Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "O-Nitroanisole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of production method of anthranil

ActiveCN102276483AReduce consumptionSimple processOrganic compound preparationAmino-hyroxy compound preparationO-nitrochlorobenzeneSodium methoxide

The invention provides a production method of oamino pheylmethyl ether, and the method comprises the following steps of: reacting ortho nitrochlorobenzene serving as a raw material with sodium methoxide for carrying out a methoxylation reaction to obtain orthonitroanisole; secondly, carrying out hydrogenation reduction on the orthonitroanisole by using methanol as a solvent in the presence of a catalyst to prepare the oamino pheylmethyl ether; and finally, carrying out dealcoholization, dehydrogenation and refining on reactants to obtain the oamino pheylmethyl ether as a finished product. The production process comprises the following steps of: preparing sodium methoxide, etherifying the ortho nitrochlorobenzene, distilling the methanol and nitroether for separation, hydrogenating the orthonitroanisole, distilling a hydrogenating solution for separating the oamino pheylmethyl ether and treating wastewater. The production method has the characteristics of simple process, short procedure, continuity in reaction, high production efficiency, good product quality, less energy consumption, concentrated purification of reaction wastewater and no emission, and is suitable for producing the oamino pheylmethyl ether by using the ortho nitrochlorobenzene as the raw material.

Owner:LIAONING SHIXING PHARMA & CHEM

Method for preparing o-nitroanisole and p-nitroanisole from mixed nitrochlorobenzene

InactiveCN103073431AAvoid costly separationsSave energyOrganic chemistryOrganic compound preparationO-nitrochlorobenzeneChlorobenzene

The invention relates to a method for preparing o-nitroanisole and p-nitroanisole from mixed nitrochlorobenzene. According to the invention, mixed nitrochlorobenzene consisting of a product obtained after nitration of chlorobenzene, o-nitrochlorobenzene, m-nitrochlorobenzene and p-nitrochlorobenzene is used as a raw material, and in a methanol system, 30% of alkali lye and a phase-transfer catalyst are added for a reaction to prepare products of o-nitroanisole and p-nitroanisole, wherein m-nitrochlorobenzene does not participate in the reaction. The method provided by the invention overcomes the problems of great investment for rectifying tower equipment, great energy consumption in rectification, high cost, long process flow, harsh operation conditions, poor operational safety performances and generation of waste residues hardly to treat in rectification-crystallization separation of mixed nitrochlorobenzene in conventional production processes for o-nitroanisole and p-nitroanisole and overcomes the technical problems of generation of considerable alkaline waste water containing sodium hyposulfite and production of a poor-quality product in a sodium sulfide reduction process.

Owner:CHANGZHOU JIASEN CHEM

Method for preparing nitroanisole from m-nitrochlorobenzene oil

ActiveCN104557557AShort reaction timeThe reaction cycle is shortenedOrganic chemistryOrganic compound preparationChlorobenzeneP-nitroanisole

The invention aims to provide a nitroanisole production method with low cost, low energy consumption, short production cycle and few three wastes (waste gas, wastewater and industrial residue), namely a method for preparing m-nitrochlorobenzene, p-nitroanisole and o-nitroanisole from m-nitrochlorobenzene oil under an anhydrous system by a high pressure method. To achieve the above purpose, the technical scheme of the invention is as follows: m-nitrochlorobenzene oil is added into an autoclave, and methanol and sodium hydroxide are respectively added, wherein the mole ratio of sodium hydroxide to m-nitrochlorobenzene oil is 0.01-2.00:1, the mole ratio of methanol to m-nitrochlorobenzene oil is 1-20:1, reaction temperature is 10-200 DEG C, reaction time is 1-20 h, and pressure is 0.1-4.0 MPa; and products obtained after the reaction undergo gas chromatography, and content changes with the composition change of the reaction raw material m-nitrochlorobenzene oil. In comparison with traditional technologies, the method provided by the invention has advantages of low production cost, short process, low energy consumption and little pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

High temperature resistant, ripple resistant, and long life electrolyte for aluminium electrolytic capacitor and preparation method thereof

ActiveCN105513801AReliable continuous workThere is no cracking or burningElectrolytic capacitorsElectrolysisO-Nitroanisole

