Three-dimensional porous Fe-N-C catalyst based on cetyl trimethyl ammonium bromide as carbon material pore-forming agent and preparation method

A hexadecyl trimethyl ammonium bromide, three-dimensional porous technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problem of high price, achieve increased contact area, good ORR catalytic performance, convenient and flexible adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

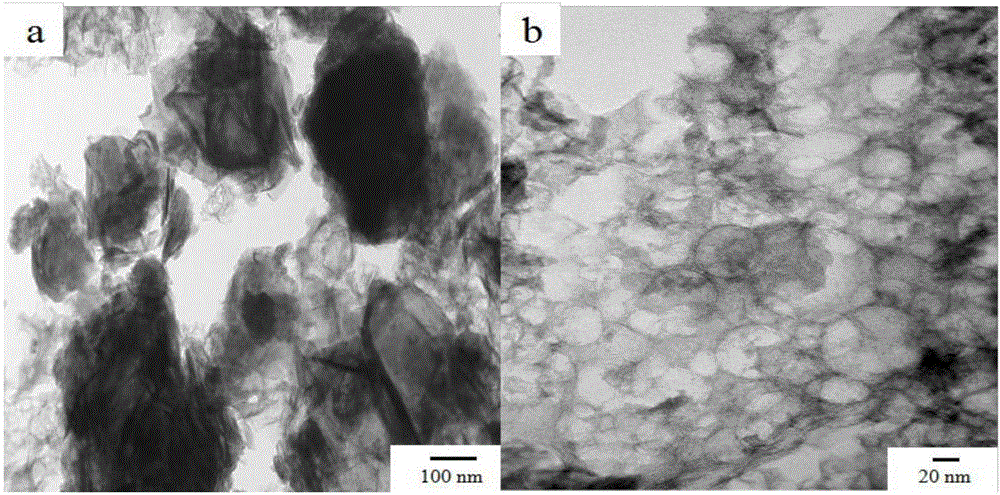

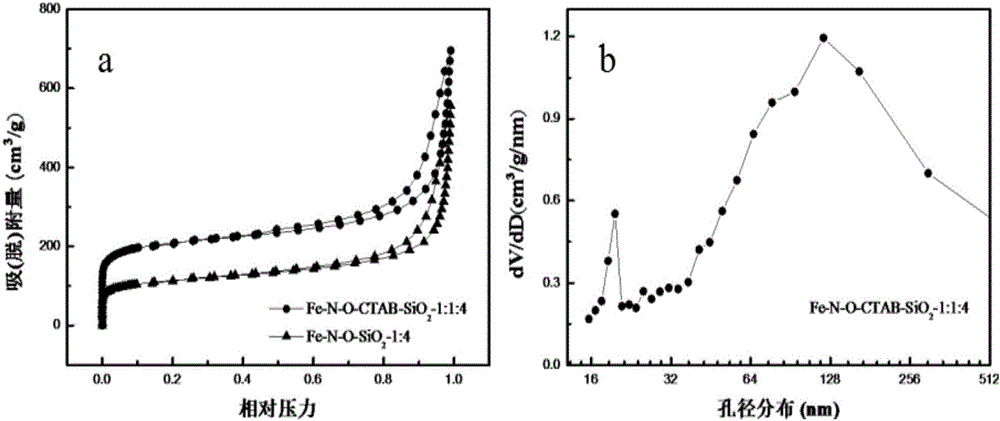

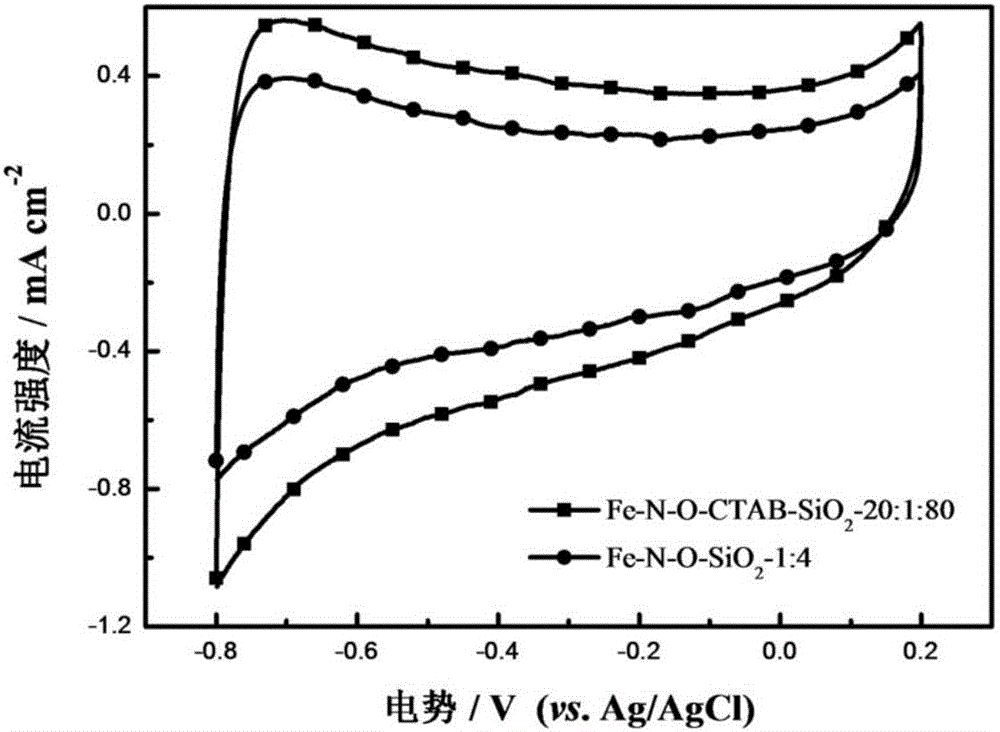

Embodiment 1

[0045] Example 1: Fe-N-O-CTAB-SiO 2 -1:1:4-900°C (Fe: FeCl 3 ·6H 2 O, Fe-N-O-CTAB-SiO 2 -1:1:4-900℃ refers to o-methylaniline, CTAB, SiO in raw materials 2 The mass ratio is 1:1:4, and the calcination temperature is 900°C)

[0046] 2g SiO 2 Disperse in 10mL of phosphoric acid aqueous solution and place in an ice-water bath, add 500μL o-methylaniline and stir evenly, then add dropwise 2.5mL of 3.7mol L -1 FeCl 3 ·6H 2 O solution and 500 μL H 2 o 2 , add CTAB (concentration of CTAB reaches 80mmol L in the solution) after dropping -1 ) and stir evenly; after the solution turns dark green, transfer the solution to an autoclave for 10 hours of reaction, then move it into an air drying oven and dry it in an air atmosphere at 100°C for 12 hours to obtain a catalyst precursor; grind the precursor evenly and place it in a quartz In the boat, under the protection of nitrogen, at 3°C min -1 After heating up to 550°C, keep the temperature for 4 hours, and then at 5°C min -1 ...

Embodiment 2

[0047] Example 2: Fe-N-O-CTAB-SiO 2 -2:1:8-900°C (Fe: FeCl 3 ·6H 2 O, Fe-N-O-CTAB-SiO 2 -2:1:8-900℃ refers to o-methylaniline, CTAB, SiO in raw materials 2 The mass ratio is 2:1:8, and the calcination temperature is 900°C)

