Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "High degree of sulfonation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer blend proton exchange membrane and method for manufacturing the same

ActiveUS20110136016A1Excellent comprehensive propertyHigh degree of sulfonationNon-metal conductorsFuel cells groupingPolymer sciencePhenolphthalein

The present invention relates to a polymer blend proton exchange membrane comprising a soluble polymer and a sulfonated polymer, wherein the soluble polymer is at least one polymer selected from the group consisting of polysulfone, polyethersulfone and polyvinylidene fluoride, the sulfonated polymer is at least one polymer selected from the group consisting of sulfonated poly(ether-ether-ketone), sulfonated poly(ether-ketone-ether-ketone-ketone), sulfonated poly(phthalazinone ether keton), sulfonated phenolphthalein poly(ether sulfone), sulfonated polyimides, sulfonated polyphosphazene and sulfonated polybenzimidazole, and wherein the degree of sulfonation of the sulfonated polymer is in the range of 96% to 118%. The present invention further relates to a method for manufacturing the polymer blend proton exchange membrane.

Owner:BEIJING PRUDENT CENTURY TECH CO LTD

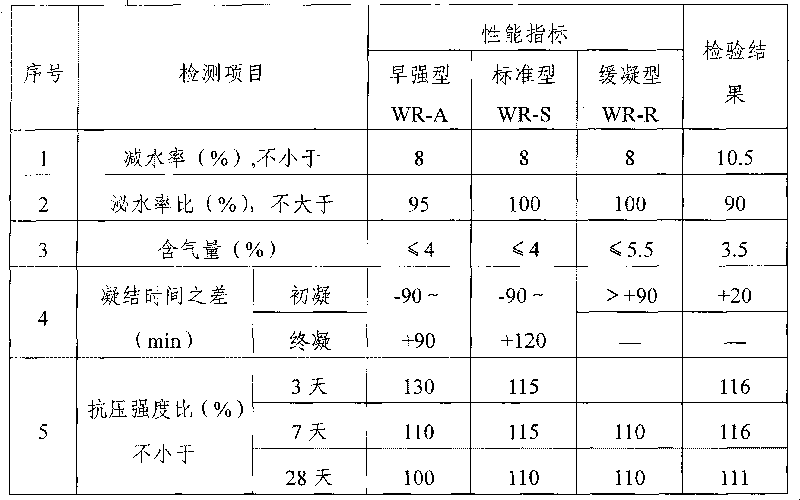

Method for preparing sodium lignin sulfonate water reducer

The invention relates to a method for preparing sodium lignin sulfonate water reducer. Black liquor which is generated by alkali cooking corncobs, acidolysis residue of the corncobs, bagasse or corn stalks is taken as a raw material, and then the sodium lignin sulfonate water reducer of low water content is prepared after coarse filtration, ultrafiltration membrane concentration, sulfonation and spray drying. Aiming at the characteristics of the raw material, the coarse filtration and ultrafiltration are combined, cellulose, other impurities and the like can be removed by the coarse filtration, lignin can be retained by the ultrafiltration, and the aim of black liquor concentration can be realized at the same time of going through alkali so as to recover and reuse the alkali; the sulfonation method, which can be operated at room temperature and pressure, is adopted, and the sulfonation degree is high. Compared with the existing method, the method for preparing the sodium lignin sulfonate water reducer has no pollution to the environment, the processes are simple and convenient, and the cost is low.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Method for preparing sodium lignin sulfonate water reducer

The invention relates to a method for preparing sodium lignin sulfonate water reducer. Black liquor which is generated by alkali cooking corncobs, acidolysis residue of the corncobs, bagasse or corn stalks is taken as a raw material, and then the sodium lignin sulfonate water reducer of low water content is prepared after coarse filtration, ultrafiltration membrane concentration, sulfonation and spray drying. Aiming at the characteristics of the raw material, the coarse filtration and ultrafiltration are combined, cellulose, other impurities and the like can be removed by the coarse filtration, lignin can be retained by the ultrafiltration, and the aim of black liquor concentration can be realized at the same time of going through alkali so as to recover and reuse the alkali; the sulfonation method, which can be operated at room temperature and pressure, is adopted, and the sulfonation degree is high. Compared with the existing method, the method for preparing the sodium lignin sulfonate water reducer has no pollution to the environment, the processes are simple and convenient, and the cost is low.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

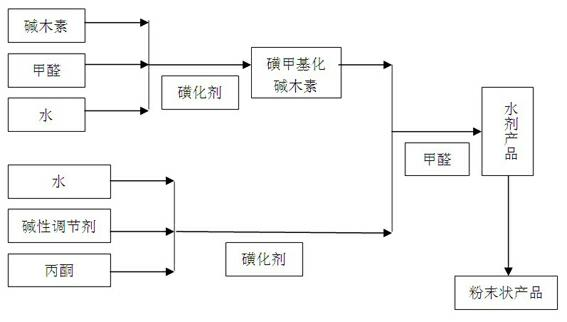

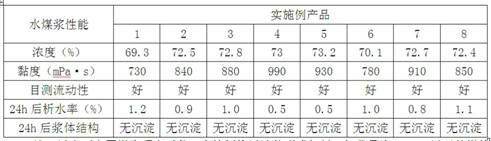

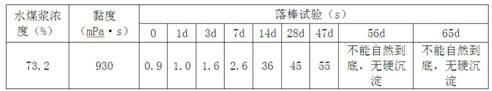

Sulfomethylated alkali lignin-formaldehyde-sulfonated acetone polymer coal water slurry additive

ActiveCN102585940AIncrease added valueRemove the burdenLiquid carbonaceous fuelsCoal waterPrepolymer

The invention discloses a sulfomethylated alkali lignin-formaldehyde-sulfonated acetone polymer coal water slurry additive and a preparation method thereof. The additive comprises the following components, by weight, 11.5-20.0 parts of alkali lignin, 4.9-10.0 parts of a sulfonating agent, 0.1-0.8 parts of an alkaline regulator, 4.5-10.0 parts of acetone, 5.4-13.5 parts of formaldehyde, and 47.3-67.2 parts of water. The preparation method comprises the following steps: 1, reacting the alkali lignin with a certain amount of formaldehyde and a certain amount of the sulfonating agent to prepare sulfomethylated alkali lignin; and 2, carrying out a catalytic sulfonation reaction on acetone by the alkaline regulator and the sulfonating agent to obtain a sulfonated acetone prepolymer, adding the prepared sulfomethylated alkali lignin and a formaldehyde solution, and carrying out a polymerization reaction to form the coal water slurry additive containing sulfo, hydroxy and alkyl active groups. So the product and the product stability are improved. The additive of the invention has the advantages of simple method, easily available raw materials, short production period, good stability, nontoxicity, no seasonal and regional restriction of the use, convenient storage and transportation, and realization of the high value utilization of lignin.

Owner:FUZHOU UNIV

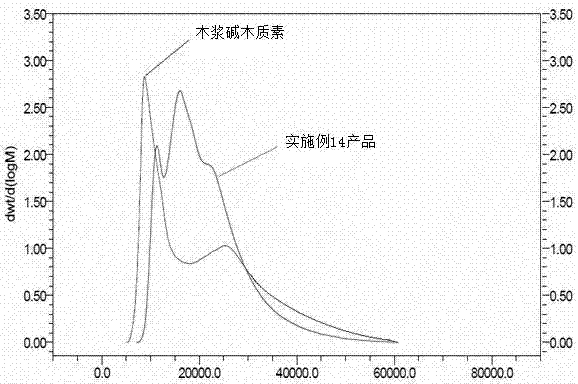

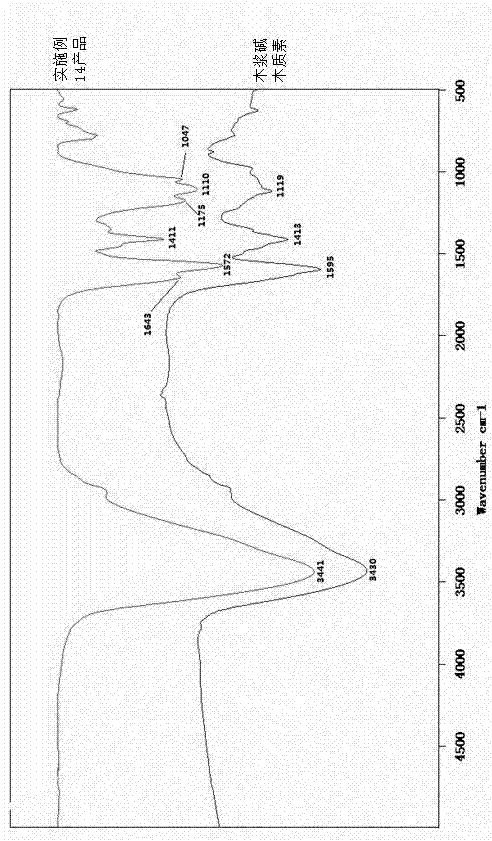

Highly efficient lignin-based water-reducing agent with high degree of sulfonation and high molecular weight, and preparation method thereof

InactiveUS20130096285A1Improve adaptabilityHigh degree of sulfonationLignin derivativesCarbonizationHigh molecular mass