The invention relates to the electrolyte technical field, and particularly to a high temperature resistant, ripple resistant, and long life electrolyte for an aluminium electrolytic capacitor and a preparation method thereof. The electrolyte comprises the following raw materials by weight parts: 4-6 parts of ammonium sebacate, 1.5-2.5 parts of ammonium pentaborate, 0.8-1.2 parts of mannitol, 10-14 parts of branch-chain carboxylic acid, 16-20 parts of spark improvers, 0.2-0.4 part of organic phosphoric acid, 2.5-3.5 parts of o-nitroanisole, 0.2-0.3 part of ammonium hypophosphite, and 45-70 parts of ethylene glycol. The prepared electrolyte has the spark voltage reaching 510V and the electric conductivity reaching 1.8ms / cm through interaction of the above raw materials and strict control of the weight ratios of the raw materials, has the advantages of good electrochemical property, high temperature resistance, ripple resistance and long life, and can be applied to the preparation of the aluminium electrolytic capacitor.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Preparation method of anhydrous system o-nitroanisole

InactiveCN102320978AIncrease profitReduce pollutionOrganic chemistryOrganic compound preparationBenzeneDistillation

The invention discloses a preparation method of anhydrous system o-nitroanisole, which comprises the following steps: mixing and stirring o-nitro benzene chloride, methanol, and an alkalization deacidification agent, heating the mixture with a heating speed of 30 DEG C / h for reflux reaction, controlling the temperature at 40-80 DEG C, performing the reflux reaction for 2-10 h, filtering, recovering methanol, performing reduced-pressure distillation to obtain the product of o-nitroanisole. The invention obtains the product by directly heating o-nitro benzene chloride, methanol, and an alkali; after the reaction, the reaction solution is directly pressed into a storage groove for precipitation; methanol is recovered (by direct recycle); the obtained product and unreacted o-nitro benzene chloride (for recycle) are treated by rectification; the utilization rate of o-nitro benzene chloride reaches above 98%, and the yield of o-nitroanisole reaches 93%-95%; the utilization rate of methanol is greatly increased; the process steps are reduced; the distillation is reduced; the energy consumption is saved; and waste water generated during a traditional process is converted into solid wastes. Compared with the traditional processes, the invention has the advantages of short process, low energy consumption, high utilization rate of o-nitro benzene chloride, and less pollution.

Owner:JIANGSU KANGHENG CHEM

Flame-retardant electrolyte and manufacturing method thereof

ActiveCN105140034APrevent oxide film hydration reactionReduce air permeabilityElectrolytic capacitorsElectrolysisHydrogen

The invention relates to a flame-retardant electrolyte and a manufacturing method thereof, wherein the flame-retardant electrolyte comprises, by weight percent, 63 percent to 86.5 percent of ethylene glycol, 1 percent to 3 percent of silicon dioxide, 5 percent to 15 percent of boric acid, 5 percent to 10 percent of ammonium pentaborate, 1 percent to 5 percent of mannitol, 0.5 percent to 2.0 percent of o-nitroanisole and 1 percent to 2 percent of phosphoric acid; the manufacturing method comprises: (a). heating the ethylene glycol to 60 to 75 DEG C, sequentially adding the boric acid, the ammonium pentaborate and the mannitol, continuously heating to 95 to 105 DEG C, and stirring till the boric acid, the ammonium pentaborate and the mannitol is completely dissolved; (b). adding the silicon dioxide into the solution and continuously stirring till the solution is completely clarified; (c). and cooling the solution to 65 to 70 DEG C, adding the o-nitroanisole and the phosphoric acid, and naturally cooling to acquire the electrolyte. According to the invention, the electrolyte has the performance to resist high temperature and high voltage and the hydrogen amount produced during the working process of an electrolytic capacitor is also reduced; and the vapor pressure of the electrolyte can be lowered, thus the electrolyte provided herein has flame-retardant performance.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

Method of preparing o-anisidine and p-anisidine through hydrogenation reduction of mixture of o-nitroanisole and p-nitroanisole

InactiveCN103073436ASimple processImprove conversion rateOrganic compound preparationChemical recyclingP-nitroanisoleO-Nitroanisole

The invention relates to a method of preparing o-anisidine and p-anisidine through hydrogenation reduction of a mixture of o-nitroanisole and p-nitroanisole. According to the method, o-nitroanisole and p-nitroanisole are used as raw materials, and o-anisidine and p-anisidine are prepared in a methanol system through hydrogenation reduction with Pt / C as a catalyst. With the method provided by the invention, the disadvantages of high energy consumption and high cost in conventional production process of o-anisidine and p-anisidine are overcome, and the technical problems of severe environmental pollution and loss of materials caused by considerable process waste water generated in the process of pretreatment in conventional production process are overcome; the method provided by the invention has the advantages of easiness, a high conversion rate, clean, green and environment-friendly process and a small amount of pollution by three wastes.

