Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "M-toluidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion-resistant oil-water separation mesh membrane as well as preparation method and applications thereof

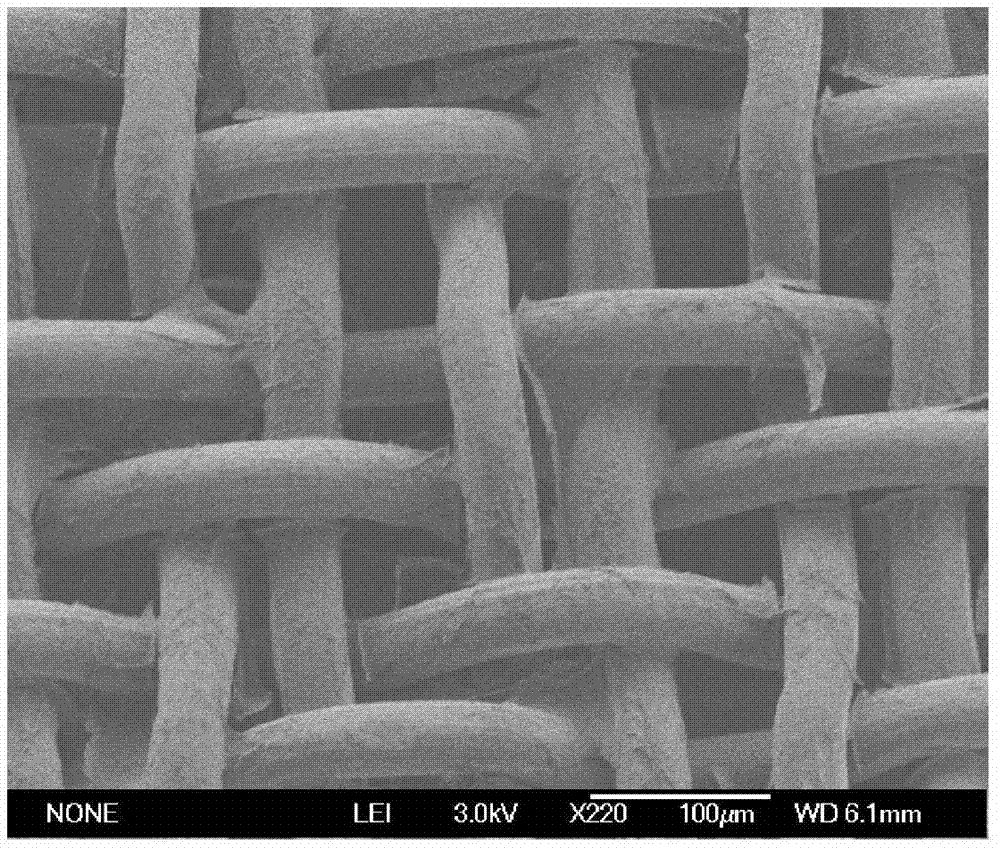

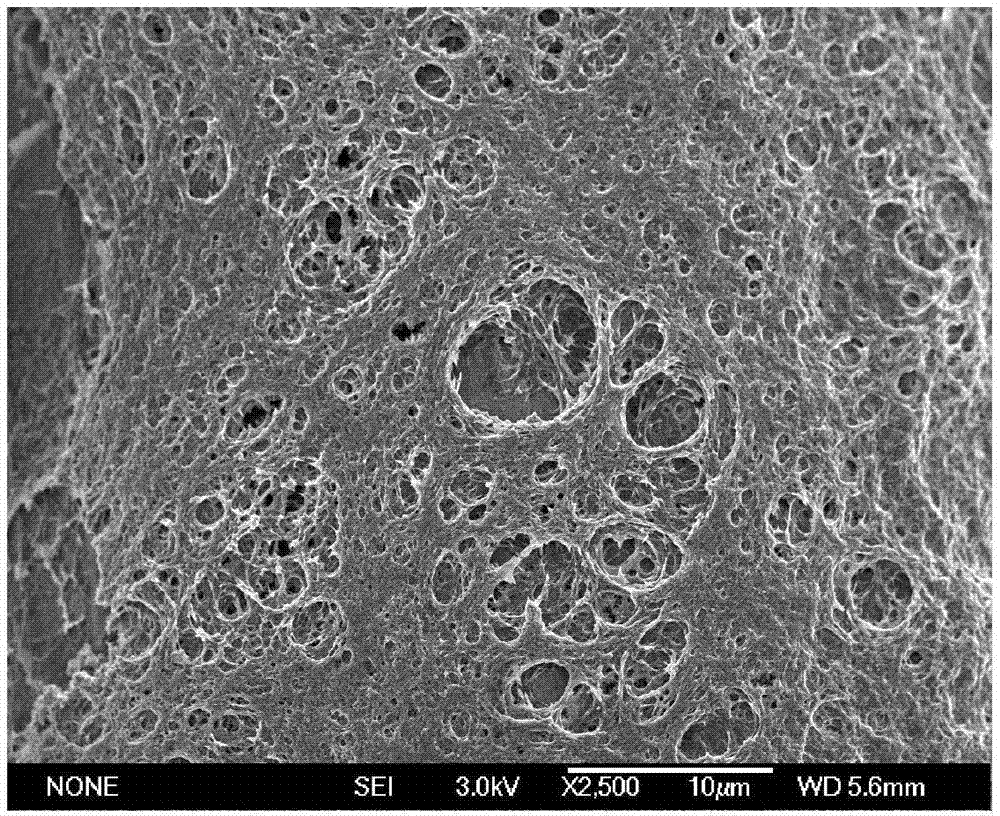

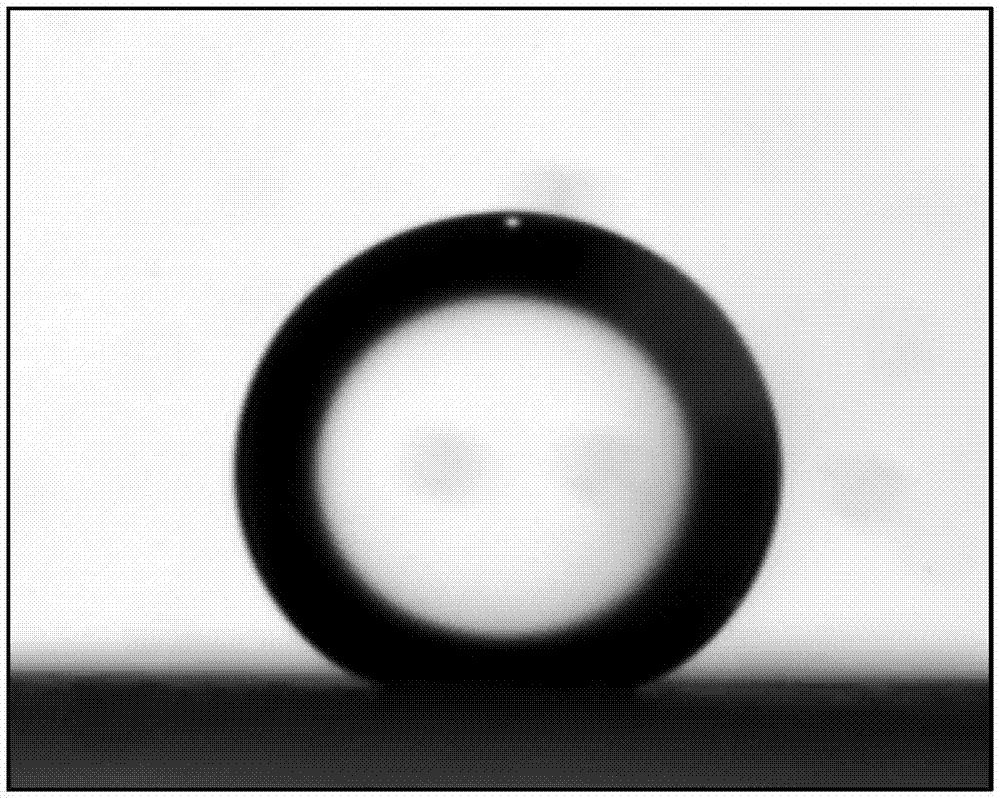

InactiveCN102728104ASimple processEasy to operateFiltration separationLiquid separationMetal fiberPolypyrrole

The invention discloses a corrosion-resistant oil-water separation mesh membrane as well as a preparation method and application thereof. The corrosion-resistant oil-water separation mesh membrane is a fiber braiding mesh coated with conducting polymer aquogel which is one or a mixture of some of polypyrrole, poly thiophene, polyaniline, polyparaphenylene, poly-m-toluidine,poly (1-methylene-2-methyl naphthalene) -N-pyrrole, poly ethylene dioxy thiophene, poly 3-ethyl thiophene, poly 3-hexyl thiophene and poly 2, 5-dimethoxy aniline; and the fiber braiding mesh is one of a metal fiber braiding mesh, an inorganic fiber braiding mesh and an organic fiber braiding mesh. The corrosion-resistant oil-water separation mesh membrane not only can implement the effective separation of different types of water and oil, but also has the favorable characteristics of salt resistance, strong acid resistance and strong alkaline resistance.

Owner:BEIHANG UNIV

Detection kit for determining content of creatinine in serum by enzymic method

InactiveCN104198408AImprove stabilityEliminate distractionsMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsCreatinine riseCreatininase

The invention discloses a detection kit for determining the content of creatinine in serum by an enzymic method. The detection kit comprises a reagent R1 and a reagent R2, wherein the reagent R1 contains 3-10g / L of buffering solution with the pH value being 7.5-8.0, 0.2-0.5g / L of EDTA, 0.5-2g / L of N-ethyl-N-(2-hydroxyl-3-sulfopropyl) m-toluidine sodium salt, 1 per mill-5 per mill of a surface active agent, 0.2-1g / L of sarcosine oxidase, 1-5KU / L of ascorbate oxidase, 2-5KU / L of creatinase and 0.5-1g / L of a stabilizing agent; the reagent R2 contains 3-10g / L of buffering solution with the pH value being 7.5-8.0, 0.1-0.5g / L of 4-aminoantipyrine, 0.1-0.4g / L of potassium ferricyanide, 2-8g / L of creatininase amidohydrolase, 1-6KU / L of peroxidase and 0.5-2g / L of a preservative. The detection kit disclosed by the invention is excellent in stability, strong in interference resistance and high in clinical application value.