This invention discloses a high-performance lignin-based water reducer with high degree of sulfonation and high molecular weight and its preparation method. This water reducer exhibits an excellent water-reducing performance, its water-reducing rate of this lignin-based water reducer reaches 25% at a dosage of 0.70 wt %, which is higher than that of the naphthalene-based water reducer and the sulfonated lignin water reducer prepared by oxidation and sulfonation of alkali lignin, and 28-days compressive strength ratio of the concrete with this water reducer to the concrete without this water reducer is up to 150:100. Furthermore, the water reducer of present invention will not be crystallized in winter, and the concrete iron won't be corroded. The water reducer of the present invention makes the concretes having a low bleeding rate, excellent properties of workability, anti-freeze and anti-carbonization.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing highly sulfonated sodium lignosulfonate

InactiveCN101475604AIncrease active hydroxylIncrease the lengthLignin derivativesMultistage water/sewage treatmentWater bathsSolubility

The invention discloses a method for preparing sodium lignin sulfonate with high sulfonation degree. A side product, namely wheat straw alkali lignin of a paper-making waste liquid is taken as a main raw material for a free radical degradation reaction under water bath heating conditions under normal pressure at a temperature of between 65 and 75 DEG C, and then an aldehyde substance is dripped to react for 10 to 20 minutes under microwave radiation conditions; and then 50 weight portions of aqueous solution containing 20 to 50 weight portions of sulfonating agent is added into the mixture to react for 1.0 to 2.5 hours under microwave power of between 300 and 1,200W to prepare the sodium lignin sulfonate with higher sulfonation degree. Compared with the prior alkali lignin sulfonation reaction, the technology prepares the sodium lignin sulfonate with high sulfonation degree and water solubility by initiating the degradation of free radicals of lignin, synergistically coordinating microwave radiation effect, using paraformaldehyde to increase active hydroxyl groups in the lignin, increasing the length of an alkyl chain, and then performing a sulfonation reaction, and the sulfonation degree of the sodium lignin sulfonate is higher than 3mmol / g.

Owner:SOUTH CHINA UNIV OF TECH

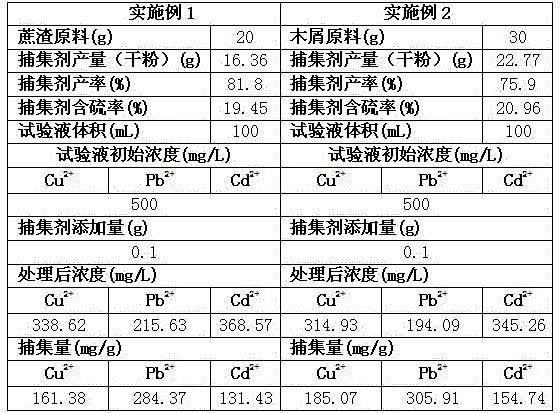

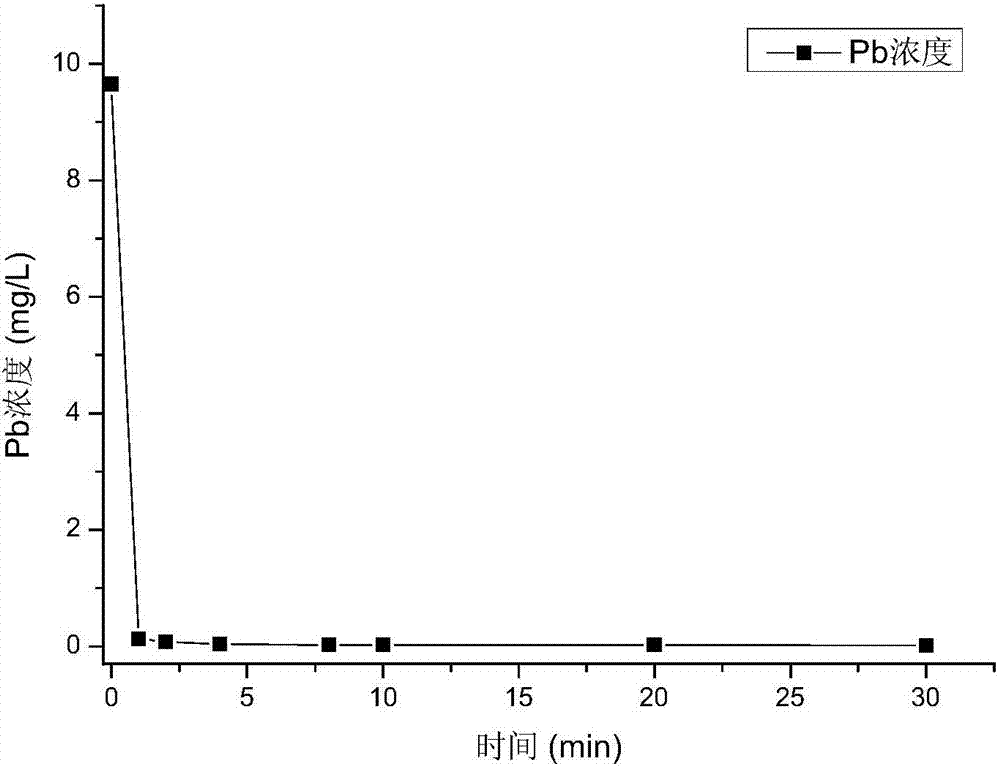

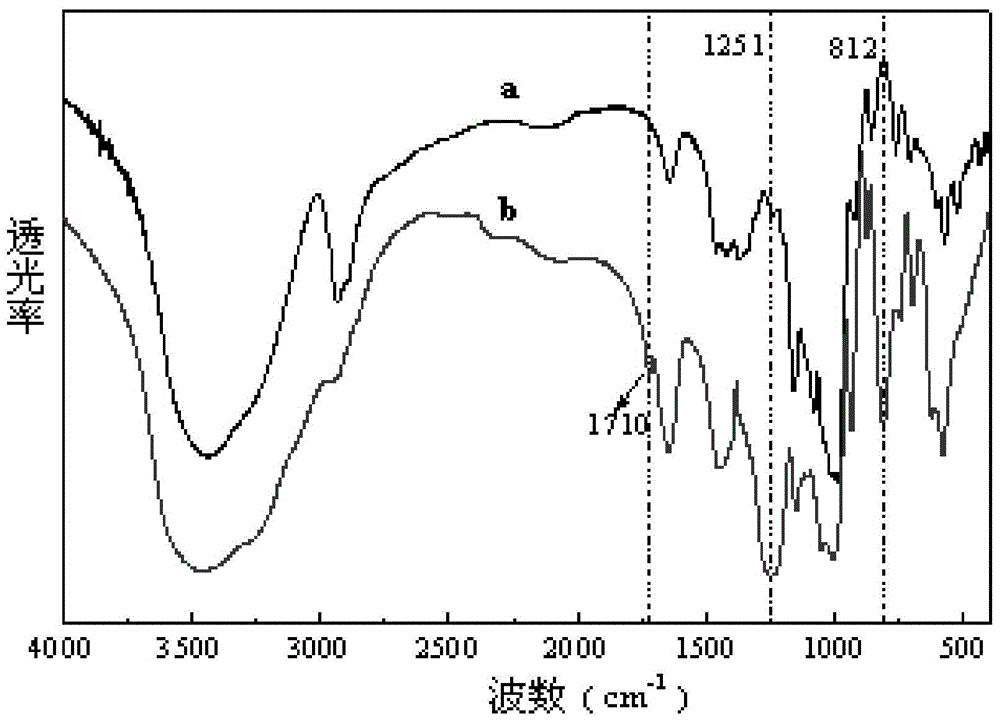

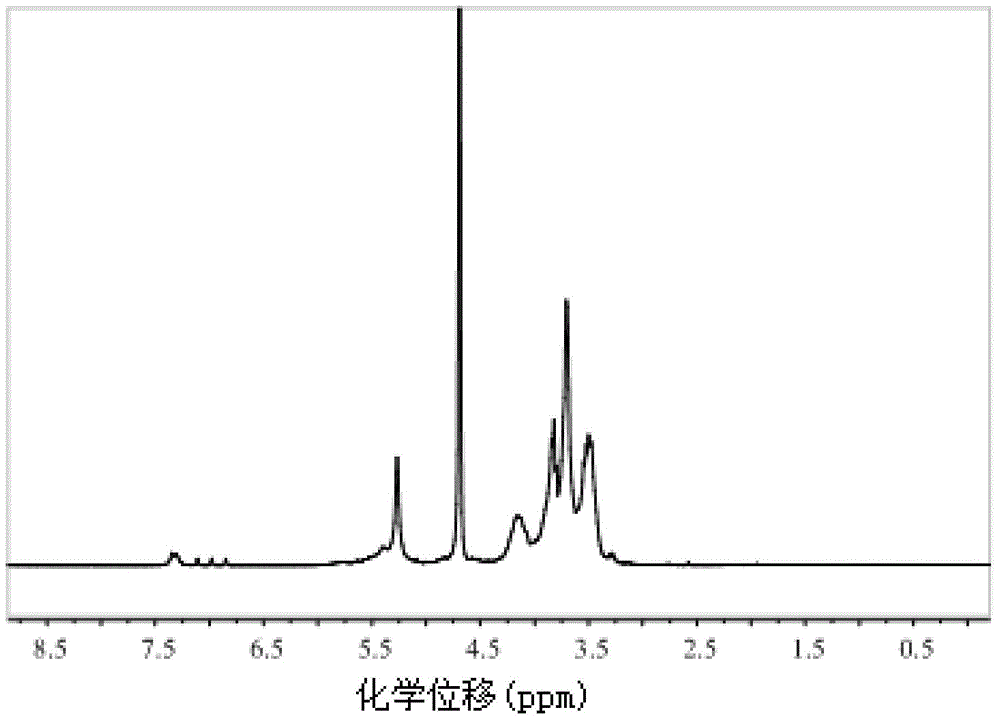

Preparation method and application method of cellulose xanthogenate heavy metal capturing agent

InactiveCN105601755AHigh alkalinityDissolve completelyWater/sewage treatment by sorptionCelluloseThiourea

The invention discloses a preparation method and an application method of a cellulose xanthogenate heavy metal capturing agent. The preparation method comprises following five steps: cellulose raw material pretreatment, cellulose alkalization, alkalized cellulose sulfonation, sulfonated product transformation reaction, and cellulose xanthogenate purification, wherein in the step of cellulose alkalization, under ice-bath conditions, concentrated alkaline swelling and urea-thiourea mixed solution dissolving are adopted to realize dissolving of cellulose. The alkalization technology is capable of reducing using amount of concentrated alkaline in cellulose alkalization, providing an environment with relatively low alkalinity for subsequent sulfonation, and reducing raw material loss caused by side reaction of carbon disulfide with the alkali in sulfonation process; and at the same time, dissolved cellulose is capable of increasing accessibility of carbon disulfide, and reaction speed of sulfonation. The preparation method possesses following advantages: the prepared cellulose xanthogenate is high in yield, sulfur content, and heavy metal capturing effect; the raw materials are easily available; waste materials high in cellulose content such as bagasse and wood flour can be recycled economically and effectively; using amount of the alkali and carbon disulfide is reduced effectively; and the preparation method possesses high economic cost competitive benefits.

