High-temperature resistant and salt-tolerance filtrate reducer for drilling fluid and preparation method thereof

A fluid loss reducer, high temperature resistant technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of inability to take into account rheology, increase production costs, and high production costs, and achieve high-efficiency resistance to high temperature fluid loss reduction. The effect of reducing the production cost and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

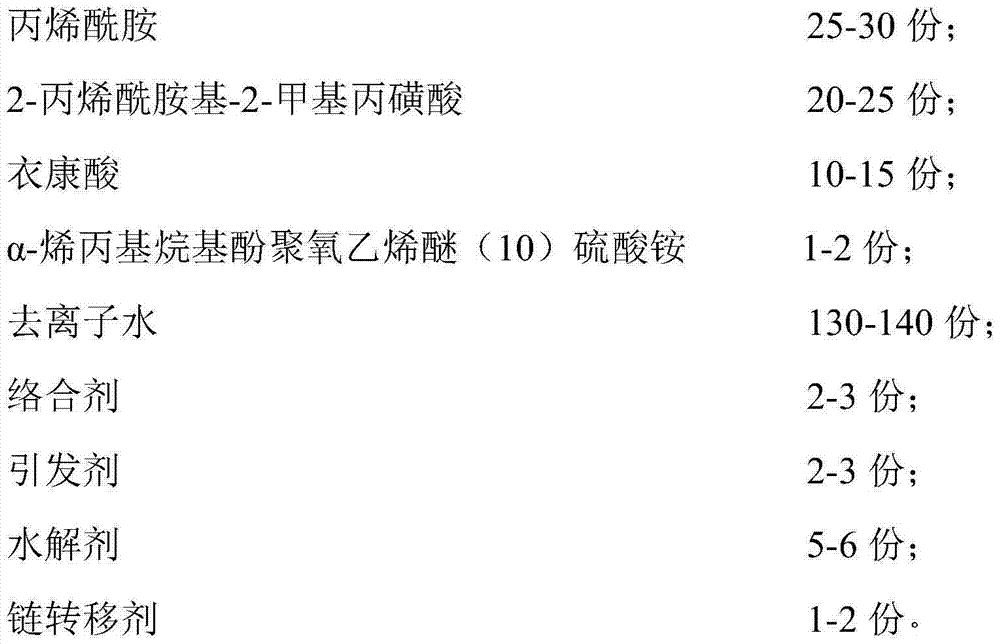

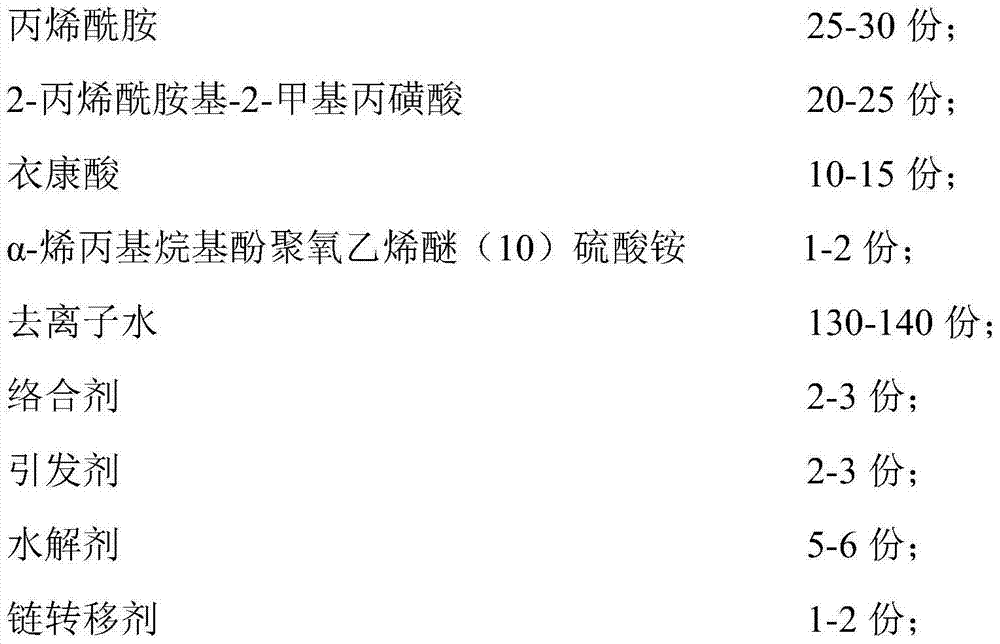

[0040] (1) Add 2g of special monomer into 134mL of deionized water, stir to dissolve completely, add 25.2g of acrylamide, 24g of 2-acrylamido-2-methylpropanesulfonic acid, 10.8g of itaconic acid, stir and dissolve to obtain a total A mixed aqueous solution with a concentration of about 30% by mass.

[0041] (2) Add the mixed solution into the reactor, add 2.4mL 5wt% EDTA solution, stir and heat up, and protect with nitrogen for 30min;

[0042] (3) The temperature was raised to 55° C., 2 mL each of 3 wt % ammonium persulfate and sodium bisulfite were added, and the reaction temperature was maintained for 4 hours;

[0043](4) Add 5g NaOH and 2mL isopropanol, stir thoroughly for 30min to obtain viscous liquid;

[0044] (5) Wash the viscous liquid with absolute ethanol to obtain a white precipitate, dry it at 105° C. and then pulverize it to obtain a high temperature resistant fluid loss reducer for drilling fluid.

Embodiment 2

[0046] (1) Add 1.5g of special monomer into 124mL of deionized water, stir to dissolve completely, add 29.4g of acrylamide, 28g of 2-acrylamido-2-methylpropanesulfonic acid, 12.6g of itaconic acid, stir to dissolve as A mixed aqueous solution with a total mass percentage concentration of about 35%.

[0047] (2) Add the mixed solution into the reactor, add 2.8mL 5wt% EDTA solution, stir and heat up, and protect with nitrogen for 40min;

[0048] (3) The temperature was raised to 50°C, 2.3 mL each of 3 wt % ammonium persulfate and sodium bisulfite was added, and the reaction temperature was maintained for 5 h;

[0049] (4) Add 6g NaOH and 2mL isopropanol, stir well for 20min to obtain viscous liquid;

[0050] (5) Wash the viscous liquid with absolute ethanol to obtain a white precipitate, dry it at 105° C. and then pulverize it to obtain a high temperature resistant fluid loss reducer for drilling fluid.

Embodiment 3

[0052] (1) Add 1.5g of special monomer into 134mL of deionized water, stir to dissolve completely, add 25.2g of acrylamide, 24g of 2-acrylamido-2-methylpropanesulfonic acid, 10.8g of itaconic acid, stir to dissolve as A mixed aqueous solution with a total mass percentage concentration of about 30%.

[0053] (2) Add the mixed solution into the reactor, add 2.4mL 5wt% EDTA solution, stir and heat up, and protect with nitrogen for 40min;

[0054] (3) The temperature was raised to 55° C., and 3 mL of 3 wt % ammonium persulfate and sodium bisulfite were added, and the reaction temperature was maintained for 4.5 hours;

[0055] (4) Add 2.5g Na 2 CO 3 and 2mL 1,4-butanediol, fully stirred for 30min to obtain a viscous liquid;

[0056] (5) Wash the viscous liquid with absolute ethanol to obtain a white precipitate, dry it at 105° C. and then pulverize it to obtain a high temperature resistant fluid loss reducer for drilling fluid.

[0057] Performance evaluation:

[0058] The per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com