Integrated composite emulsion type clean fracturing fluid capable of being blended on line and preparation method thereof

A technology for cleaning fracturing fluid and compound emulsion, which is applied in the field of integrated compound emulsion type clean fracturing fluid and its preparation, can solve the problems of large manpower, material resources, and financial resources, complex fluid preparation process, low proppant concentration, etc. , to achieve a wide range of industrial value, simplify the liquid dispensing process, and the effect of simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

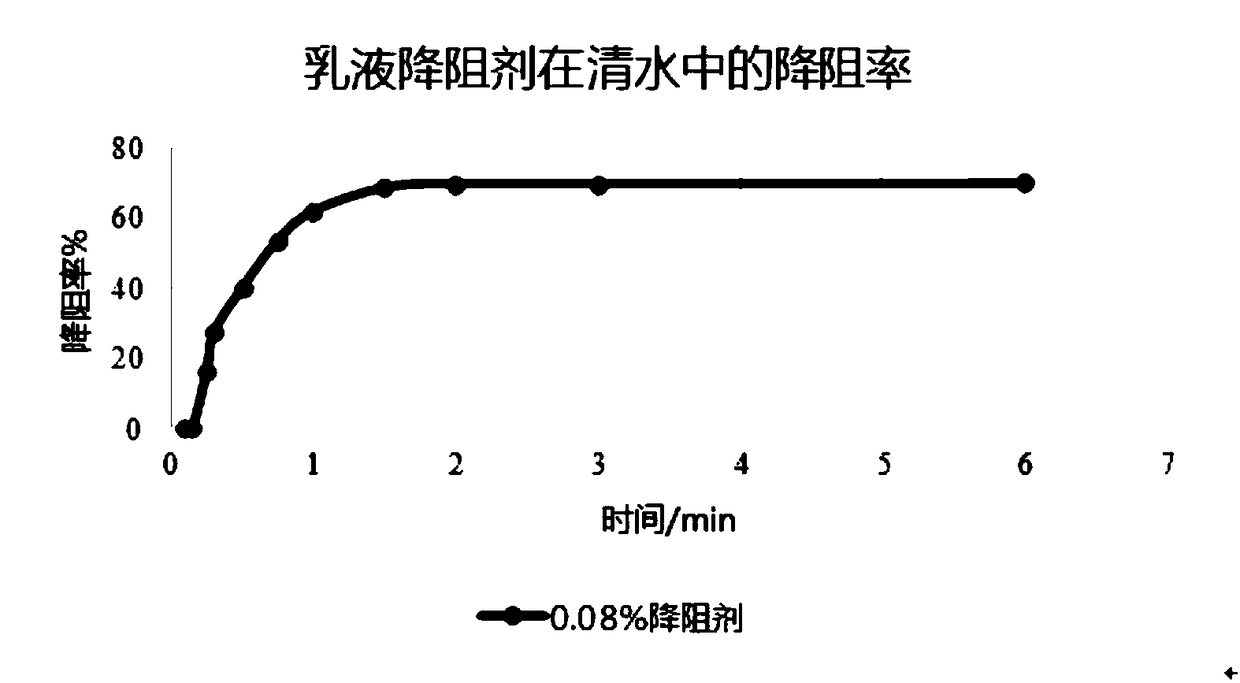

[0044] The integrated compound emulsion type clean fracturing fluid that can be mixed online provided in this example is made from the following components in terms of mass fraction: slick water consists of 0.08% emulsion thickener, 0.15% drainage aid, 0.35 % of the clay stabilizer and the balance of water;

[0045] The linear glue is composed of 0.6% emulsion thickener, 0.15% drainage aid, 0.35% clay stabilizer and the rest of water;

[0046] The cross-linked glue is composed of 0.6% emulsion thickener, 0.4% cross-linking agent, 0.15% drainage aid, 0.35% clay stabilizer and the rest of water;

[0047] The emulsion thickener includes water-soluble polyacrylamide polymers and derivatives thereof, with a molecular weight of 5 million;

[0048] The crosslinking agent includes sodium dodecylbenzenesulfonate.

Embodiment 2

[0050] The integrated compound emulsion type clean fracturing fluid that can be mixed online provided in this example is made from the following components in terms of mass fraction: slick water consists of 0.04% emulsion thickener, 0.1% drainage aid, 0.3 % of the clay stabilizer and the balance of water;

[0051] The linear glue is composed of 0.12% emulsion thickener, 0.1% drainage aid, 0.3% clay stabilizer and the rest of water;

[0052] The cross-linked glue is composed of 0.12% emulsion thickener, 0.2% cross-linking agent, 0.1% drainage aid, 0.3% clay stabilizer and the rest of water;

[0053] The emulsion thickener includes water-soluble polyacrylamide polymers and derivatives thereof, with a molecular weight of 30 million;

[0054] The crosslinking agent includes organic titanium crosslinking agent.

[0055] The crosslinking agent provided in this embodiment is mainly made of the following components in parts by weight:

[0056] Water-soluble high-valent metal salt: ...

Embodiment 3

[0065] The integrated compound emulsion type clean fracturing fluid that can be mixed online provided in this example is made from the following components in terms of mass fraction: slick water consists of 0.12% emulsion thickener, 0.4% drainage aid, 0.5 % of the clay stabilizer and the balance of water;

[0066] The linear glue is composed of 1% emulsion thickener, 0.4% drainage aid, 0.5% clay stabilizer and the rest of water;

[0067] The cross-linked glue is composed of 1% emulsion thickener, 0.8% cross-linking agent, 0.4% drainage aid, 0.5% clay stabilizer and the rest of water;

[0068] The emulsion thickener includes water-soluble polyacrylamide polymers and derivatives thereof, with a molecular weight of 10 million;

[0069] The crosslinking agent includes organic zirconium crosslinking agent.

[0070] The crosslinking agent provided in this embodiment is mainly made of the following components in parts by weight:

[0071] Water-soluble high-valent metal salt: 4 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com