Owner:SHENZHEN DUOYUAN TUOZHAN ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing sulfonated polystyrene (strongly acid type) cation exchange resin

InactiveCN102040694AWide range of usesEfficiently catalyzes the synthesis ofChlorosulfuric acidReaction temperature

The invention relates to a method for preparing sulfonated polystyrene (strongly acid type) cation exchange resin by taking chlorosulfonic acid as a sulfonating agent. The method has the following characteristics: 1. the advantages of low reaction temperature, short time, less dosage, high sulfonation degree, cost saving, environmental protection and the like can be achieved since chlorosulfonic acid is used as a sulfonating agent; and 2. the sulfonation degree of the resin prepared by using chlorosulfonic acid as a sulfonating agent is controllable in the range of 0.01-95%.

Owner:NANJING UNIV OF TECH

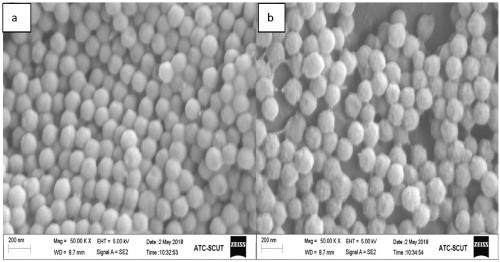

Preparation method and application of nano-sulfonated polystyrene microspheres

InactiveCN107501448AUniform particle sizeHigh degree of sulfonationOther chemical processesWater contaminantsMicrospherePolystyrene microsphere

The invention belongs to the technical field of nano-adsorption materials and discloses a preparation method and an application of nano-sulfonated polystyrene microspheres. The preparation method comprises the steps of: adding a styrene monomer, an emulsifier, a buffer agent and an initiator to water, heating the mixture to 68-78 DEG C and performing a reaction for 15-24 h, and washing and drying a solid product to prepare nano polystyrene microspheres; and adding the nano polystyrene microspheres to concentrated sulfuric acid, performing a sulfonation reaction at 20-50 DEG C for 0.5-12 h, and washing and drying a reaction product to obtain the nano-sulfonated polystyrene microspheres. In the method, a sulfonic group is introduced to the surfaces of the polystyrene microspheres so as to prepare the nano-sulfonated polystyrene microspheres. The microspheres have uniform particle size, allows nano-scale self-assembly to form an orderly-arranged array, has high adsorption capacity to heavy metal ions in water, and is high in processing speed.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method and application of hydrophobic starch sulfate ester in cement water-reducing agent

The invention relates to a preparation method and an application of a hydrophobic starch sulfate ester in a cement water-reducing agent, and belongs to the fields of chemistry and chemical engineering. The preparation method comprises the following steps: adding a sulfamic acid, starch, urea, aliphatic tertiary alcohol or aryl methyl alcohol and water into a reactor under the conditions that the molar ratio of the sulfamic acid to the starch is (0.5-3.0):1, the molar ratio of the urea to the starch is (0.1-3.0):1, the molar ratio of the aliphatic tertiary alcohol or the aryl methyl alcohol to the starch is (0.1-1) and the adding amount of the water accounts for 10% to 30% of the dry weight of the starch; and reacting for 1 to 10 hours at a temperature of 80 DEG C to 150 DEG C, thereby obtaining the hydrophobic starch sulfate ester in which the sulfonyl substitution degree is between 0.04 and 0.89 as well as the alkyl substitution degree is between 0.01 and 0.2. The hydrophobic starch sulfate ester is applied to the cement water-reducing agent, wherein the mass percent of the hydrophobic starch sulfate ester accounts for 0.1% to 1.0% of that of cement. According to the method, a dry method and one-pot reaction are adopted, so that the environmental pollution caused by the application of an organic solvent is avoided. Thus, the production cost is decreased.

Owner:DALIAN UNIV OF TECH

Method for preparing modified kraft pulp sodium lignosulphonate

ActiveCN101445522AHigh degree of sulfonationProcess ScienceLignin derivativesInorganic saltsBlack liquor

The invention relates to a method for preparing modified kraft pulp sodium lignosulphonate. Craft pulp black liquor in paper mill is used as raw material, and CO2 enriched in flue exhaust gas is used as an acid-extracting agent to obtain macromolecular raw lignin by acid extraction. Then the raw lignin is washed in water for removing salt to obtain refined lignin. Finally, the refined lignin is made into the modified kraft pulp sodium lignosulphonate by sulphonation condensation reaction. The preparation method has the characteristics of scientific technology, simple operation, etc. The thermal stability of a product is more than 150 DEG C; the content of inorganic salt is not more than 2 percent; and side product talloel does not exist. In addition, the raw material is the waste liquor of the paper mill, the flue exhaust gas has series pollution and damage effect towards the environment, and the technical proposal produces the macromolecular modified kraft pulp sodium lignosulphonate by the process modification of harmful and exhaust liquor and exhaust gas, so that the invention has high economic value and environmental protection value.

Owner:ZHEJIANG JIEFA TECH

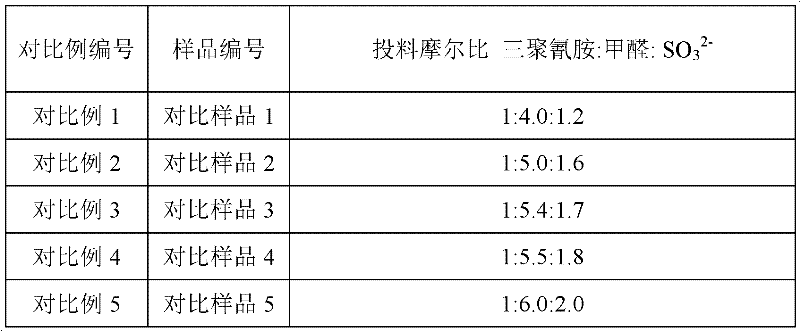

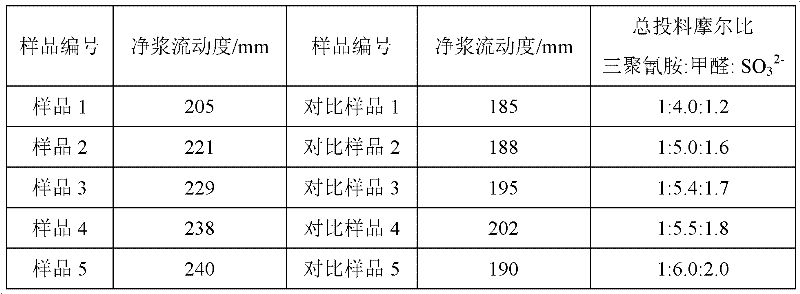

Sulfonated melamine-formaldehyde polycondensate water reducer and preparation method thereof

The invention relates to a sulfonated melamine-formaldehyde polycondensate water reducer and a preparation method thereof. The preparation method for the sulfonated melamine-formaldehyde polycondensate water reducer comprises the following steps of: (1) primary sulfonation reaction, namely performing primary sulfonation reaction on melamine, a first part of formaldehyde and a first part of sulfite sulfonating agent, wherein a molar ratio of SO32- provided by the melamine, the first part of formaldehyde and the first part of sulfite sulfonating agent is 1:(3.0-4.0):(1.0-1.5); (2) condensation reaction; and (3) secondary sulfonation reaction, namely adjusting the pH value to be 8-9, adding a second part of formaldehyde and a second part of sulfite sulfonating agent, ensuring that a molar ratio of SO32- provided by the melamine added in the step (1), the second part of formaldehyde and the second part of sulfite sulfonating agent is 1:(1.0-3.0):(0.2-1.0), adjusting the pH value of the reaction, and performing the secondary sulfonation reaction.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

Method for producing high-efficiency concrete additive by using bark rich in tannic acid

InactiveCN101492267AHigh degree of sulfonationEasy to useOrganic chemistrySolid waste disposalSulfite saltLarch