Owner:上海睿康生物科技有限公司

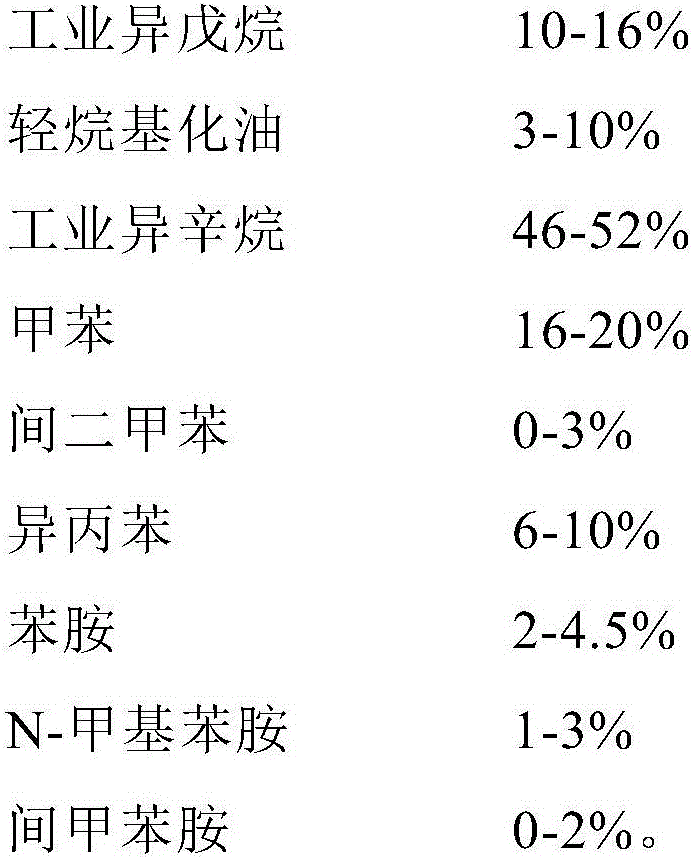

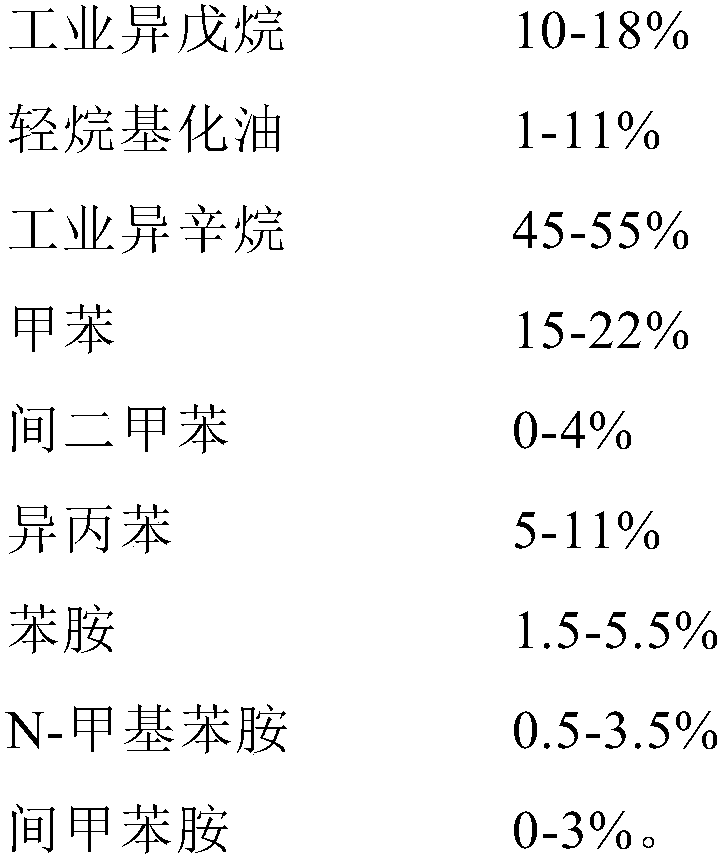

100# lead-free aviation gasoline and preparation method thereof

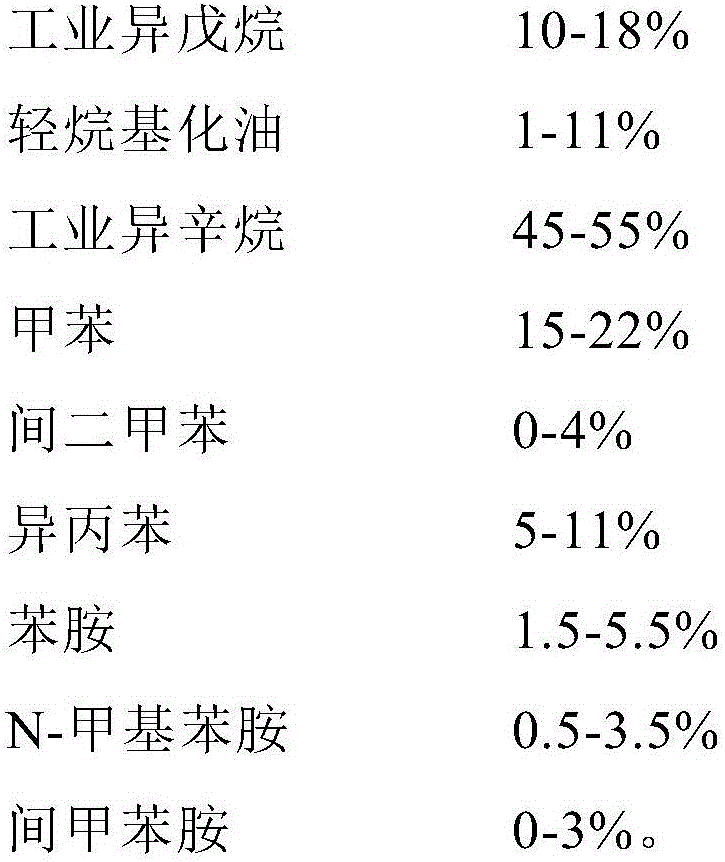

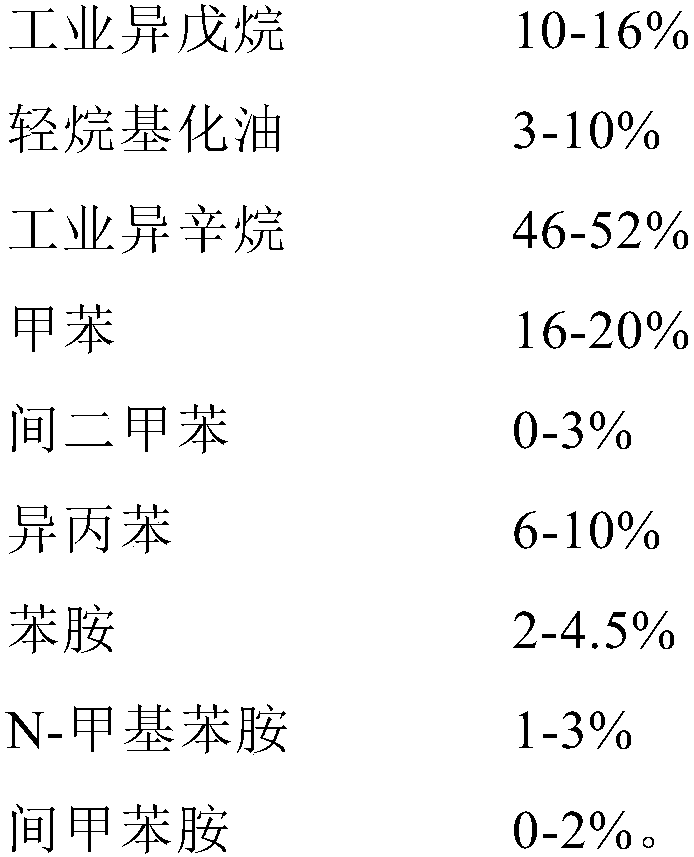

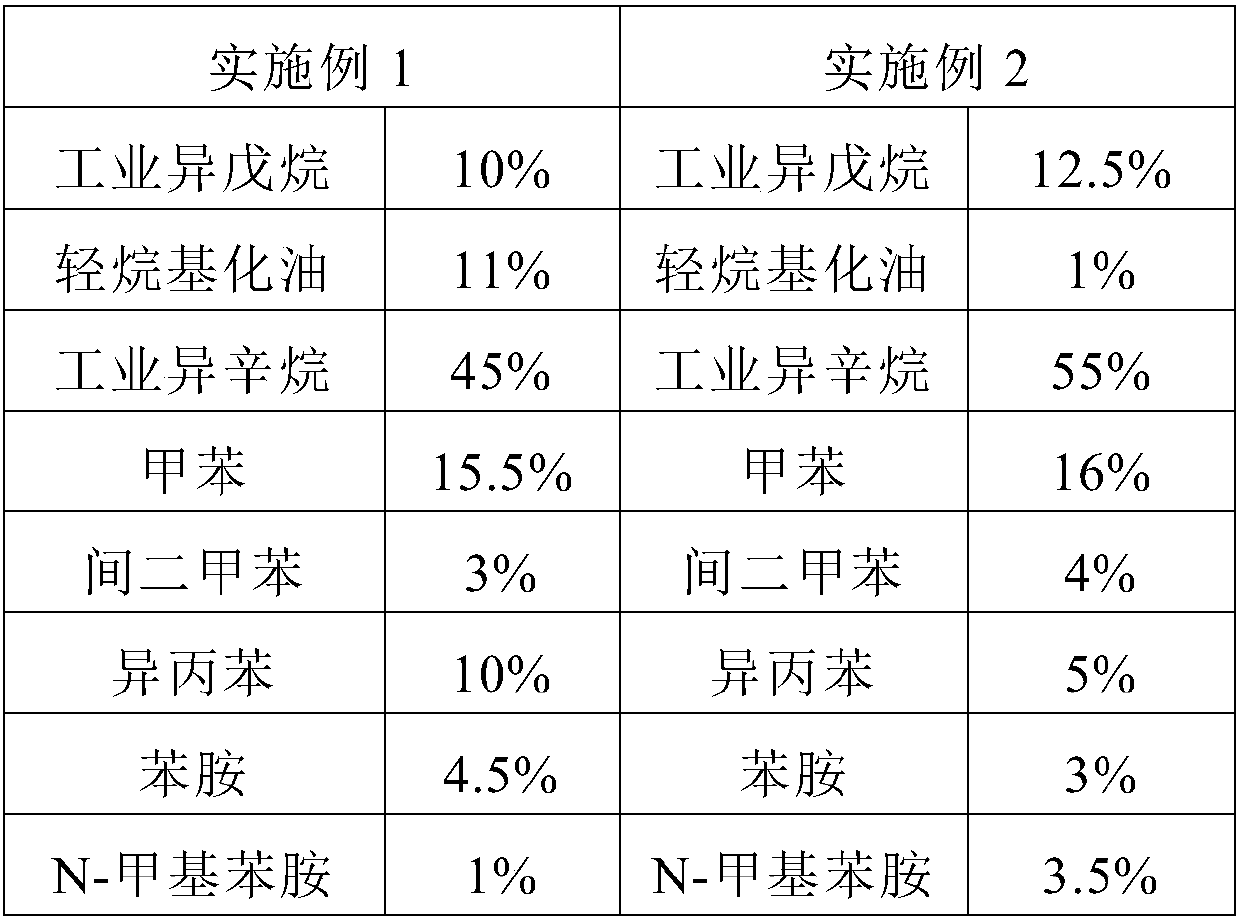

ActiveCN106398783AMeet the quality standard requirementsTackling lead pollutionLiquid carbonaceous fuels2-methylbutaneAviation

The invention relates to 100# lead-free aviation gasoline and a preparation method thereof. The 100# lead-free aviation gasoline comprises, by volume, 10-18% of industrial isopentane, 1-11% of light alkylated oil, 45-55% of industrial isooctane, 15-22% of toluene, 0-4% of m-xylene, 5-11% of cumene, 1.5-5.5% of aniline, 0.5-3.5% of N-methyl aniline and 0-3% of m-toluidine. The components are blended to form the finished product. Compared with the prior art, the 100# lead-free aviation gasoline does not contain lead and solves the problem of lead pollution of aviation gasoline. Through the optimized combination of the components, the 100# lead-free aviation gasoline quality is high and the 100# lead-free aviation gasoline satisfies the quality index requirements. The 100# lead-free aviation gasoline has a high economic value. The 100# lead-free aviation gasoline blending process is simple and is conducive to industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

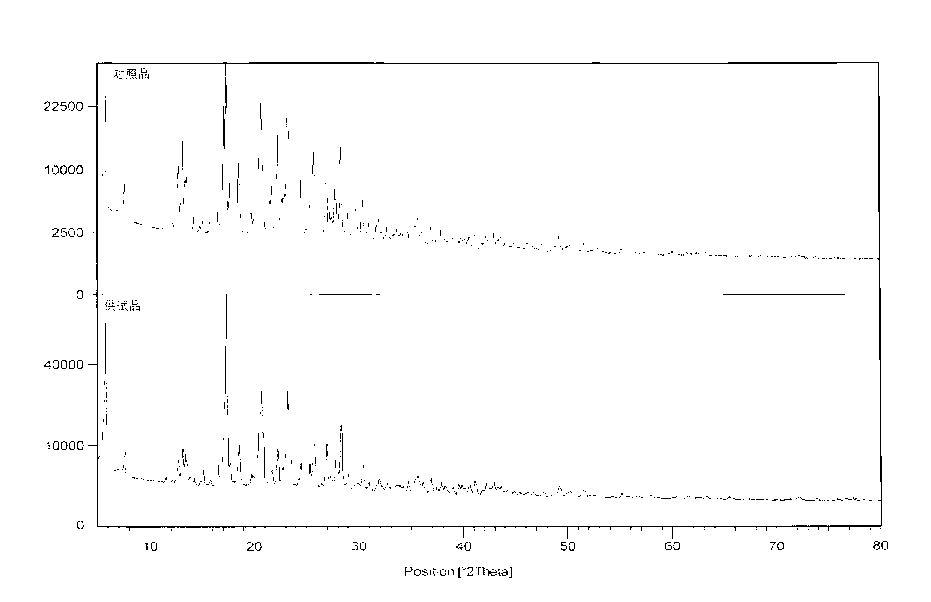

Method for preparing high-purity torasemide and crystal form I thereof

ActiveCN102702089AOvercome the disadvantages of greater toxicityHigh purityOrganic chemistryIsopropamideGranularity

The invention discloses a method for preparing high-purity torasemide and a crystal form I thereof. The method comprises the following steps of: reacting 4-chloro-3-pyridine sulfonamide and m-toluidine serving as raw materials to obtain 3-sulfamoyl-4-(3-methyl phenyl) aminopyridine, refining, and reacting with 1,1'-carbonyldimidazole and isopropamide, directly introducing isopropyl carbamyl, thus obtaining the high-purity torasemide, wherein the purity (high performance liquid chromatography (HPLC)) of the torasemide is more than 99.5 percent. The prepared torasemide has proper granularity, seed crystal is not required for crystal transformation, the torasemide can be directly transformed into the variant crystal form I, and a chemically pure torasemide variant I is obtained. The preparation method is strong in process controllability, easy and convenient to operate and high in reproducibility, and facilitates industrialized production.

