Preparation method and application of hydrophobic starch sulfate ester in cement water-reducing agent

A technology of starch sulfate and hydrophobization, which is applied in the field of chemistry and chemical engineering, to achieve the effect of widening the application range, low raw material cost and good water reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

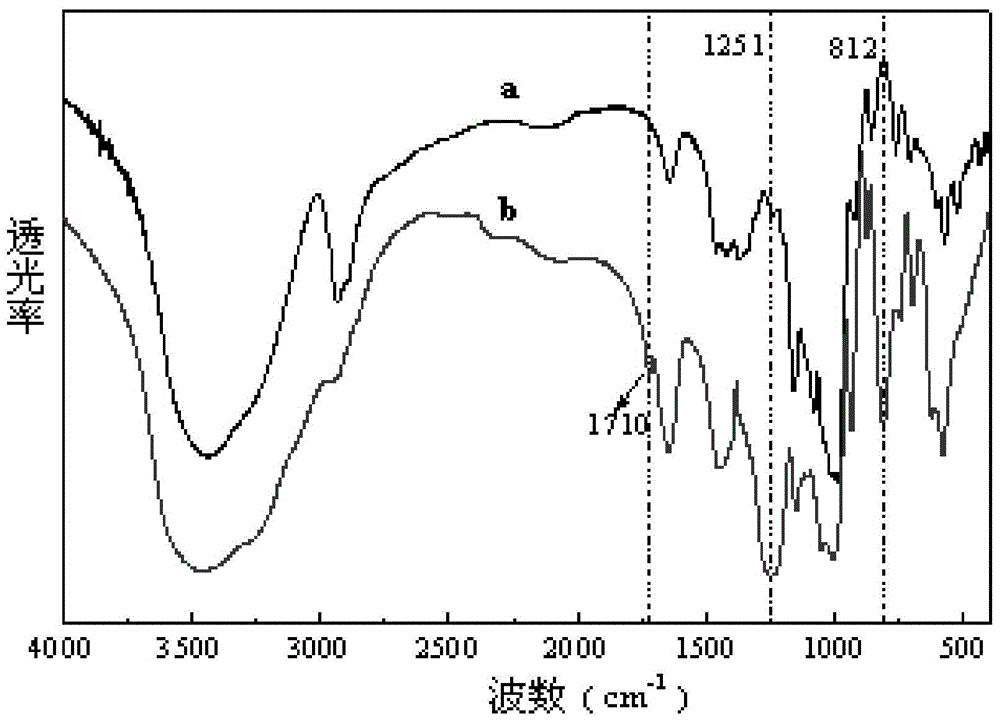

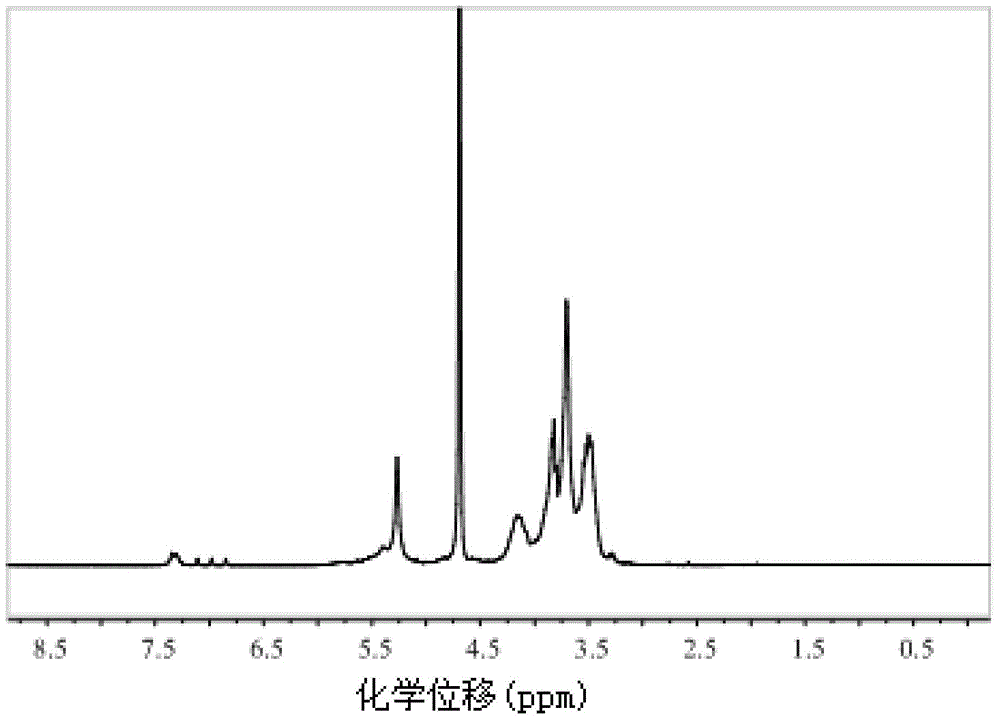

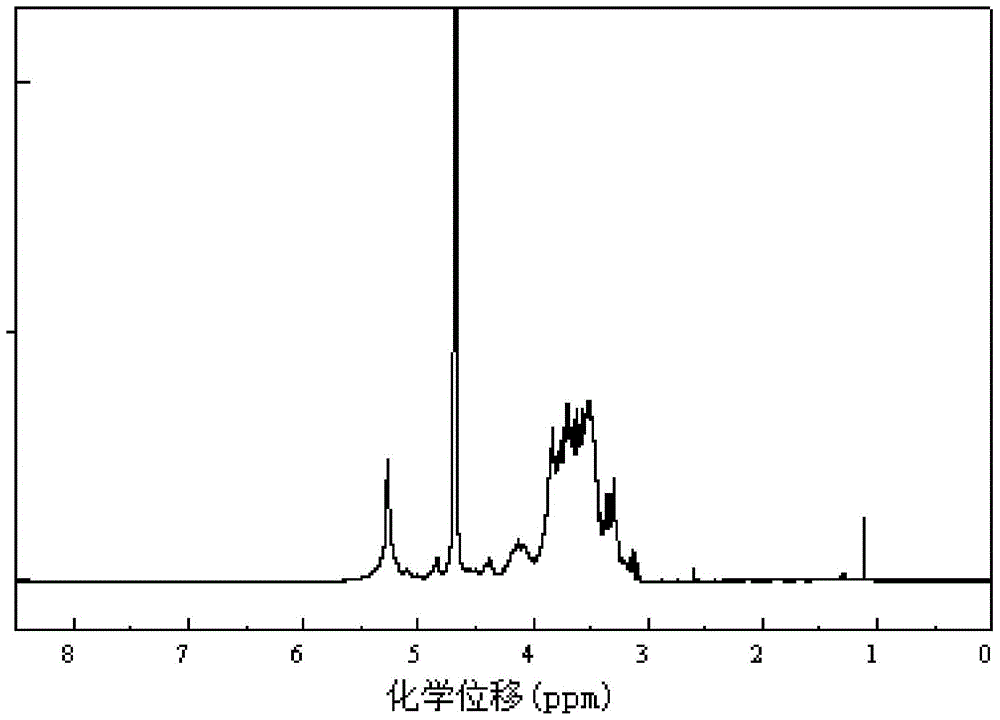

Method used

Image

Examples

Embodiment 1

[0018] 19.4g of sulfamic acid and 2.4g of urea are fully ground and mixed, add 12.96g of dry cornstarch, mix evenly again, add a mixture of 2.5g of deionized water and 1.632g of benzyl alcohol, stir and mix evenly in a mixing cup, put Put it into an oven at 120° C. for 6 hours to obtain a crude product of benzyl hydrophobized starch sulfate. Add 50g of deionized water to the crude product to dissolve it, precipitate it with anhydrous methanol, wash it three times with 90% methanol aqueous solution, and dry the filter cake at 50°C for 4 hours to obtain a sulfonic acid group substitution degree of 0.71, a benzyl substitution degree of 0.04 benzyl hydrophobized starch sulfate.

Embodiment 2