The invention discloses a method for preparing a high-efficiency concrete admixture by using barks rich in tannin, which comprises the following steps: (1) crushing and screening the barks, namely crushing the barks into crushed aggregates of 0.5 to 20 millimeters; (2) leaching and modifying, namely adding water into a leaching pot according to the ratio of solid to liquid of between 1 to 4 and 1 to 6, heating the water and the crushed aggregates and controlling the temperature to between 70 and 120 DEG C, leaching the mixture for 5 to 12 times and 4 to 15 hours step by step by using 4 to 8 normal pressure pot groups, adding a composite modifier consisting of sodium sulfite and sodium bisulfite into the mixture, wherein the adding amount of the composite modifier is 6 to 30 percent of the quality of the barks; and (3) condensing and drying, namely preparing the mixture into powered solid to obtain the high-efficiency concrete admixture. The method not only solves the problem of waste of the barks of trees such as larch, myrica esculenta, black wattle, emblica, coast oak, spruce, eucalyptus, and the like rich in tannin, but also develops a new path for producing a concrete admixture product with high added value by using the barks of the trees such as the larch, the myrica esculenta, the black wattle, the emblica, the coast oak, the spruce, the eucalyptus, and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Multi-cyandiamine monomer and preparation and application thereof

InactiveCN103193674AHigh degree of sulfonationSmall swelling coefficientCarboxylic acid nitrile preparationOrganic compound preparationFuel cellsProton

The invention relates to a multi-cyandiamine monomer and preparation and application thereof, and belongs to the technical field of polymer materials and synthesis thereof. The multi-cyandiamine monomer includes tricyandiamine monomers and tetrocyandiamine monomers. The multi-cyandiamine monomer is polymerized with anhydride to obtain polyimide. Various multi-cyanpolyimide polymers are obtained by chemistry ring-closure and heat ring-closure methods. The polyimide polymer is dissolved in a solvent and a plate coating method is used for paving a film to obtain a desired polyimide film material. The multi-cyanpolyimide material of the invention possesses high thermal stability, excellent film-forming property and excellent adsorbability and dimension stability caused by microscopic intermolecular interaction. The cyan can also be introduced to a sulfonate polyimide material to enhance intermolecular forces between main chains, reduce a swelling coefficient of the sulfonate polyimide material, and enhance dimension stability of the film material which can be used as a proton conduction film material for a fuel cell.

Owner:JILIN UNIV

Lignin serial coal water slurry dispersing agent and preparation method thereof

ActiveCN103045317AIncreased average molecular massImprove hydrophilicityLiquid carbonaceous fuelsSulfite saltPolyethylene glycol

The invention relates to lignin serial coal water slurry dispersing agent and a preparation method thereof, and belongs to the technical field of dispersing agent which is prepared by coal water slurry. The dispersing agent comprises the following raw material components in parts by weight: 1,000 parts of alkali lignin, 20 to 50 parts of polyethylene glycol, 2 to 10 parts of carboxylic acid, 1 to 5 parts of concentrated sulfuric acid, 0.1 to 1 part of hydroquinone, 20 to 60 parts of acrylic acid, 60 to 150 parts of vinyl monomer, 200 to 400 parts of sodium sulfite, 300 to 500 parts of acetaldehyde solution, 30 to 50 parts of oxidant and 10 to 20 parts of reducing agent. Compared with the prior art, the lignin serial coal water slurry dispersing agent adopts the alkali lignin as a raw material, so that the cost is reduced, the average molecular mass of the lignin is remarkably improved, the hydrophily is obviously enhanced, and the dispersing effect is prominently improved; and in addition, the dispersing agent has the advantages of low cost, simple preparation technique, more generality of raw materials, wide sources of the raw materials, cheaper price and good modifying effect; and the resource utilization is implemented for wastes, so that the environmental pollution from the wastes is reduced.

Owner:DONGFANG ELECTRIC CORP LTD

Compound modified water coal slurry additive prepared from landfill leachate raw material and preparation method

InactiveCN105316051AHigh molecular weightIncrease the rate of chemical reactionsLiquid carbonaceous fuelsLiquid wasteSludge

The invention discloses a compound modified water coal slurry additive prepared from a landfill leachate raw material and a preparation method. The additive is prepared from 20-50 parts of landfill leachate, 10-25 parts of active sludge, 1-15 parts of coarse naphthalene, 20-35 parts of industrial waste liquor, 10-25 parts of decomposed coal or coal slime, 10-20 parts of H2SO4 or Na2SO3 and 5-15 parts of formaldehyde. The preparation method comprises the steps of: preparing materials; mixing the materials; sulfonating the materials; condensing the materials; carrying out graft copolymerization; carrying out subsequent steps and the like. The additive disclosed by the invention has the advantages that resourceful treatment is carried out on various wastes to turn wastes into wealth, so that the influence on the environment is avoid and the utilization value of wastes is improved; the obtained product is high and good in quality, the stability and slurry forming concentration of industrial water coal slurry are effectively improved, the use level of additives is reduced, and the pulping cost is lowered.

Owner:XINJIANG SHENGHENGQING ENVIRONMENTAL PROTECTION TECH CO LTD

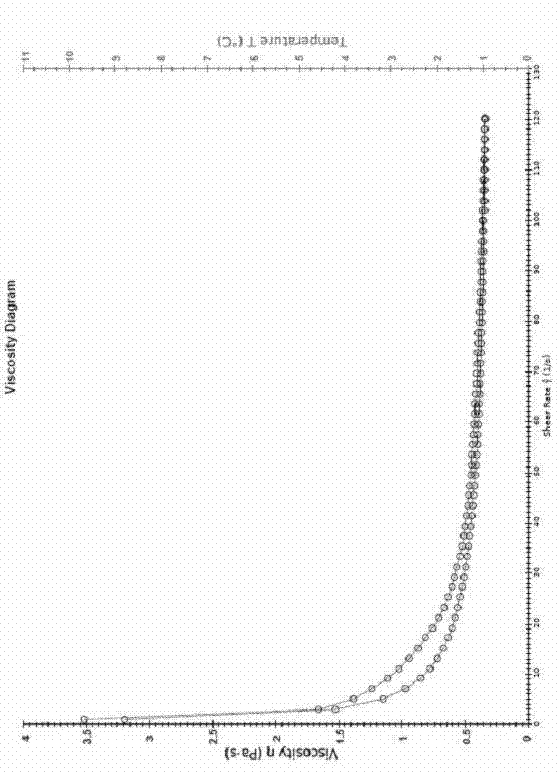

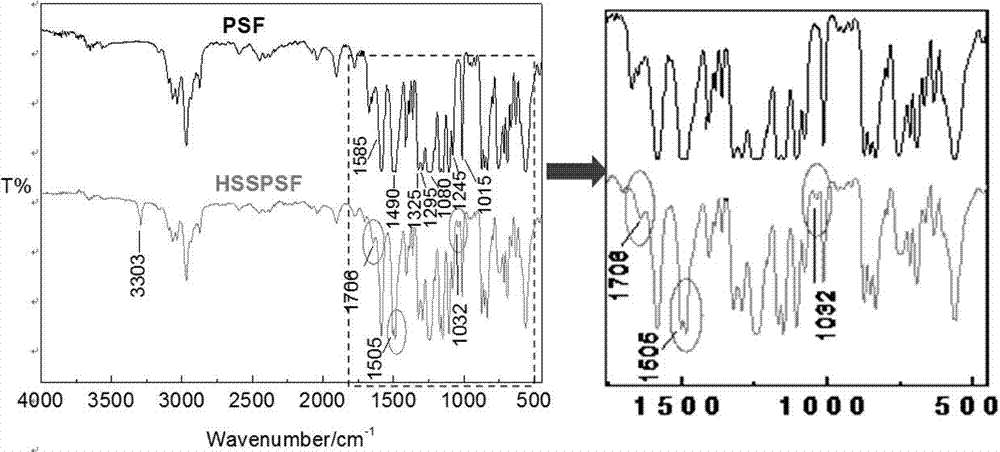

Preparation method of polysulfone cation-exchange membrane

ActiveCN103937019AHigh degree of sulfonationEasy to prepareSolid electrolyte fuel cellsFuel cell detailsDibutyltin dilaurateBenzenesulfinic acid

The invention discloses a preparation method of a polysulfone cation-exchange membrane, relating to sulfonated polysulfone. The method comprises the following steps: (1) dissolving 0.65-0.7g of PSF in 48-55mL of N,N-dimethyl acetamide, adding 1.3-1.5mL of chloroethyl isocyanate and 1.3-1.5mL of anhydrous SnCl4, and reacting at 60-70 DEG C for 20-24 hours to obtain a transparent solution; (2) heating the transparent solution to 100 DEG C, adding 5.00-5.50g of sodium 4-hydroxybenzenesulfonate and 0.04-0.05g of dibutyltin dilaurate, reacting for 10-15 hours, adding 200mL of ethanol, separating, and alternately washing with distilled water and ethanol to obtain sulfonated modified polysulfone (PSF-sas); and (3) dissolving the PSF-sas in chloroform, running to form a film, and drying to remove the solvent, thereby obtaining the finished product. The preparation method is simple; and the product has higher degree of sulfonation and cation-exchange membrane properties, and can be used in proton-exchange membrane fuel batteries.

