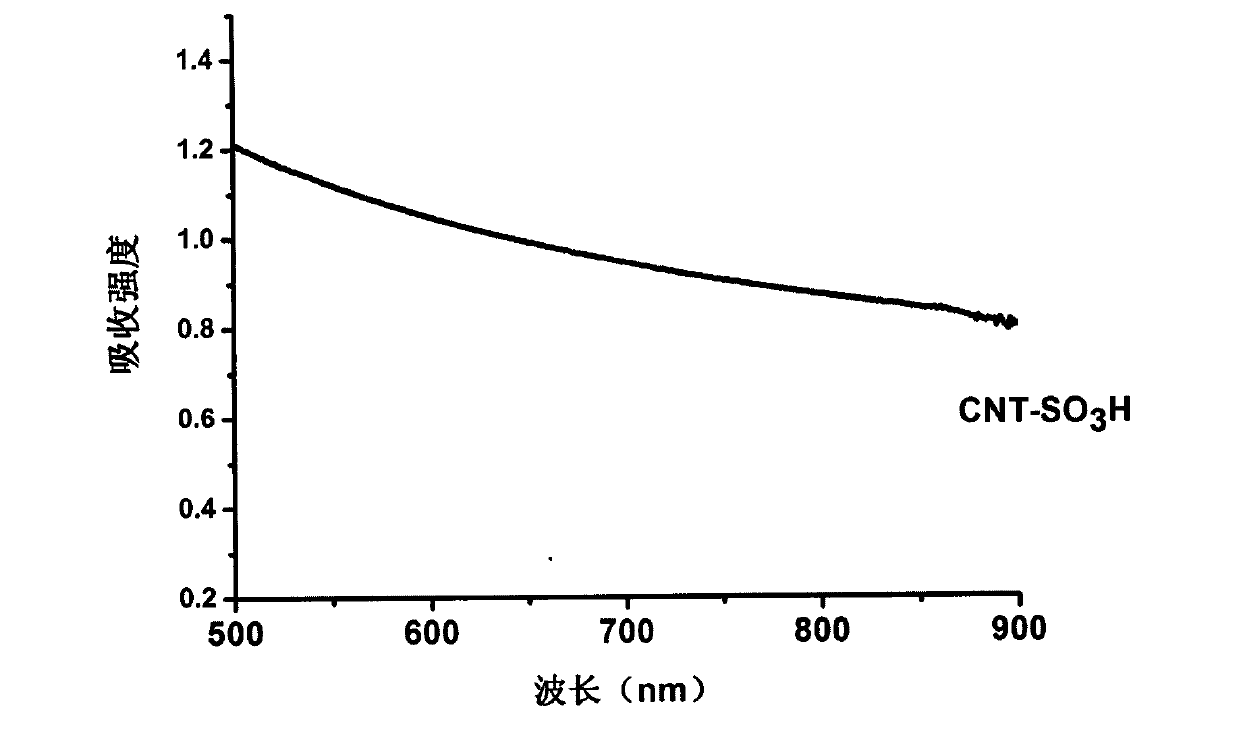

[0018] 1) Preparation of functionalized carbon nanotubes: the carbon nanotubes used in this example have an average length of 5um and an average diameter of 25nm. Take 10ml of sulfuric acid with a mass concentration of 98% and 30ml of nitric acid with a mass concentration of 37% to form a mixed solution. Put 150mg of carbon nanotubes into the above mixed solution and stir at room temperature for 2 hours, suction filter, wash with deionized water until neutral; redisperse the obtained carbon nanotubes in 150g of deionized water and ultrasonically for 1.5 hours; 239.3mg of p-aminobenzene Dissolve sulfonic acid in a mixed solution of 32g water and 2.6g 1mol / L hydrochloric acid; dissolve 93.7mg sodium nitrite in 20g water, add the above aqueous solution of sodium nitrite dropwise to the p-aminobenzenesulfonic acid solution, and react in an ice bath for 1 hours, to obtain the diazonium salt solution of p-aminobenzenesulfonic acid: then add 333 mg of diazonium salt of p-aminobenzenes...

Embodiment 2

[0022] 1) The preparation process of functionalized carbon nanotubes is the same as Step 1) of Example 1.

