Crotonic acid system polycarboxylic acid high-performance water reducer

A crotonic acid and water reducing agent technology, applied in the chemical industry, can solve the problems of high production cost, large reactivity gap, poor product dispersion, etc., and achieves improved design flexibility, low cost, and slump retention performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

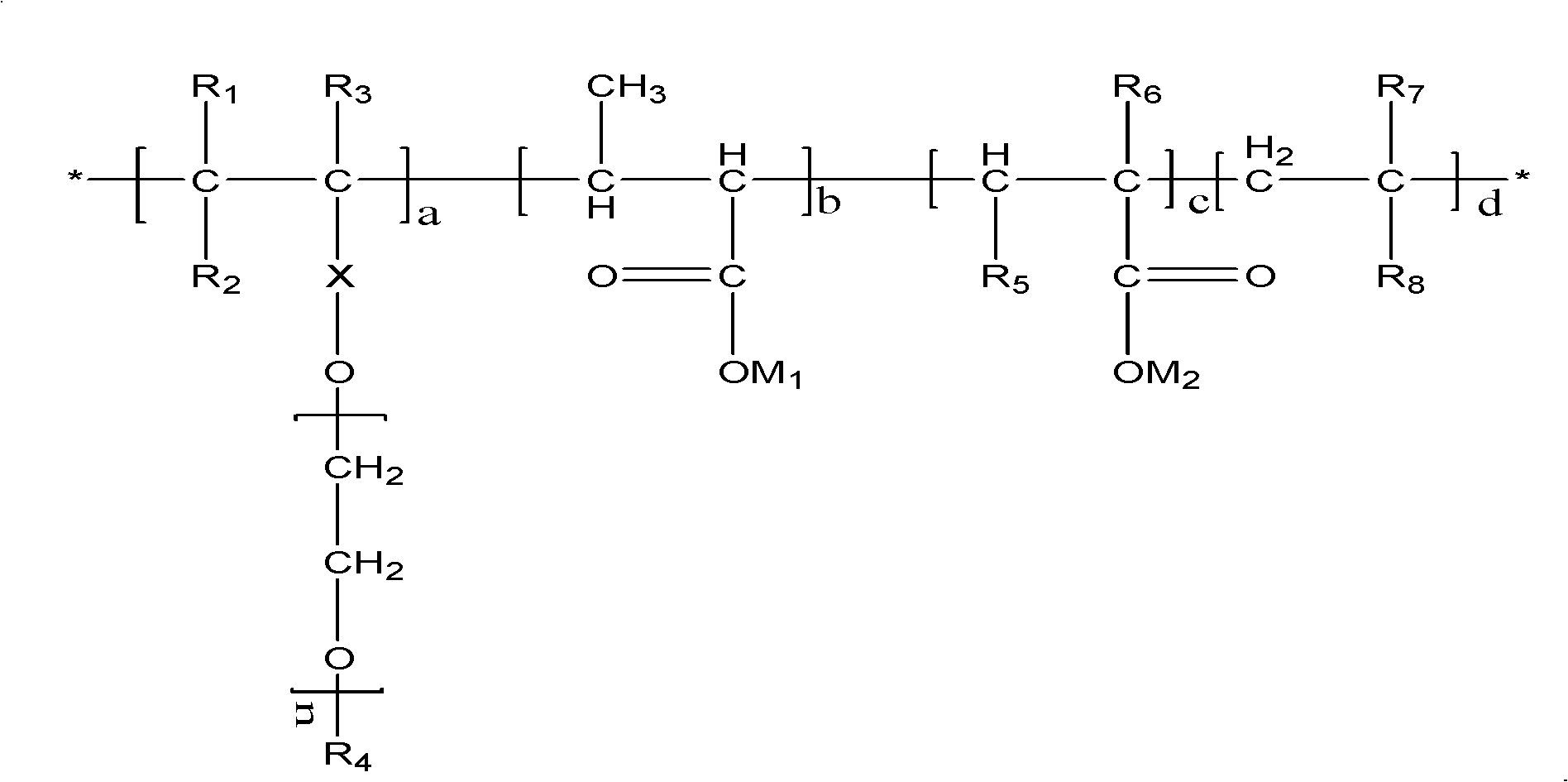

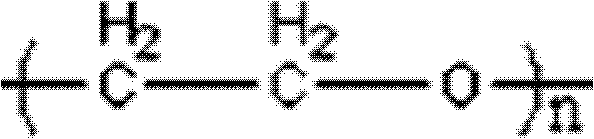

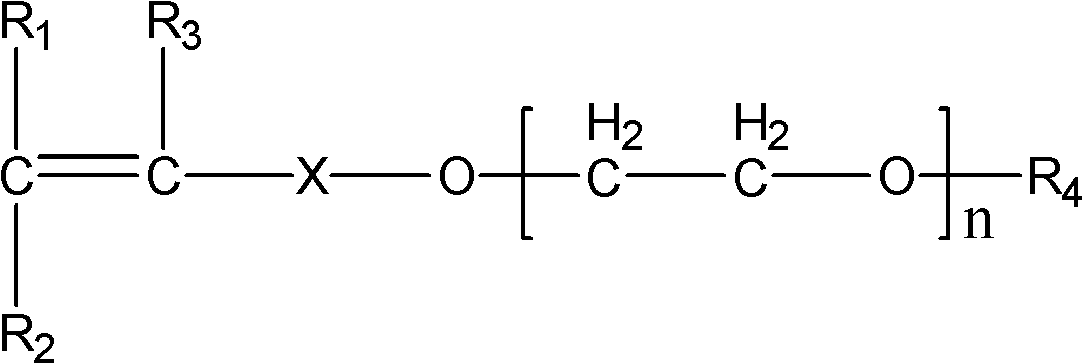

[0062] The present invention also provides a preparation process for the above-mentioned water reducer, wherein the raw materials include monomers in the following weight fractions:

[0063] The first monomer whose structure is represented by formula II accounts for 60-80% of the total mass of the monomer, and the average molecular weight of the first monomer is 800-2400;

[0064]

[0065] Formula II

[0066] Among them, R 1 , R 2 , R 3 , R 4 selected from hydrogen or methyl;

[0067] The second monomer, accounting for 20-40% of the total mass of monomers, said second monomer is one or more mixtures of crotonic acid or crotonic acid derivatives;

[0068] The third monomer, accounting for 0-20% of the total mass of monomers, said third monomer is one or a mixture of two or more of carboxylic acid, sulfonic acid, carboxylic acid derivative or sulfonic acid derivative;

[0069] Under the condition of cutting off the air, mix the first monomer and water according to the m...

Embodiment 1

[0098] Add 160 g of methoxypolyethylene glycol and 21 g of crotonic acid into a 250 ml nitrogen-protected four-necked flask, raise the temperature of the system to 130° C., and react for 2 hours to obtain methoxypolyethylene glycol crotonic acid ester.

