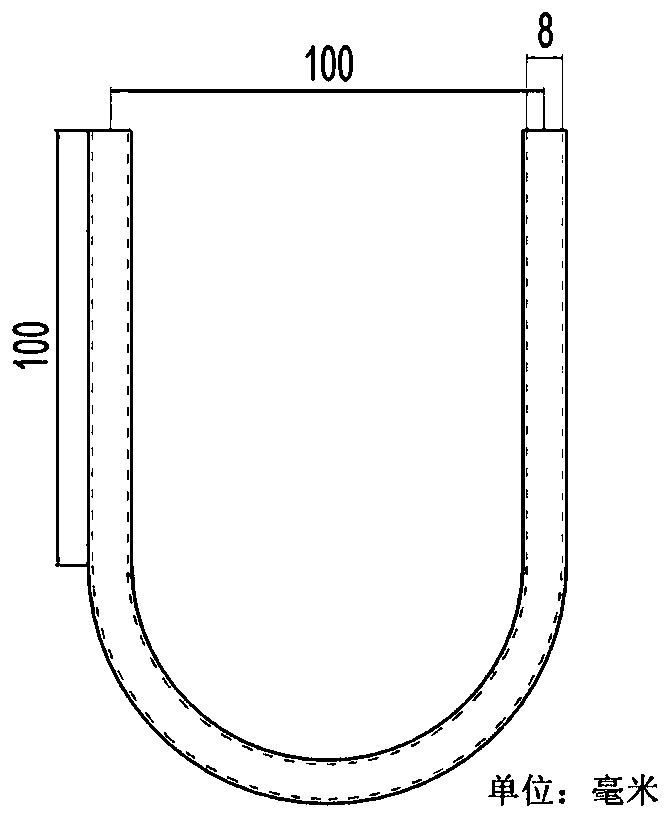

Preparation method of super-wetting coating on inner surface of U-shaped titanium tube

A super-wetting and inner surface technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of small size and other problems, achieve the effect of low cost, simple and convenient operation process, and low equipment price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method for a super-wetting coating on the inner surface of a U-shaped titanium tube, characterized in that, comprising the following steps:

[0037] 1) In the embodiment, the inner diameter of the U-shaped titanium tube 1 to be processed is 3-30 mm, and the ratio of the bending diameter to the inner diameter of the tube is 0.5-30. The U-shaped titanium tube 1 is ultrasonically cleaned with detergent, tap water, isopropanol, deionized water, and alcohol in sequence, and the cleaning time is 10-30 minutes. Then dry it. When drying, blow dry with a nitrogen spray gun first, and then keep warm in an oven at 40-110°C for 0.5-10 hours.

[0038] 2) Connect the first nozzle of the three-way pipe I4 and the first nozzle of the three-way pipe II5 to the two nozzles of the U-shaped titanium pipe 1 respectively. see figure 1 , the three-way pipe I4 and the three-way pipe II5 are fixed above the U-shaped titanium pipe 1. The U-shaped titanium tube 1 is fixed by a b...

Embodiment 1

[0052]With above-mentioned specific embodiment, present embodiment provides a kind of preparation method of U-shaped titanium tube inner surface superwetting coating, it is characterized in that, comprises the following steps:

[0053] 1) In the embodiment, see figure 2 , the inner diameter of the U-shaped titanium tube 1 to be treated is 8 mm, and the ratio of the bending diameter to the inner diameter of the tube is 6.25. The U-shaped titanium tube 1 is treated with detergent, tap water, isopropanol, deionized water, and alcohol in turn. Ultrasonic cleaning, cleaning time is 30min. Then dry it. When drying, blow dry with a nitrogen spray gun, and then keep it in an oven at 40°C for 10 hours.

[0054] 2) such as figure 1 As shown, it is connected according to the method of step 2 of the specific embodiment, wherein the diameter of the flexible carbon fiber filament 2 is 1 mm. Nine small polytetrafluoroethylene insulating balls 3 with a diameter close to 8 mm are used.

...

Embodiment 2

[0067] The difference from Example 1 is:

[0068] 1. Step 1] The inner diameter of the U-shaped titanium tube is 3 mm, the ratio of the bending diameter to the inner diameter of the tube is 30, and the cleaning time is 10 minutes. The drying temperature is 110°C and the drying time is 0.5h.

[0069] 2. In step 2), the diameter of the carbon fiber is 0.1 mm, and the insulating ball is a polypropylene holed ball with a diameter of 3 mm.

[0070] 3. In step 3), the flow rate of the electrolyte is 30ml / min, and the concentration of the sodium chloride electrolyte is 1moL / L. The voltage of electrochemical etching is 150V, and the etching time is 1h.

[0071] 4. In step 6), the flow rate of the electrolyte solution is 30ml / min, and the solvent of the electrolyte solution 2 is ethylene glycol solution, which contains 0.1wt% ammonium fluoride and 1vol% deionized water. The anodizing voltage is 80V, and the oxidation time is 3h.

[0072] 5. Step 8] The soaking time of the medium an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com