Emulsion type drag reduction thickener used for oil and gas well fracturing, and preparation method thereof

A thickening agent, emulsion type technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of long construction period, loss, large site occupation area, etc., achieve good sand carrying performance, stable performance, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

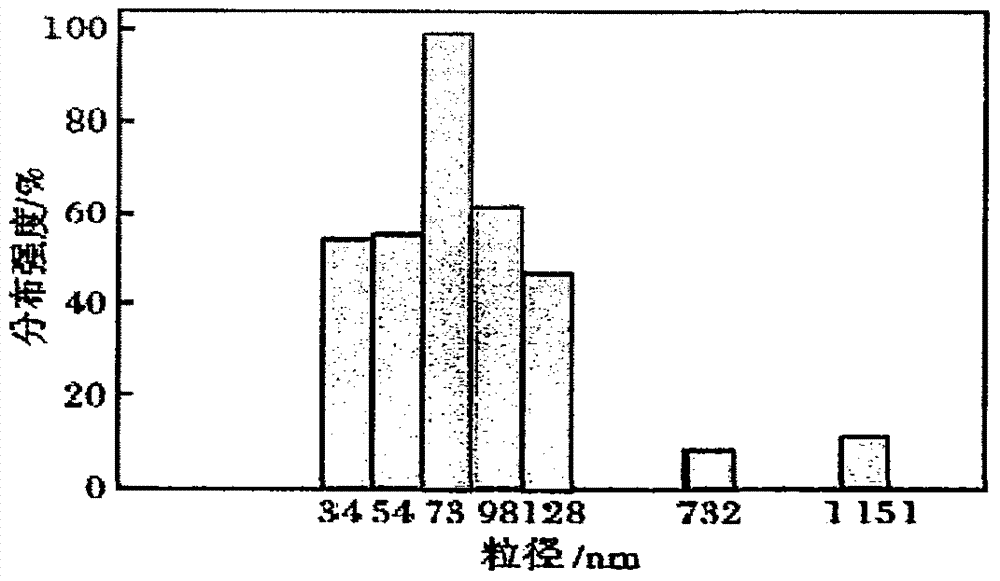

Image

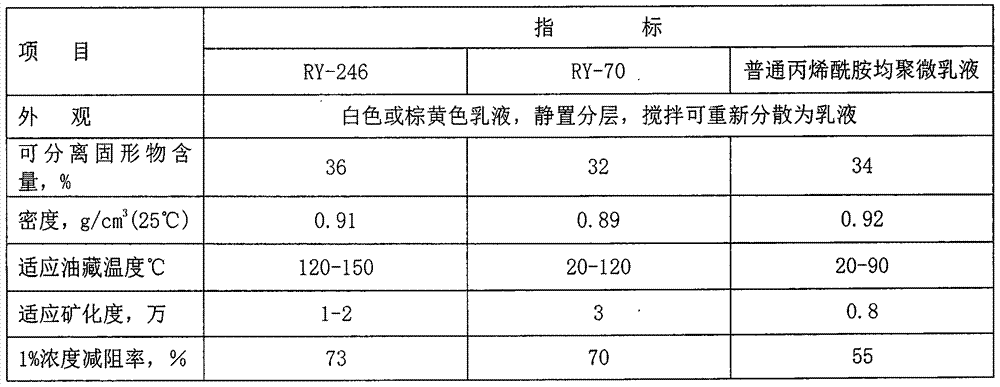

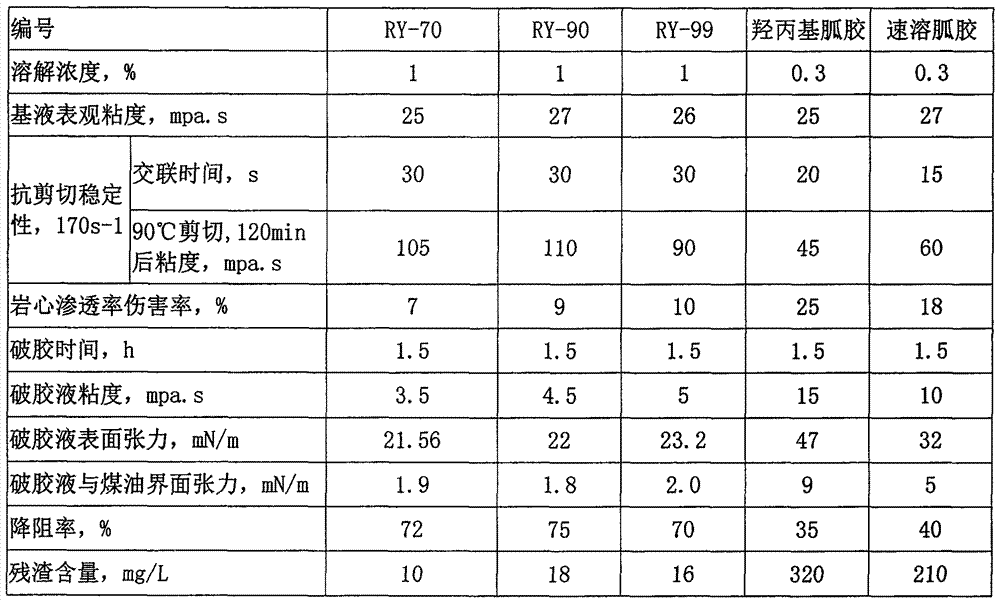

Examples

preparation example Construction

[0027] The preparation method of the emulsion-type drag-reducing thickener of the present invention will be described in detail below, and the specific embodiment is only for the purpose of illustration, and is not intended to limit the protection scope of the present invention.

[0028] The manufacture method of emulsion type drag-reducing thickener of the present invention, comprises the steps:

[0029] 1) Weigh the raw materials according to weight ratio, wherein the ratio of raw materials is: acrylamide monomer 15-25wt%, functional monomer 5-15wt%, Span 80 5-25wt%, potassium persulfate 0.1-0.5wt%, cyclic Hexane 30-40wt%, deionized water 5-20wt%, OP-10 1-5wt%;

[0030] 2) At room temperature, add Span 80 dispersant and cyclohexane into a four-necked flask equipped with a thermometer, agitator, and condensing reflux device, stir and mix evenly to form solution A;

[0031] 3) Add the potassium persulfate initiator after the acrylamide monomer and the functional monomer are c...

Embodiment 1