[0020] 5.82g of sulfamic acid and 9.6g of urea are fully ground and mixed evenly, add 12.96g of dry cornstarch, mix evenly again, add a mixture of 3.0g deionized water and 0.816g benzyl alcohol, stir and mix evenly in a mixing cup, put Put it into an oven at 100° C. for 8 hours to obtain a crude product of benzyl hydrophobized starch sulfate. Add 50g of deionized water to the crude product to dissolve it, precipitate it with anhydrous methanol, wash it three times with 90% methanol aqueous solution, and dry the filter cake at 50°C for 4 hours to obtain a sulfonic acid group substitution degree of 0.25, benzyl substitution degree 0.03 benzyl hydrophobized starch sulfate.

Embodiment 3

[0022] 14.56g of sulfamic acid and 4.8g of urea are fully ground and mixed, add 12.96g of dry cornstarch, mix evenly again, add a mixture of 3.5g of deionized water and 1.30g of benzyl alcohol, stir and mix evenly in a mixing cup, put Put it into an oven at 100° C. for 10 h to obtain a crude product of benzyl hydrophobized starch sulfate. Add 50g of deionized water to the crude product to dissolve it, precipitate it with anhydrous methanol, wash it three times with 90% methanol aqueous solution, and dry the filter cake at 50°C for 4 hours to obtain a sulfonic acid group substitution degree of 0.54, benzyl substitution degree 0.04 benzyl hydrophobized starch sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com