Owner:ZHONGBEI UNIV

Preparation method for maleic anhydride esterified starch air-entraining and water-reducing agent

Owner:ANHUI FUNAN LVYUAN CHEM

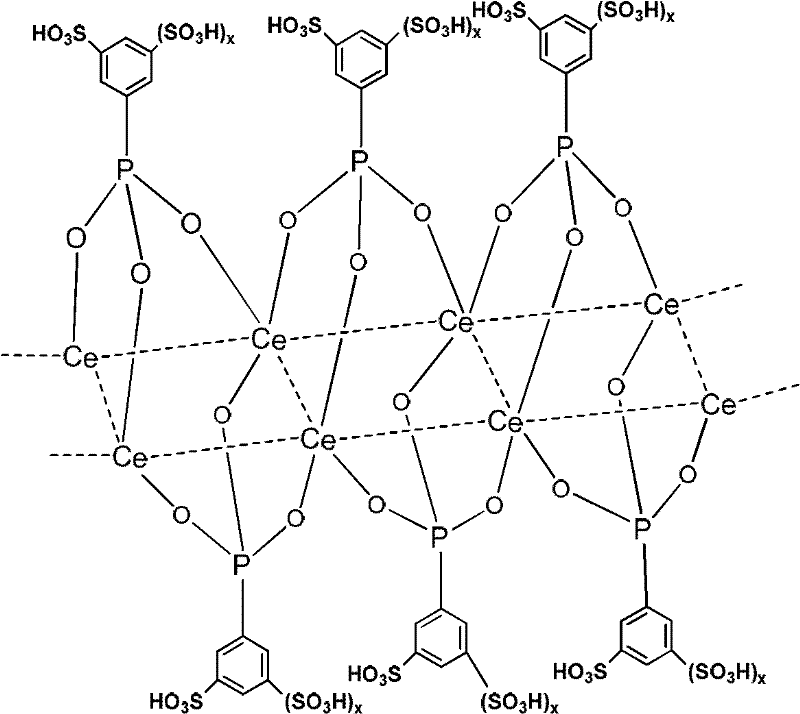

Solid acid catalyst for preparing biodiesel and preparation method thereof

InactiveCN102441432AEliminate vacuum dehydration processHigh degree of sulfonationFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsBiodieselCerium

The invention belongs to the field of catalyst preparation, and relates to a solid acid catalyst for preparing biodiesel and a preparation method thereof. The solid acid catalyst is sulfonated cerium phenyl phosphinate, and the sulfonation degree is 100-200%. The preparation method comprises the following two steps: introducing SO3 into a mixed solution of phenylphosphonic acid and 1,2-dichloroethane, thus preparing sulfonated phenylphosphonic acid; and adding ammonium ceric nitrate completely dissolved in a nitric acid solution into the sulfonated phenylphosphonic acid solution, stirring while heating, centrifuging, repeatedly washing the precipitate, and drying. The catalyst is widely applicable to the reactant raw grease, can be easily recycled, and has the advantages of low requirements for water and other impurities in the raw material, moderate reaction, high catalytic activity and no pollution.

Owner:SHANDONG UNIV OF TECH

Aqueous treatment compositions and polymers for use therein

InactiveUS20070185295A1High degree of sulfonationLess expensiveWater/sewage treatmentSulfonatePhosphate

Owner:AKZO NOBEL NV

Micron-sized sulfonated polystyrene microspheres as well as preparation method and application thereof

InactiveCN107556412AUniform particle sizeHigh degree of sulfonationWater contaminantsWater/sewage treatment by sorptionAlcoholMicrosphere

The invention belongs to the technical field of adsorbing materials and discloses micron-sized sulfonated polystyrene microspheres as well as a preparation method and an application thereof. The preparation method comprises steps as follows: styrene monomers, a dispersing agent and an initiator are added to absolute ethyl alcohol, a mixture is heated to 65-78 DEG C and subjected to a reaction for10-24 h, solid products are washed and dried, and polystyrene microspheres are obtained; the polystyrene microspheres are added to concentrated sulfuric acid and subjected to a sulfonation reaction for 8-24 h at the temperature of 30-80 DEG C, reaction products are washed and dried, and the micron-sized sulfonated polystyrene microspheres are obtained. Sulfonic acid groups are introduced into surfaces of the polystyrene microspheres for preparation of the micron-sized sulfonated polystyrene microspheres, particle sizes of the microspheres are uniform, and the micron-sized sulfonated polystyrene microspheres have the characteristics of high adsorption capacity, high treatment speed and the like for heavy metal ions in water.

Owner:广东华凯明信科技有限公司

Polymer blend proton exchange membrane and method for manufacturing the same

ActiveUS8486579B2Excellent comprehensive propertyHigh degree of sulfonationNon-metal conductorsFuel cells groupingPhenolphthaleinPolymer science

The present invention relates to a polymer blend proton exchange membrane comprising a soluble polymer and a sulfonated polymer, wherein the soluble polymer is at least one polymer selected from the group consisting of polysulfone, polyethersulfone and polyvinylidene fluoride, the sulfonated polymer is at least one polymer selected from the group consisting of sulfonated poly(ether-ether-ketone), sulfonated poly(ether-ketone-ether-ketone-ketone), sulfonated poly(phthalazinone ether ketone), sulfonated phenolphthalein poly (ether sulfone), sulfonated polyimides, sulfonated polyphosphazene and sulfonated polybenzimidazole, and wherein the degree of sulfonation of the sulfonated polymer is in the range of 96% to 118%. The present invention further relates to a method for manufacturing the polymer blend proton exchange membrane.

Owner:BEIJING PRUDENT CENTURY TECH CO LTD

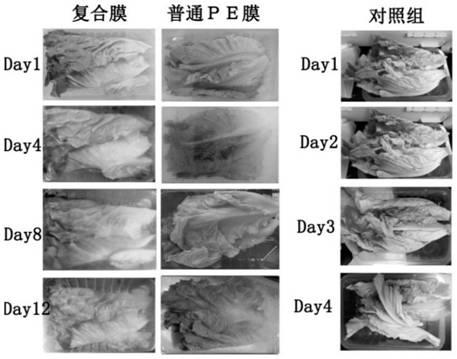

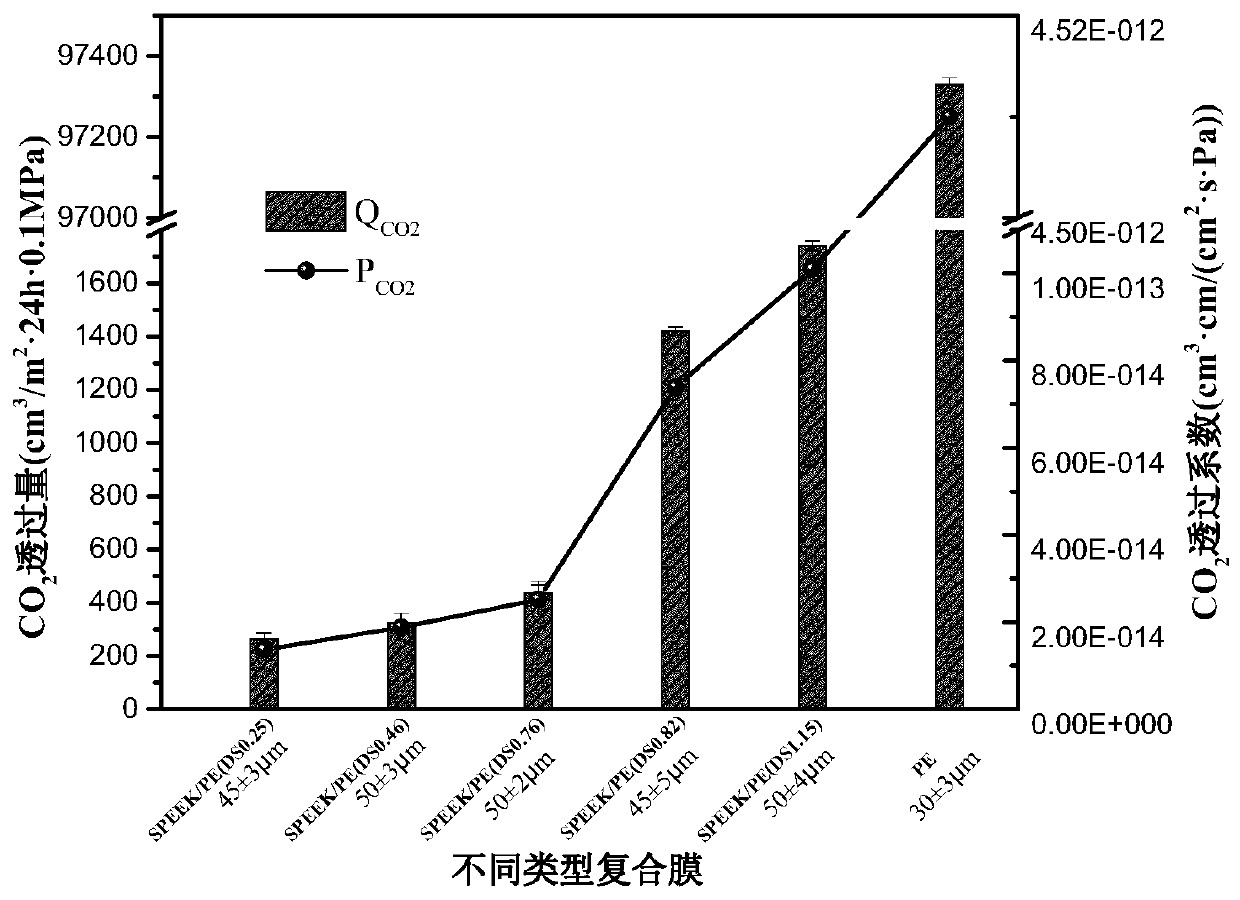

Anti-fog SPEEK/PE controlled atmosphere composite film with high separation performance, and preparation method and applications thereof

ActiveCN110330680ALow costImprove breathabilitySemi-permeable membranesDispersed particle separationBlow moldingComposite film

