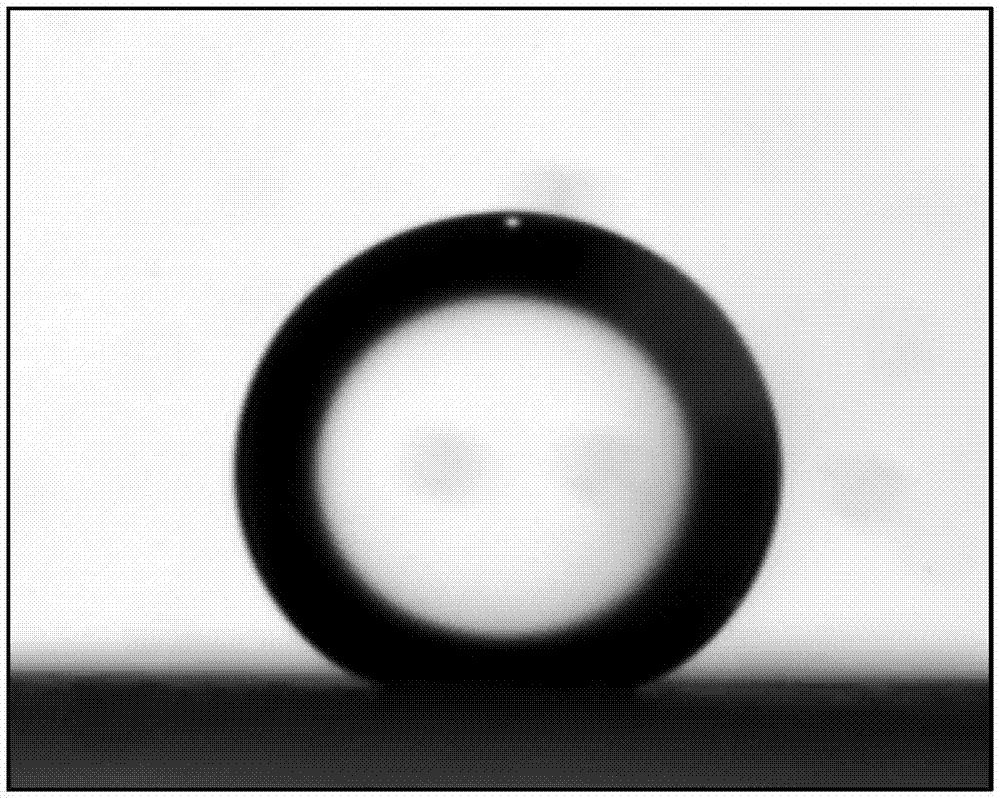

Corrosion-resistant oil-water separation mesh membrane as well as preparation method and applications thereof

An oil-water separation membrane and corrosion-resistant technology, applied in separation methods, filtration separation, liquid separation, etc., can solve the problems of complex oil-water system, unreported, inability to withstand various acids and alkaline solutions, etc., and achieve technological process Simple and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this example, each mole part is 1 mole.

[0040] The preparation method of the corrosion-resistant oil-water separation omentum of the present embodiment comprises the following steps:

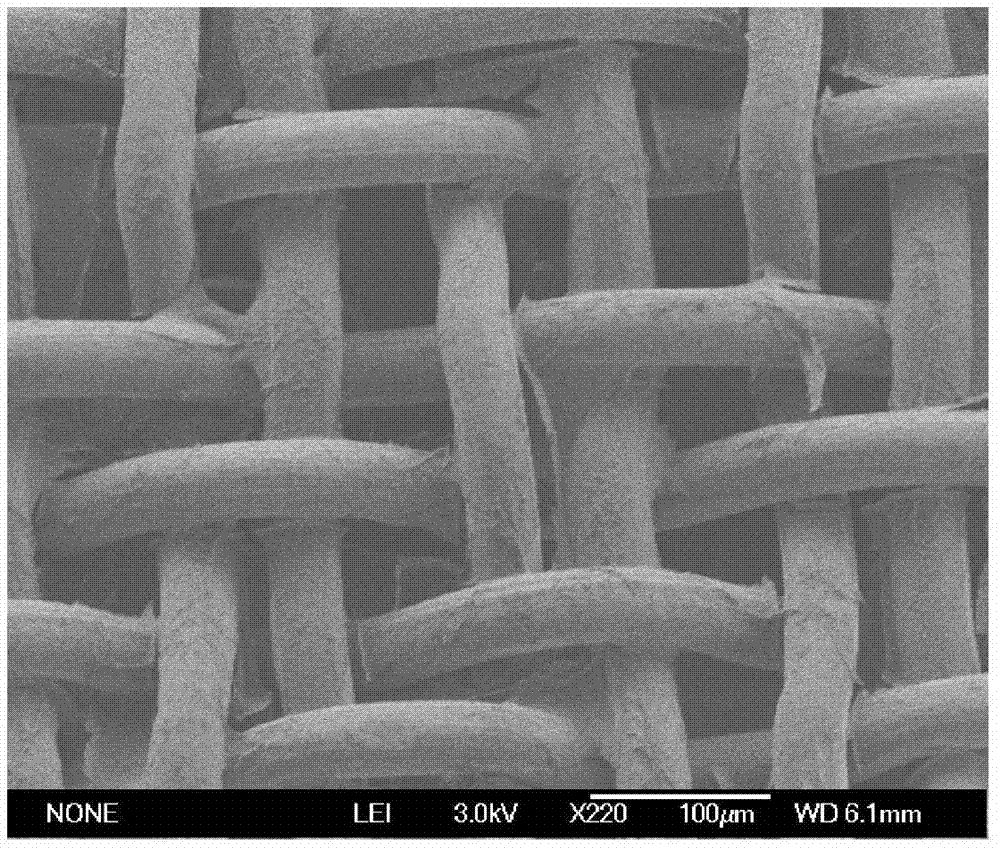

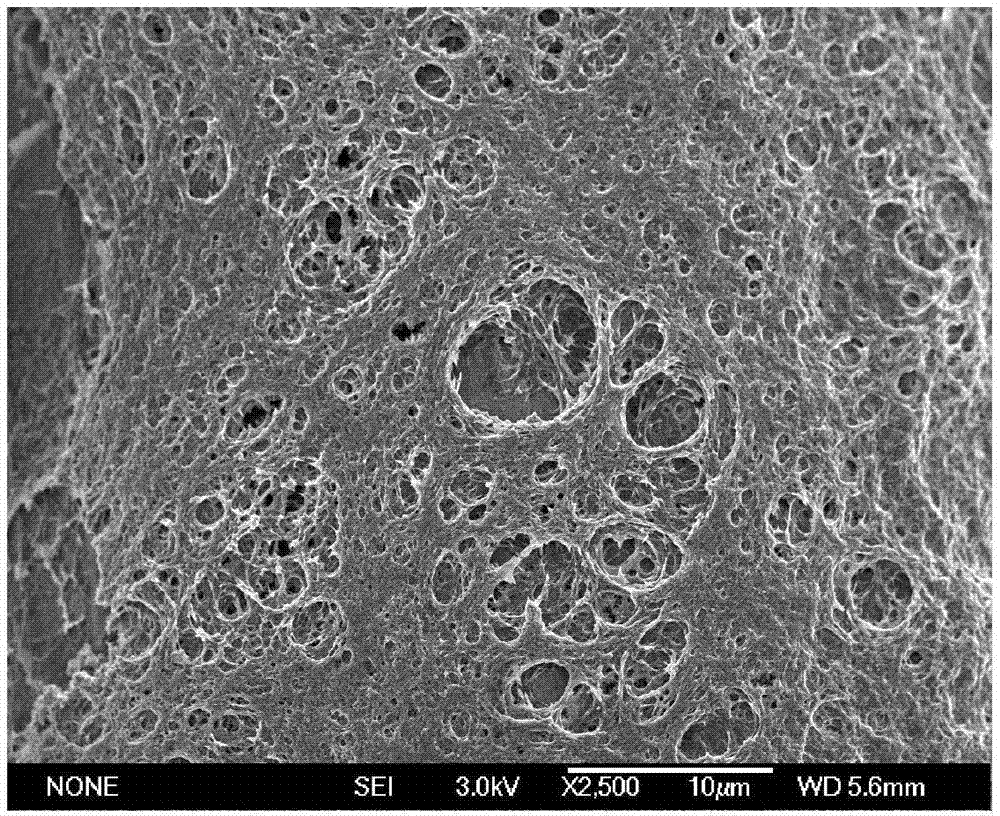

[0041] Step 1: Alternately immerse the 300-mesh metal iron fiber woven net in deionized water and absolute ethanol for ultrasonic cleaning, and dry it at room temperature;

[0042] Step 2: Prepare conductive polymer precursor solution and ultrasonically disperse it into emulsion;

[0043] Wherein, the conductive polymer precursor solution is composed of 1 molar part of 3,4-ethylenedioxythiophene, 1 molar part of sodium p-styrenesulfonate, 2 molar parts of ferric nitrate, 1 molar part of ethanol and 2 The water composition of molar part; Here, 3,4-ethylenedioxythiophene is conductive polymer monomer; Sodium p-styrene sulfonate is dopant; Ferric nitrate is oxidant;

[0044] Step 3: Immerse the metal iron fiber braided net cleaned in step 1 into the emulsion described in step 2. After...

Embodiment 2

[0050] The preparation method of the corrosion-resistant oil-water separation omentum of the present embodiment comprises the following steps:

[0051]Step 1: Alternately immerse the 200-mesh metal copper fiber braided mesh in deionized water and absolute ethanol for ultrasonic cleaning, and dry it at room temperature;

[0052] Step 2: Prepare conductive polymer precursor solution and ultrasonically disperse it into emulsion;

[0053] Wherein, the conductive polymer precursor solution is composed of 10 molar parts of thiophene, 7 molar parts of sodium p-styrenesulfonate, 50 molar parts of ferric chloride, 10 molar parts of ethanol and 20 molar parts of water; Here, thiophene is a conductive polymer monomer; sodium p-styrenesulfonate is a dopant; ferric chloride is an oxidizing agent;

[0054] Step 3: immerse the metal copper fiber braided mesh cleaned in step 1 into the emulsion described in step 2, and after 2 minutes, take it out and stand for 30 hours for polymerization to...

Embodiment 3

[0058] The preparation method of the corrosion-resistant oil-water separation omentum of the present embodiment comprises the following steps:

[0059] Step 1: Alternately immerse the 100-mesh metal stainless steel fiber woven mesh in deionized water and absolute ethanol for ultrasonic cleaning, and dry it at room temperature;

[0060] Step 2: Prepare conductive polymer precursor solution and ultrasonically disperse it into emulsion;

[0061] Wherein, the conductive polymer precursor solution is composed of 4 molar parts of aniline, 2 molar parts of p-styrenesulfonic acid, 28 molar parts of cerium chloride, 6 molar parts of ethanol and 15 molar parts of water; here, Aniline is a conductive polymer monomer; p-styrenesulfonic acid is a dopant; cerium chloride is an oxidant;

[0062] Step 3: Immerse the metal stainless steel fiber braided mesh cleaned in step 1 into the emulsion described in step 2. After 4 minutes, take it out and stand for 28 hours to polymerize to obtain a me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com