[0099] Add methoxy polyethylene glycol crotonate 100g, maleic anhydride 24.5g, deionized water 100g in the four-necked flask that is equipped with thermometer, booster stirrer, dropping funnel, condenser, nitrogen protection, will The temperature of the system was raised to 65°C, and at the same time, 3.1g of ammonium persulfate and 30g of crotonic acid were added dropwise to make a solution for 2.5 hours, and 1.2g of thioglycolic acid was made into a solution for 3 hours. ℃, add a certain amount of caustic soda for neutralization, and obtain a light yellow solution with a solid content of more than 20% and a weight-average molecular weight of about 15,000. The structure is shown in formula I.

[0100]

[0101] Formula I

[...

Embodiment 2

[0109] Add 360.0 g of TPEG and 155.0 g of deionized water into a four-neck flask equipped with a thermometer, booster stirrer, dropping funnel, and condenser, protect the system with nitrogen, raise the temperature of the system to 50 ° C, and add ammonium persulfate at the same time 2.5g, 45.2g of crotonic acid and 45.2g of crotonic acid were added dropwise for 2.5 hours, 0.98g of thioglycolic acid was made into solution for 3 hours, and then kept at 65°C for 1h, cooled to 45°C, neutralized by adding a certain amount of caustic soda, and a light yellow solution was obtained , the solid content is more than 40%, the weight average molecular weight is 28500, and the structure is shown in formula I, wherein, X is methylene; R 1 , R 2 is methyl; R 3 , R 4 is hydrogen; M 1 , M 2 is -Na; n=40, a is an integer within the range of 1-2, b is an integer within the range of 3-7, c=0, d=0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com