Owner:连云港杰瑞药业有限公司

Environment-friendly type lubricating oil additive

InactiveCN104974825AImprove wear resistanceImprove extreme pressure performanceAdditivesToluidineActive agent

An environment-friendly type lubricating oil additive is composed of the following raw materials in parts by weight: 7 to 12 parts of castor oil polyoxyethylene ether, 3 to 6 parts of molybdenum disulfide colloid, 2 to 7 parts of n-octadecanoic acid, 4 to 8 parts of critic acid, 6 to 13 parts of molybdenum dialkyldithiophosphate, 4 to 8 parts of butyl oleate, 3 to 6 parts of tackifier, 5 to 8 parts of o-toluidine / m-toluidine, 6 to 8 parts of methyl citrate, 4 to 7 parts of triphenyl phosphorothionate, 6 to 12 parts of sulfurized isobutylene, 5 to 8 parts of benzotriazole amine, 2 to 6 parts of n-butyl acetate, 1 to 4 parts of p-methoxyl styrene, 8 to 16 parts of linoleic acid, 4 to 6 parts of methanol, 7 to 13 parts of polyethylene glycol monomethyl ether, 4 to 7 parts of magnesium silicate, and 4 to 6 parts of fluorine surfactant. The provided environment-friendly type lubricating oil additive can improve the wear-resistant performance, extreme pressure resistant performance, and oxidation resistant performance of lubricating oil, has the advantages of convenient operation and environment-friendliness, and is according with the green and environment-protection requirements.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

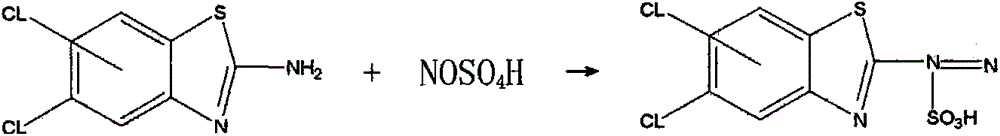

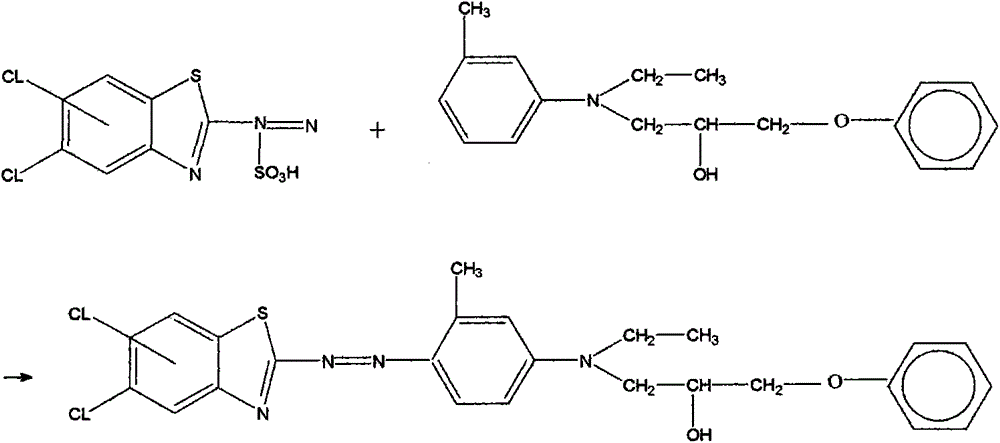

Preparation method for disperse red 343:1 dye

The invention discloses a preparation method for disperse red 343:1 dye. The preparation method comprises the following steps: 1) diazotization, to be specific, adding water into a reaction kettle, cooling with cooling water, adding sulfuric acid, and then, dropwise adding nitrosyl sulfuric acid; after completing adding the nitrosyl sulfuric acid, adding 2-amino-5, 6-dichloro benzothiazole, stirring, and performing standing to obtain diazonium salt; 2) coupling, to be specific, adding water, glacial acetic acid, sulfamic acid and peregal into a coupling bucket, adding N-ethyl-N-benzoyloxy ethyl m-toluidine, adding ice for cooling, pressing-in the diazonium salt, and coupling; 3) after completing the coupling, and adding water for heating; 4) performing press-filtering, and washing, so as to obtain dye filter cakes; 5) mixing the dye filter cakes and an auxiliary agent, so as to obtain the disperse red 343:1 dye. According to the invention, the disperse red 343:1 dye serves as a substitute object of disperse red 343, the preparation technology is simple, only one-time coupling reaction is performed, the process route is shortened, the waste water discharge is greatly reduced, the yield is increased, the cyanation reaction adopting plenty of virulent cyanide is avoided, the possibility for harming human beings and the environment is reduced, and the finally prepared disperse red 343:1 dye is high in light fastness and can meet the use requirements of textiles on high-solarization dye.

Owner:ZHEJIANG HUADIE CHEM

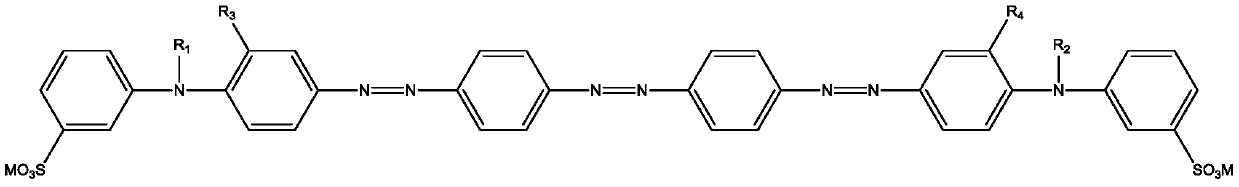

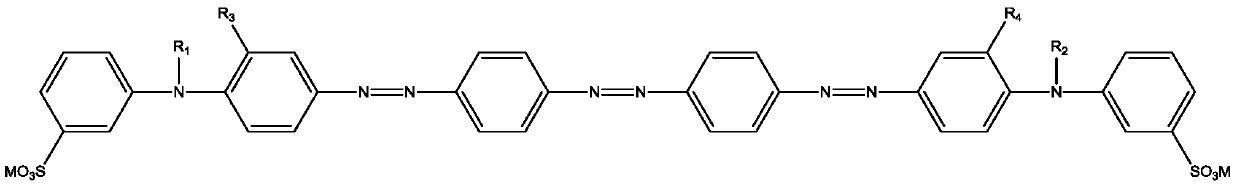

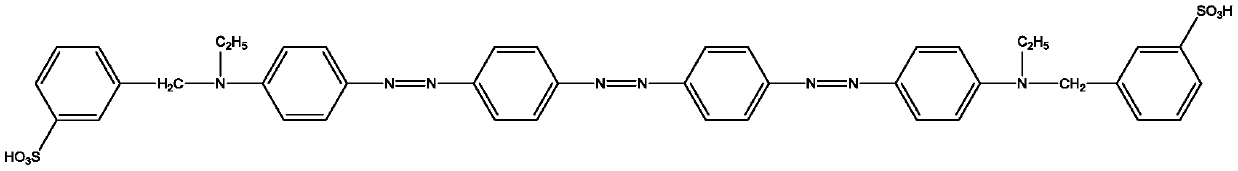

Trisazo carmoisine and preparation method thereof

ActiveCN111040466AHigh color fastnessGood water solubilityTrisazo dyesDyeing processEthyl groupAniline

The invention discloses a trisazo carmoisine, and also discloses a preparation method thereof. The preparation method comprises the following steps: diaminoazobenzene, hydrochloric acid and a sodium nitrite solution react in water, and residual nitrous acid is eliminated after the reaction to obtain a diazonium salt solution; and reaction raw materials react with the diazonium salt solution to finally obtain the corresponding trisazo carmoisine, wherein the reaction raw materials are N-ethyl-N-benzyl aniline-3'-sulfonic acid and N-ethyl-N-benzyl m-toluene-3'-sulfonic acid. The trisazo carmoisine disclosed by the invention does not contain carcinogenic dye or heavy metal dye, and belongs to safe and environment-friendly dye. The dye composition has good water solubility, is gentle in dyeingin a dyeing system and good in leveling property, can be efficiently combined with protein and polyamide fibers, is high in dyeing rate, enables dyed fibers to have excellent color fastness, and is an ideal substitute for metal complex dyes.

Owner:JINHUA SHUANGHONG CHEM CO LTD

A kind of No. 100 unleaded aviation gasoline and preparation method thereof

ActiveCN106398783BMeet the quality standard requirementsTackling lead pollutionLiquid carbonaceous fuelsAviationGasoline

Owner:EAST CHINA UNIV OF SCI & TECH

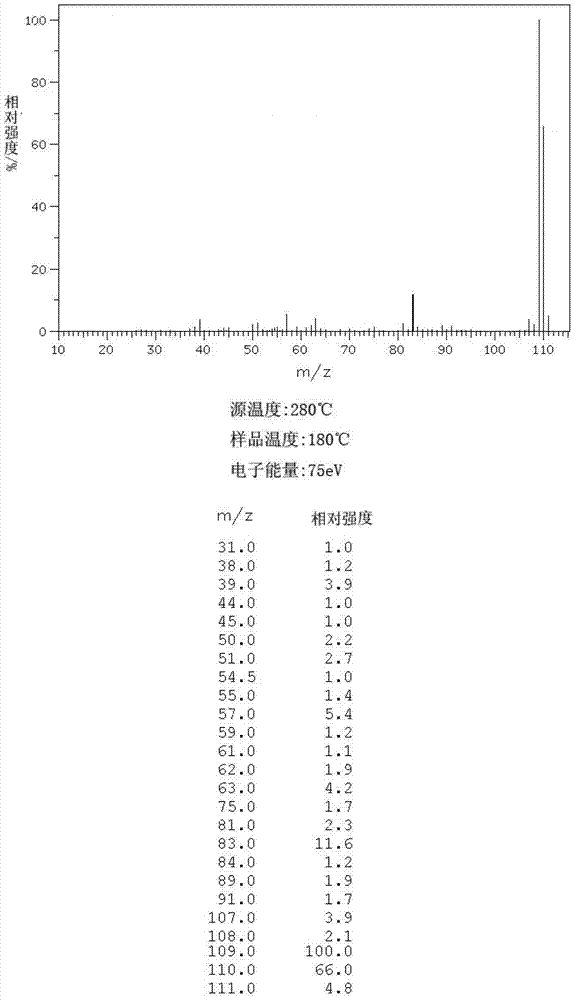

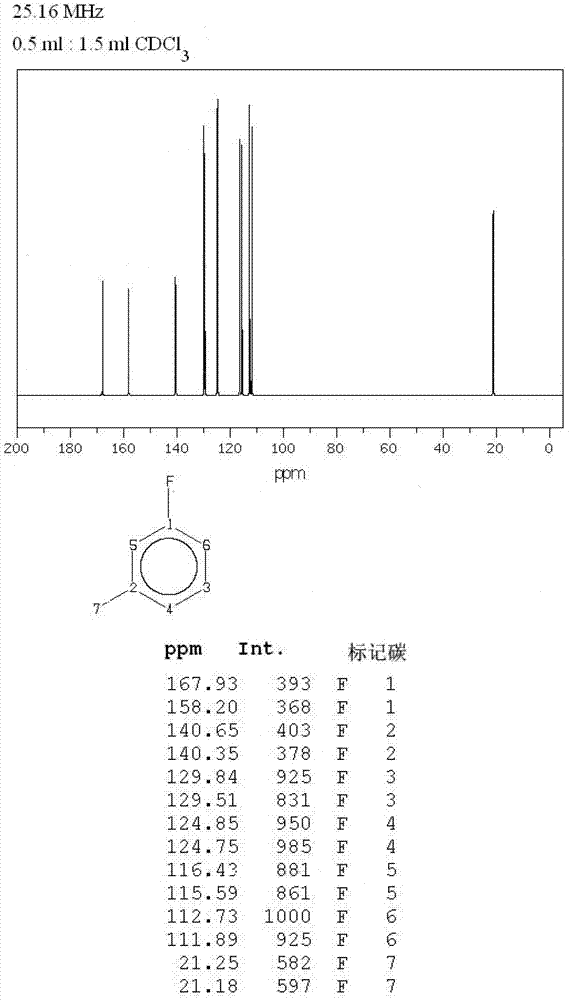

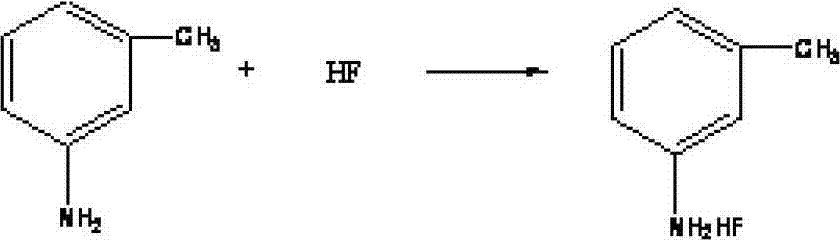

Preparation method of m-fluorotoluene

ActiveCN102786385AAvoid diversionLess side effectsFluorine/hydrogen-fluorideHalogenated hydrocarbon preparationHydrofluoric acidToluidine

The invention relates to a preparation method of m-fluorotoluene, and the preparation method has the advantages of fewer steps, high yield and high purity of the obtained product. The preparation method of m-fluorotoluene provided by the invention comprises the following steps: (1) salt formation step: anhydrous hydrofluoric acid and m-toluidine are mixed at a mole ratio of (2-5):1 to obtain a mixture 1 through dripping the whole m-toluidine into anhydrous hydrofluoric acid within 7-10 hours at a constant rate and then reacting for 1-3 hours at 5-7 DEG C; (2) diazotization step: sodium nitrate is dripped into the mixture 1 at a mole ratio of sodium nitrate to m-toluidine in the salt formation step of (1-1.5):1 to obtain a mixture 2 through dripping the whole sodium nitrate into the mixture 1 within 8-10 hours at a constant rate and then reacting for 1-3 hours at 0-3 DEG C; and (3) thermal decomposition step: the mixture 2 is heated to decompose at 0-50 DEG C.