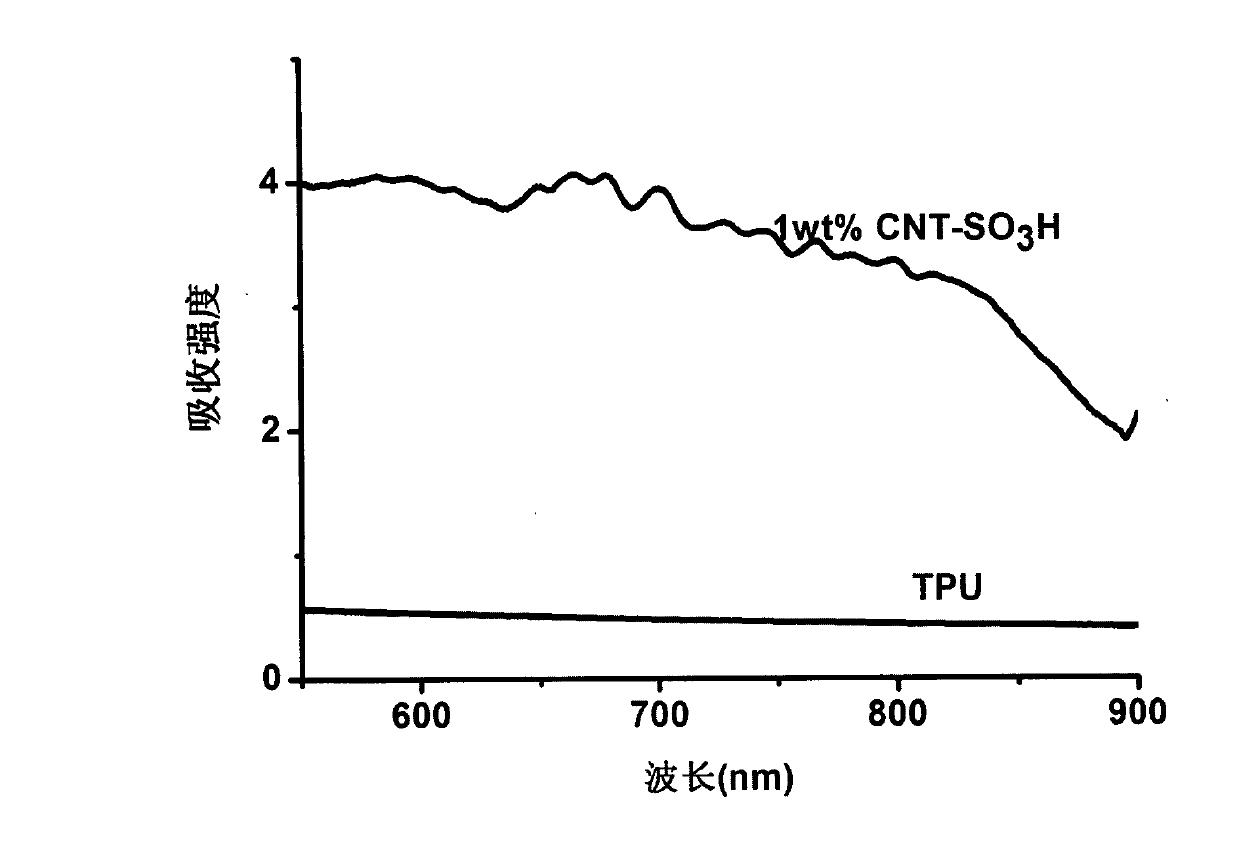

[0023] 2) Preparation of 1wt% functionalized carbon nanotubes / thermoplastic polyurethane light-responsive-driven smart material film: disperse 20 mg of functionalized carbon nanotubes into 14 ml of N,N dimethylformamide, and disperse by ultrasonic for 1 hour. Add 2 g of thermoplastic polyurethane to the above solution, heat at 75° C. for 1 hour, and then ultrasonically disperse for 1.5 hours. The obtained mixed solution was poured into a tetrafluoroethylene mold, and vacuum-dried at 60° C. for 36 hours to obtain a carbon nanotube / thermoplastic polyurethane light-responsive intelligent driving material with a film thickness of about 2 mm.

[0024] The carbon nanotube / thermoplastic polyurethane light-responsive intelligent driving material film has good light-driven performance. The composite film containing 1wt% carbon nanotubes can lift a 50g weight up 3cm under the irra...

Embodiment 3

[0026] 1) The preparation process of functionalized carbon nanotubes is the same as Step 1) of Example 1.

[0027] 2) Preparation of 2wt% functionalized carbon nanotubes / thermoplastic polyurethane photoresponsive-driven smart material film: disperse 40 mg of functionalized carbon nanotubes into 14 ml of N,N dimethylformamide, and disperse by ultrasonic for 1 hour. Add 2 g of thermoplastic polyurethane to the above solution, heat at 75° C. for 1 hour, and then ultrasonically disperse for 1.5 hours. The obtained mixed solution was poured into a polytetrafluoroethylene mold, and vacuum-dried at 60° C. for 36 hours to obtain a carbon nanotube / thermoplastic polyurethane light-responsive intelligent driving material with a film thickness of about 2 mm.

[0028] The carbon nanotube / thermoplastic polyurethane light-responsive intelligent driving material film has good light-driven performance. The composite film containing 1wt% carbon nanotubes can lift a 50g weight up 3cm under the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com