Owner:CHANGZHOU JIASEN CHEM

Method for preparing o-nitro anisole by using micro-channel reaction apparatus

InactiveCN105503610APrecise control of reaction conditionsEasy to operateOrganic chemistryOrganic compound preparationO-NitroanisoleReaction rate

The present invention provides a new method for preparing o-nitro anisole by using a micro-channel reactor, particularly application of a micro-channel reactor with an enhanced mass transfer unit structure to carry out a continuous flow o-nitro chloro benzene etherification reaction. According to the present invention, the mass transfer and the heat transfer can be completed dependent on the kinetic energy of the fluid without the mechanical stirring process under the reactor operation condition higher than the normal temperature, the space time reaction rate of the micro-channel reactor can be substantially improved, the temperature fluctuation and the concentration fluctuation during the reaction process can be avoided, the phenomena such as temperature runaway and overheating do not exist, and the reaction process is safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

O-aminoanisole electrochemical synthesis method

InactiveCN101187033AMild reaction conditionsEasy to produceElectrolysis componentsElectrolytic organic productionSupporting electrolyteO-Nitroanisole

Provided is an electrochemical synthetic method of ortho-anisidine, which includes four steps that firstly the method needs to be accomplished in an two-chamber electrolysis bath which is separated by employing a cation-exchange membrane, a copper sheet is taken as a negative electrode, a ruthenium net is taken as a positive electrode, a saturated calomel electrode is taken as a reference electrode, the negative electrode and the reference electrode are installed inside a cathode chamber of the electrolysis bath, and the positive electrode is installed inside an anode chamber of the electrolysis bath. Secondly methanol is taken as solvent, sulphuric acid is taken as supporting electrolyte, ortho-nitroanisole is taken as electrolytic reaction substrate, the solvent and solution of the supporting electrolyte are injected into the cathode chamber and the anode chamber, and the electrolytic reaction substrate is injected into the cathode chamber. Thirdly the electrolyzation is performed under the condition of normal temperature and pressure and the condition that the negative electrode is added with a certain constant voltage relative to the reference electrode, the voltage value of the constant voltage is between -0.6 to -1.0V. Fourthly after the electrolyzation is finished, the electrolyte is post-processed to prepare the product of the ortho-anisidine with the production ratio between 19.1-53.4%. The method has the advantages of simple requirement, mild reaction conditions, easy preparation of the electrodes, low price, small pollution in the process of reaction and the like, which is a greening production line.

Owner:EAST CHINA NORMAL UNIV

Method for preparing o-nitroanisole

The invention discloses a method for preparing o-nitroanisole. The method comprises the following steps: performing a methoxylation reaction in organic solvent and basic state; and collecting the o-nitroanisole from a reactant by adopting a conventional method, wherein the molar yield of the finished product reaches over 90 percent. The method has reasonable process route; and the finished productprepared by adopting the method has higher yield and purity, thus has larger industrial prospect.

Owner:夏恩将

Electrolyte used for electrolysis capacitor, and preparation method thereof

InactiveCN109411237AImprove high temperature resistanceImprove flame retardant performanceElectrolytic capacitorsElectrolysisO-Nitroanisole

The invention discloses electrolyte used for an electrolysis capacitor, and a preparation method thereof, and relates to the technical field of electrolyte. The electrolyte used for the electrolysis capacitor consists of the following raw materials in parts by weight: 20-60 parts of ethylene glycol, 5-9 parts of ammonium metatungstate, 2-10 parts of glycerol, 5-13 parts of ammonium sebate, 1-5 parts of polyvinyl alcohol succinate, 1-5 parts of sodium hypophosphite, 2-6 parts of o-nitroanisole, 2-14 parts of maleic anhydride, 0.5-3 parts of maleic anhydride, 3-11 parts of sodium tetraborate decahydrate, 0.3-0.7 part of nitrophenol and 1-9 parts of fire retardant. After the above technical scheme is adopted, the electrolyte has the beneficial effects that the electrolyte has an excellent flame retardant property while the electrolyte has good high-temperature-resistant performance, potential safety hazards are unlikely to happen, and therefore, the electrolyte is worth being popularizedand used.

Owner:NANTONG RUIDA ELECTRONICS MATERIAL

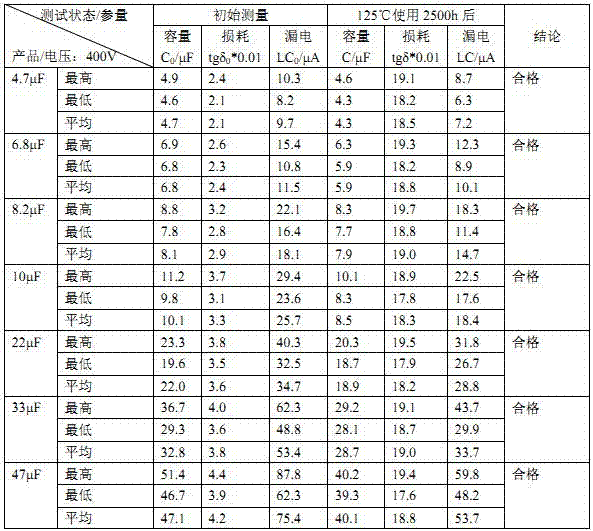

400 V electrolytic capacitor and production technology thereof

ActiveCN103680980AIncrease in sizeGuaranteed to workLiquid electrolytic capacitorsCapacitor terminalsElectrolysisO-Nitroanisole