Owner:山东福尔有限公司

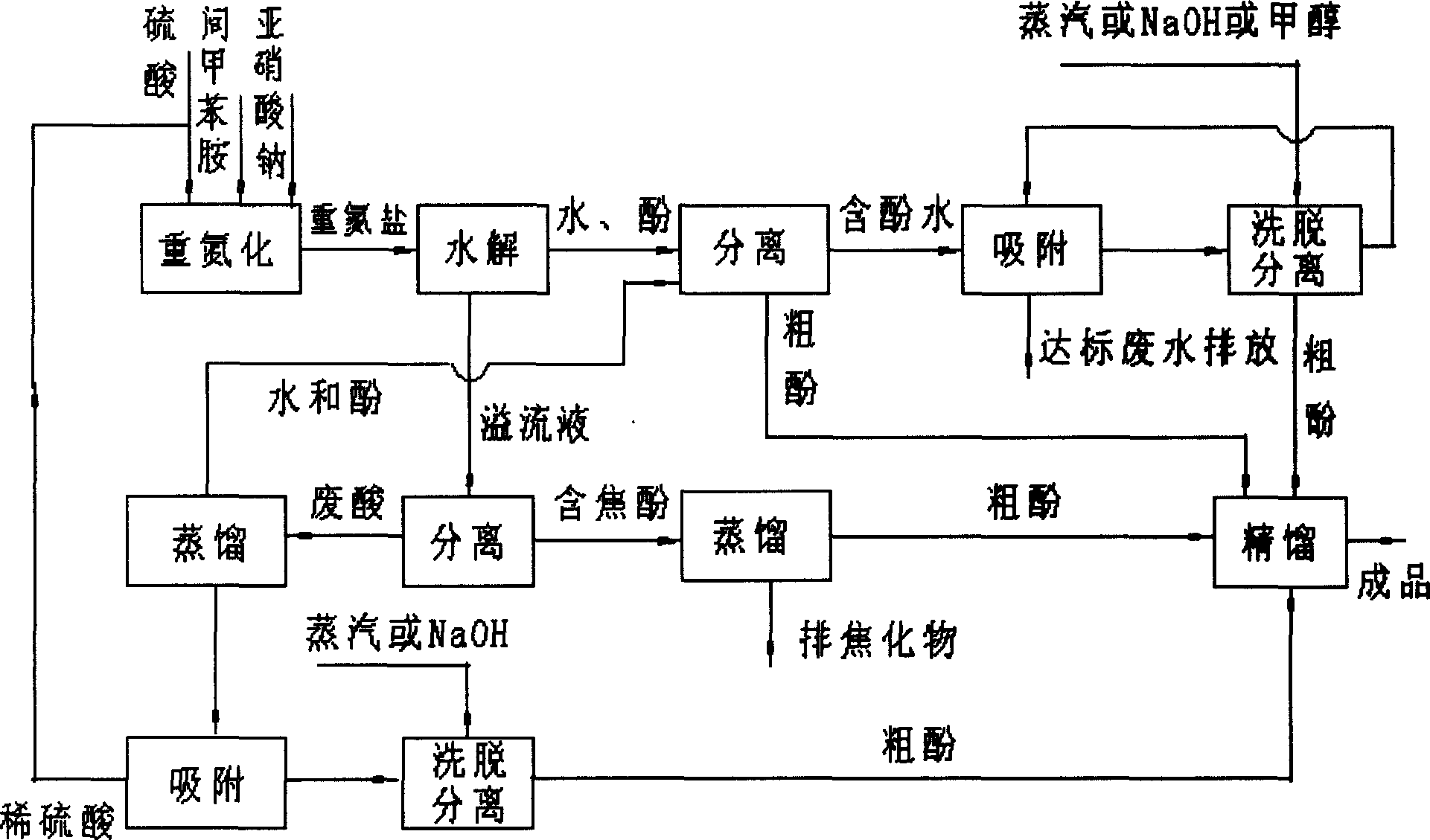

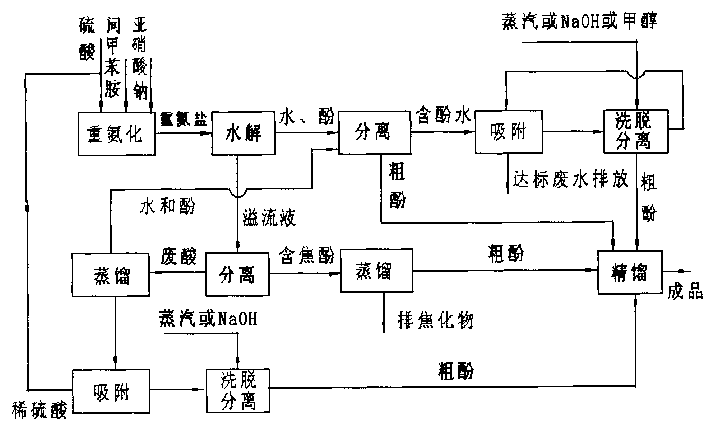

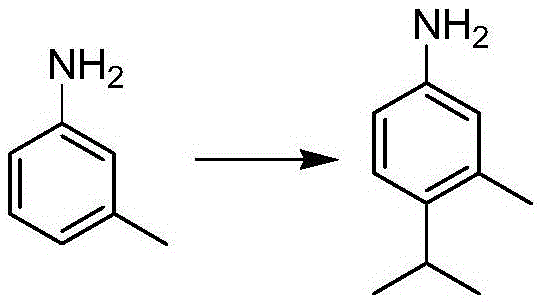

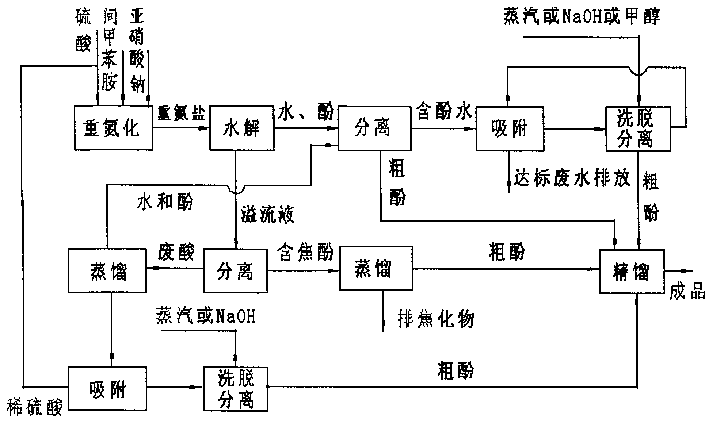

Process for preparing m-cresol by nitrogen oxide gas

InactiveCN101774893AElimination of inorganic saltsLow costOrganic chemistryOrganic compound preparationSalt freeM-Cresol

The invention discloses a process for preparing m-cresol by a nitrogen oxide gas, which comprises the following steps: infusing the nitrogen oxide gas in m-toluidine sulfate for carrying out diazotization, hydrolyzing in the presence of an organic solvent and under an acidic condition, carrying out flash evaporation on the acid phase under the condition of negative pressure, returning the acid phase to a salifying step, dehydrogenating and rectifying the organic phase to obtain m-cresol products. The invention uses the nitrogen oxide gas as a diazotizing agent and inorganic salts do not existin a waste acid so that the waste acid is possibly used industrially. The hydrolysis is carried out in the presence of the organic solvent, the m-toluidine generated by the hydrolysis is quickly dissolved in the organic phase, the side product tarry matters generated in the reaction is few, the yield of the m-toluidine is improved, the salt-free waste acid is subjected to the flash evaporation under the negative pressure at a certain temperature, organic matters are stripped while the reaction water is removed, sulfuric acid is used, the dosage of the sulfuric acid is reduced, the purity of the m-toluidine products prepared by the process of the invention is 99.7% and the yield is more than 90%.

Owner:JIANGSU HUAIHE CHEM

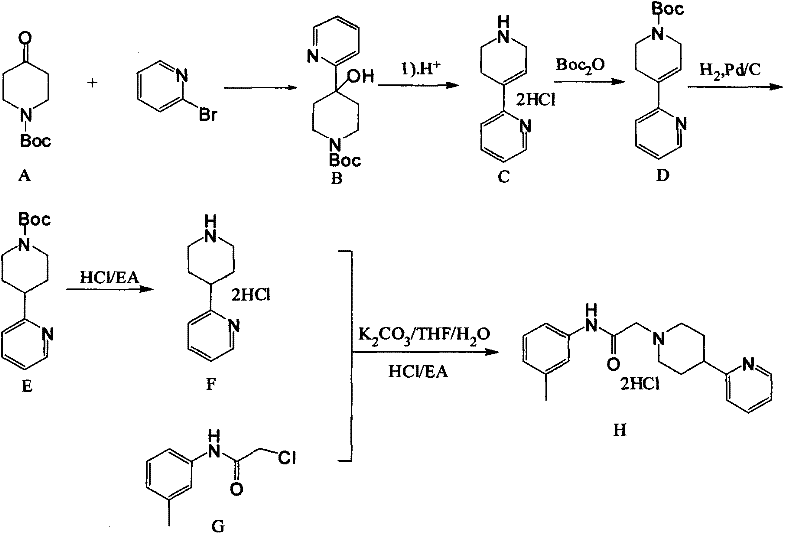

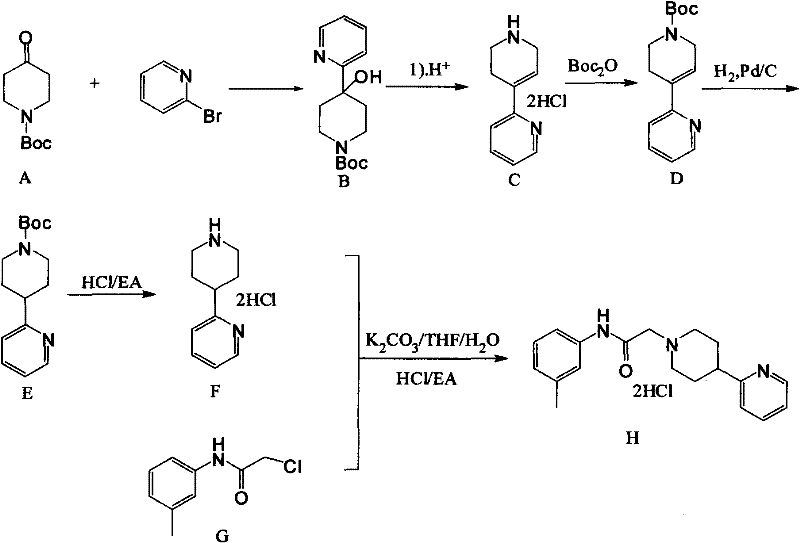

Method for producing hydrochloride of dopamine D4 receptor agonist A-412997

The invention discloses a method for producing hydrochloride of a dopamine D4 receptor agonist A-412997. The method comprises the following steps of: obtaining lithium pyridine by using a cheap reagent of butyl lithium as an exchange reagent; reacting with N-Boc-4-piperidone to obtain a compound of 1-N-Boc-4-(2-pyridyl)-4-hydroxypiperidine; removing water molecules, adding Boc, hydrogenating, removing the Boc and performing other steps to obtain a compound of 4-(2-pyridyl)piperidine dihydrochloride; and performing substitution on the 4-(2-pyridyl)piperidine dihydrochloride and a compound of chloracetyl m-toluidine to obtain the target product, namely the hydrochloride of the dopamine D4 receptor agonist A-412997. The process flow is simple, the method is suitable for industrial production, the reagent has low price, the yield is high, the total yield is 44.5 percent, and the method is an effective method for producing the hydrochloride of A-412997.

Owner:ITIC MEDCHEM CO LTD

Treatment method of residues from nitrotoluene rectification kettle

InactiveCN103772208ASimple processShort processOrganic compound preparationAmino compound preparationMethylanilineP-nitrotoluene

The invention discloses a treatment method of residues from a nitrotoluene rectification kettle. The method comprises the following steps: performing a hydrogenation reduction reaction on the residues from the rectification kettle and hydrogen in the presence of a catalyst, thereby generating methylaniline comprising three isomers, namely, o-toluidine, m-toluidine and p-toluidine, from the mononitrotoluene in the kettle residues and generating diaminotoluene comprising two isomerides, namely, 2,4-diaminotoluene and 2,6-diaminotoluene, from the dinitrotoluene in the kettle residues; and then performing rectification separation, thereby obtaining a methylaniline finished-product and a diaminotoluene finished-product. The method is simple in process, short in procedure, clean and environment-friendly, and realizes the rational utilization of waste resources, i.e., the products with high additional values are produced by utilizing low-value resources, thereby bringing economic benefits to enterprises. As a result, the recycling of waste materials, the energy conservation and the emission reduction are realized.

