Slickwater fracturing fluid suitable for being used at hypersalinity condition

A high-salinity, water fracturing technology, applied in the direction of drilling compositions, chemical instruments and methods, can solve the problems of poor salt resistance, poor sand-carrying performance, poor swelling, etc., to achieve low friction, Easy flowback, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

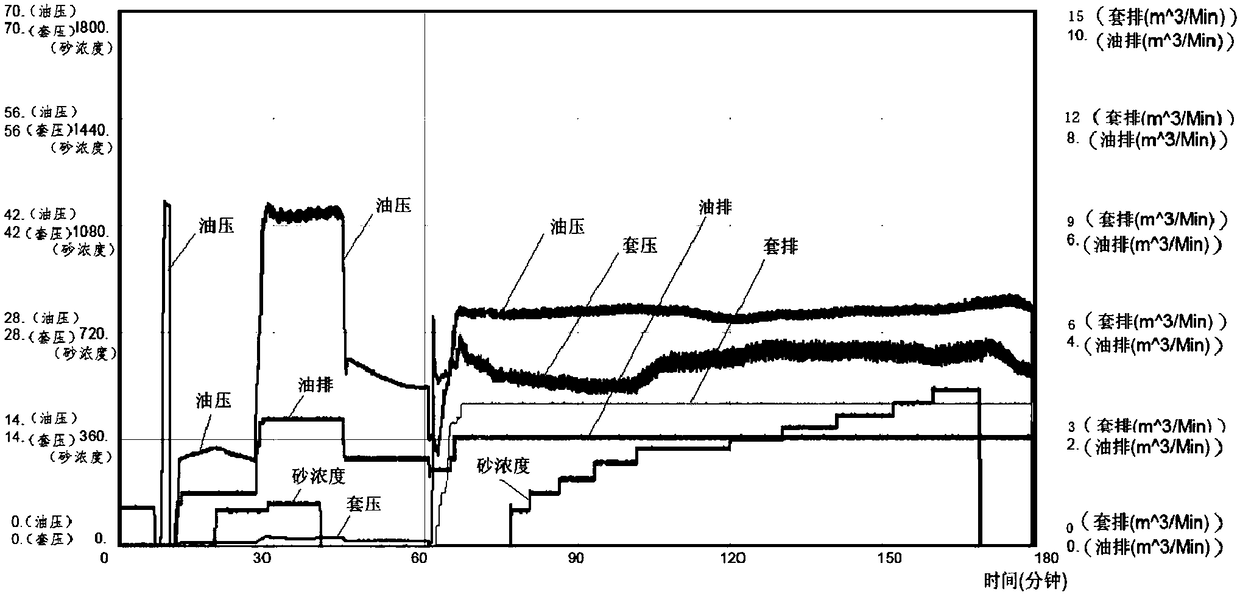

[0042] By weight percentage, 50m on site 3 The container is filled with dosing water, and slowly add 0.06% EDTA and 0.02% citric acid, 0.05% ammonium polyacrylate, 0.03% fatty alcohol polyoxyethylene ether under the condition of pump circulation, circulate for 5 minutes, and then add 0.25% % polymer thickener with 0.03% clay stabilizer for 15 minutes to ensure that the liquid is fully mixed to form a homogeneous solution, after full circulation to form a slick water fracturing fluid, add 0.30% sodium lauryl sulfate during fracturing construction and 0.02% ammonium persulfate and 0.01% vitamin C. It can meet the sand concentration of 720Kg / m under the condition of high salinity of 150000mg / L 3 Fracturing construction needs.

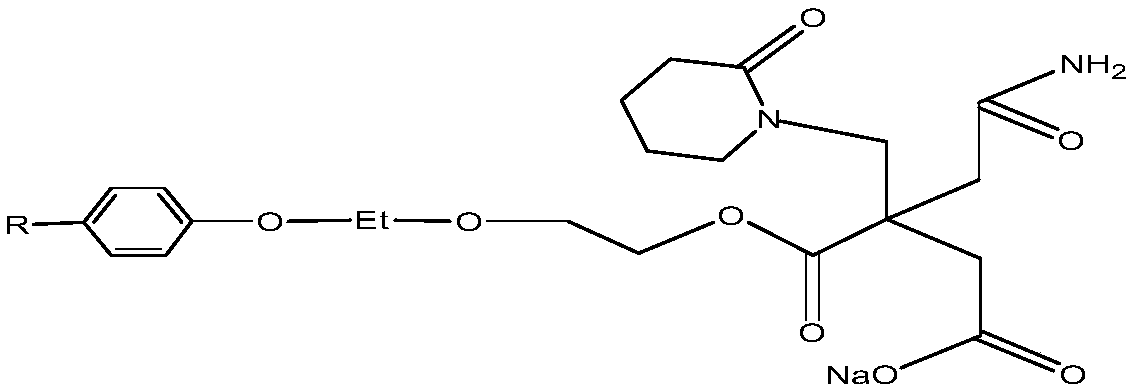

[0043] Among them, the polymer thickener is obtained through the following process: by mass percentage, weigh 35% acrylamide, 6% acrylamide octadecyl methacrylate, 1% sodium dodecylbenzenesulfonate, 0.5% Ammonium persulfate-sodium thiosulfate, 0.18% hyd...

