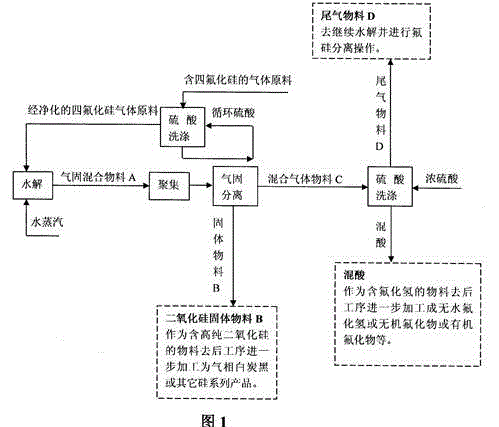

Gas phase hydrolysis and fluoride-silicon separation method of silicon tetrafluoride

A technology of silicon tetrafluoride and gas phase hydrolysis, applied in the directions of silicon oxide, silicon dioxide, fluorine/hydrogen fluoride, etc., can solve the problems of high investment in industrial production equipment, difficult industrialization of silicon tetrafluoride, and failure to realize industrialization, etc. To achieve the effect of reducing the requirements of equipment structure and material, the method is simple, and the hydrolysis temperature is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Use concentrated sulfuric acid to contain dust, liquid foam, H 2 Gas raw materials with impurities such as O and HF are washed and purified, and the concentration of concentrated sulfuric acid used for washing and purification is determined by H 2 SO 4 Calculated as 98%, the temperature of concentrated sulfuric acid in the washing treatment is controlled at 50°C; after purification and removal, SiF-containing 4 The gas raw material, the volume percentage composition of the gas raw material is: SiF 4 content of 45%, the balance is air and other inert gases; 3 / min flow rate and 0.6kg / min flow rate of water vapor are continuously fed into the reactor to mix for continuous gas-phase hydrolysis reaction and continuous fluorine-silicon separation operation. The molar ratio of silicon tetrafluoride gas and water vapor in the gas raw material is 1.2: 1. Control the temperature of the gas-phase hydrolysis reaction at 95-105°C, stay in the reactor for 5 seconds, and the...

Embodiment 2

[0040] In this embodiment, a closed-circuit circulation process is adopted to circulate the tail gas material D as a gas raw material containing silicon tetrafluoride for hydrolysis reaction and fluorine-silicon separation operation: the gas raw material is purified by the same purification method as in Example 1 to remove dust, liquid foam, H 2 O, HF and other impurities to obtain SiF 4 The gaseous raw material, its SiF 4 The content is 99.5%, and the balance is air and other inert gases; the above gas raw materials are mixed with 1M 3 / min flow rate, the tail gas material D that is recycled and returned is 11.4M 3 / min (SiF 4Content 99.5%) flow rate and 2kg / min flow rate of water vapor are continuously fed into the reactor to mix for continuous gas-phase hydrolysis reaction and continuous fluorine-silicon separation operation. The molar ratio of silicon tetrafluoride gas and water vapor in the gas raw material is 5:1; control the temperature of the gas phase hydrol...

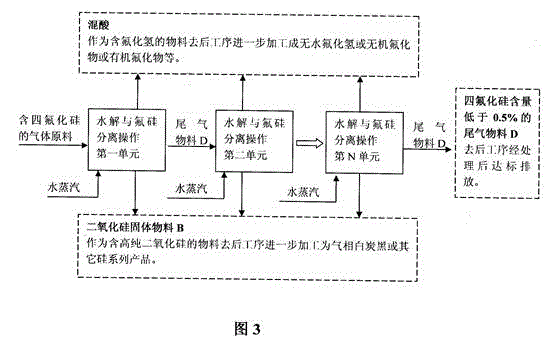

Embodiment 3

[0042] This embodiment adopts an open-circuit process, that is, the tail gas material D enters seven "hydrolysis and fluorine-silicon separation" operation units connected in series in sequence, and the tail gas material D discharged from the previous operation unit is used as the silicon tetrafluoride-containing silicon tetrafluoride in the next operation unit. Gas feedstock up to SiF in silicon tetrafluoride-containing gas feedstock input from the first operating unit 4 After 7 operating units are exhausted, the operation of each unit is as follows:

[0043] (1) The operation in the first unit is: the gas raw material entering the first operation unit is purified SiF-containing 4 The gaseous raw material, its SiF 4 The volume percentage content is 6%, air and other inert gases are 94%, and the control gas raw material is 20M 3 / min flow rate and 1.0kg / min flow rate of water vapor are continuously fed into the reactor to mix for continuous gas phase hydrolysis rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com