Owner:淮安嘉诚高新化工股份有限公司

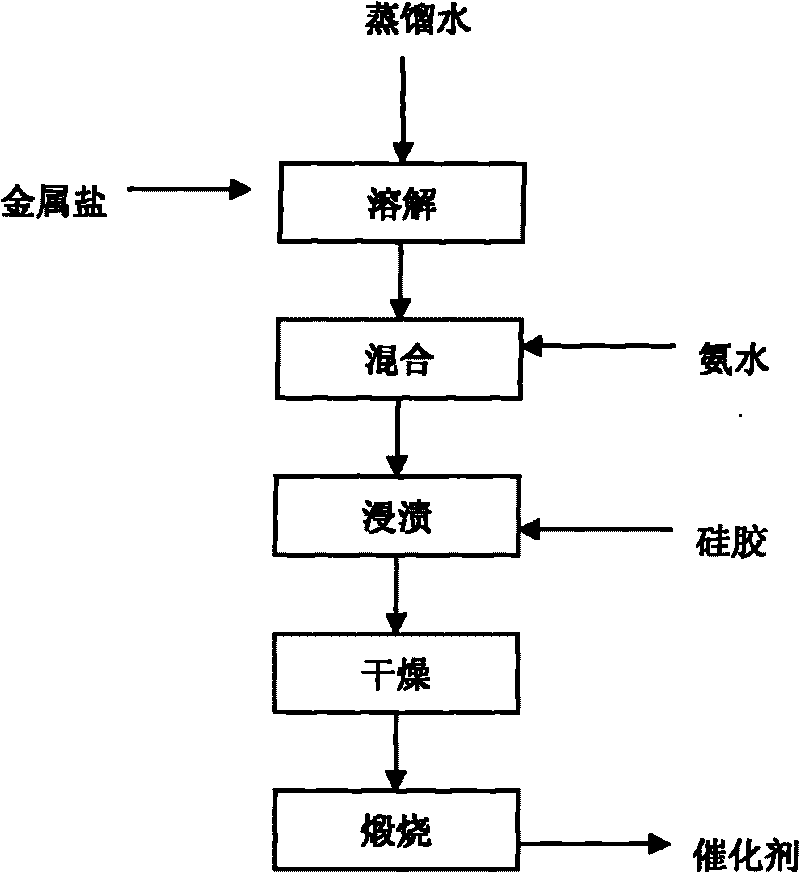

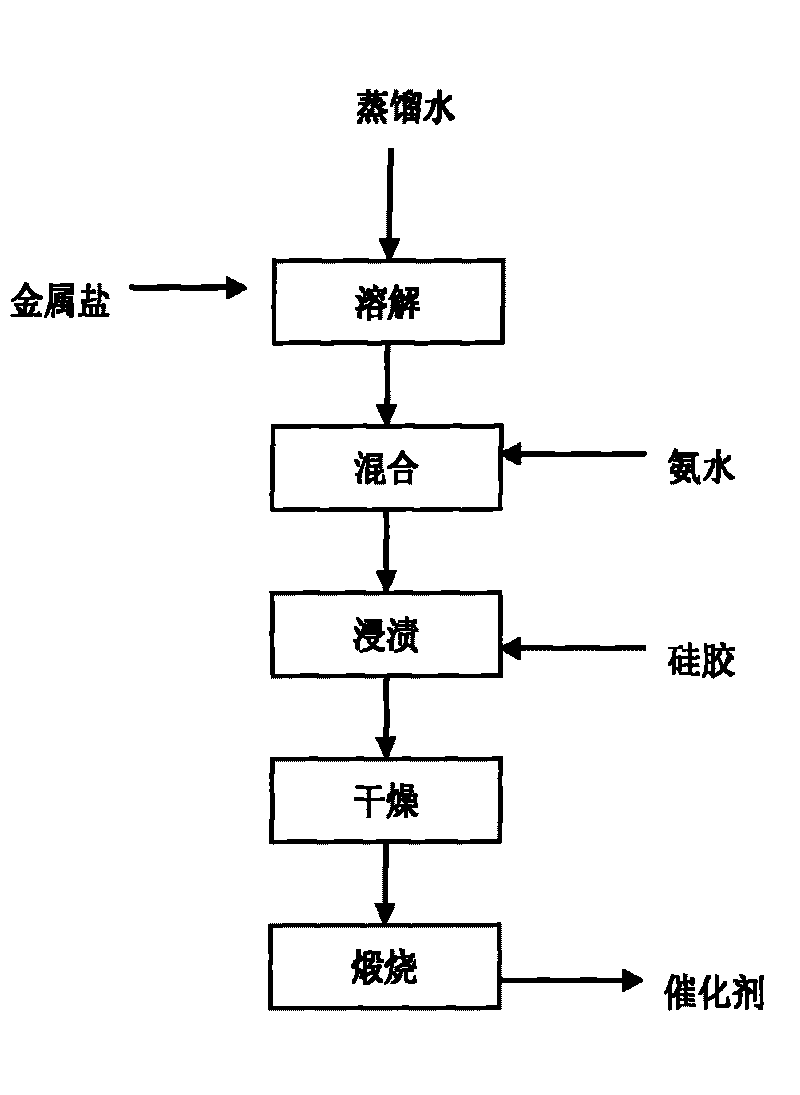

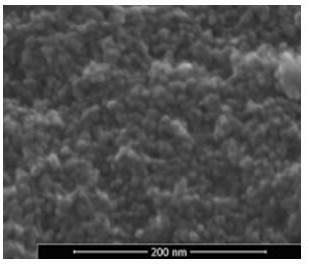

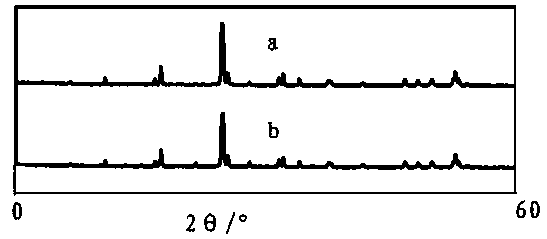

Catalyst for m-toluidine prepared from m-nitrotoluene through gas phase hydrogenation, preparation method and regeneration method thereof

InactiveCN101733099AHigh catalytic activityHigh selectivityOrganic compound preparationChemical recyclingGas phaseCopper nitrate

The invention discloses a catalyst for m-toluidine prepared from m-nitrotoluene through gas phase hydrogenation, a preparation method and a regeneration method thereof. In the catalyst, SiO2 is used as a carrier and copper is used as a main active ingredient; and based on the weight of the catalyst, Cu accounts for 10 to 30 percent and the balance is SiO2. The method for preparing the catalyst comprises the following steps: weighing copper nitrate and silica gel; adding distilled water into the copper nitrate until the copper nitrate is fully dissolved; adding solution of ammonia water into the mixture until no precipitate is generated in the solution; adjusting the pH value; adding the silica gel into the prepared solution and stirring the solution; filtering and washing the obtained solution until the filtrate becomes colorless; and finally drying and baking the filtrate to obtain the catalyst. The catalyst after being inactivated can be regenerated through an air oxidizing roasting method. The catalyst has the advantages of long service life, excellent catalytic activity, high selectivity, simple preparation and regeneration methods and low cost, and wide application.

Owner:NANJING UNIV OF SCI & TECH

Method used for catalytic degradation of arylamine waste water using photocatalysis material

ActiveCN109179559AEasy to prepareRealize industrializationWater/sewage treatment by irradiationWater treatment compoundsWater useNickel salt

The invention belongs to the technical field of chemical waste water processing, and more specially relates to a method used for catalytic degradation of arylamine waste water using a photocatalysis material. According to the method, apatite is taken as a carrier, a nitrate hexahydrate, zinc nitrate hexahydrate, and sodium tungstate dehydrate are taken as raw materials, hydro-thermal reaction is adopted to prepare the nickel salt modified zinc tungstate photocatalysis material. The preparation method is simple; the obtained photocatalysis material is capable of degrading arylamines such as phenylamine, parachloroaniline, or m-toluidine, and the degradation rate of phenylamine is as high as 98.6%.

Owner:赵兴海

Accelerator mixture for peroxide hardener and two-component mortar system containing same

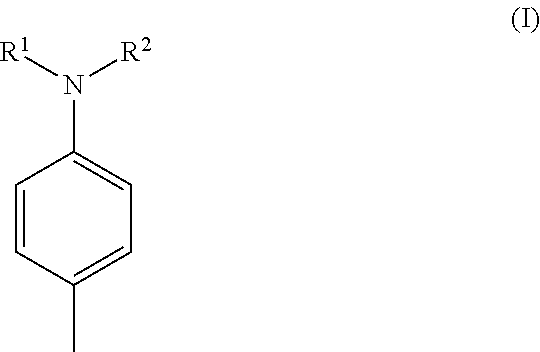

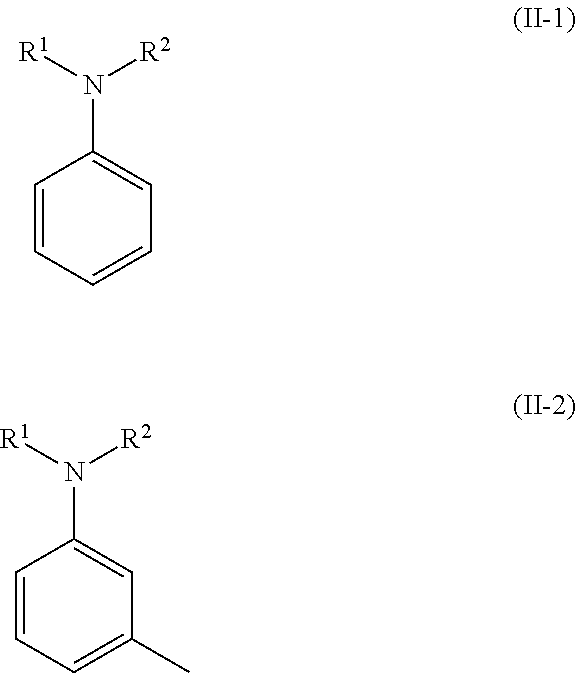

ActiveUS9463449B2Satisfactory load ratingCuringOrganic compounds purification/separation/stabilisationOrganic-compounds/hydrides/coordination-complexes catalystsLow temperature curingM-toluidine

An accelerator mixture for peroxide hardeners, in particular an accelerator mixture for an organic peroxide-curing resin mixture, a two-component mortar system containing the same for chemical fastening and use of the same for chemical fastening of anchoring elements in boreholes are disclosed. Using a mixture of bis-N-substituted p-toluidines with bis-N-substituted anilines or bis-N-substituted m-toluidines, it is possible to provide a mortar composition for chemical fastening of anchoring elements in boreholes, which will have an improved low-temperature curing and improved load ratings at high temperatures with an extended gel time.

Owner:HILTI AG

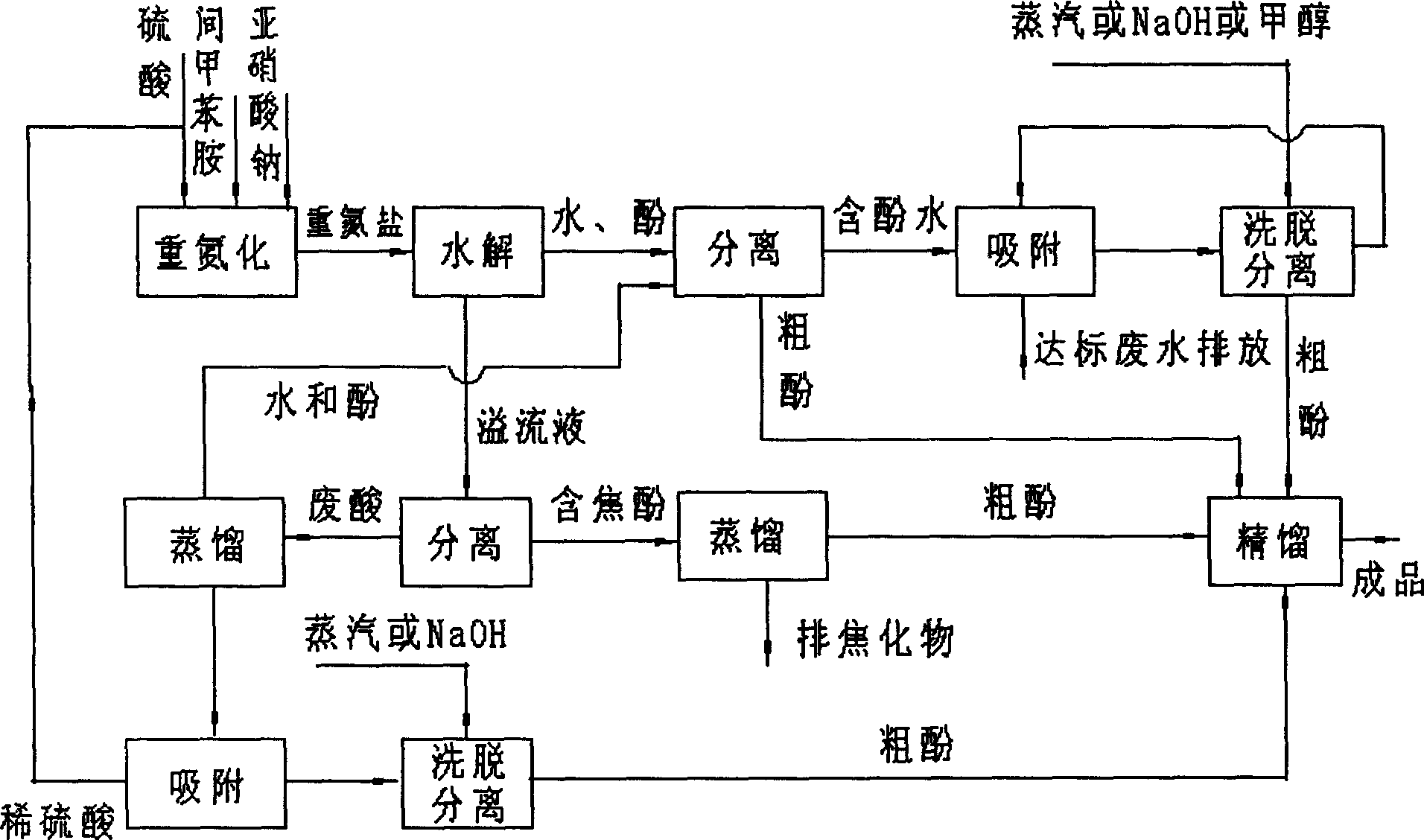

Continuous preparation of m-toluidine

InactiveCN1472184AReduce manufacturing costLess investmentOrganic chemistryOrganic compound preparationReaction temperatureM-toluidine

A process for continuously preparing meta-tolylphenol includes such steps as continuously adding the diazonium salt of meta-tolylamine to diluted sulfuric acid, and reacting at 106-150 deg.C while controlling the concentration of sulfuric acid to 25-64 wt.%. Its advantages are low cost, high output rate, small reactor volume, and cyclic use of sulfuric acid after treated by macroreticular resin.

