Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Low hydrolysis temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

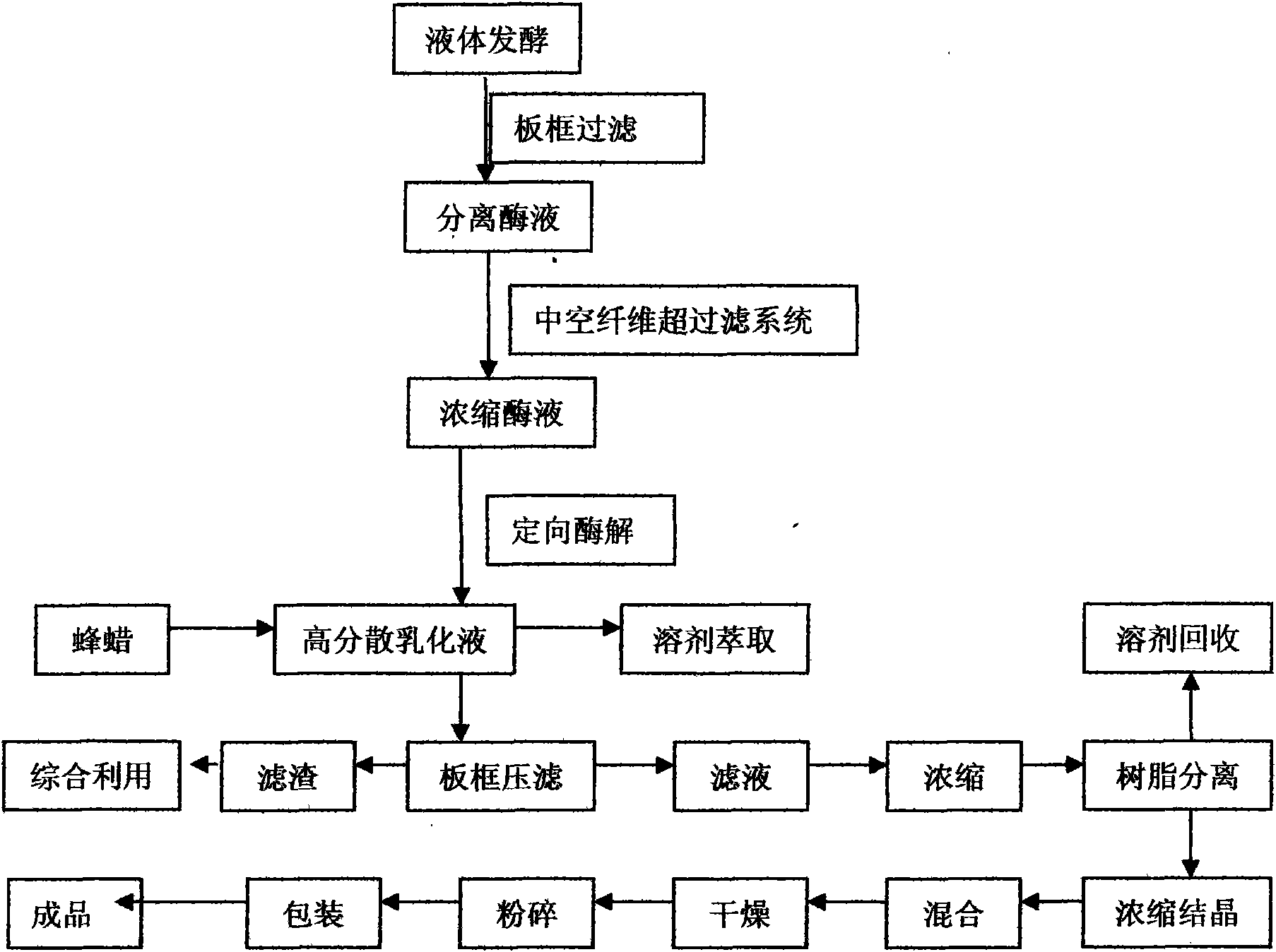

Biological enzyme preparation method of natural brassinolide

ActiveCN101684483AEasy to getLow costMicroorganism based processesFermentationBrassinolideFiltration

The invention relates to a preparation method of a biological enzyme, particularly relates to a biological enzyme preparation method of natural brassinolide. The method includes: steps of inoculationfermentation, pressure filtration, ultrafiltration, emulsification, enzymolysis, extraction, pressure filtration, concentration, resin absorption, concentration crystallization, vacuum filtration, drying and packaging. The invention has advantages of simple process method, low energy consumption in production process, high product purity and environmental conservation.

Owner:CHENGDU NEWSUN CROPSCI

Application of carbon microsphere solid acid formed by one-step fructose hydrothermal synthesis to catalyzing hydrolysis of cellulose

InactiveCN103949238ASimple processSave energyPhysical/chemical process catalystsGlucose productionCellulosePtru catalyst

The invention discloses carbon microsphere solid acid formed by one-step fructose hydrothermal synthesis and applied to a catalyzed hydrolysis process of cellulose, and belongs to the field of conversion and utilization of biomass resources and energy. A carbon microsphere solid acid catalyst disclosed by the invention has the molecular formula of CH0.0847O0.523S0.00840. The preparation conditions of the catalyst are mild; through one-pot reaction of fructose and sulfo salicylic acid under the hydrothermal condition of 150 DEG C, the preparation of solid microspheres and the loading of sulfo groups are realized simultaneously; the defects that a large amount of concentrated sulfuric acid is used and a large amount of sulfuric acid waste liquid is produced in a conventional process of preparing the solid acid by soaking the concentrated sulfuric acid by using activated carbon are overcome. The prepared carbon microsphere solid acid has high the catalytic activity on the hydrolysis of the cellulose. The solid acid catalyst has mild preparation conditions, no pollution, no corrosion and high activity, and can be used repeatedly for the hydrolysis of the cellulose. The carbon microsphere solid acid is prepared from the fructose and is applied to efficient hydrolysis of the cellulose; a new way is provided for the high value of the biomass resources.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

