Corrosion-resistant and resistance-reduction conductive concrete for acid soil areas

A conductive concrete and acid soil technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of expensive carbon nanotubes, not easy to promote, and high price of conductive concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

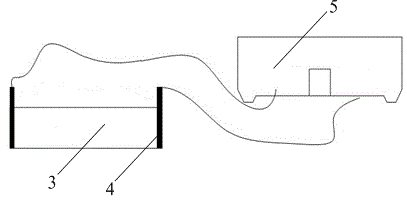

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0026] This embodiment provides a kind of anti-corrosion and resistance-reducing conductive concrete used in acidic soil areas, including the following raw materials: cement, polyaniline and filling materials, wherein the polyaniline is composed of the following components by weight: 20 to 40 parts of aniline, 5~15 parts of acid catalyst, 30~40 parts of oxidizing agent, 3~20 parts of solvent;

[0027] The filling material can be one or more of sand, gravel, fly ash and rock ash;

[0028] The acid catalyst is 10% hydrochloric acid, 10wt% phosphoric acid, 10wt% picric acid, 10wt% dodecylbenzenesulfonic acid (DB-SA), 10wt% dinonyl naphthalenesulfonic acid, 10wt% dioctyl succinate One or more of sulfonic acids;

[0029] Oxidizing agent can be one or more in ammonium persulfate, potassium dichromate, hydrogen peroxide, potassium iodate and pot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com