Supercritical carbon dioxide based fracturing liquid system and application thereof

A carbon dioxide and supercritical technology, applied in production fluid, drilling composition, bulk chemical production, etc., can solve the problem that the water-based fracturing fluid system is no longer applicable, reduce the permeability of the proppant packing layer, fracturing fluid Incomplete gel breaking and other problems, to achieve good sand-carrying performance, facilitate crude oil extraction, and improve formation permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

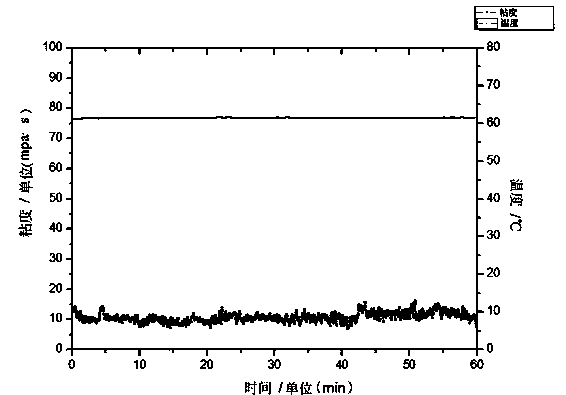

Embodiment 1

[0034] The carbon dioxide is heated to 62°C in the chamber, and the pressure rises to 20MPa. Take 5% viscosity increasing agent and 6.5% conditioning agent and add it to 88.5% carbon dioxide through closed injection equipment, stir and dissolve to prepare a supercritical carbon dioxide fracturing fluid system. The system has been tested for temperature resistance and shear resistance, and the viscosity fluctuates within 9-12mPa·s, see the attached figure 1 .

[0035] The above percentages are all percentages by mass. Described viscosity raising agent is higher fatty acid fat, and it is formed by the compounding of glycerin and higher fatty acid in molar ratio 1:3, and higher fatty acid is the combination of palmitic acid, stearic acid, oleic acid, linoleic acid, The molar ratio is 1.5:1:2:0.5. The conditioner is a combination of cyclohexane and tetrachloromethane, the molar ratio is 1:1.

Embodiment 2

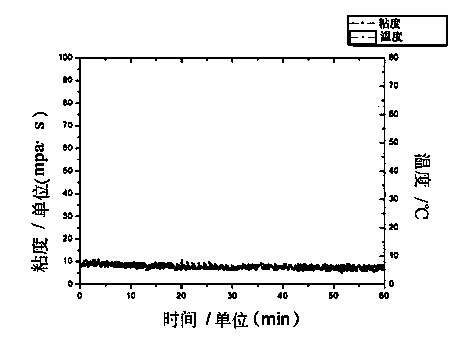

[0037] The carbon dioxide is heated to 63°C in the room, and the pressure rises to 20MPa. Take 0.1% viscosity increasing agent and 0.3% conditioning agent and add to 99.6% carbon dioxide through closed injection equipment, stir and dissolve to prepare supercritical carbon dioxide fracturing fluid system. The system has passed the temperature and shear resistance test, and the viscosity value fluctuates within 4-8mPa·s, see the attached figure 2 .

[0038] The above percentages are all percentages by mass. The viscosity-raising agent is a higher fatty acid fat, which is formed by combining glycerin and a higher fatty acid in a molar ratio of 1:2. The higher fatty acid is a combination of palmitic acid, stearic acid, oleic acid, and linolenic acid. The ratio is 1:1:1:0.2. The conditioner is a combination of cycloheptane, tetrachloromethane and difluorodichloromethane, and the molar ratio is 1:1:1.

Embodiment 3

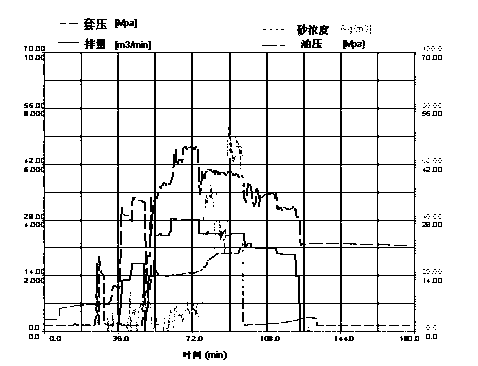

[0040] The carbon dioxide is heated to 63°C in the room, and the pressure rises to 20MPa. Take 2% viscosity increasing agent and 2% conditioning agent and add them into 96% carbon dioxide through closed injection equipment, stir and dissolve to prepare a supercritical carbon dioxide fracturing fluid system. The system has been tested for temperature resistance and shear resistance, and the viscosity value fluctuates within 6-10mPa·s, see the attached image 3 .

[0041] The above percentages are all percentages by mass. Described viscosifying agent is higher fatty acid fat, and it is formed by the compounding of glycerol and higher fatty acid in molar ratio 1:1, and higher fatty acid is the combination of palmitic acid, oleic acid, linoleic acid, ricinoleic acid , the molar ratio is 1:1:1:10. The conditioner is a combination of cyclohexane, dicyclodecane, tetrachloromethane and difluorodichloromethane, and the molar ratio is 1:1:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com