The invention discloses a 400 V electrolytic capacitor and a production technology thereof. The 400 V electrolytic capacitor comprises a shell, a core, a sealing plug, a negative wire and a positive wire, wherein the core comprises a cathode foil and an anode foil; the core further comprises insulating electrolytic paper; electrolyte is added to the insulating electrolytic paper; the electrolyte is composed of ethylene glycol accounting for 40%-50%, diethylene glycol accounting for 10%-20%, triethylene glycol accounting for 10%-20%, glycerol accounting for 10%-20%, gamma-hydroxybutyrate lactone accounting for 10%-20%, sebacic acid accounting for 1%-10%, ammonium sebacate accounting for 1%-10%, o-nitroanisole accounting for 0.1%-0.9%, p-nitrobenzyl alcohol accounting for 0.1%-0.9%, benzene accounting for 0.1%-1%, polyvinyl alcohol accounting for 0.1%-1% and citric acid accounting for 0%-0.5%. The electrolytic capacitor has good temperature tolerance and long service life, and the load life reaches to 10000-15000 hours at 105 DEG C.

Owner:FOSHAN LIMING ELECTRONICS GAOMING

Production process for o-aminoanisole and preparation method thereof

InactiveCN107673981AEasy to getSimple production processOrganic compound preparationChemical recyclingO-NitroanisoleWastewater

The invention discloses a production process for o-aminoanisole. The production process for the o-aminoanisole comprises the following steps: carrying out etherification by using methanol and sodium hydroxide as methoxyl reagents to obtain o-nitroanisole; and reducing the o-nitroanisole by sodium sulphide under the effect of a catalyst to synthesize the o-aminoanisole. According to specific reaction, main reaction is as shown in specification. In the production process for the o-aminoanisole, production raw materials are easily obtained; the production process is simple and easy; the problemsof difficulty in recycling of the catalyst and serious fire in hydrogenation reduction are solved, a certain amount of waste water is generated by reduction through sodium sulfide, and the productionprocess for the o-aminoanisole has the advantages of good product quality and high safety factors.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Method for synthesizing o-aminoanisole by hydrogenation method

InactiveCN109053472AIncrease contact areaHigh purityOrganic compound preparationAmino-hyroxy compound preparationO-nitrochlorobenzeneSodium methoxide

The invention discloses a method for synthesizing o-aminoanisole by a hydrogenation method. The synthesis method specifically comprises the following steps: adding metallic sodium to excess methanol to prepare a methanol solution of sodium methoxide, and then spraying o-nitrochlorobenzene and the methanol solution of sodium methoxide into an etherification kettle; firstly, performing centrifugal separation, then transferring to a distillation kettle for distillation, and then crystallizing and filtering; firstly, introducing the hydrogen gas to exhaust the gas, atomizing o-nitroanisole, usinga catalyst for catalyzing the reaction, introducing nitrogen gas to the kettle to exhaust the gas after the reaction is completed, then cooling and crystallizing, centrifuging at low temperature for separation and filtering, and repeatedly operating for 2 to 3 times to obtain o-aminoanisole. The method for synthesizing o-aminoanisole by the hydrogenation method uses nitrogen-doped porous carbon asa carrier for the catalyst, and the catalyst is made into a lattice. Contact area of the reactant is large, and the reaction proceeds rapidly. A methoxy reagent is directly prepared from the metallicsodium and methanol, and the methoxy reagent is dissolved with methanol to prepare a solution for spraying, so as to accelerate the reaction and promote the reaction to proceed forward.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Synthesis method of o-amino pheylmethyl ether

InactiveCN104086448AEasy to useEasy to prepareOrganic compound preparationAmino-hyroxy compound preparationChemical industryO-nitrochlorobenzene