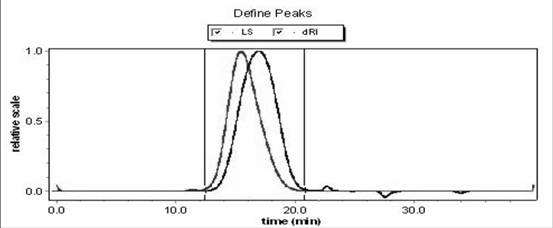

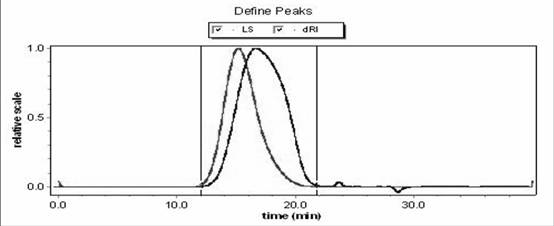

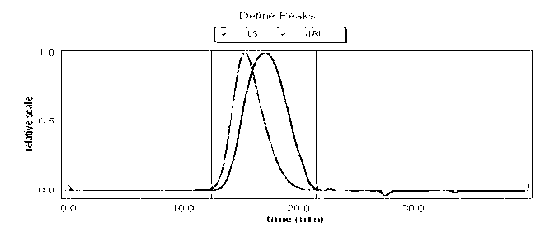

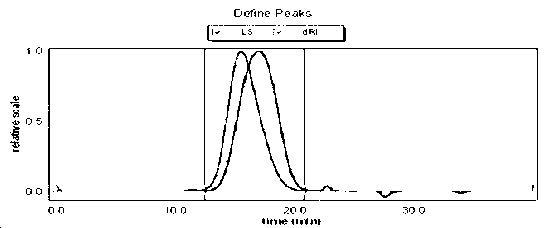

Preparation method of narrow-distribution medium-molecular-weight hydroxyethyl starch

The invention relates to the field of medical chemistry, in particular to a preparation method of narrow-distribution medium-molecular-weight hydroxyethyl starch. The method comprises the following steps of: dispersing wax corn starch with purified water, and hydrolyzing with an inorganic acid; performing gradient temperature change control and controlling the hydrolyzing degree by using dynamic viscosity; and performing hydroxyethylation, carbon removing filtration, ultrafiltration and spray drying on a hydrolysate to obtain a narrow-distribution medium-molecular-weight hydroxyethyl starch raw material. According to the method, the weight average molecular weight of the medium-molecular-weight hydroxyethyl starch is controlled more accurately, and the molecular weight distribution is more concentrated.

Owner:SHANDONG QIDU PHARMA

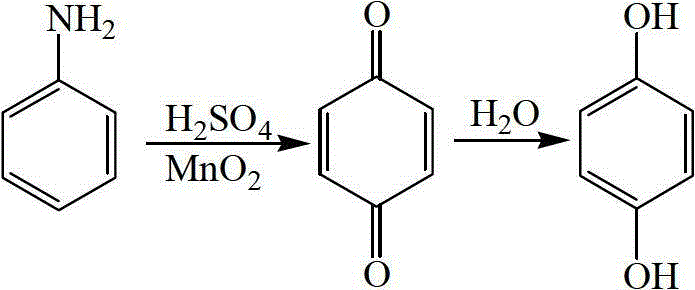

Hydrolysis process for hydroquinone

InactiveCN102746122AMake up for the disadvantage of high priceRealize cleaner productionOrganic chemistryOrganic compound preparationP-AminophenolReaction temperature

The invention discloses a hydrolysis process for hydroquinone and relates to a hydrolysis process during hydroquinone synthesis by subjecting p-aminophenol to diazotization and hydrolysis processes. The process includes: adding basic cupric carbonate, cupric sulfate and solvents into a hydrolysis reaction kettle, dropwise adding diazonium solution of 0+ / -0.5 DEG C obtained by subjecting sodium nitrite and dilute sulfuric acid to diazotization and performing hydrolysis reaction at a reaction temperature of 85 DEG C-88 DEG C. Raffinate phase does not generate waste acid, and the copper recovery rate reaches to more than 99.5%, so that a disadvantage of high copper price is made up; and sodium sulfate is obtained by means of concentration and crystallization of filtrate, concentrated water is used for preparing acid for diazo reaction, and crystallized mother solution of the sodium sulfate is used for preparing cupric sulfate solution for hydrolysis, so that clean production is realized.

Owner:JIANGSU YANGNONG CHEM GROUP +1

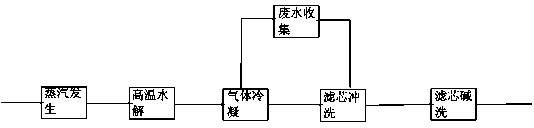

Method for washing CPF-PT series type melt filters

ActiveCN104069674AEasy to operatePollution no pollutionFiltration separationSolventProcess engineering

The invention discloses a method for washing a CPF-PT series type melt filters and aims at solving the defects in the prior art that solvents are used for washing the filters in an existing method for washing the CPF-PT series type melt filters, so that the pollution to the environment is caused and a certain risk is caused; due to the application of vacuum calcinations, the destructive influence on the filters is caused, and thus the service life of filter elements is shortened. By virtue of the method, a polymer is quickly hydrolyzed in the presence of high-temperature steam so as to generate compounds which are low in molecular weight, so that the macromolecular compounds are high in viscosity and adhesion, and can be separated from the polluted filter elements to be washed, and the purpose of washing the filter elements can be achieved. The method is convenient to operate and has almost no pollution to the environment; the method is an economical and applicable method for washing the filter elements; moreover, the hydrolysis temperature is lower than the calcinations temperature of a calcinations furnace; the hydrolysis time can be used for adjusting the washing time according to the factors such as the size and the number of the washed filter elements, and the like.