Embodiment 2

[0046] Percentage by weight, 50m on site 3 Fill the container with clean water, then slowly add 0.08% ethylenediamine and 0.03% gluconic acid, 0.06% ammonium polyacrylate, 0.02% alkylphenol polyoxyethylene ether under the condition of pump circulation, circulate for 10 minutes, and then press the formula Add 0.05% clay stabilizer to 0.30% thickener polymer and continue to circulate for 15 minutes until the solution is uniformly dispersed.

[0047] Among them, the polymer thickener is obtained through the following process: by mass percentage, weigh 35% acrylamide, 6% acrylamide octadecyl methacrylate, 1% sodium dodecylbenzenesulfonate, 0.5% Ammonium persulfate-sodium thiosulfate, 0.18% hydroxyethyl methacrylate, and water as the balance; it was heated to 30°C under stirring, and then nitrogen gas was introduced for 60 minutes, and then ammonium persulfate-sodium thiosulfate was added. Adopt microemulsion polymerization reaction for 8-10 hours, add hydroxyethyl methacrylate, c...

Embodiment 3

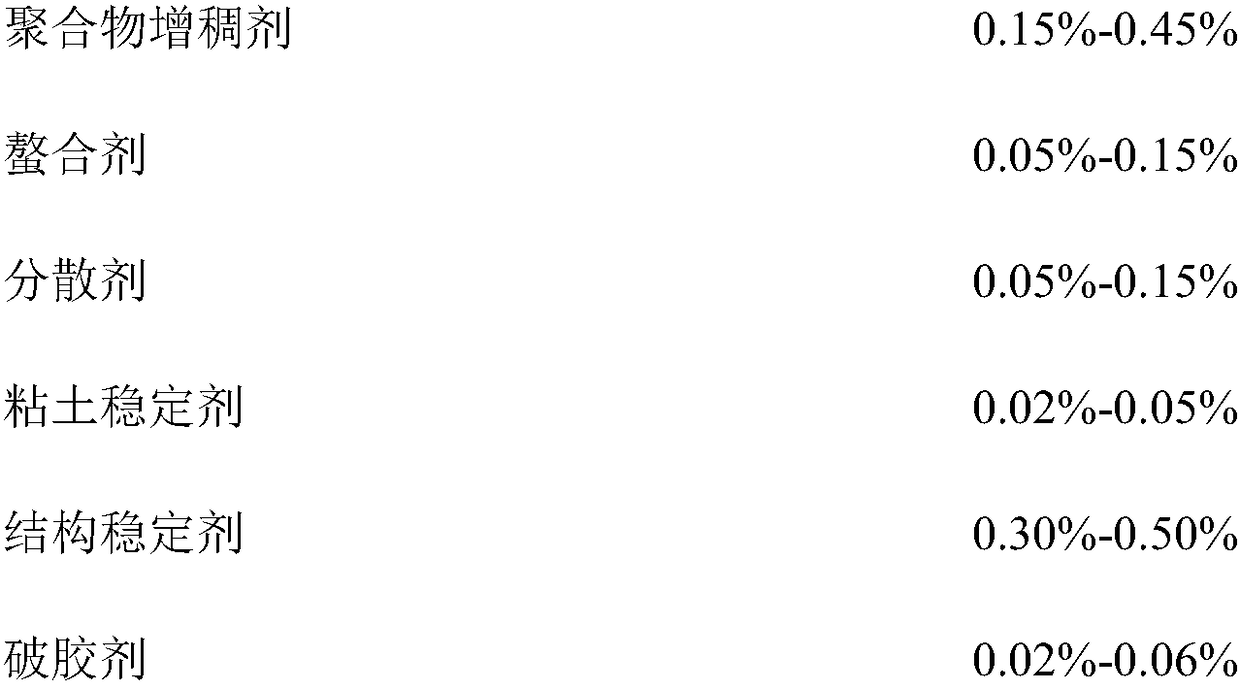

[0053] A slick water fracturing fluid suitable for use under high salinity conditions, consisting of the following components by weight percentage:

[0054]

[0055] The remaining ingredients are water; wherein, the dispersant includes a surfactant.

[0056] Wherein, the polymer thickener is obtained by the following method: by mass percentage, weigh 50% of acrylamide, 6% of acrylamide octadecyl methacrylate, 2% of sodium dodecylbenzenesulfonate, 0.5% ammonium persulfate-sodium thiosulfate and 0.25% hydroxyethyl methacrylate, the balance is water; water, acrylamide, acrylamide octadecyl methacrylate and sodium dodecylbenzenesulfonate , heated to 30°C under stirring, then nitrogen gas was introduced for 60 minutes, then ammonium persulfate-sodium thiosulfate was added, reacted for 8 hours, hydroxyethyl methacrylate was added, and cooled to room temperature to obtain a polymer thickener.

[0057] The chelating agent is formed by mixing substance A and substance B at a mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com