The invention belongs to the field of controlled atmosphere film, and discloses an anti-fog SPEEK / PE controlled atmosphere composite film with high separation performance, and a preparation method andapplications thereof. The preparation method comprises following steps: low density PE particles are subjected to extrusion blow molding film forming so as to obtain PE film, the PE film is uniformlycoated with a DMF solution of SPEEK through scraping coating, drying is carried out, and the anti-fog SPEEK / PE controlled atmosphere composite film with high separation performance is obtained aftercomplete volatilization of DMF solvent. The SPEEK material is excellent in gas permeability and separation performance, the PE material is low in cost and moisture permeability, so that the prepared anti-fog SPEEK / PE controlled atmosphere composite film is high in gas permeability and separation performance, and low in moisture permeability, and can be used in vegetable fresh keeping; and high research value and promising practical application prospect in solving of vegetable processing and fresh keeping common key technology problems, promoting domestic vegetable after-harvesting storage andtransportation technology system improvement, and accelerating fresh e-commerce development are achieved.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for improving sulfonation process of naphthalene-based water reducer

InactiveCN102746195AProcess stabilityReduce contentSulfonic acid preparationVacuum pumpingProduct gas

The invention relates to a method for improving the sulfonation process of a naphthalene-based water reducer, characterized by cascading a heat exchanger and a vacuum-pumping device to the cover of a reaction vessel, sulfonating the naphthalene-based water reducer for 0.5-1h, then generating negative pressure by extracting the gas of the reaction vessel every 0.5 h to bring out the moisture generated by the reaction; simultaneously letting in steam to the air inlet of the heat exchanger while extracting to let the industrial naphthalene volatilized and crystallized in the extracting process melt and relux to the sulfonation system and circulate continuously to be sulfonated, after finishing the sulfonation reaction, conducting hydrolysis, condensation and neutralization to obtain a powder product. According to the invention, the content of the toxic raw material industrial naphthalene in the water reducer is reduced, the production cost is reduced, the pollution of the materials to the environment is eliminated, and the method is easy to operate, and the operation is convenient.

Owner:JIANGSU NIGAO SCI & TECH

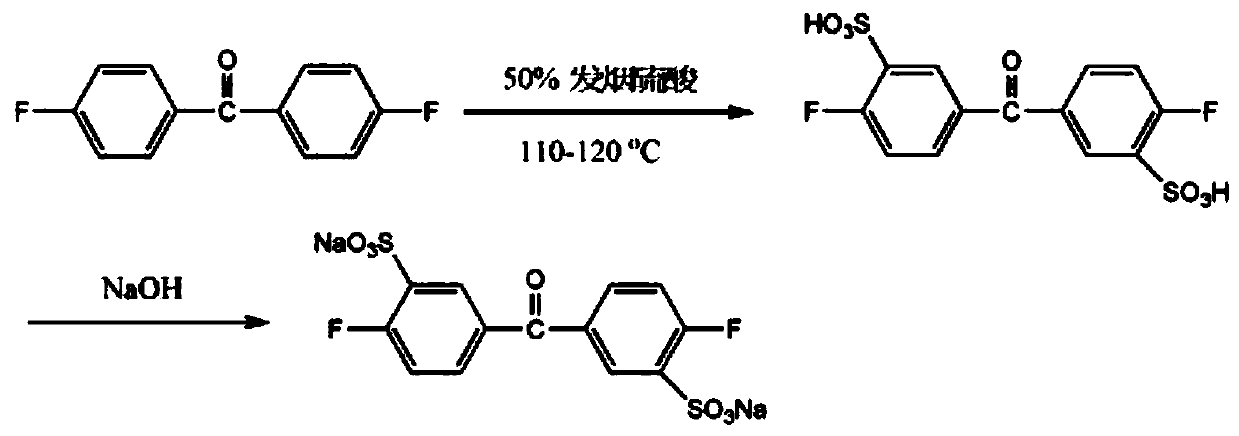

Preparation method of hyperbranched sulfonated polyether ether ketone

The invention relates to a preparation method of hyperbranched sulfonated polyether ether ketone. The preparation method of the hyperbranched sulfonated polyether ether ketone comprises the followingsteps that D1, a sulfonated difluoro benzophenone monomer is prepared, and the difluoro benzophenone monomer is sulfonated to obtain a sulfonated fluorine ketone monomer; D2, the hyperbranched sulfonated polyether ether ketone is prepared, 2,4',6-trifluoro-benzophenone, tetramethyl biphenol, the sulfonated difluoro benzophenone monomer and K2CO3 are matched at the molar ratio of 1:1: (1.5-2):0.4 and dissolved into a DMSO solution, the whole process is carried out under a nitrogen atmosphere, and the hyperbranched sulfonated polyether ether ketone is obtained through drying. According to the preparation method of the hyperbranched sulfonated polyether ether ketone, the sulfonated difluoro benzophenone monomer is adopted, the sulfonated polyether ether ketone is generated, the sulfonation degree can be controlled, the sulfonated polyether ether ketone with the high sulfonation degree is obtained, nucleophilic reaction is used for generating a hyperbranched structure, due to a special three-dimensional space structure of a branched polymer, various performance of the branched polymer and a transmission linear polymer have great difference, and compared with a traditional linear polymer, a three-dimensional space is more stable.