Owner:ZHEJIANG YUFENG MACHINERY CO LTD

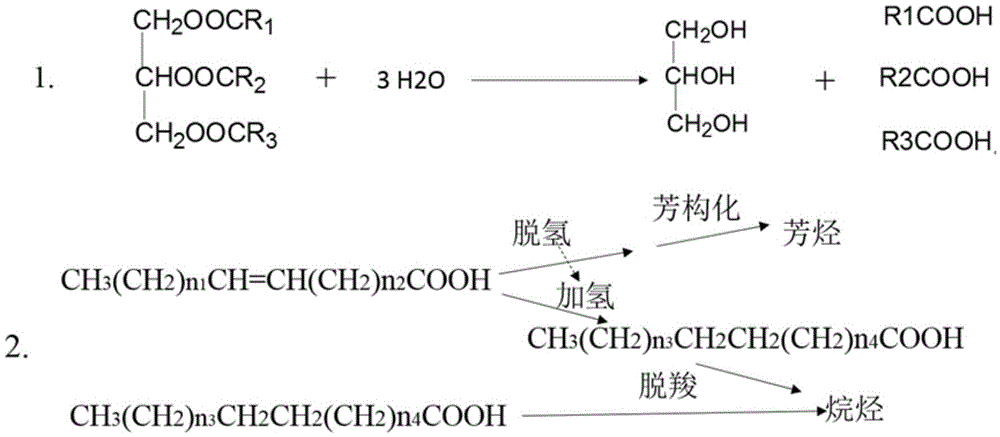

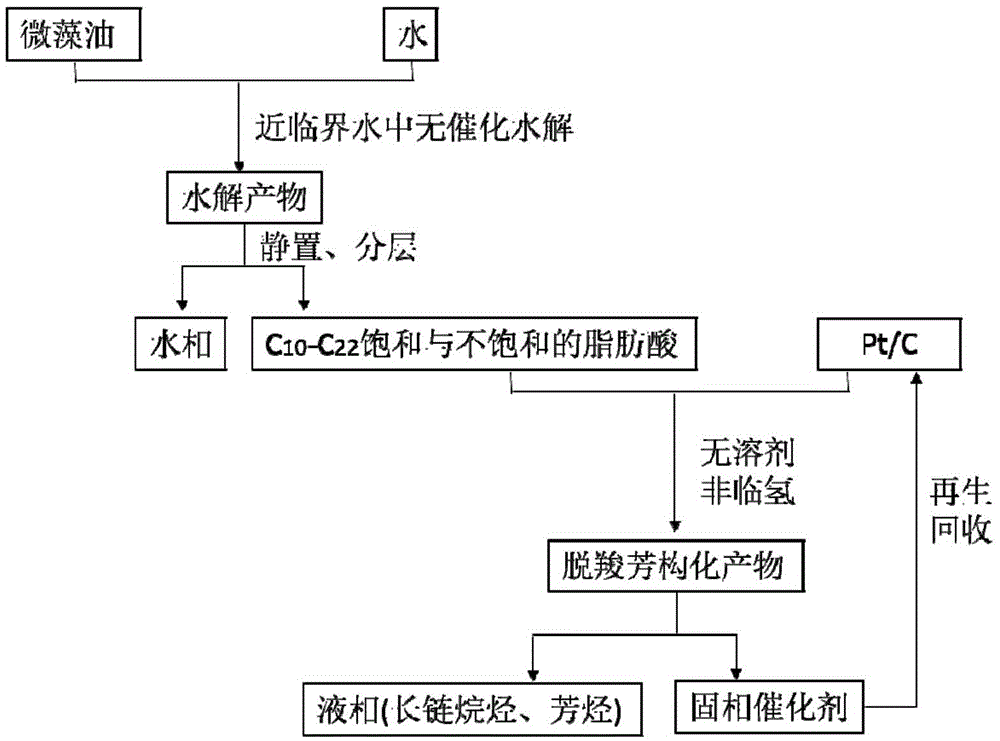

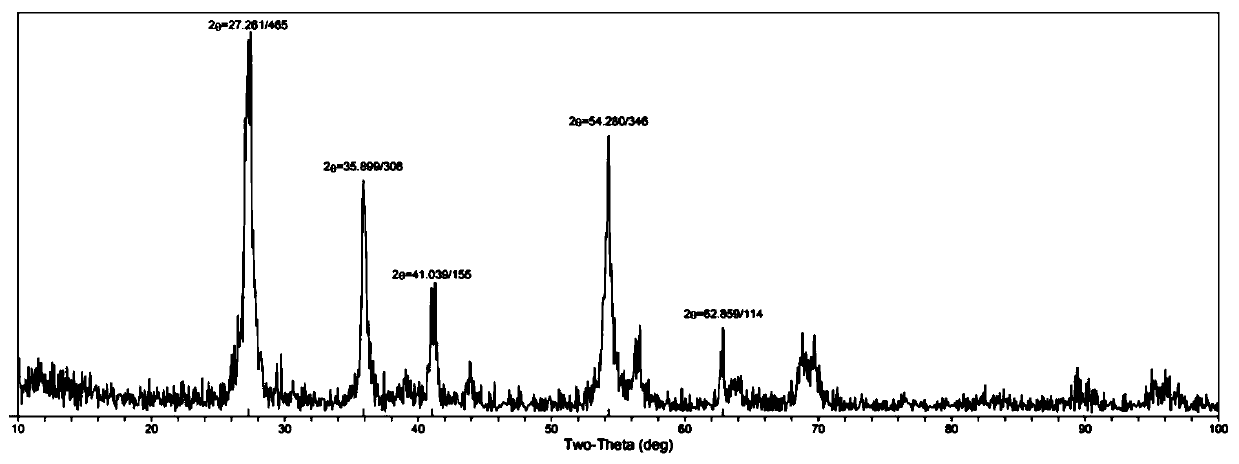

Method for simultaneously preparing long-chain alkane and arene by taking microalgae oil as raw material

ActiveCN105567284ALow hydrolysis temperatureWidely distributedLiquid hydrocarbon mixture productionBio-feedstockSolventFischer–Tropsch process

The invention relates to a method for simultaneously preparing long-chain alkane and arene by taking microalgae oil as a raw material. The method comprises the following steps: (1) mixing the microalgae oil with water, then, heating for hydrolysis reaction, and performing treatment to obtain C10-C22 fatty acid; (2) adding the C10-C22 fatty acid and a catalyst into a high-temperature and high-pressure reactor together, heating to 280 to 380 DEG C for decarboxylation aromatization reaction for 1 to 7 hours, wherein the catalyst is Pt / C; (3) cooling a reaction product, dissolving with an organic solvent, and filtering to obtain a liquid product and a solid catalyst. According to the method disclosed by the invention, without adding any hydrogen source or solvent, high-yield long-chain alkane and arene, i.e., an important component of aircraft fuel, hard to obtain through other hydrodeoxygenation or Fischer-Tropsch synthesis are obtained from the microalgae oil, and the long-chain alkane and the arene separately reach more than 71.6 percent and 23.1 percent in yield.

Owner:ZHEJIANG UNIV

Method for preparing D-glucosamine hydrochloride

InactiveCN102492000AThe concentration of hydrochloric acid is stableRapid hydrolysisSugar derivativesSugar derivatives preparationHydrolysateDecomposition

A method for preparing D-glucosamine hydrochloride includes the steps: placing chitin into a reaction tank, adding hydrochloric acid with stirring and heating the reaction tank for hydrolysis; uninterruptedly leading hydrochloric acid gas into hydrolysate in backflow hydrolysis; obtaining a solid crude product after cooling, precipitating and leaching the hydrolysate; adding deionized water and activated carbon into the crude product for decolorization prior to filtering so that faint yellow liquor is obtained; and the hydrochloric acid is recovered by means of vacuum concentration, obtaining a wet refined product by centrifugally dewatering concentrated materials and washing the wet refined product in alcohol prior to vacuum drying so that finished product crystals are obtained. Since the hydrochloric acid gas is led into the hydrolysate, the concentration of the hydrochloric acid of the hydrolysate is kept stable, a hydrolysis process is accelerated, and time for hydrolysis reaction is shortened. Besides, by the aid of increase of the hydrochloric acid concentration, the hydrolysis temperature can be decreased, and decomposition of the D-glucosamine hydrochloride is reduced. By the aid of the method, yield is increased, quality of the D-glucosamine hydrochloride is improved, and energy consumption and production cost are reduced.