The invention discloses a preparation method of o-amino pheylmethyl ether, and relates to the technical field of chemical industry. The method comprises the following steps: adding o-chloronitrobenzene, methanol and a 40-percent sodium hydroxide solution into a high-pressure reaction kettle in sequence, raising the temperature in the kettle to 40 DEG C, and stirring; raising the temperature to 85 DEG C, controlling the pressure at 0.28-0.32MPa, reacting for 8 hours, distilling, removing an internal methanol solution, adding hot water of 70 DEG C for washing, standing for delaminating, and performing liquid separation to obtain o-nitroanisole for later use; putting o-nitroanisole into the high-pressure reaction kettle, adding a sodium sulfide aqueous solution, controlling the pressure at 0.05MPa, controlling the temperature at 118-120 DEG C, pressurizing, refluxing, cooling to 50-60 DEG C, preserving heat for 5 hours, performing liquid separation, removing internal waste water, distilling, crystalizing, drying to obtain finished o-amino pheylmethyl ether, packaging and warehousing. The preparation method has the beneficial effects of convenience and easiness in preparation, environmental friendliness, pollution freeness, ready availability of raw materials, small equipment investment, high purity and convenience in operation. The prepared o-amino pheylmethyl ether has a good use effect, and is safe and reliable.

Owner:安徽佑骏商品混凝土有限公司

Production method of oamino pheylmethyl ether

ActiveCN102276483BReduce consumptionSimple processOrganic compound preparationAmino-hyroxy compound preparationO-nitrochlorobenzeneSodium methoxide

The invention provides a production method of oamino pheylmethyl ether, and the method comprises the following steps of: reacting ortho nitrochlorobenzene serving as a raw material with sodium methoxide for carrying out a methoxylation reaction to obtain orthonitroanisole; secondly, carrying out hydrogenation reduction on the orthonitroanisole by using methanol as a solvent in the presence of a catalyst to prepare the oamino pheylmethyl ether; and finally, carrying out dealcoholization, dehydrogenation and refining on reactants to obtain the oamino pheylmethyl ether as a finished product. The production process comprises the following steps of: preparing sodium methoxide, etherifying the ortho nitrochlorobenzene, distilling the methanol and nitroether for separation, hydrogenating the orthonitroanisole, distilling a hydrogenating solution for separating the oamino pheylmethyl ether and treating wastewater. The production method has the characteristics of simple process, short procedure, continuity in reaction, high production efficiency, good product quality, less energy consumption, concentrated purification of reaction wastewater and no emission, and is suitable for producing the oamino pheylmethyl ether by using the ortho nitrochlorobenzene as the raw material.

Owner:LIAONING SHIXING PHARMA & CHEM

100V electrolytic capacitor and producing process thereof

ActiveCN103700507AGuaranteed to workImprove temperature resistanceLiquid electrolytic capacitorsCapacitor electrodesElectrolysisElectrolytic capacitor

The invention discloses a 100V electrolytic capacitor and a producing process thereof, wherein the capacitor comprises a shell, a core, a seal plug, a cathode lead and an anode lead; the core comprises a cathode foil and an anode foil and also comprises insulation electrolytic paper; components of electrolyte added to the insulation electrolytic paper comprise 40-70% of ethylene glycol, 10-40% of glycerin, 10-40% of gamma-hydroxybutyrate lactone, 1-10% of ammonium benzoate, 1-10% of azelaic acid EG (ethylene glycol) solution, 2-8% of ammonium hydrogen maleate, 0.1-0.9% of ortho-nitroanisole, 0-0.5% of citric acid, 0.1-0.5% of phosphotungstic acid and 0-0.1% of molybdic acid. The electrolytic capacitor is good in temperature resistance and long in service life, and achieves the load life of 10,000-15,000 hours under the condition of 105 DEG C.

Owner:FOSHAN LIMING ELECTRONICS GAOMING

Refining process of o-nitrophenol

ActiveCN102617354AReduce manufacturing costHigh purityOrganic chemistryOrganic compound preparationActivated carbonChemical oxygen demand

The invention belongs to the technical field of chemical engineering and particularly relates to a refining process of o-nitrophenol. According to the refining process of the o-nitrophenol, 100kg of o-nitroanisole is excessively recovered from per 10 tons of waste water, and the production cost of the o-nitroanisole is reduced. Active carbon is added for absorption, the purity of the o-nitrophenol is improved, and the original content lower than 95 percent is improved to the content higher than 99 percent. The activated carbon regeneration is carried out, the o-nitroanisole is further extracted, activated carbon can be cyclically utilized, and meanwhile, the recovery rate of the o-nitroanisole is improved. In the original process, the purification can be carried out only through the rectification. According to the refining process provided by the invention, the purity of the o-nitrophenol can be improved through distillation, and energy sources and equipment are saved. The waste water chemical oxygen demand (COD) is reduced by a half through being compared with the results of the original process, impurities are absorbed by the active carbon, the content of the impurities is greatly reduced, and the waste water treatment by resin absorption is favorably realized.

