Preparation of o-nitro p-methylsulfonylbenzoic acid

A technology of methylsulfonyl benzoic acid and o-nitro group, which is applied in the field of preparation of o-nitro-p-methylsulfonyl benzoic acid, can solve the problems of large amount of hydrogen peroxide, high production cost, easy decomposition and the like, and achieves reduction of waste liquid treatment and recycling , production cost reduction, the effect of cleaner production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

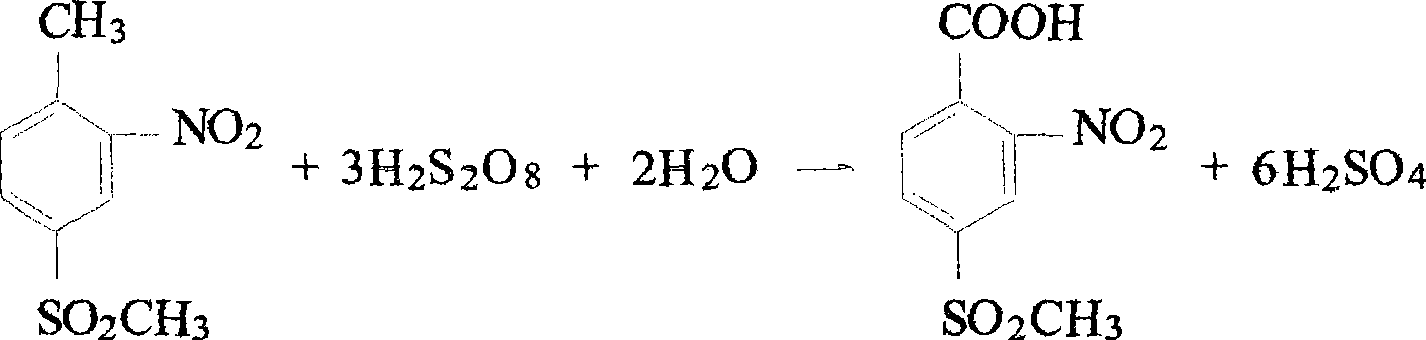

[0013] The preparation method of this o-nitro-p-methylsulfonyl benzoic acid is to oxidize o-nitro-p-methylsulfone toluene with persulfuric acid to obtain o-nitro-p-methylsulfonyl benzoic acid, and its process is:

[0014] (a) hydrogen peroxide and oleum are mixed at low temperature to prepare persulfuric acid;

[0015] (b) dissolving o-nitro-p-methylsulfone toluene in 70% sulfuric acid;

[0016] (c) adding the persulfuric acid obtained in step a dropwise to the liquid obtained in step b, and the reaction obtains o-nitro-p-methylsulfonyl benzoic acid. After cooling, crystals were precipitated, and the product was obtained by suction filtration.

[0017] In the preparation method of this o-nitro-p-methylsulfonyl benzoic acid, in step a, the concentration of oleum is 20-60% by weight, and the concentration of hydrogen peroxide is 50% by weight; the concentration of sulfuric acid used in step b is 70% weight percent concentration; the amount that each raw material adds in the re...

Embodiment 1

[0028] 1. Preparation of persulfuric acid:

[0029] Place 25.5g of fuming sulfuric acid with a concentration of 60% (weight percent concentration, the same in the future) in a 100mL three-necked round-bottomed flask, under magnetic stirring, slowly add 25.5g of concentration 50% (weight percent concentration, all the same hereafter) H 2 O 2 (0.375mol), the temperature of the ice bath was controlled below 30°C, and the stirring was continued for 15 minutes after the completion of the dropwise addition.

[0030] 2. Preparation of o-nitro-p-methylsulfonyl benzoic acid:

[0031] 5.4g (0.025mol) of o-nitro-p-methylsulfone toluene and 37.6g of 70% H 2 SO 4 The reaction flask was added and the reaction mixture was heated to 80°C. Slowly add 51 g of persulfuric acid prepared in the previous step to the mixed solution dropwise within 4 to 5 hours, control the reaction temperature to 80-100°C during the dropwise addition, cool down to 6°C after the reaction, and obtain ortho-nitrat...

Embodiment 2

[0033] 1. Preparation of persulfuric acid:

[0034] Put 20.0g of 50% oleum in a 100mL three-necked round-bottomed flask, and slowly add 15.3g of 50% H into it dropwise under magnetic stirring. 2 O 2 (0.225mol), the temperature of the ice bath was controlled to be below 30°C, and the stirring was continued for 15 minutes after the dropwise addition, and it was set aside.

[0035] 2. Preparation of o-nitro-p-methylsulfonyl benzoic acid:

[0036] 5.4g (0.025mol) of o-nitro-p-methylsulfone toluene and 37.6g of 70% H 2 SO 4 The reaction flask was added and the reaction mixture was heated to 80°C. 35.3 g of persulfuric acid prepared in the previous step was slowly added dropwise to the mixed solution within 4 to 5 hours, and the reaction temperature was controlled to 80-130°C during the dropwise addition. Nitro-p-methylsulfonylbenzoic acid is 4.3 g of white solid, the yield is 70.0%, and the content by liquid chromatography analysis is 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com