Owner:石狮市华宝海洋生物化工有限公司

Rutile metatitanic acid and titanium dioxide, and preparation methods thereof

PendingCN111453768AImprove qualityReduce energy consumptionFerric oxidesTitanium dioxidePhysical chemistryChloride

The invention provides rutile metatitanic acid and titanium dioxide, and preparation methods thereof, belonging to the technical field of pigment preparation. The preparation method of rutile metatitanic acid comprises the following steps: hydrolyzing a mixed solution of a seed crystal solution and a ferrotitanium solution at 90-100 DEG C, and keeping the temperature to obtain a mixed solution containing metatitanic acid, ferrous chloride and hydrochloric acid, wherein the seed crystal solution is obtained by curing a part of the ferrotitanium solution at 90-100 DEG C, iron ions in the ferrotitanium solution are divalent iron ions, the content of Ti<4+> in the ferrotitanium solution is 100-200 g / L in terms of TiO2, and a iron-titanium ratio is 0.1-0.3. The rutile metatitanic acid is prepared by adopting the method. The preparation method of the titanium dioxide comprises the preparation method of the rutile type metatitanic acid, and comprises a step of calcining the metatitanic acid.The titanium dioxide is prepared by using the method. The rutile metatitanic acid is prepared by the method, and the method is simple in process and low in reaction energy consumption and can preparehigh-quality titanium dioxide .

Owner:福建富仕新材料有限责任公司

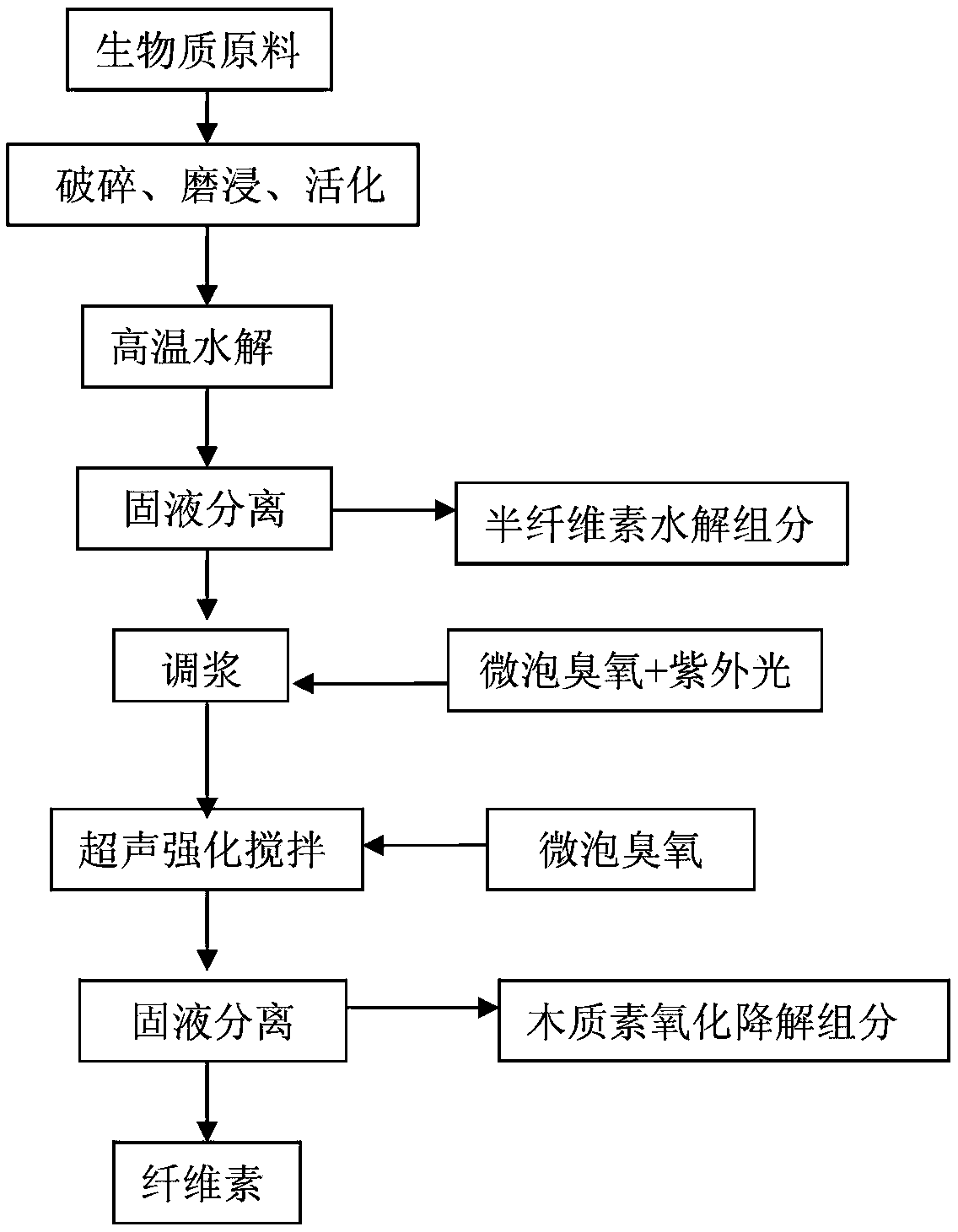

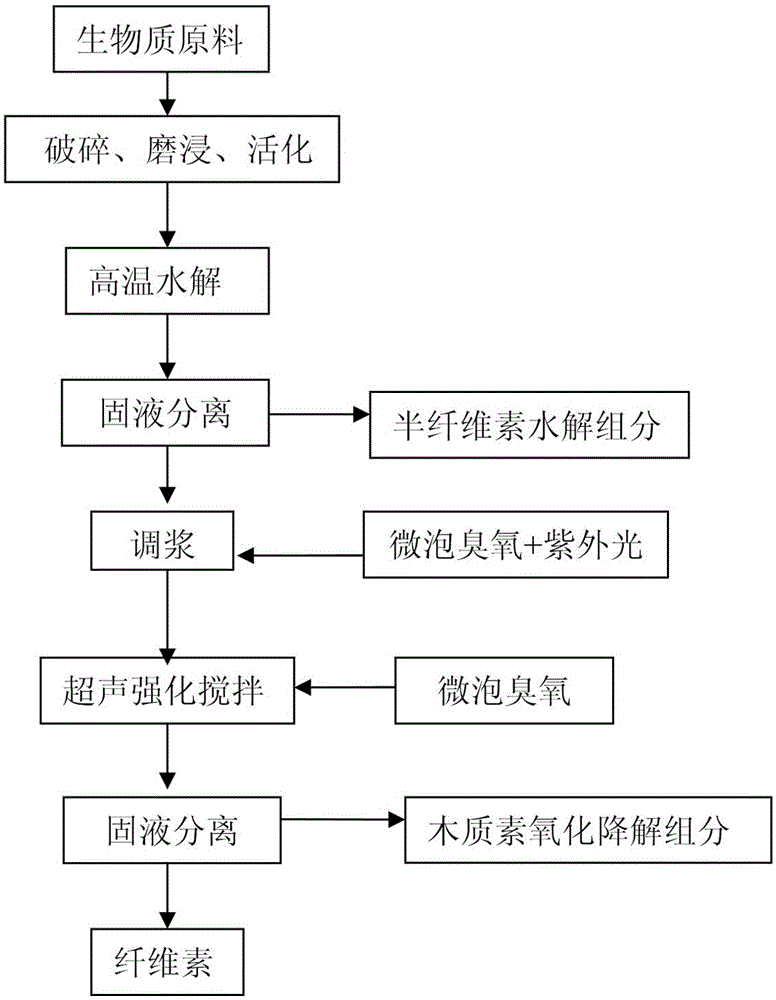

Environment-friendly separation process for valuable components in biomass materials