Owner:王林

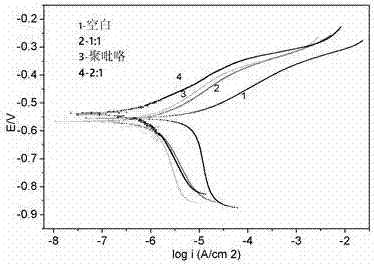

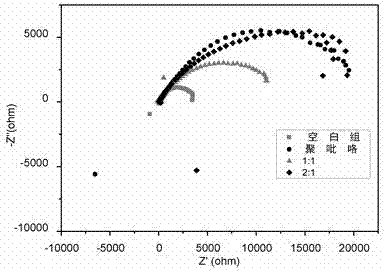

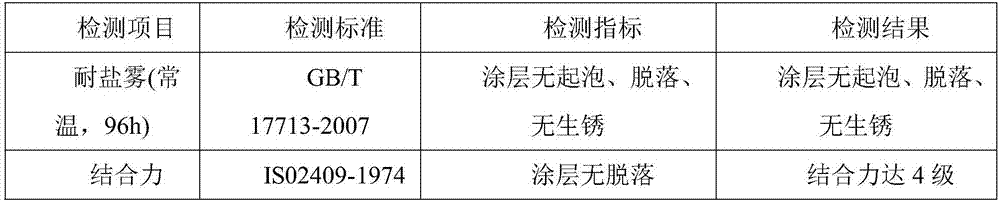

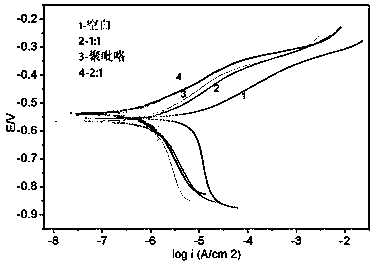

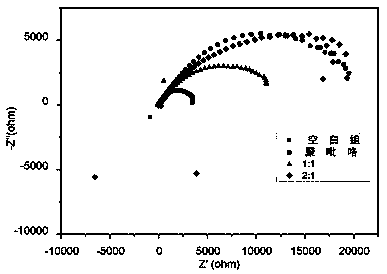

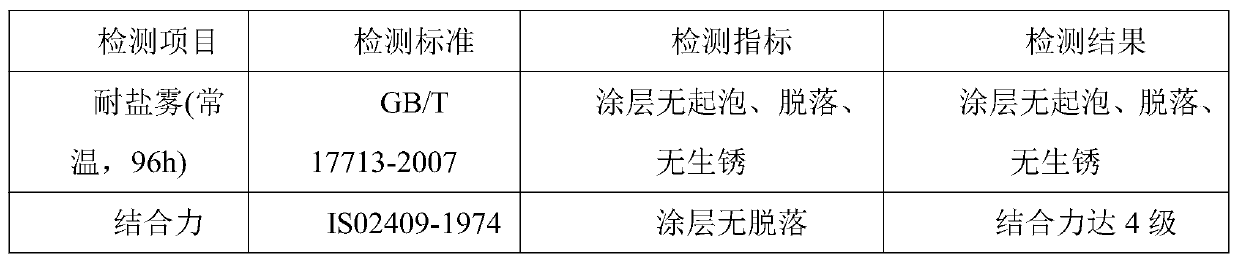

Preparation methods of acid-doped pyrrole-m-toluidine copolymer and modified anticorrosive coating

ActiveCN107245146AImprove conductivityImprove anti-corrosion performanceFireproof paintsAnti-corrosive paintsEpoxyPolypyrrole

The invention provides preparation methods of an acid-doped pyrrole-m-toluidine copolymer and a modified anticorrosive coating. An acid-doped pyrrole-m-toluidine copolymer material is prepared by a chemical oxidative polymerization method, E-44 epoxy resin is modified with the pyrrole-m-toluidine copolymer material, the acid-doped pyrrole-m-toluidine copolymer material is added in the epoxy resin, Q235 carbon steel is coated with the modified epoxy resin, and the anticorrosive performance of the coated Q235 carbon steel is studied. When the volume ratio of pyrrole and m-toluidine is 2 to 1, the synthesized copolymer, as filler, is added in the epoxy resin to be used as a coating, and a coating layer of the coating is largest in resistance and smallest in corrosion current density, i.e. the corrosion resistance performance of the coating is the best. By passing through binding force rating, the coating can reach a primary standard and has very good constructability. The coating has dual advantages of polypyrrole and the m-toluidine and is very good in conductivity, good in anticorrosive performance, small in pollution and low in cost.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Process for preparing m-cresol by nitrogen oxide gas

InactiveCN101774893BElimination of inorganic saltsLow costOrganic chemistryOrganic compound preparationSalt freeM-Cresol

The invention discloses a process for preparing m-cresol by a nitrogen oxide gas, which comprises the following steps: infusing the nitrogen oxide gas in m-toluidine sulfate for carrying out diazotization, hydrolyzing in the presence of an organic solvent and under an acidic condition, carrying out flash evaporation on the acid phase under the condition of negative pressure, returning the acid phase to a salifying step, dehydrogenating and rectifying the organic phase to obtain m-cresol products. The invention uses the nitrogen oxide gas as a diazotizing agent and inorganic salts do not existin a waste acid so that the waste acid is possibly used industrially. The hydrolysis is carried out in the presence of the organic solvent, the m-toluidine generated by the hydrolysis is quickly dissolved in the organic phase, the side product tarry matters generated in the reaction is few, the yield of the m-toluidine is improved, the salt-free waste acid is subjected to the flash evaporation under the negative pressure at a certain temperature, organic matters are stripped while the reaction water is removed, sulfuric acid is used, the dosage of the sulfuric acid is reduced, the purity of the m-toluidine products prepared by the process of the invention is 99.7% and the yield is more than 90%.

Owner:JIANGSU HUAIHE CHEM

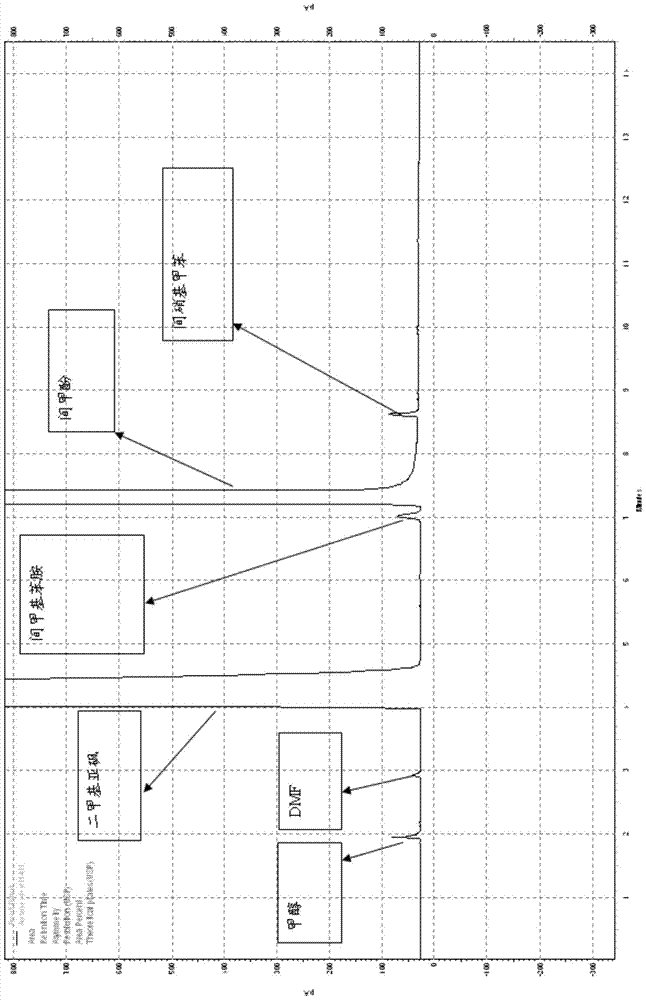

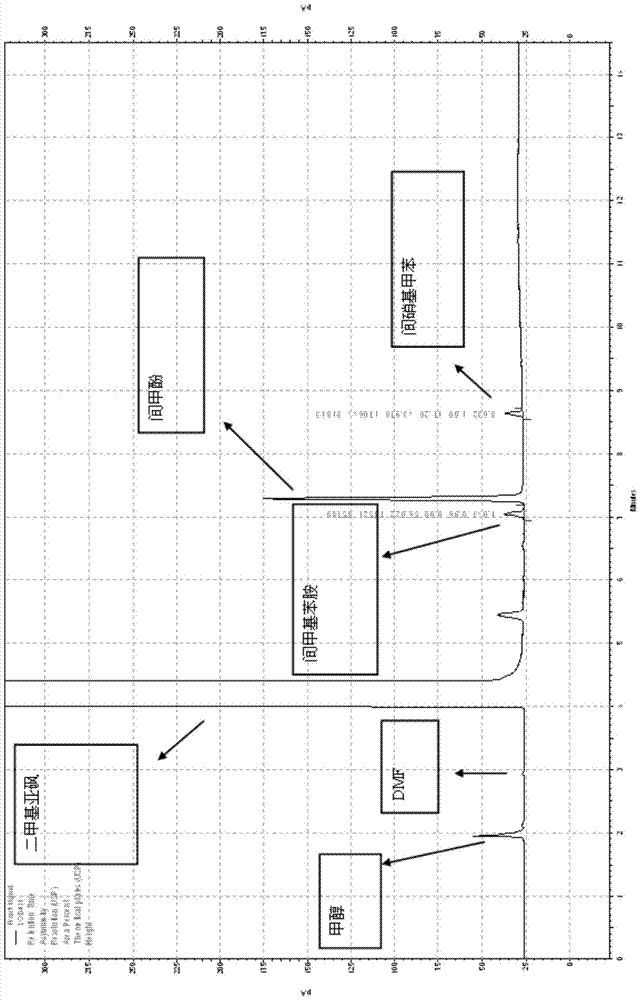

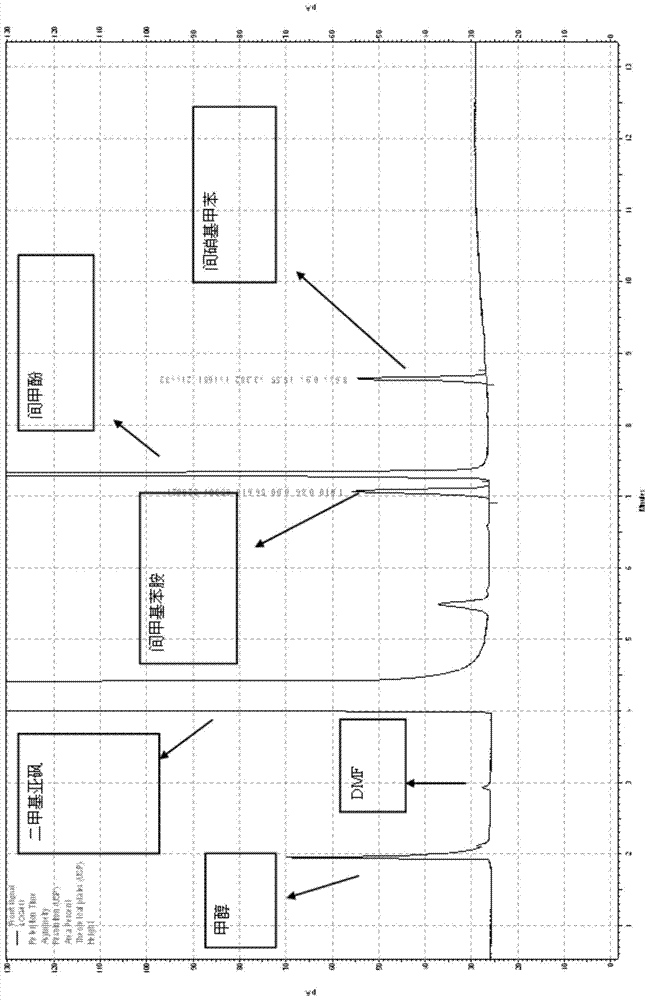

Method for detecting impurities, namely meta-methylnitrobenzene and m-toluidine, in m-cresol simultaneously

InactiveCN106932505AGood peak shapeGood linear relationshipComponent separationChemical industryGas phase

The invention relates to the technical field of chemical industry and discloses a method for detecting impurities, namely meta-methylnitrobenzene and m-toluidine, in m-cresol simultaneously. The method comprises the following steps: diluting a to-be-detected m-cresol sample by using a mixed solvent of dimethyl sulfoxide, methanol and DMF to obtain a test sample solution, and taking the mixed solution of the meta-methylnitrobenzene and the m-toluidine as a control product solution; and performing sample introduction on the test sample solution and the control production solution by a headspace mode, performing gas chromatographic detection, and calculating the content of the impurities, namely the meta-methylnitrobenzene and the m-toluidine, in the m-cresol according to an external standard method and based on peak area. The sample is diluted by the mixed solvent of the dimethyl sulfoxide, the methanol and the DMF, sample instruction is conducted by the headspace mode, and chromatographic detection is conducted, so that the content of the minute amount of meta-methylnitrobenzene and m-toluidine in the product can be detected simultaneously and accurately, the detection sensitivity is greatly improved, and important practical value on production control of the product and quality control of the product is achieved.