Owner:AZUREWAVE TEHNOLOGIES INC

Anhydrous ultralow-temperature wide temperature working electrolyte and preparation method thereof

ActiveCN106653370AImprove electrochemical performanceWide operating temperatureElectrolytic capacitorsO-NitroanisoleFree cooling

The invention relates to anhydrous ultralow-temperature wide temperature working electrolyte which comprises, according to the parts by weight, 55-70 parts of gamma-butyrolactone, 10-20 parts of ortho-nitroanisole, 0.3-0.5 part of additive, 3-8 parts of gluconic acid delta lactone, 10-15 parts of ammonium succinate and 2-8 parts of passivant. The preparation method comprises the steps that firstly the gamma-butyrolactone, the ortho-nitroanisole and the gluconic acid delta lactone are mixed and the system is heated and the heat is preserved; then the ammonium succinate is added and the system is heated and the heat is preserved; and finally the additive and the passivant are added and the system is heated and the heat is preserved, then the temperature decreases to 80-90 DEG C within 5-10min and the heat is preserved, and finally the system is heated to 120-140 DEG C within 20-30min and the heat is preserved and then the system is naturally cooled. The anhydrous ultralow-temperature wide temperature working electrolyte has great electrochemical property.

Owner:WUXI TAIWEI ELECTRONICS CO LTD

Method for preparing o-anisidine by catalytic hydrogenation

InactiveCN102391134AReduce energy consumptionHigh yieldOrganic compound preparationAmino-hyroxy compound preparationO-NitroanisolePhysical chemistry

The invention discloses a method for preparing o-anisidine by catalytic hydrogenation. The method comprises the following steps of: mixing o-nitroanisole, methanol and a catalyst Raney-Ni, adding the mixture into a pressure kettle, performing replacement by hydrogen, introducing the hydrogen to maintain the pressure of between 0.5 and 2MPa, heating to the temperature of between 40 and 80 DEG C, introducing the hydrogen continuously for 3 to 10 hours, recovering the methanol, separating liquid and rectifying to obtain the o-anisidine. The method has the advantages of environment friendliness, low energy consumption, high yield and high quality of products.

Owner:JIANGSU KANGHENG CHEM

Electrolyte suitable for high-voltage aluminum electrolytic capacitor and preparation method thereof

ActiveCN110010354AImprove heat resistanceExtended service lifeElectrolytic capacitor manufactureBenzoic acidO-Nitroanisole

The invention discloses an electrolyte suitable for a high-voltage aluminum electrolytic capacitor and a preparation method thereof and belongs to the technical field of high-voltage aluminum electrolytic capacitors. The electrolyte solution suitable for the high-voltage aluminum electrolytic capacitor comprises the following raw materials including, by weight, 40 to 60 parts of 4-hydroxybutyrolactone, 60 to 80 parts of polyethylene glycol, 50 to 70 parts of ethylene glycol, 30 to 50 parts of ethylene carbonate, 40 to 60 parts of propylene carbonate, 30 to 40 parts of diethyl carbonate, 20 to30 parts of dimethyl carbonate, 10 to 20 parts of ethyl methyl carbonate, 20 to 40 parts of ammonium azelate, 30 to 50 parts of ammonium dodecanedioate, 10 to 30 parts of benzoic acid, 40 to 60 partsof ammonium formate, 40 to 50 parts of diammonium hydrogen phosphate, 30 to 40 parts of phthalic acid, 10 to 20 parts of boric acid, 10 to 20 parts of p-nitrophenol, 5 to 10 parts of sodium hypophosphite, 10 to 20 parts of o-nitroanisole, and 20 to 30 parts of monobutyl phosphate. The preparation method of the invention has a simple preparation method and has a broad application prospect.

Owner:HUNAN AIHUA GRP +1

Preparation method of o-aminoanisole

InactiveCN103709051AReduce energy consumptionNo distillationOrganic compound preparationAmino-hyroxy compound preparationHydrogenO-Nitroanisole

The invention discloses a preparation method of o-aminoanisole. The preparation method comprises the following steps: adding 4000L of o-nitroanisole into a reduction reaction kettle by using a feeding pump; closing all valves of a reduction reactor; entirely replacing oxygen in the reaction kettle by nitrogen; turning on a stirring device of the reduction reactor after replacing; adding 15kg of a catalyst, heating to 60 DEG C and introducing 600m<3> of hydrogen; heating through reaction heat; keeping the temperature at 130 DEG C by using a jacket and a coiler to cool; controlling a reaction temperature at 60-150 DEG C and a reaction pressure within a range of 0.8-3.0MPa in a reaction process; reducing a temperature inside the kettle to 40 DEG C after the reaction; stopping stirring to settle the catalyst; filtering out the catalyst; sending o-aminoanisole to a layering device; standing for layering; and finally, rectifying to obtain refined o-aminoanisole. The preparation method disclosed by the invention has no need of distillation; the energy consumption of steam is reduced by more than 80%; the yield can be doubled.