The invention discloses an environment-friendly separation process for valuable components in biomass materials. The environment-friendly separation process comprises the following steps of crushing the biomass materials; adding water for pulverizing-leaching treatment on the crushed biomass materials; activating the pulverized and leached materials in a stirring device; conveying the activated materials to a reaction kettle for pyrohydrolysis, wherein the temperature is controlled to 150-220 DEG C and the pressure is controlled to 0.5-3MPa during pyrohydrolysis; filtering a reaction product after pyrohydrolysis, wherein filter liquor mainly comprises hydrolysis components of hemicellulose in the biomass materials, filter residue can be subsequently treated, a lignin degradation component, cellulose and other components can be further separated through subsequent oxydative degradation. The method has the advantages of convenient operation, low equipment investment, low-price and easily obtained materials, environment friendliness, circular using of biomass resource and the like.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Preparation method of narrow-distribution medium-molecular-weight hydroxyethyl starch

The invention relates to the field of medical chemistry, in particular to a preparation method of narrow-distribution medium-molecular-weight hydroxyethyl starch. The method comprises the following steps of: dispersing wax corn starch with purified water, and hydrolyzing with an inorganic acid; performing gradient temperature change control and controlling the hydrolyzing degree by using dynamic viscosity; and performing hydroxyethylation, carbon removing filtration, ultrafiltration and spray drying on a hydrolysate to obtain a narrow-distribution medium-molecular-weight hydroxyethyl starch raw material. According to the method, the weight average molecular weight of the medium-molecular-weight hydroxyethyl starch is controlled more accurately, and the molecular weight distribution is more concentrated.

Owner:SHANDONG QIDU PHARMA

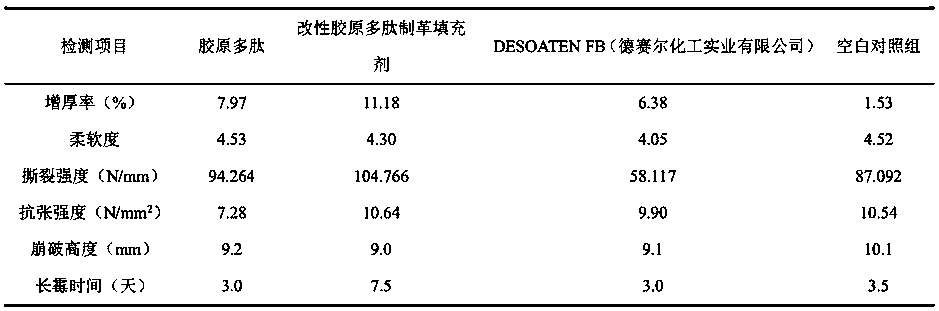

Method for preparing modified collagen polypeptide leather making filler from chrome-free polymetal tanning leather meal

ActiveCN109852742AModerate molecular weightHigh molecular weightTanning treatmentLeather impregnationEconomic benefitsOrganic chemistry

The invention relates to the technical field of leather making chemistry and engineering and provides a method for preparing a modified collagen polypeptide leather making filler from chrome-free polymetal tanning leather meal. According to the method for preparing the modified collagen polypeptide leather making filler from the chrome-free polymetal tanning leather meal, the pollution to environments caused by leather making can be reduced, the problem that leather meal of enterprises is difficult in treatment is solved, meanwhile, resources can be saved, the leather making cost is reduced, and meanwhile, the economic benefit of the enterprises is improved; the modified collagen polypeptide leather making filler prepared by the method is moderate in molecular weight and high in hydrolysisyield and has electropositivity and antibacterial and mildewproof properties; and when the modified collagen polypeptide leather making filler is applied to leather making procedures, an off shade phenomenon of leather can be avoided, the absorption of other anionic materials in the leather making procedures can be promoted, and the leather is endowed with mildew resistance.

Owner:宏兴汽车皮革(福建)发展有限公司

Novel hair hydrolyzing technique

InactiveCN101503385AChemically activeLow hydrolysis temperatureHydropoly/poly sulfide preparationAcid hydrolysisAcid concentration

The invention discloses a new hair hydrolyzing process comprising three steps, i.e. hair treatment before hydrolysis, acid hydrolysis and alkali neutralization for adjusting isoelectric point so as to precipitate corresponding amino acid. The method is characterized in that the conditions for the acid hydrolysis are as follows: acid solution is trichloroacetic acid aqueous solution, acid concentration is 3-8 mol / L, the temperature of the acid hydrolysis is 60-80 DEG C, the time of the acid hydrolysis is 7-9 h, and the mass ratio of the hair and the trichloroacetic acid is 0.1-3. The conditions for the acid hydrolysis not only realizes the aim of obtaining the amino acid during hair hydrolysis, but also can obtain clear and transparent hair hydrolysa, thereby solving the problem that black hydrolysa in the prior art affects the accurate control and adjustment of the isoelectric point of various amino acids after hydrolysis. In addition, the temperature of the acid hydrolysis is low, thereby not only saving energy during production but also avoiding the generation of a few secondary reactions, and not only improving the yield rate but also being favorable for the separation and purification of the amino acid.