Owner:SHANDONG XINGHUO SCI TECH INSTITYTE

Method for preparing lignin sulfonate by utilizing papermaking black liquid

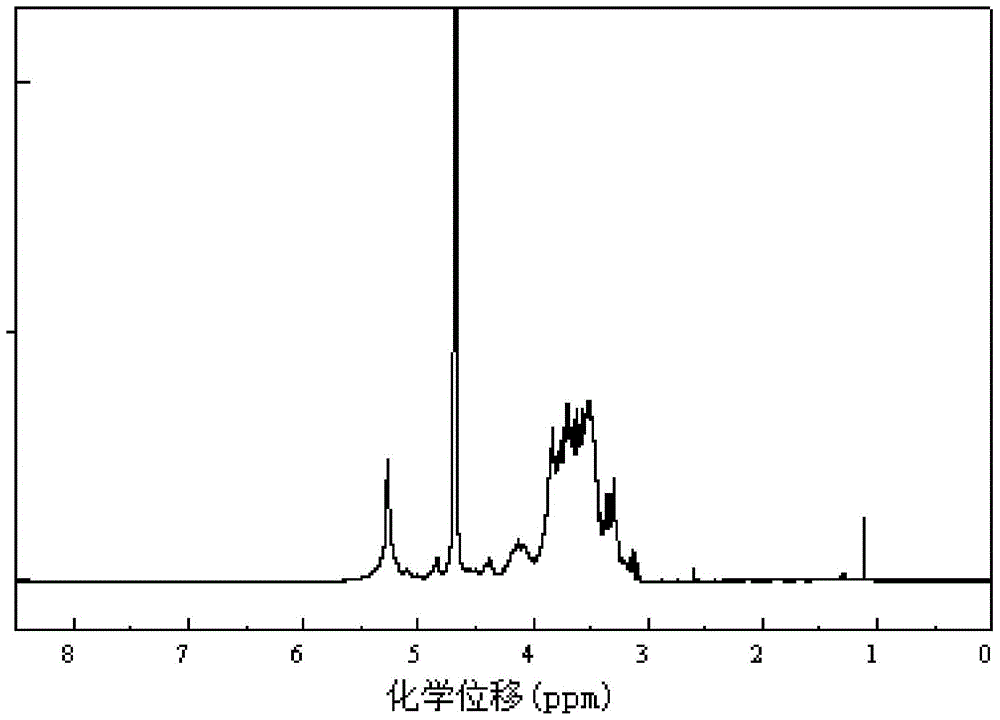

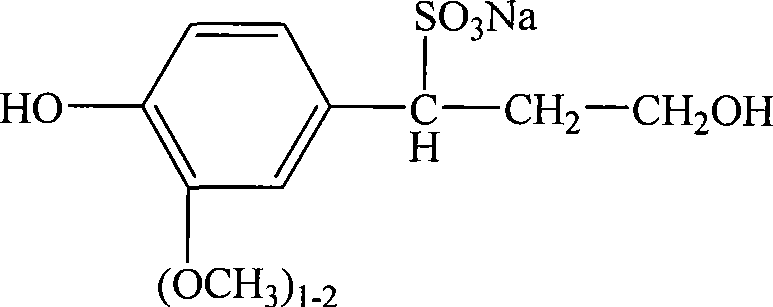

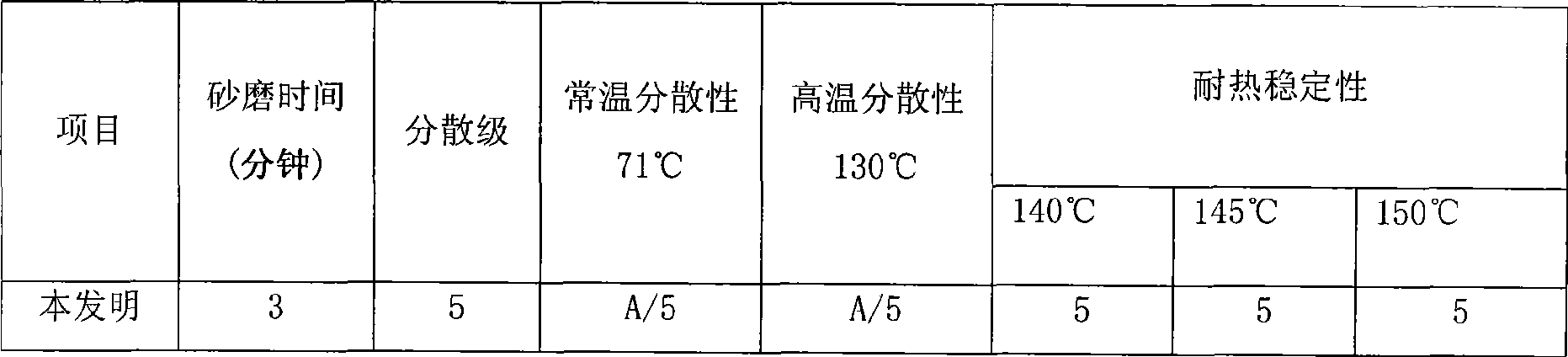

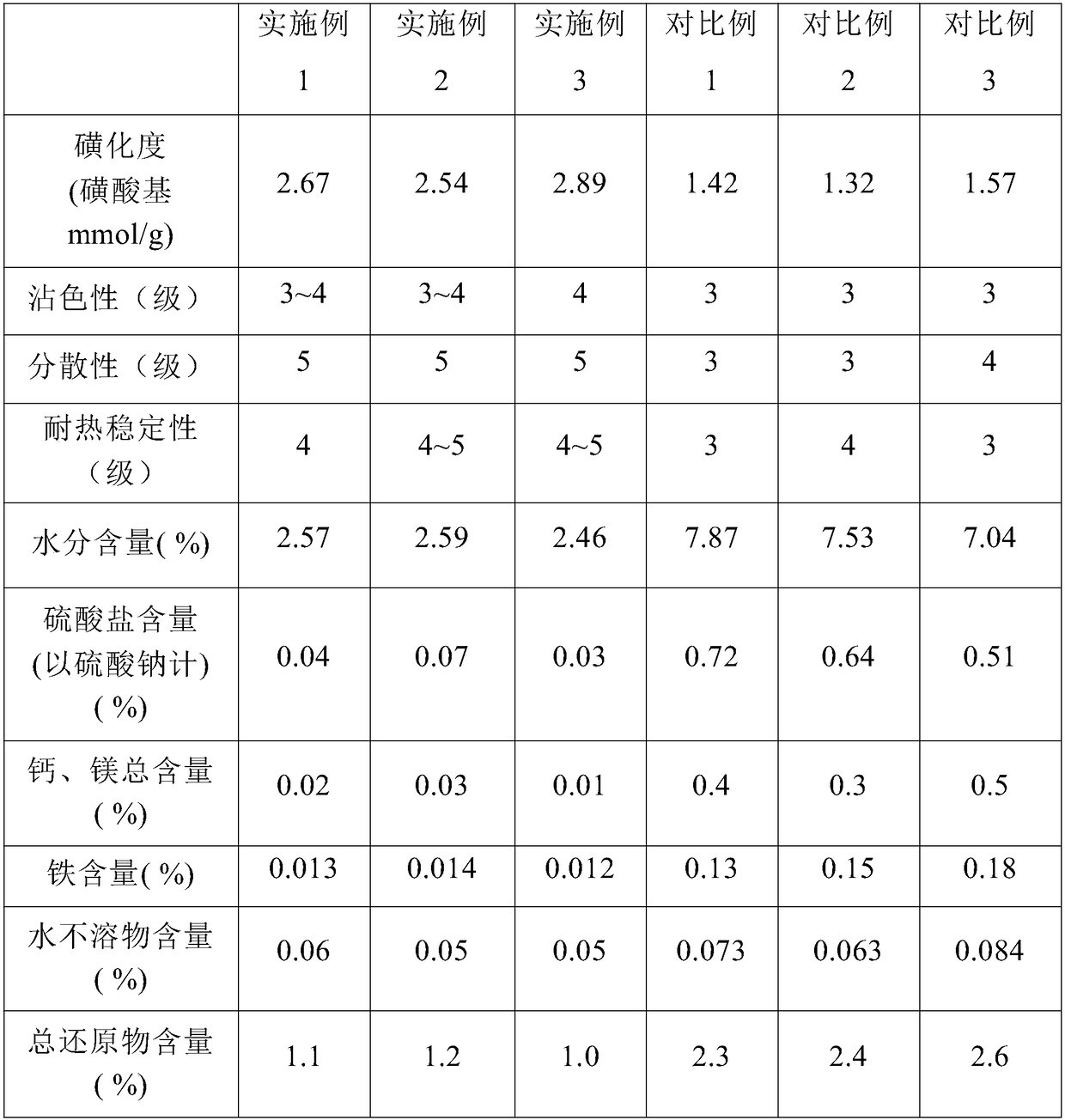

The invention discloses a method for preparing lignin sulfonate by utilizing papermaking black liquid. The method comprises the following steps: S1, preparing raw materials: preparing the raw materials such as the papermaking black liquid, anhydrous sodium sulfite and formaldehyde, wherein the use amount of the sodium sulfite is 2.9 to 3.2 mmol per gram of lignin, the use amount of the formaldehyde is 0.8 to 1.2 mmol per gram of lignin, and the formaldehyde is prepared into a formaldehyde solution; S2, performing reaction: adding the papermaking black liquid into a reaction kettle, adding thesodium sulfite and the formaldehyde solution, stirring and heating, gradually heating to 158 to 165 DEG C, and continuously stirring to perform reaction for 2.5 to 3.5 hours, wherein the consumed timein the heating process is 80 to 100 minutes and the temperature is increased by 1 to 5 DEG C per minute; and S3, discharging: cooling after the reaction, and discharging when the temperature is reduced to 60 to 70 DEG C. The lignin sulfonate prepared by the method has high sulfonation degree and excellent tainting property, dispersibility and heat-resistant stability, has low water content and low content of sulfate, calcium, magnesium, iron, water insoluble matters and total reducing matters, has excellent comprehensive quality and can be widely applied in various fields.

Owner:HAINAN JINHAI PULP & PAPER

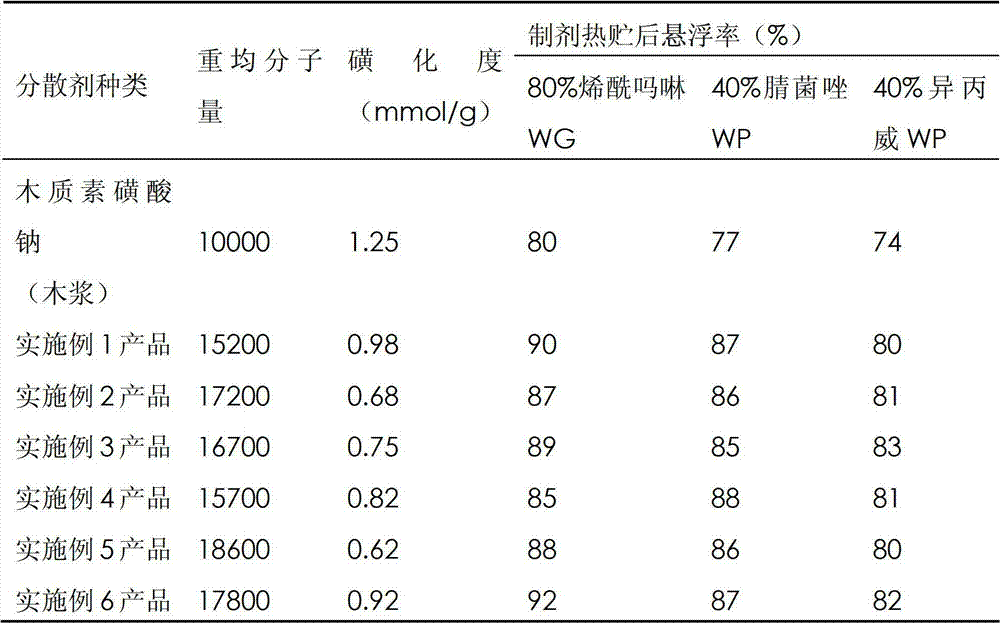

High molecular weight and moderate sulfonation degree lignin-based pesticide dispersant and its preparation method

ActiveCN102786697AThe distribution of hydrophilic groups and lipophilic groups is obviousStrong adsorption capacityBiocideAnimal repellantsWater dispersibleChemistry