Owner:HYBIO PHARMA

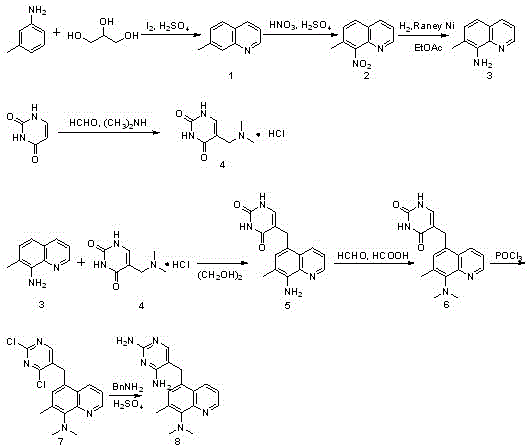

A kind of preparation method of baquiprime

The invention provides a preparation method of baquiloprim. The preparation method is mild in conditions, convenient to operate, high in yield and low in cost. Specifically the preparation method comprises the following steps: taking m-toluidine as an initial raw material, performing a Skraup reaction, nitration, and nitroreduction to obtain an intermediate 8-amino-7-methylquinoline; taking uracil as the initial raw material, and performing a Mannich reaction to obtain an intermediate 5-dimethylamine methyl uracil hydrochloride; performing condensation, Eschweiler-Clarke methylation, chlorination and aminolysis and the like on the intermediate 8-amino-7-methylquinoline and the intermediate 5-dimethylamine methyl uracil hydrochloride to synthesize baquiloprim. The preparation method is easily available in raw materials, easy to operate and favorable for industrialization production.

Owner:QINGDAO VLAND BIOTECH INC

Clutch pump piston and preparation method thereof

The invention discloses a clutch pump piston and a preparation method thereof. The preparation method comprises the steps of 1) smashing sweet potato, putting the smashed sweet potato into a yeast solution for fermentation, then filtering and taking a filter cake, so as to obtain a modifier; 2) calcining bentonite and iron-ore slag, then putting the calcined bentonite and iron-ore slag in X-rays for activating treatment, so as to obtain an activator; 3) mixing makrolon, an ethylene-vinyl acetate copolymer, cellulose propionate, vinyl propionate, n-butyl alcohol, nanometer magnesia, a rare-earth oxide, a potassium titanate whisker, m-toluidine, anilmomethyl triethoxy silane, pyrimidine, p-benzoquinone, simethicone and the modifier with the activator, cooling, molding and pelleting to obtain a clutch pump piston material; 4) melting the clutch pump pulling bar material at 195 to 205 DEG C, and then the clutch pump piston is obtained by extrusion molding. The clutch pump piston prepared by the method has excellent mechanical property.

Owner:WUHU HENGKUN AUTO PARTS

High-strength clutch shifter material and preparation method thereof

The invention discloses a high-strength clutch shifter material and a preparation method thereof. The preparation method comprise the following steps: 1) wood chips and plant ash are soaked in a hydrochloric acid solution, filtering is carried out for preparing a filter cake, a vapor treatment is carried out for the filter cake, in order to obtain a modifier; 2) bentonite and iron-ore slag are calcined, an activation treatment is carried out with existence of X-ray, in order to prepare an activator; 3) polycarbonate, an ethene-vinyl acetate copolymer, cellulose propionate, vinyl propionate, 1-butanol, nanometer magnesium oxide, rare earth oxide, potassium titanate whiskers, m-toluidine, anilino-methyl-triethoxysilane, pyrimidine, p-benzoquinone, dimethicone, the modifier and the activator are mixed, cooled, moulded and granulated, in order to obtain the high-strength clutch shifter material. The prepared clutch shifter material has excellent mechanical properties.

Owner:WUHU HENGKUN AUTO PARTS

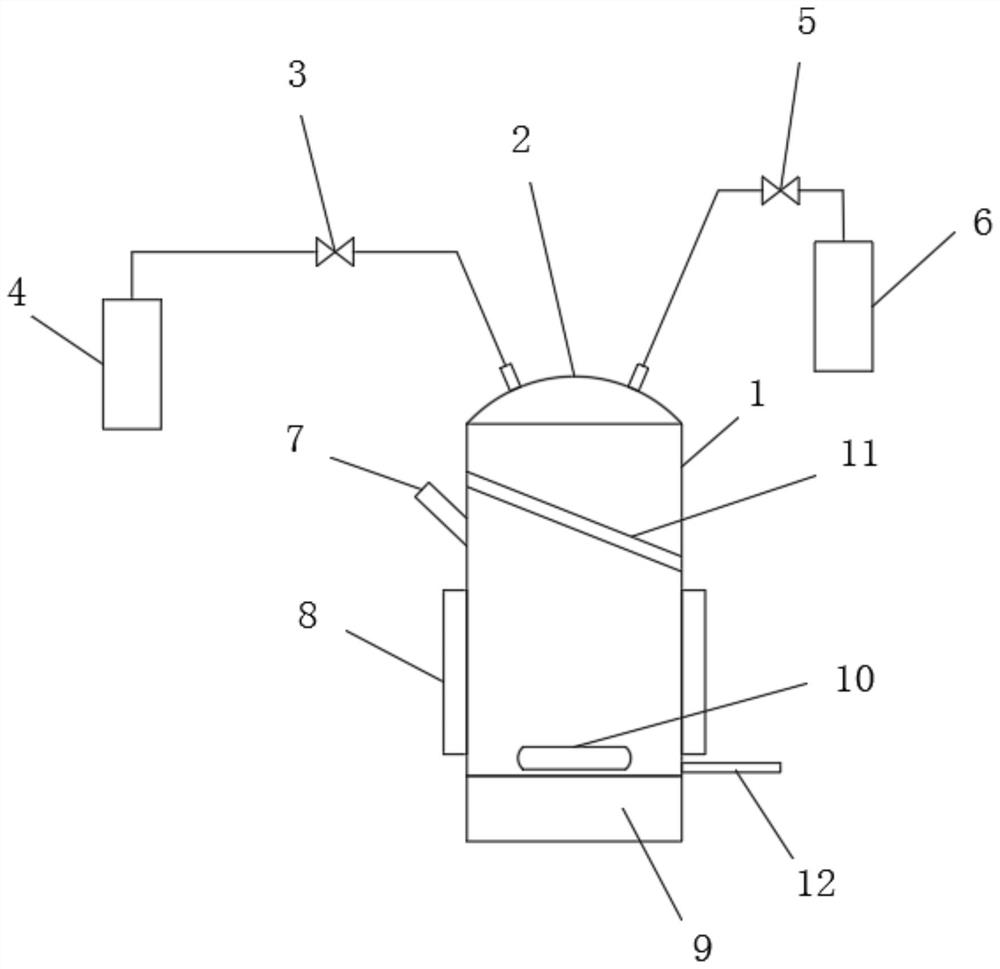

High-strength polyimide, preparation method and production equipment

PendingCN114656789AHigh strengthAvoid formingChemical/physical/physico-chemical stationary reactorsFiberYarn

The invention discloses a preparation method of high-strength polyimide, which comprises the following steps: (1) preparing an organic solvent, and mixing transparent fibers in the organic solvent in a dispersed manner; (2) adding pyromellitic dianhydride and m-toluidine into an organic solvent, and polymerizing the pyromellitic dianhydride and the m-toluidine; (3) adding the biphenyl tetracarboxylic dianhydride, the oxydiphthalic anhydride or the benzophenone tetracarboxylic dianhydride into the organic solvent, and polymerizing the biphenyl tetracarboxylic dianhydride, the oxydiphthalic anhydride or the benzophenone tetracarboxylic dianhydride and the m-toluidine; and (4) carrying out imidization on the polyimide acid generated in the organic solvent. The invention also provides high-strength polyimide and production equipment. According to the present invention, the dispersed transparent fiber yarn is added in the organic solvent in advance, the transparent fiber yarn and the polyimide are subjected to composite molding after the polyimide is subjected to tape casting, and the transparent fiber yarn has the high strength, such that the prepared polyimide has the good strength;

Owner:苏州合尔达电子科技有限公司

Environmentally friendly preparation method of solvent blue 63 dye

ActiveCN106748833AHigh reaction purityLess side effectsOrganic chemistryOrganic compound preparationFiltrationSolvent

The invention relates to an environmentally friendly preparation method of a solvent blue 63 dye. The preparation method comprises (a) adding m-toluidine into a reaction container, orderly adding 1-methylamino-4-bromoanthraquinone, an alkali metal hydroxide and a copper salt into the reaction container along with stirring, heating the mixture to 100 to 130 DEG C and carrying out a reaction process for 4 to 7 hours until a terminal point, wherein a mass ratio of 1-methylamino-4-bromoanthraquinone, m-toluidine, alkali metal hydroxide to copper salt is 6: 12-16: 3-4: 0.04-0.08, and (b) cooling the product obtained by the step a to 60-70 DEG C, then adding methanol into the product, carrying out separation, carrying out stirring, carrying out cooling to 30-50 DEG C, and carrying out filtration, washing and drying. The method has the advantages of high reaction purity, few side reactions, short reaction time, obvious crystallization, washing easiness and less washing wastewater.

Owner:安徽清科瑞洁新材料有限公司

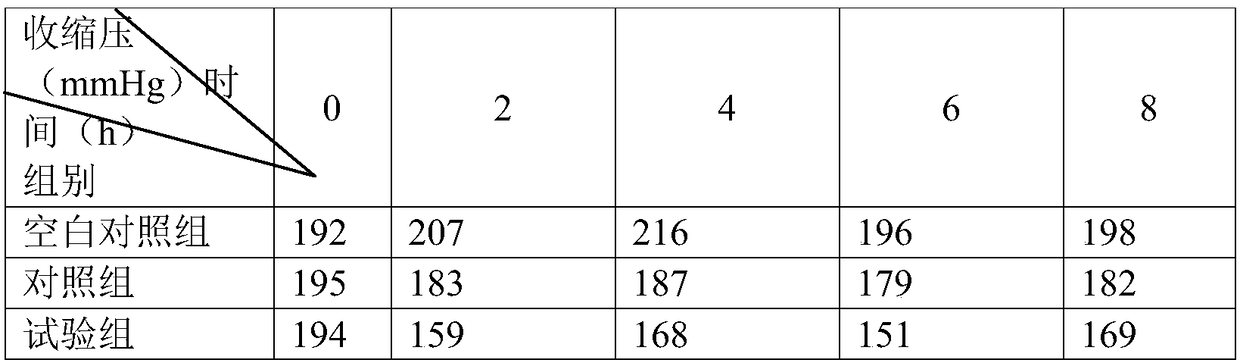

A preparing method for a sea sedge baked piece capable of reducing blood pressure

InactiveCN108541908AGood sheetingReduce crackingFood ingredient functionsCooking & bakingAlloisoleucine

The invention discloses a preparing method for a sea sedge baked piece capable of reducing blood pressure. The method includes the following step: pulping, first baking, seasoning, second baking and slicing and package. The slurry comprises, by weight: 15-25 parts of carrot slurry, 1.5-5.5 parts of leavening agent liquid, 1.0-3.0 parts of thickening agent liquid, 100-120 parts of laver slurry, 0.2-0.4 part of alloisoleucine and 0.01-0.03 part of N,N-bis-n-propyl-m-toluidine. The beneficial effects are that the sea sedge baked piece prepared by the method has good piece-forming ability and film-forming ability, has high the sense organ fraction, is rich in gamma-aminobutyric acid (GABA), and has excellent effects of reducing blood pressure and protecting cardiac muscle. Especially the alloisoleucine and N,N-bis-n-propyl-m-toluidine are added into the laver slurry, the combination force between the active constituent and ACE activity structural domain of the laver is enhanced, the substrate competitiveness is improved, so that the effect of reducing blood pressure of the sea sedge baked piece is improved.