Owner:SHANGHAI UNIV OF ENG SCI

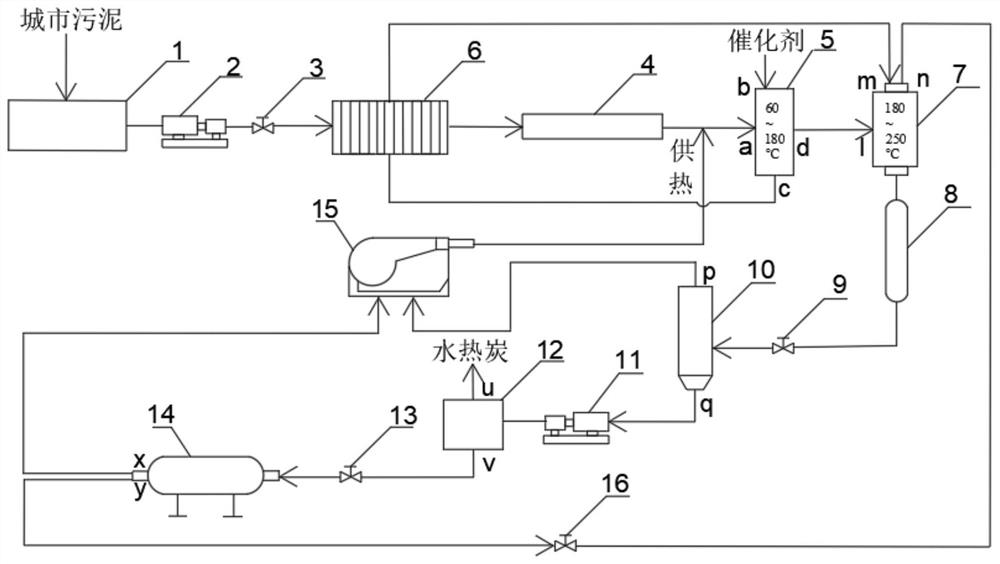

Sludge treatment system and method based on catalytic thermal hydrolysis assisted hydrothermal carbonization

ActiveCN113185071AIncreased release rateReduce energy consumptionSpecific water treatment objectivesSludge treatment by pyrolysisProduct recoveryIndustrial waste

The invention discloses a sludge treatment system and method based on catalytic thermal hydrolysis assisted hydrothermal carbonization and belongs to the technical field of sludge treatment. The sludge treatment system comprises a sludge thermal hydrolysis pretreatment unit, a sludge hydrothermal carbonization unit and a product recovery unit; the structure of the system is designed by combining a thermal hydrolysis technology and a hydrothermal thermal carbonization technology, biomass and industrial waste are subjected to resource treatment, secondary pollution generated during waste treatment is very small, and in the sludge treatment process, due to the existence of water with high fluidity, the energy consumption and the operation cost of the system are reduced; the whole system has economical efficiency and ecological value, and provides a certain thought for waste disposal and sludge resource utilization.

Owner:XI AN JIAOTONG UNIV

Method for preparing butyl alcohol by using green soy bean straws

InactiveCN105925624AWide variety of sourcesLow costBiofuelsMicroorganism based processesAlcoholRoom temperature

The invention discloses a method for preparing butyl alcohol by using green soy bean straws, and belongs to the technical field of biomass energy. The butyl alcohol is prepared by the steps of drying, crushing, pretreating, hydrolyzing and fermenting the green soy bean straws. The method disclosed by the invention is wide in raw material source and low in cost of preparing butyl alcohol, has a high glucose conversion rate, and generates a small amount of residues, so that the method is a green and environment-friendly process. Compared with fuel prepared by a petroleum refining method, the biofuel, namely butyl alcohol, prepared by the method disclosed by the invention has a significant environmental protection effect and can effectively reduce the emission of room temperature gases. Meanwhile, the method also provides a new solution for solving the problem of shortage of energy.

Owner:广西南宁荣威德新能源科技有限公司

Method of preparing butanol from corn straws

InactiveCN105936921AWide variety of sourcesLow costBiofuelsMicroorganism based processesSugarPre treatment

The invention discloses a method of preparing butanol from corn straw, and belongs to the technical field of biomass energy. The butanol is obtained through the following steps: drying corn straws, grinding, and carrying out pretreatment, hydrolysis, and fermentation. The raw material sources are wide, the preparation cost is low; the sugar conversion rate is high, the generated residue amount is little, the technology is green and environment-friendly; compared with the fuel obtained through petroleum refining, the biological fuel namely butanol has a prominent environment-friendly effect, and the discharge of greenhouse gas is effectively reduced. At the same time, the problem of energy shortage is solved.

Owner:广西南宁荣威德新能源科技有限公司

Continuous process method for preparing hydroquinone

ActiveCN102731267BImplement loopingReduce material requirementsOrganic chemistryOrganic compound preparationMethyl isobutyl ketoneHydroquinone Compound

The present invention relates to a continuous process method for preparing hydroquinone. The method comprises the following steps: (1) adding a sodium nitrite aqueous solution to a sulfuric acid solution of para-aminophenol in a dropwise manner to carry out a diazotization reaction to obtain a dark brown diazo solution; (2) continuously feeding methyl isobutyl ketone from the bottom, continuously feeding a copper sulfate solution from the middle part, collecting extraction residue water from the bottom, collecting an extraction oil layer from the upper overflow port, adjusting flow and in-out balance, and then continuously feeding a diazo solution from the middle part, wherein the extraction oil layer is subjected to precipitation, decoking and crystallization to obtain the hydroquinone finished product.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Novel hair hydrolyzing technique

InactiveCN101503385BChemically activeLow hydrolysis temperatureHydropoly/poly sulfide preparationAcid hydrolysisAcid concentration

The invention discloses a new hair hydrolyzing process comprising three steps, i.e. hair treatment before hydrolysis, acid hydrolysis and alkali neutralization for adjusting isoelectric point so as to precipitate corresponding amino acid. The method is characterized in that the conditions for the acid hydrolysis are as follows: acid solution is trichloroacetic acid aqueous solution, acid concentration is 3-8 mol / L, the temperature of the acid hydrolysis is 60-80 DEG C, the time of the acid hydrolysis is 7-9 h, and the mass ratio of the hair and the trichloroacetic acid is 0.1-3. The conditions for the acid hydrolysis not only realizes the aim of obtaining the amino acid during hair hydrolysis, but also can obtain clear and transparent hair hydrolysa, thereby solving the problem that blackhydrolysa in the prior art affects the accurate control and adjustment of the isoelectric point of various amino acids after hydrolysis. In addition, the temperature of the acid hydrolysis is low, thereby not only saving energy during production but also avoiding the generation of a few secondary reactions, and not only improving the yield rate but also being favorable for the separation and purification of the amino acid.

Owner:SHANGHAI UNIV OF ENG SCI

Method for preparing butanol by rice straws

InactiveCN106119301AWide variety of sourcesLow costBiofuelsMicroorganism based processesSec-ButanolBiofuel

The invention discloses a method for preparing butanol by rice straws, and belongs to the technical field of biomass energy. The rice straws are dried, crushed, pretreated, hydrolyzed and fermented to obtain the butanol. Raw material sources are extensive, and butanol preparation cost is low. The method is simple in preparation process, less in investment and suitable for large-scale popularization and application. The bio-fuel butanol prepared by the method has a remarkable environment-friendly effect as compared with a fuel prepared by a petroleum refining method, and emission of greenhouse gas can be effectively reduced. Besides, a novel scheme is provided for solving the problem of energy shortage.

