Clean fracturing fluid for oil fields and preparation method thereof

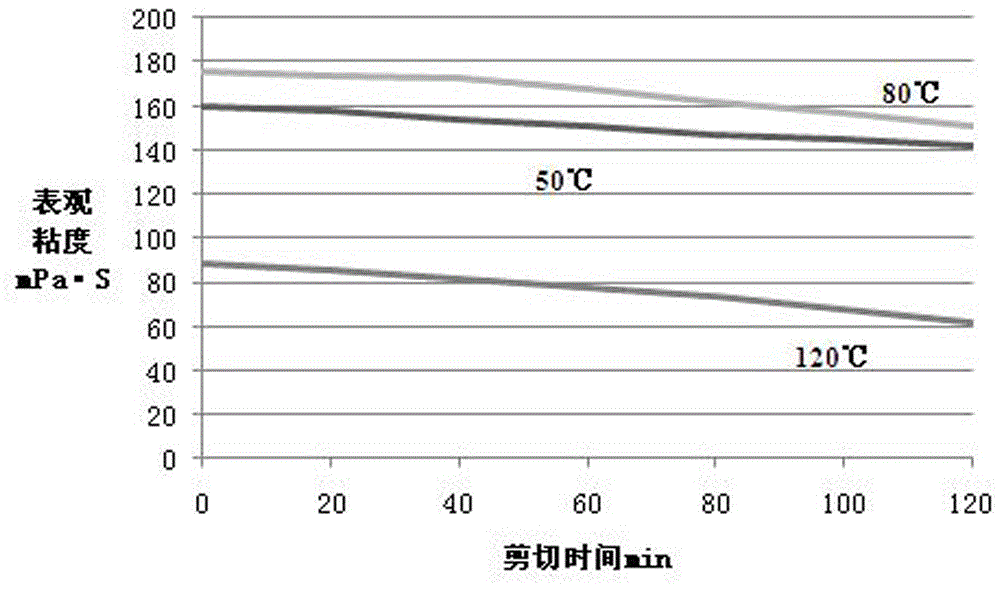

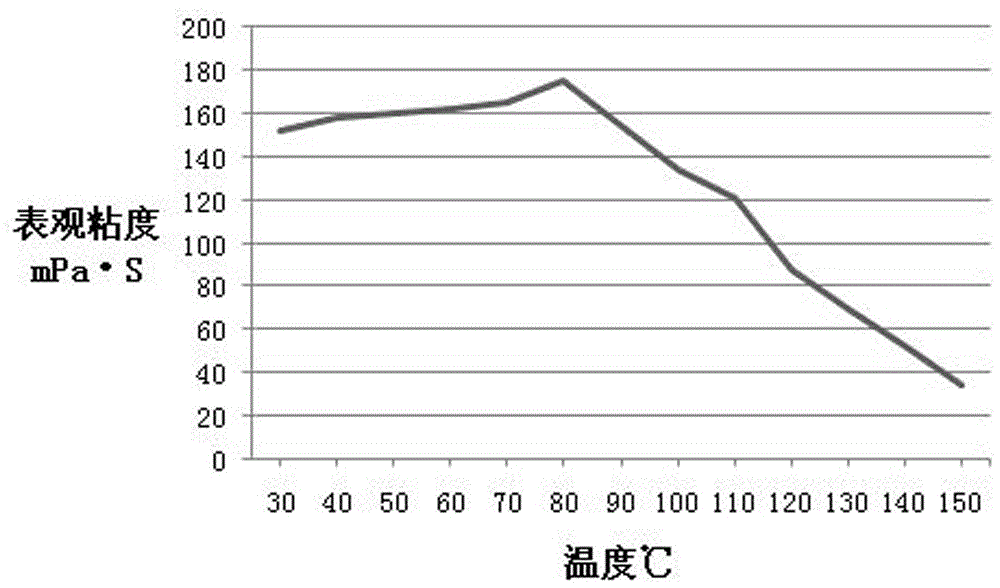

A technology for cleaning fracturing fluids and oil fields, applied in chemical instruments and methods, and drilling compositions, etc., can solve problems such as inability to meet the requirements of high-temperature oil and gas fields, low temperature resistance of clean fracturing fluids, and inconvenient use on site , to achieve the effect of good sand carrying performance, low cost and convenient on-site use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

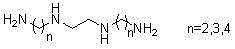

[0023] Molar ratio: stearic acid: acetic acid: 4-amino-N,N-dimethylaniline: N,N'-diaminoethyl ethylenediamine: potassium hydroxide=1:2:1:1:0.3 , Stearic acid: acetic acid: 1,3-dichloro-2-propanol = 1:2:3 prepare the raw materials. Mixed solvent is V Ethanol :V water =1:1, the added mass is 10% of the total mass of the reactants.

[0024] In the reactor equipped with electric stirrer, condenser, thermometer and oil bath heating, add stearic acid, acetic acid, 4-amino-N,N-dimethylaniline, N,N in the above molar ratio. '-Diaminoethylethylenediamine and potassium hydroxide were stirred and heated to 90°C, kept at the temperature for 8 hours, and cooled to room temperature to obtain an intermediate. Mix the intermediate and 1,3-dichloro-2-propanol uniformly in the mixed solvent, stir and raise the temperature to 70°C, keep the temperature for 6 hours, and cool to room temperature. The resulting reddish-brown liquid is the gemini surfactant of the present invention . The Gemini su...

Embodiment 2

[0026] According to the molar ratio: stearic acid: erucic acid: 2-amino-N,N-dimethylacetamide: N,N'-diaminopropyl ethylenediamine: sodium ethoxide=1:1:1:1: 0.1, stearic acid: erucic acid: 1,3-dibromo-2-propanol=1:1:2 prepare the raw materials. Mixed solvent is V Isopropanol :V water =1:1.5, the added mass is 20% of the total mass of the reactants.

[0027] In the reactor equipped with electric stirrer, condenser, thermometer and oil bath heating, add stearic acid, erucic acid, 2-amino-N,N-dimethylacetamide, N , N'-Diaminopropyl ethylenediamine and sodium ethoxide, stirred and heated to 110°C, kept the temperature for 10 hours, and cooled to room temperature to obtain an intermediate. Mix the intermediate and 1,3-dibromo-2-propanol in a mixed solvent uniformly, stir and raise the temperature to 80°C, keep the temperature to react for 8 hours, and cool to room temperature. The resulting reddish-brown liquid is the gemini surfactant of the present invention . The Gemini surfac...

Embodiment 3

[0029] According to the molar ratio: benzenesulfonic acid: oleic acid: 4-methyl-N,N-dimethylbenzeneacetamide: N,N'-diaminobutylethylenediamine: sodium ethoxide=1:2:1: 1:0.3, benzenesulfonic acid: oleic acid: 1,3-dibromo-2-propanol=1:2:4, prepare the raw materials. Mixed solvent is V Ethanol :V water =1.5:1, the added mass is 10% of the total mass of the reactants.

[0030] Add benzenesulfonic acid, oleic acid, 4-methyl-N,N-dimethylbenzeneacetamide in the reactor equipped with electric stirrer, condenser, thermometer and oil bath heating conditions according to the above molar ratio , N,N'-Diaminobutylethylenediamine and sodium ethoxide, stir and raise the temperature to 100°C, keep the temperature for 12 hours, and cool to room temperature to obtain the intermediate. Mix the intermediate and 1,3-dibromo-2-propanol in a mixed solvent uniformly, stir and raise the temperature to 60°C, keep the temperature for 12 hours, and cool to room temperature. The resulting reddish-brown li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com