Self heat-generating and gas-generating clean fracturing fluid

A technology of cleaning fracturing fluid and self-generating heat, applied in the field of fracturing fluid, it can solve the problems of ineffective reduction of the amount of residue, long gel breaking time, high damage, and achieve excellent sand carrying stability, improve seepage ability, and sand carrying performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

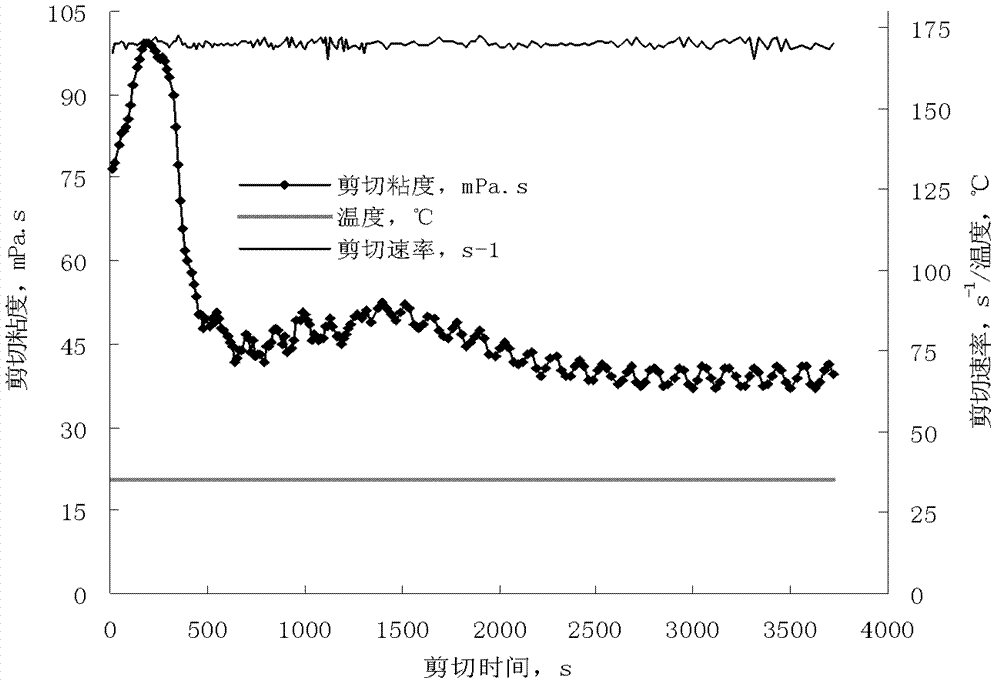

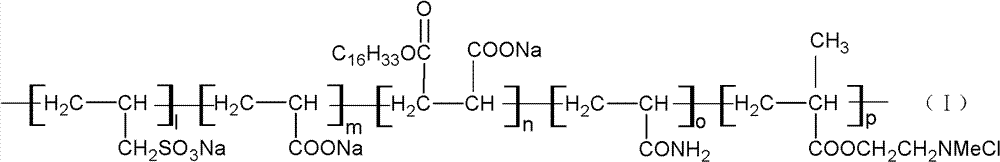

Embodiment 1

[0018] Well Xiquan 11 is the layer where the transformation is carried out: T 1 j: 3133.0-3177.0m, target zone temperature: 83°C, using this self-generating gas generation clean fracturing fluid system, the configuration of fracturing fluid is as follows: (1) 4% ammonium chloride, 3.5% sodium nitrite, sodium sulfite Add 0.1%, 1,3-dialkylammonium chloride-2-propanol 1% in sequence to the Wuyin mixer filled with 1000mL tap water, and make the mixer stir at a high speed of about 600r / min About 5 minutes to make it form a uniform solution, then add 3g of water-soluble hydrophobic polymer to it, stir at a high speed of about 600r / min for about 10 minutes to make it form a uniform solution, pour it into a beaker and cover it, and place it at room temperature for 5 minutes Hours, the base viscosity tends to be stable. (2) Add 25% of 18-alkyl-3-methylammonium chloride, 10% of formaldehyde, 20% of methanol, and the rest as water into the Wuyin blender, and stir at a high speed of abou...

Embodiment 2

[0021] The layer where W8705 well is stimulated: T 2 K 2 : 1210.0-1238.0m, target zone temperature: 35.2°C, using the self-generated heat gas clean fracturing fluid system, the fracturing fluid configuration is as follows: (1) 5% ammonium chloride, 4.5% sodium nitrite, sodium sulfite Add 0.1%, 1,3-dialkylammonium chloride-2-propanol 1% in sequence to the Wuyin mixer filled with 1000mL tap water, and make the mixer stir at a speed of about 600r / min About 5 minutes to make it form a uniform solution, then add 2.5g of water-soluble hydrophobic polymer to it, stir at a high speed of about 600r / min for about 10 minutes to make it form a uniform solution, pour it into a beaker and cover it, and place it at room temperature After 5 hours, the base viscosity tends to be stable. (2) Add 20% of 18-alkyl-3-methylammonium chloride, 10% of formaldehyde, 20% of methanol and the rest as water into the Wuyin blender, and stir at a high speed of about 600r / min for about 2min to make it Form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com