Owner:于宝江

Refining process of o-nitrophenol

ActiveCN102617354BReduce manufacturing costHigh purityOrganic chemistryOrganic compound preparationActivated carbonChemical oxygen demand

The invention belongs to the technical field of chemical engineering and particularly relates to a refining process of o-nitrophenol. According to the refining process of the o-nitrophenol, 100kg of o-nitroanisole is excessively recovered from per 10 tons of waste water, and the production cost of the o-nitroanisole is reduced. Active carbon is added for absorption, the purity of the o-nitrophenol is improved, and the original content lower than 95 percent is improved to the content higher than 99 percent. The activated carbon regeneration is carried out, the o-nitroanisole is further extracted, activated carbon can be cyclically utilized, and meanwhile, the recovery rate of the o-nitroanisole is improved. In the original process, the purification can be carried out only through the rectification. According to the refining process provided by the invention, the purity of the o-nitrophenol can be improved through distillation, and energy sources and equipment are saved. The waste water chemical oxygen demand (COD) is reduced by a half through being compared with the results of the original process, impurities are absorbed by the active carbon, the content of the impurities is greatly reduced, and the waste water treatment by resin absorption is favorably realized.

Owner:AZUREWAVE TEHNOLOGIES INC

Capacitor electrolytic solution, preparation method and application thereof

ActiveCN112038097ACost controlImprove high temperature resistanceElectrolytic capacitorsBenzoic acidCapacitance

The invention discloses a capacitor electrolytic solution, a preparation method and application thereof. The capacitor electrolytic solution comprises the following components in parts by weight: 40-70 parts of ethylene glycol, 2-5 parts of polyethylene glycol, 10-20 parts of dimethylformamide-2, 15-45 parts of a long-carbon-chain hydroxyl mixture, 5-10 parts of a synthesis compound of polyvinyl alcohol and a high-temperature-resistant material thereof, 1-2 parts of mannitol, 2-4 parts of ammonium sebacate, 8-12 parts of ammonium adipate, 3-5 parts of ammonium benzoate, 0.5-1.0 part of m-nitroacetylbenzene, 0.2-0.8 part of o-nitroanisole, 0.5-1.0 part of ammonium dihydrogen phosphate and 8-10 parts of 1,2-ethylene glycol. According to the EG series electrolytic solution provided by the invention, the cost of the liquid chip capacitor is controlled; and an aluminum electrolytic capacitor produced by the EG series electrolytic solution provided by the invention can meet the electrical performance of a product, and is better than a GBL series in high temperature resistance, wherein the upper limit temperature is increased by at least 5 DEG C.

Owner:南通星晨电子有限公司

Battery composite electrolyte and preparation method thereof

InactiveCN108493492AImprove thermal stabilityDoes not affect conductivityLead-acid accumulatorsSecondary cells servicing/maintenanceHigh temperature storageEnvironmental resistance

The invention discloses a battery composite electrolyte and a preparation method thereof. The composite electrolyte comprises, by weight, 10-20 parts of ethylene carbonate, 5-15 parts of lithium tetrafluoroborate, 4-12 parts of fluoroethylene carbonate, 8-18 parts of sodium silicate, 6-14 parts of magnesium carbonate, 2-6 parts of corrosion inhibitor, 2-8 parts of 2-phenylimidazoline quaternary ammonium salt, 3-9 parts of fatty alcohol polyoxyethylene ether, 4-10 parts of 2,3-dimethyl sebacic acid, 2-6 parts of o-nitroanisole and 1-4 parts of flame retardant. The preparation method is simple,the prepared composite electrolyte is environmentally friendly and non-toxic and is beneficial for improving the thermal stability of an electrolyte system, the high temperature cycle and high temperature storage performance of a battery can be improved, and the safety is high.

Owner:崔晓迪

Crystallizing separating tech. of nitro methyl-phenoxide mixture

InactiveCN1861566AReduce energy consumptionAchieve separabilityOrganic chemistryOrganic compound preparationP-nitroanisoleO-Nitroanisole

A crystallizing process for separation of nitro phenylmether mixture includes such steps as thermal dissolving of said mixture in methanol, decoloring, removing impurities, filtering to obtain refined liquid, cooling step by step for crystallizing, filtering to obtain p-nitro phenylmether and o-nitro phenylmether, respectively recrystallizing in methol, separation and refining to obtain refined two products.