Owner:兰溪市捷喜食品加工技术有限公司

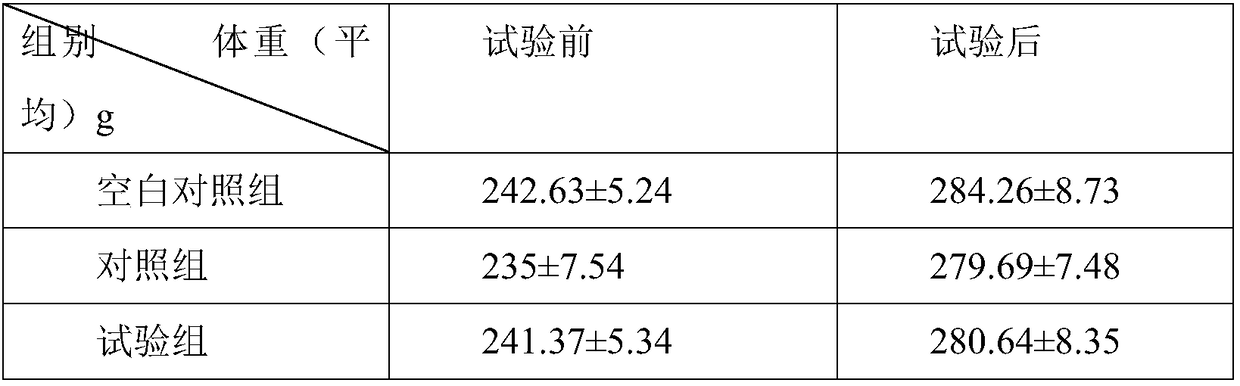

Purification method of N-(2-aminoethyl)-N-ethyl m-toluidine

InactiveCN112679366ALower requirementReduce difficultyAmino compound purification/separationToluidineEthyl group

The invention relates to the technical field of purification of asymmetric substituted ethylenediamine, and particularly discloses a purification method of N-(2-aminoethyl)-N-ethyl m-toluidine, which comprises the following steps: adding ethyl acetate into an N (2-aminoethyl)-N-ethyl m-toluidine crude product, uniformly mixing, and heating to obtain an oil-water mixture; performing standing and cooling the oil-water mixture to separate out crystals from the oil-water mixture, and then controlling the vacuum degree to be -0.09-0.06 Mpa for filter pressing for 1 hour to 2 hours to obtain a primary filter cake and primary filter liquor; adding ethanol into the obtained primary filter cake, uniformly mixing, and then heating to obtain a mixture I; adding ethyl acetate into the mixture I, uniformly mixing, and stirring to obtain a mixture II; and carrying out pressure filtration on the obtained mixture II, standing and cooling the obtained filtrate, carrying out pressure filtration under control, and drying the filter cake obtained by pressure filtration to obtain the N (2-aminoethyl)-N-ethyl-m-toluidine refined product. The purification method provided by the invention has the advantages of simple operation and high yield and purity of the final product.

Owner:上海俪源科技有限公司

Preparation method of acid-doped pyrrole-m-toluidine copolymer and modified anticorrosion coating

ActiveCN107245146BImprove conductivityImprove anti-corrosion performanceFireproof paintsAnti-corrosive paintsEpoxyPolypyrrole

The invention provides preparation methods of an acid-doped pyrrole-m-toluidine copolymer and a modified anticorrosive coating. An acid-doped pyrrole-m-toluidine copolymer material is prepared by a chemical oxidative polymerization method, E-44 epoxy resin is modified with the pyrrole-m-toluidine copolymer material, the acid-doped pyrrole-m-toluidine copolymer material is added in the epoxy resin, Q235 carbon steel is coated with the modified epoxy resin, and the anticorrosive performance of the coated Q235 carbon steel is studied. When the volume ratio of pyrrole and m-toluidine is 2 to 1, the synthesized copolymer, as filler, is added in the epoxy resin to be used as a coating, and a coating layer of the coating is largest in resistance and smallest in corrosion current density, i.e. the corrosion resistance performance of the coating is the best. By passing through binding force rating, the coating can reach a primary standard and has very good constructability. The coating has dual advantages of polypyrrole and the m-toluidine and is very good in conductivity, good in anticorrosive performance, small in pollution and low in cost.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

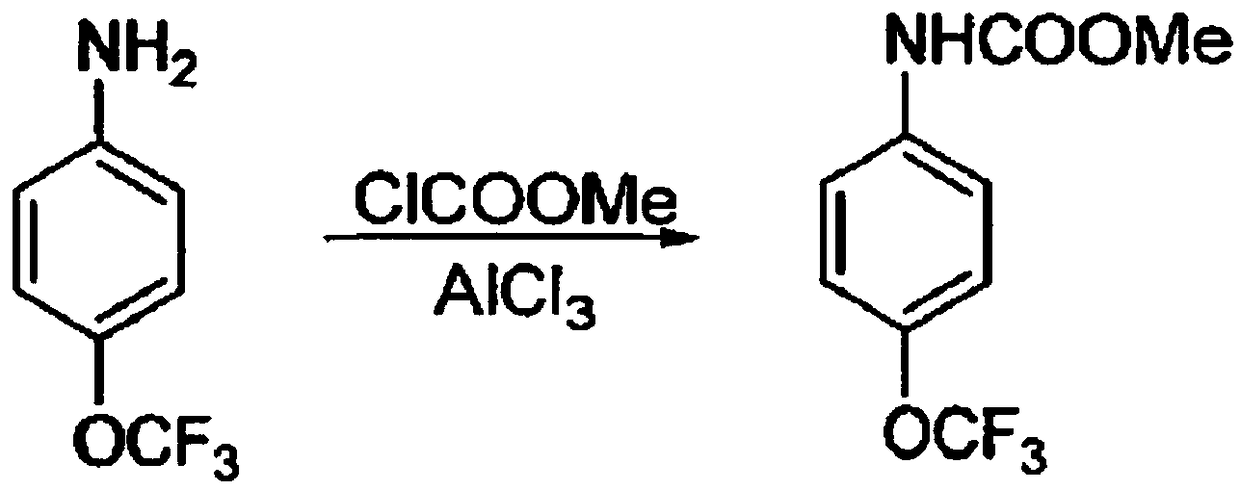

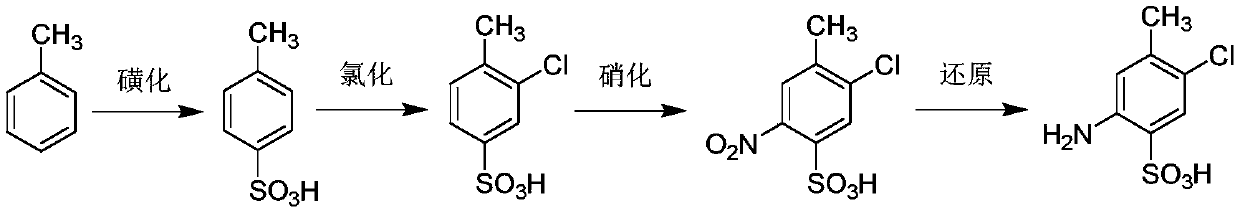

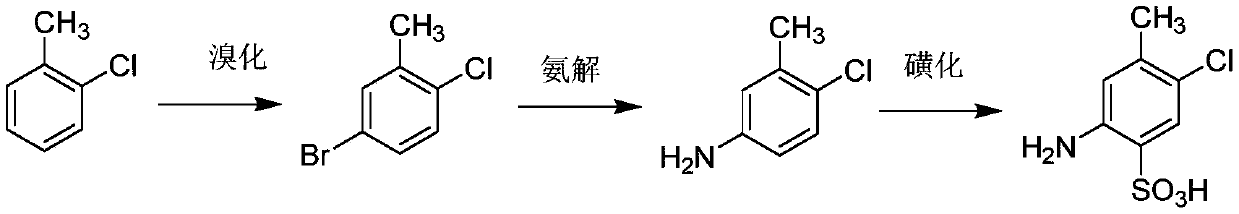

Method for preparing CLT acid by taking m-toluidine as raw material

ActiveCN110483339ALow equipment requirements"Three wastes" lessOrganic compound preparationCarboxylic acid amides preparationChemical synthesisEnvironmental resistance

The invention discloses a method for preparing CLT acid by taking m-toluidine as a raw material, and belongs to the field of chemical synthesis. The method solves the problems that existing CLT acid production is low in yield, not environmentally friendly and the like. The method comprises: S01) an acylation step, namely a step of reacting m-toluidine and acetic anhydride to obtain acylation reaction solution; S02) a chlorination step, namely a step of adding acetic acid and concentrated hydrochloric acid into the acylation reaction solution, then adding hydrogen peroxide, and finally adding an aqueous solution containing sodium sulfite to obtain a chlorination reaction solution; S03) a hydrolyzing step to form salt, namely a step of adding concentrated sulfuric acid into the chlorinationreaction solution, and removing the solvent after reaction; S04) a transposition sulfonation step, namely a step of adding chlorobenzene into the solvent-removed reaction solution obtained in the stepS03, heating the mixture, adding dichlorobenzene, heating the mixture again, reacting the mixture for 7-10 hours with the temperature of the system being maintained at a temperature higher than 170 DEG C, and stopping heating; and S05) a step of post-treatment to obtain a finished product that is the CLT acid. The method has the advantages of environmental protection and the like.

Owner:ZHEJIANG UNIV OF TECH

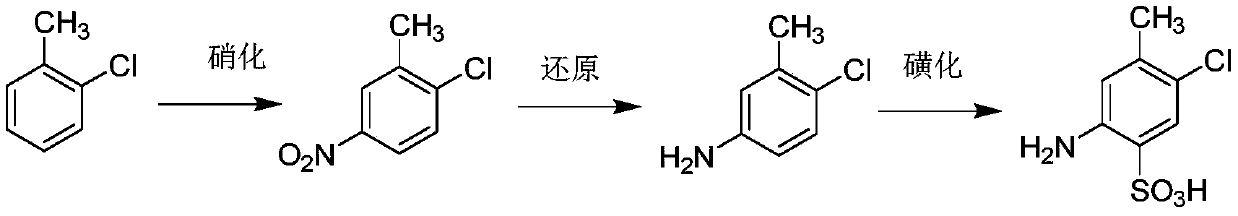

Preparation method of 3-methyl-4-isopropylaniline

ActiveCN105622428AMild reaction conditionsHigh yieldAmino compound purification/separationAmino preparation from aminesAlkyl transferM-toluidine

The invention relates to a preparation method of 3-methyl-4-isopropylaniline. The preparation method includes the following steps: (1) dissolving m-toluidine in sulfuric acid solution 50-98% in mass concentration as a component 1, then adding an isopropylation reagent into another container to serve as a component 2, simultaneously feeding the component 1 and the component 2 into a jet mixer with the flow rate of 5-10:1 to be mixed at the temperature of 10-35 DEG C, and then reacting at the temperature of 60-95 DEG C through a quartz reaction tube to obtain reaction solution for alkylation reaction; (2) subjecting the reaction solution obtained in the step (1) to separation and purification to obtain 3-methyl-4-isopropylaniline. The 3-methyl-4-isopropylaniline prepared through the method has the advantages of mild reaction condition, high yield, few by-products, less pollution and the like, and the problems of a lot of by-products, strict conditions and severe pollution in the preparation process of the 3-methyl-4-isopropylaniline in the prior art are solved effectively.

Owner:ZHEJIANG DINGLONG TECH +1

Continuous preparation of m-toluidine

InactiveCN1202057CReduce manufacturing costLess investmentOrganic chemistryOrganic compound preparationAcid hydrolysisToluidine

The invention relates to a method for continuously preparing m-cresol. The m-toluidine diazonium salt is continuously added to dilute sulfuric acid of 25 to 64 wt%, and the concentration of sulfuric acid in the reactor is controlled at 25 to 64 wt%, and the reaction temperature is 106 ~150°C to obtain m-cresol. The invention has the following advantages: not only the production cost is low, but also the finished product yield of m-cresol with a content ≥ 99.5% is above 84%, which is about 10% higher than that of the discontinuous preparation method. The reaction volume is small, and the volume of the hydrolysis reactor is only 2 / 5 of the intermittent production, which not only reduces investment, but also saves energy consumption and reduces operating costs. The invention can be carried out without solvent, saves the trouble of separating and recovering the solvent, and greatly reduces material consumption. The waste sulfuric acid produced by the hydrolysis reaction can be recycled as a raw material for the preparation of m-toluidine diazonium salt after being treated by the macroporous adsorption resin, which solves the problem of a large amount of waste acid discharge in the intermittent hydrolysis reaction.

Owner:王林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com