Owner:广西南宁荣威德新能源科技有限公司

A kind of application method of modified collagen polypeptide leather filler

ActiveCN109852742BModerate molecular weightHigh molecular weightTanning treatmentLeather impregnationEconomic benefitsPulp and paper industry

Owner:宏兴汽车皮革(福建)发展有限公司

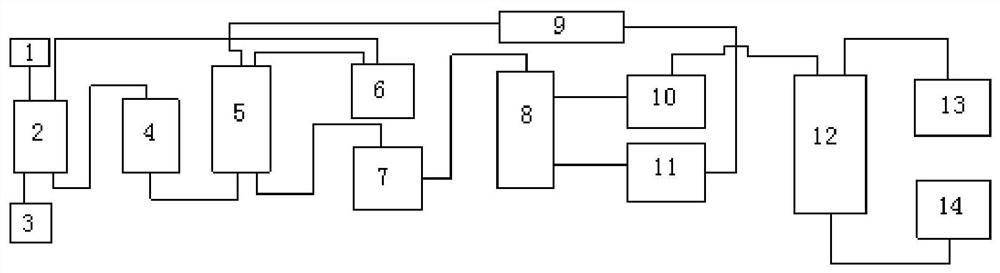

A double-cycle furfural production system and process

The invention discloses a double-circulation furfural production system, and technology. The technology comprises following steps: 1, corn cob and low concentration acetic acid are subjected to hydrolysis reaction so as to obtain a mixed solution of xylose and acetic acid, wherein the concentration of the low concentration acetic acid is controlled to be 1 to 2%, v / v; 2, acetic acid, sodium chloride, and o-nitroanisole are added into the mixed solution of xylose and acetic acid obtained in step 1, wherein the acetic acid concentration is controlled to be 3 to 6%, v / v, the sodium chloride concentration is controlled to be 5 to 10% by mass, the volume ratio of o-nitroanisole to the mixed solution is controlled to be 1:0.8-1.2, and in the reaction process, the reaction system is stirred continuously; 3, after reaction, the obtained reaction system is allowed to stand for a preset time period for layering, an upper layer water phase is recycled back into the step 1 to provide an acidic environment for corn cob hydrolysis, and a lower layer extracted phase is conveyed into a distillation column for separation of crude furfural and o-nitroanisole; and 4, the o-nitroanisole obtained through separation is recycled back into the step 3.

Owner:山东乔克环境科技有限公司

Method for utilizing rosa banksiae to co-produce ethyl alcohol, acetone and butanol

InactiveCN106047948AWide variety of sourcesLow costBiofuelsMicroorganism based processesAlcoholNew energy

The invention discloses a method for utilizing rosa banksiae to co-produce ethyl alcohol, acetone and butanol and belongs to the technical field of biomass energy. The ethyl alcohol, the acetone and the butanol are prepared through the steps of rosa banksiae drying, smashing, pretreatment, hydrolysis, fermentation and the like. The raw material is wide in source, and the cost for co-producing the ethyl alcohol, the acetone and the butanol is low. The glucose conversion rate of the butanol prepared by means of the method is 92.22%-92.93%, the yield of the butanol is 66.54%-67.57%, the purity of the butanol is 99.59%-99.71%, it is shown that the glucose conversion rate and the yield of the butanol are high, and the high-yield ethyl alcohol, acetone and butanol can be achieved by means of the method. By the adoption of the method, a variety of new energy resources can be co-produced, and a new solution is provided for the energy shortage problem.

Owner:广西南宁荣威德新能源科技有限公司

Method for preparing ethyl alcohol from Chinese gooseberry stems

The invention discloses a method for preparing ethyl alcohol from Chinese gooseberry stems, and belongs to the technical field of biomass energy. The ethyl alcohol is prepared from the Chinese gooseberry stems through the steps of drying, pulverization, pretreatment, hydrolysis, fermentation and the like. The uncertainty of a microbial enzyme fermentation sugar making process can be avoided, and the technical risk is lowered. The glucose conversion rate is high; the generated residue quantity is small; the method belongs to a green and environmentally-friendly process. The preparation process is simple; the investment is low; the method is suitable for large-scale popularization and application.

Owner:广西南宁荣威德新能源科技有限公司

Method for preparing butanol from cotton straw

InactiveCN105925623AWide variety of sourcesLow costBiofuelsMicroorganism based processesBiofuelPre treatment

The invention discloses a method for preparing butanol from cotton straw, and belongs to the technical field of biomass energy. Butanol is prepared from steps of cotton straw drying, crushing, pretreatment, hydrolysis, fermentation and the like. The method is wide in raw material resource and low in butanol preparation cost; the method is simple in preparation process, small in investment and applicable to large-scale popularization and application; compared with fuel prepared by using a petroleum refining method, the bio-fuel butanol prepared by using the method disclosed by the invention has a remarkable environment-friendly effect, and is capable of effectively reducing emission of greenhouse gas. In addition, a novel solving scheme is provided for the issue of energy scarcity.

Owner:广西南宁荣威德新能源科技有限公司

Method for washing CPF-PT series type melt filters

ActiveCN104069674BTo achieve the purpose of cleaning the filter elementEasy to operateFiltration separationWater vaporProcess engineering

The invention discloses a method for washing a CPF-PT series type melt filters and aims at solving the defects in the prior art that solvents are used for washing the filters in an existing method for washing the CPF-PT series type melt filters, so that the pollution to the environment is caused and a certain risk is caused; due to the application of vacuum calcinations, the destructive influence on the filters is caused, and thus the service life of filter elements is shortened. By virtue of the method, a polymer is quickly hydrolyzed in the presence of high-temperature steam so as to generate compounds which are low in molecular weight, so that the macromolecular compounds are high in viscosity and adhesion, and can be separated from the polluted filter elements to be washed, and the purpose of washing the filter elements can be achieved. The method is convenient to operate and has almost no pollution to the environment; the method is an economical and applicable method for washing the filter elements; moreover, the hydrolysis temperature is lower than the calcinations temperature of a calcinations furnace; the hydrolysis time can be used for adjusting the washing time according to the factors such as the size and the number of the washed filter elements, and the like.

Owner:ZHEJIANG YUFENG MACHINERY CO LTD

Method for preparing ethanol from loofah stems

The invention discloses a method for preparing ethanol from loofah stems, and belongs to the technical field of biomass energy. The ethanol is prepared by conducting such steps as drying, crushing, pre-processing, hydrolyzing and fermenting the loofah stems and the like. With the application of the method provided by the invention, the uncertainty of a microbial enzyme fermentation sugar making process can be avoided, so that technical risks are reduced; the method provided by the invention, as a green and environment-friendly process, is high in sugar conversion rate and low in the amount of generated residues; and the method provided by the invention is relatively low in hydrolysis temperature, low in energy consumption and is conducive to the popularization and application of related technologies.