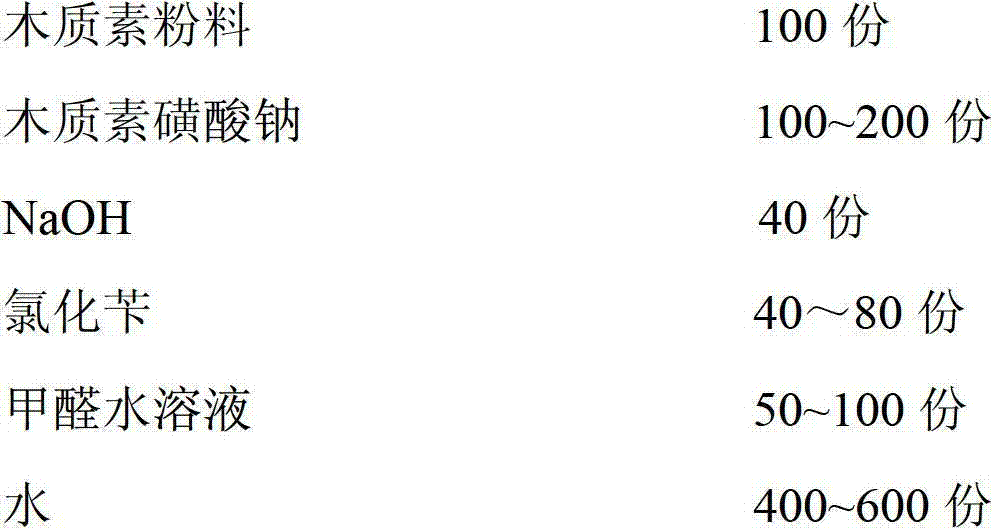

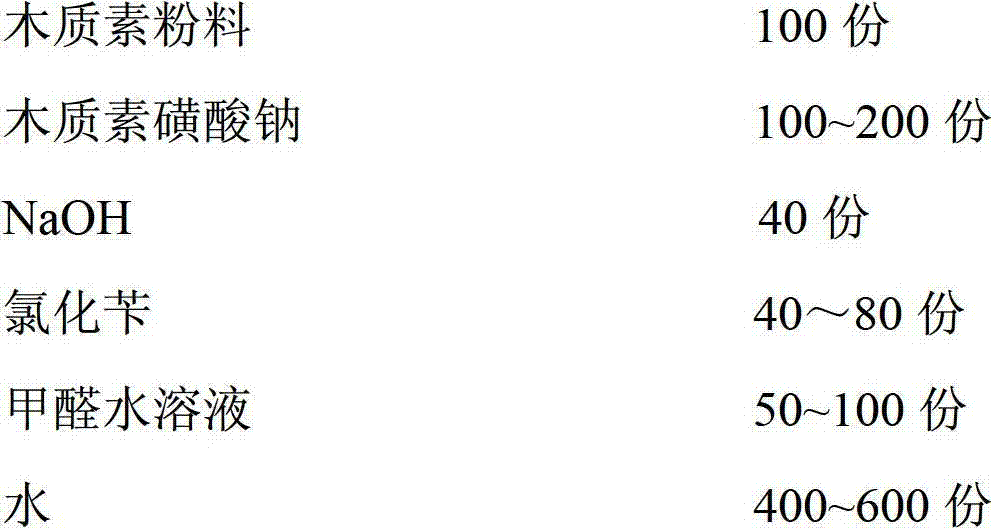

The invention discloses a high molecular weight and moderate sulfonation degree lignin-based pesticide dispersant and its preparation method. The preparation method consists of: first adding a NaOH solution into lignin powder to conduct swelling for 30-60min; adding benzyl chloride, and under the condition of an oil bath at 95-110DEG C, carrying out an etherification reaction for 2-4h; then adding water, sodium lignosulphonate, and a formaldehyde aqueous solution to perform a copolymerization reaction at 80-95DEG C for 1-3h; and adjusting the pH value to 5-9, thus obtaining the high molecular weight and moderate sulfonation degree lignin-based pesticide dispersant. The dispersant prepared in the invention has a weight-average molecular weight of more than 15000 and a sulfonation degree of 0.6-1.0mmol / g, is applicable to 80% dimethomorph water dispersible granules, 80% carbendazim water dispersible granules, 40% myclobutanil wettable powder, and a plurality of pesticide preparations and dosage forms, and has excellent dispersibility, stability, wettability and thermal storage performance.

Owner:SOUTH CHINA UNIV OF TECH +1

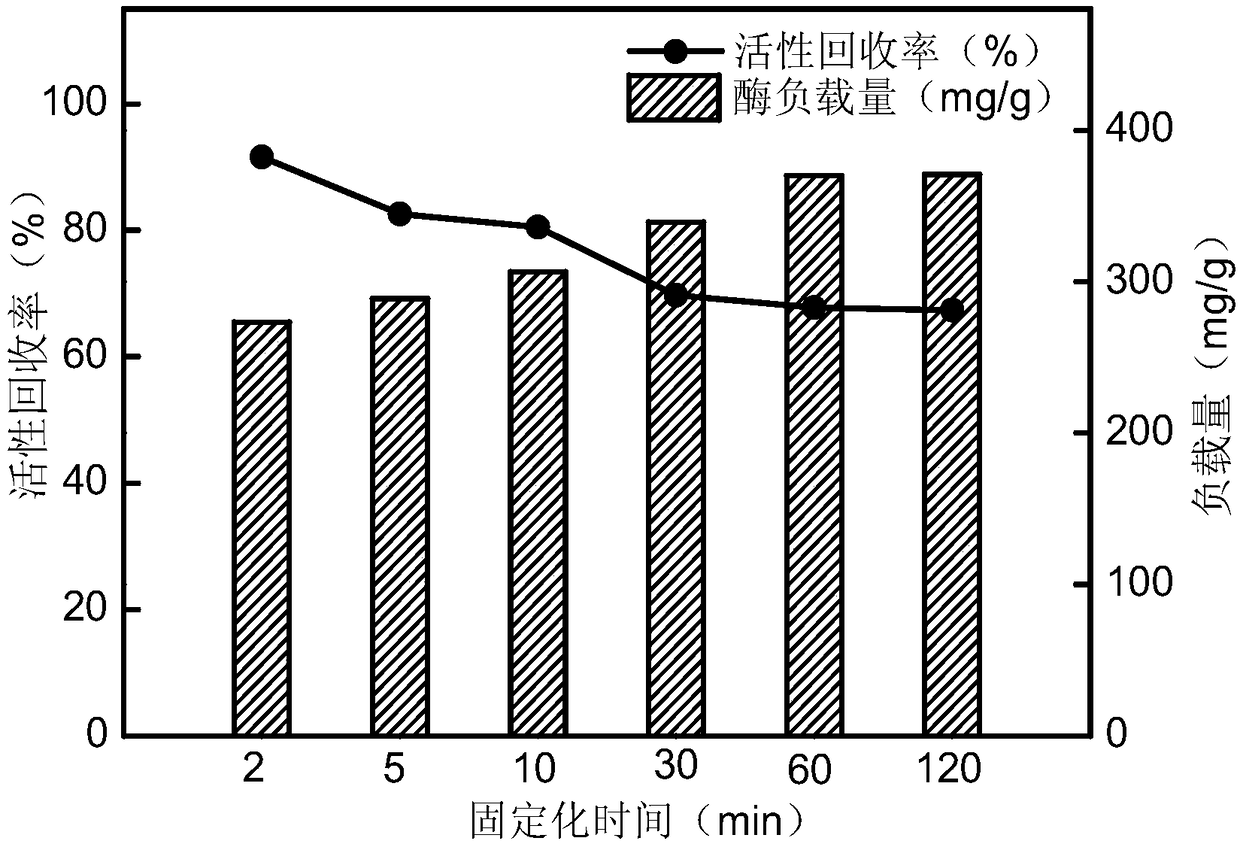

Sulfonated polystyrene microsphere immobilized alkaline protease and preparation method thereof

InactiveCN109182325ALarge specific surface areaSimple methodOn/in organic carrierPeptidasesAlkaline proteaseMicrosphere

The invention belongs to the technical field of immobilized enzymes and discloses sulfonated polystyrene microsphere immobilized alkaline protease and a preparation method thereof. The preparation method comprises the following steps: ultrasonically dispersing sulfonated polystyrene microspheres into distilled water; then adding into an alkaline protease solution and carrying out adsorption and immobilization reaction; and separating and washing a product to obtain the sulfonated polystyrene microsphere immobilized alkaline protease. The sulfonated polystyrene microsphere immobilized alkalineprotease prepared by the invention not only has high activity and recycling rate and a high loading amount, but also has a simple and rapid immobilization process; and the problem that the effect of atraditional immobilized enzyme is not ideal is solved.

Owner:SOUTH CHINA UNIV OF TECH +1

Landfill leachate raw material preparation composite modified coal water slurry additive and preparation method

InactiveCN105316051BHigh molecular weightIncrease the rate of chemical reactionsLiquid carbonaceous fuelsLiquid wasteCoal water

The invention discloses a compound modified water coal slurry additive prepared from a landfill leachate raw material and a preparation method. The additive is prepared from 20-50 parts of landfill leachate, 10-25 parts of active sludge, 1-15 parts of coarse naphthalene, 20-35 parts of industrial waste liquor, 10-25 parts of decomposed coal or coal slime, 10-20 parts of H2SO4 or Na2SO3 and 5-15 parts of formaldehyde. The preparation method comprises the steps of: preparing materials; mixing the materials; sulfonating the materials; condensing the materials; carrying out graft copolymerization; carrying out subsequent steps and the like. The additive disclosed by the invention has the advantages that resourceful treatment is carried out on various wastes to turn wastes into wealth, so that the influence on the environment is avoid and the utilization value of wastes is improved; the obtained product is high and good in quality, the stability and slurry forming concentration of industrial water coal slurry are effectively improved, the use level of additives is reduced, and the pulping cost is lowered.

Owner:XINJIANG SHENGHENGQING ENVIRONMENTAL PROTECTION TECH CO LTD

Method for increasing sulfonation degree of polyetheretherketone

The invention relates to a method for increasing the sulfonation degree of polyetheretherketone. The method comprises the following steps: mixing polyetheretherketone with a composite sulfonating agent and stirring for reaction at 50 DEG C for 4-8 hours; cooling down to room temperature after the reaction is finished, and pouring the mixed solution into an ice-water mixture for separating out theproduct; washing the resulting product for multiple times with a large amount of pure water until the pH value of the product is neutral, and then subjecting the product to heat treatment for 1-2 hours with heated pure water and carrying out filtering; carrying out drying at 60 DEG C for 12 hours in a drying oven, and then drying at 90 DEG C for 24 hours in a vacuum drying oven to obtain sulfonated polyetheretherketone. The sulfonated polyetheretherketone prepared by the method disclosed in the invention has a high sulfonation degree, which ranges from 50% to 70%, and has excellent film-forming and anti-swelling properties and good mechanical stability; and the preparation process is simple and convenient.

Owner:SHANDONG XINGHUO SCI TECH INSTITYTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com