[0040] Weigh the raw materials by weight ratio, wherein the raw material ratio is: acrylamide 15wt%, 2-acrylamide-2-methylpropanesulfonate sodium anti-salt functional monomer 15wt%, Span 80 10wt%, potassium persulfate 0.15wt %, cyclohexane 30wt%, deionized water 10wt%; at room temperature, add Span 80 dispersant and cyclohexane into a container equipped with a thermometer, a stirrer, and a condensing reflux device, stir and mix evenly to form solution A; Dissolve the acrylamide monomer and functional monomer in deionized water, add the potassium persulfate initiator after it is completely dissolved, stir until the potassium persulfate is completely dissolved, the stirring speed is 400r / min, add the dissolved mixture Step 2) in solution A; the container is placed in a constant temperature water bath at 40°C, under nitrogen protection, slowly add a 10% sodium bisulfite aqueous solution as a reducing initiator, and the amount of sodium bisulfite added is the total weight 0.5wt%; ...

Embodiment 2

[0042] Weigh the raw materials by weight ratio, wherein the raw material ratio is: acrylamide 25wt%, 2-acrylamide-2-methylpropanesulfonate sodium anti-salt functional monomer 5wt%, Span 80 25wt%, potassium persulfate 0.1wt %, cyclohexane 30wt%, deionized water 5wt%; at room temperature, add Span 80 dispersant and cyclohexane into a container equipped with a thermometer, a stirrer, and a condensing reflux device, stir and mix to form a solution A; Dissolve the acrylamide monomer and functional monomer in deionized water, add the potassium persulfate initiator after it is completely dissolved, stir until the potassium persulfate is completely dissolved, the stirring speed is 400r / min, add the dissolved mixed solution to the step 2) in the solution A; the container is placed in a 37 ℃ constant temperature water bath, under the protection of nitrogen, slowly add the sodium bisulfite aqueous solution with a concentration of 10% as the reducing initiator, the addition of sodium bisul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com