Owner:广西南宁荣威德新能源科技有限公司

One-step hydrothermal synthesis of carbon microspheres solid acid from fructose for catalyzing cellulose hydrolysis

InactiveCN103949238BSimple processSave energyPhysical/chemical process catalystsGlucose productionCellulosePtru catalyst

The invention discloses carbon microsphere solid acid formed by one-step fructose hydrothermal synthesis and applied to a catalyzed hydrolysis process of cellulose, and belongs to the field of conversion and utilization of biomass resources and energy. A carbon microsphere solid acid catalyst disclosed by the invention has the molecular formula of CH0.0847O0.523S0.00840. The preparation conditions of the catalyst are mild; through one-pot reaction of fructose and sulfo salicylic acid under the hydrothermal condition of 150 DEG C, the preparation of solid microspheres and the loading of sulfo groups are realized simultaneously; the defects that a large amount of concentrated sulfuric acid is used and a large amount of sulfuric acid waste liquid is produced in a conventional process of preparing the solid acid by soaking the concentrated sulfuric acid by using activated carbon are overcome. The prepared carbon microsphere solid acid has high the catalytic activity on the hydrolysis of the cellulose. The solid acid catalyst has mild preparation conditions, no pollution, no corrosion and high activity, and can be used repeatedly for the hydrolysis of the cellulose. The carbon microsphere solid acid is prepared from the fructose and is applied to efficient hydrolysis of the cellulose; a new way is provided for the high value of the biomass resources.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

Method for co-producing ethyl alcohol, acetone and butanol through boston ivies

InactiveCN106119298AWide variety of sourcesLow costBiofuelsMicroorganism based processesAlcoholNew energy

The invention discloses a method for co-producing ethyl alcohol, acetone and butanol through boston ivies and belongs to the technical field of biomass energy. The ethyl alcohol, the acetone and the butanol are prepared through the steps of boston ivy drying, smashing, pretreatment, hydrolysis, fermentation and the like. The source of the raw material is wide, and the cost of co-producing of the ethyl alcohol, the acetone and the butanol is low. The sugar yield is 92.26%-92.97%, the butanol yield is 66.58%-67.61%, the butanol purity is 99.59%-99.69%, it states that the sugar conversion rate and the butanol yield are high, and by means of the method, the ethyl alcohol, the acetone and the butanol can be produced in a high yield mode. By means of the method, multiple new energy resources can be co-produced, and a new solution is provided for the energy shortage problem.

Owner:广西南宁荣威德新能源科技有限公司

Method for preparing butanol from rape stalks

InactiveCN106399395AWide variety of sourcesLow costBiofuelsMicroorganism based processesBiofuelMicrobial enzymes

The invention discloses a method for preparing butanol from rape stalks, and belongs to the technical field of biomass energy. The butanol is prepared by conducting such steps as drying, crushing, pre-processing, hydrolyzing and fermenting the rape stalks and the like. With the application of the method provided by the invention, the uncertainty of a microbial enzyme fermentation sugar making process can be avoided, so that technical risks are reduced; the method provided by the invention, as a green and environment-friendly process, is high in sugar conversion rate and low in the amount of generated residues; the method provided by the invention is relatively low in hydrolysis temperature, low in energy consumption and is conducive to the popularization and application of related technologies. The bio-fuel, namely the butanol prepared by virtue of the method provided by the invention, in comparison with fuel prepared by virtue of a petroleum refining method, is more significant in environmental protection effect, and the emission of greenhouse gas can be effectively reduced. Meanwhile, a novel solution is provided for solving the problem of energy shortage.

Owner:广西南宁荣威德新能源科技有限公司

Environmentally friendly separation process of valuable components in biomass raw materials

The invention discloses an environment-friendly separation process for valuable components in biomass materials. The environment-friendly separation process comprises the following steps of crushing the biomass materials; adding water for pulverizing-leaching treatment on the crushed biomass materials; activating the pulverized and leached materials in a stirring device; conveying the activated materials to a reaction kettle for pyrohydrolysis, wherein the temperature is controlled to 150-220 DEG C and the pressure is controlled to 0.5-3MPa during pyrohydrolysis; filtering a reaction product after pyrohydrolysis, wherein filter liquor mainly comprises hydrolysis components of hemicellulose in the biomass materials, filter residue can be subsequently treated, a lignin degradation component, cellulose and other components can be further separated through subsequent oxydative degradation. The method has the advantages of convenient operation, low equipment investment, low-price and easily obtained materials, environment friendliness, circular using of biomass resource and the like.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

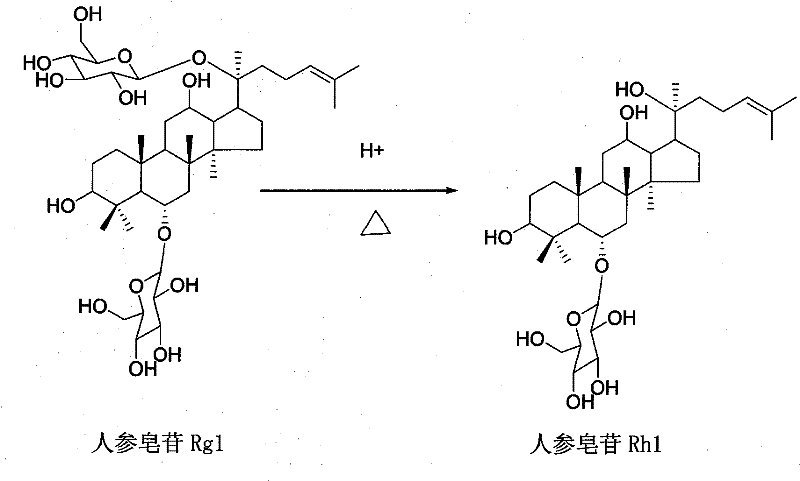

Method for preparing ginsenoside Rh1

ActiveCN101671384BLow hydrolysis temperatureEase of industrial productionSteroidsAcetic acidAcid hydrolysis

The invention discloses a method for preparing ginsenoside Rh1. Although the acid-hydrolysis method is applied to the preparation of total saponins and preparation thereof from ginsenoside, the complex procedure is needed for deacidification after acid-hydrolysis and no reports indicate that the special method for preparing high-purity Rh1 exists. The invention provides a method for preparing ginsenoside Rh1, which is characterized by comprising the steps of adding glacial acetic acid in protopanaxtriolsaponins for hydrolysis, obtaining Icariside part enriched with ginsenoside Rh1 by chromatography deacidification of macroporous resin column, carrying out purification by reversed-phase medium-pressure column chromatography, and finally obtaining the ginsenoside Rh1 with the purity of morethan 90%. The method adopts the macroporous resin column for chromatography deacidification, ensures high metastasis rate of the total saponins, has moderate hydrolysis condition and short reaction period, effectively saves cost and energy resource, is easy for industrial production, thus ensuring the high yield of Rh1 and improving purity.

Owner:YUXI WINHEY BIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com