[0048] 2g SiO 2 Disperse in 10mL of phosphoric acid aqueous solution and place in an ice-water bath, add 500μL o-methylaniline and stir evenly, then add dropwise 2.5mL of 3.7mol L -1 FeCl 3 ·6H 2 O solution and 500 μL H 2 o 2 , add CTAB (concentration of CTAB reaches 40mmol L in the solution) after dropping -1 ) and stir evenly; after the solution turns dark green, transfer the solution to an autoclave for 10 hours of reaction, then move it into an air drying oven and dry it in an air atmosphere at 100°C for 12 hours to obtain a catalyst precursor; grind the precursor evenly and place it in a quartz In the boat, under the protection of nitrogen, at 3°C min -1 After heating up to 550°C, keep the temperature for 4 hours, and then at 5°C min -1 ...

Embodiment 3

[0049] Example 3: Fe-N-O-CTAB-SiO 2 -5:1:20-900°C (Fe: FeCl 3 ·6H 2 O, Fe-N-O-CTAB-SiO 2 -5:1:20-900℃ refers to o-methylaniline, CTAB, SiO in raw materials 2 The mass ratio is 5:1:20, and the calcination temperature is 900°C)

[0050] 2g SiO 2 Disperse in 10mL phosphoric acid aqueous solution and place it in an ice-water bath, then add 500μL o-toluidine to the solution and stir evenly, then add 2.5mL 3.7mol L -1 FeCl 3 ·6H 2 O solution and 500 μL H 2 o 2 , add CTAB (CTAB concentration reaches 16mmol L in the solution) after dropping -1) and stir evenly; after the solution turns dark green, transfer the solution to an autoclave for 10 hours of reaction, then move it into an air drying oven and dry it in an air atmosphere at 100°C for 12 hours to obtain a catalyst precursor; grind the precursor evenly and place it in a quartz In the boat, under the protection of nitrogen, at 3°C min -1 After heating up to 550°C, keep the temperature for 4 hours, and then at 5°C min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com