Owner:CHANGZHOU JIASEN CHEM +1

350V electrolytic capacitor and production process thereof

ActiveCN103680984AIncrease in sizeGuaranteed to workLiquid electrolytic capacitorsCapacitor terminalsHydroxybutyric acidElectrolytic agent

The invention discloses a 350V electrolytic capacitor and a production process thereof. The 350V electrolytic capacitor comprises a shell, a core, a sealing plug, a negative wire and a positive wire, the core comprises a cathode foil, an anode foil and insulation electrolytic paper, and electrolyte is added on the insulation electrolytic paper and comprises, in weight percent, 40%-70% of ethylene glycol, 10%-40% of benzyl alcohol, 10%-40% of gamma-hydroxybutyric acid lactone, 1%-10% of branched-chain polycarboxylic acid ammonium salt, 1%-10% of azelaic acid EG(ethylene glycol) liquid, 0.1%-0.9% of ortho-nitroanisole, 0.1%-1% of benzene, 0.1%-1% of phosphotungstic acid and 0.1%-1% of molybdic acid. The electrolytic capacitor is fine in temperature resistance and long in service life, and the load life of the electrolytic capacitor reaches 10000-15000 hours at the temperature of 105 DEG C.

Owner:FOSHAN LIMING ELECTRONICS GAOMING

Electrolyte for aluminum electrolytic capacitor with high temperature resistance, grain resistance and wavelength life and preparation method thereof

ActiveCN105513801BReliable continuous workThere is no cracking or burningElectrolytic capacitorsElectrolysisO-Nitroanisole

The invention relates to the electrolyte technical field, and particularly to a high temperature resistant, ripple resistant, and long life electrolyte for an aluminium electrolytic capacitor and a preparation method thereof. The electrolyte comprises the following raw materials by weight parts: 4-6 parts of ammonium sebacate, 1.5-2.5 parts of ammonium pentaborate, 0.8-1.2 parts of mannitol, 10-14 parts of branch-chain carboxylic acid, 16-20 parts of spark improvers, 0.2-0.4 part of organic phosphoric acid, 2.5-3.5 parts of o-nitroanisole, 0.2-0.3 part of ammonium hypophosphite, and 45-70 parts of ethylene glycol. The prepared electrolyte has the spark voltage reaching 510V and the electric conductivity reaching 1.8ms / cm through interaction of the above raw materials and strict control of the weight ratios of the raw materials, has the advantages of good electrochemical property, high temperature resistance, ripple resistance and long life, and can be applied to the preparation of the aluminium electrolytic capacitor.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

Capacitor electrolytic blending liquid and preparation method thereof

InactiveCN111883363AAchieve performanceMeet the requirementsLiquid electrolytic capacitorsElectrolytic agentCapacitance

The invention discloses a capacitor electrolytic blending liquid and a preparation method thereof. The capacitor electrolytic blending liquid comprises the following components in parts by weight: 35-50 parts of ethylene glycol, 1-2 parts of o-nitroanisole, 10-20 parts of a long-carbon-chain hydroxyl mixture, 10-20 parts of polyvinyl alcohol and a composition of a high-temperature-resistant material of the polyvinyl alcohol, 2-6 parts of ammonium sebacate, 0.5-0.8 part of ammonium hypophosphite and 10-20 parts of 1,2-ethylenediol. The capacitor electrolysis blending liquid can be used for blending electrolyte scrapped due to the performance of the electrolyte, so that the electrolyte can be reutilized, and the cost is reduced. In an electrolyte blended by the capacitance electrolysis blending liquid, the performance is tested by a conductivity tester, a PH tester, a sparking voltage tester, a silver nitrate titration method for detecting the content of chloride ions and the like, and the following parameters are obtained by testing at 30 DEG C: the sparking voltage, the conductivity, the PH value and the content of chloride ions are all normal, and the electrolyte is not abnormal after silver nitrate titration; and the requirement of electrolyte performance blending can be met.

Owner:南通星晨电子有限公司

Tech. of producing ortho nitro methyl-phenoxide para nitro methyl-phenoxide and meta nitro chlorobenzene from chlorobenzene

InactiveCN100368377CReduce manufacturing costImprove production stabilityNitro compound preparationChlorobenzeneP-nitroanisole

A process for preparing o-nitro phenylmether, p-nitro phenylmether and meta-nitro chlorobenzene from chlorobenzene includes such steps as nitrifying reaction to obtain the nitro chlorobenzene mixture, etherifying reaction in etherifying agent, separating, and refining to obtain said products.

Owner:CHANGZHOU JIASEN CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com