Method for preparing 3-chloro-p-toluidine-6-sulfonic acid by liquid-phase baking method

A p-toluidine, liquid-phase technology, applied in the production of chemical raw material intermediates, can solve problems such as increased energy consumption, and achieve the effects of reducing oxidative carbonization, extremely high waste water volume, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

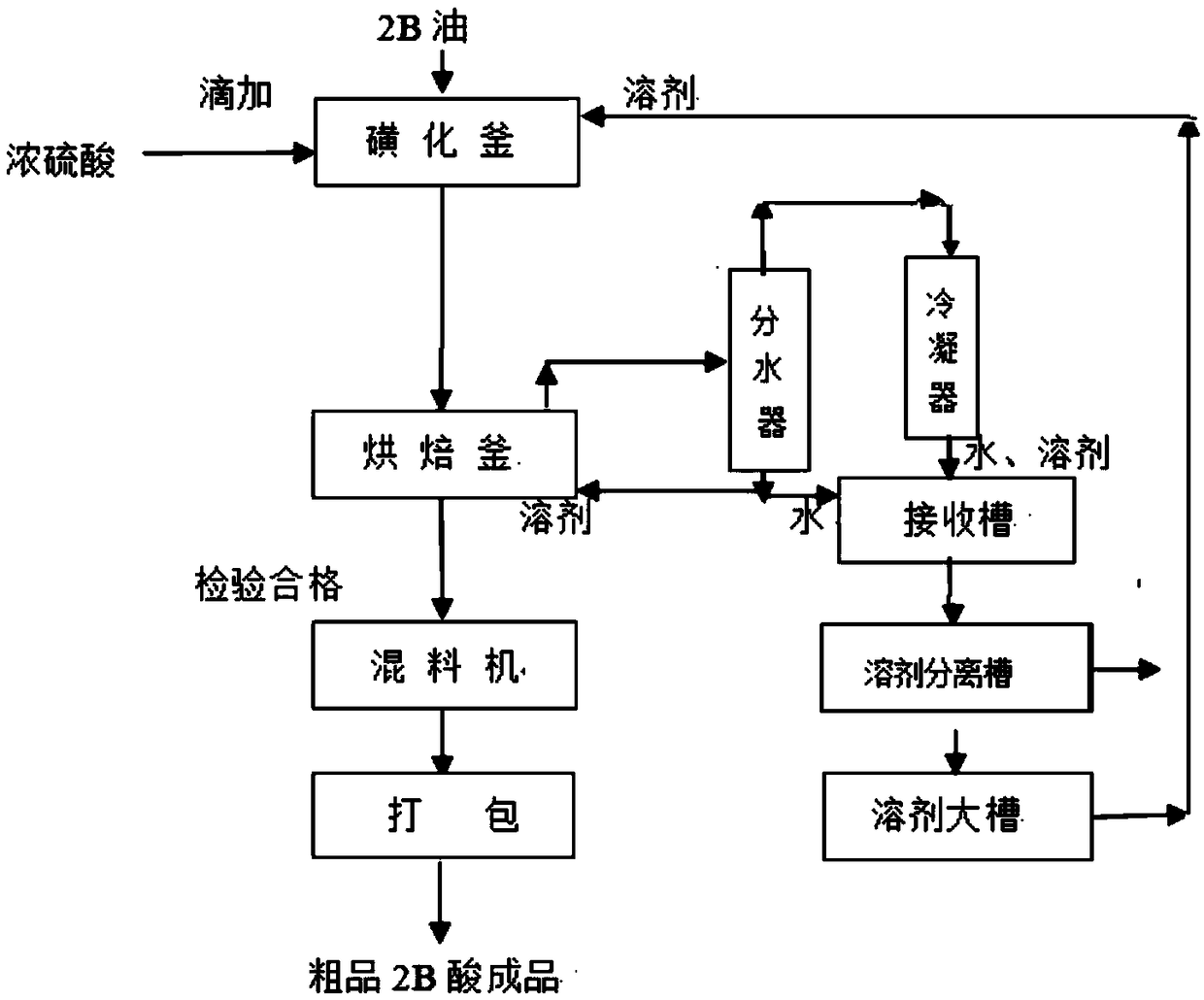

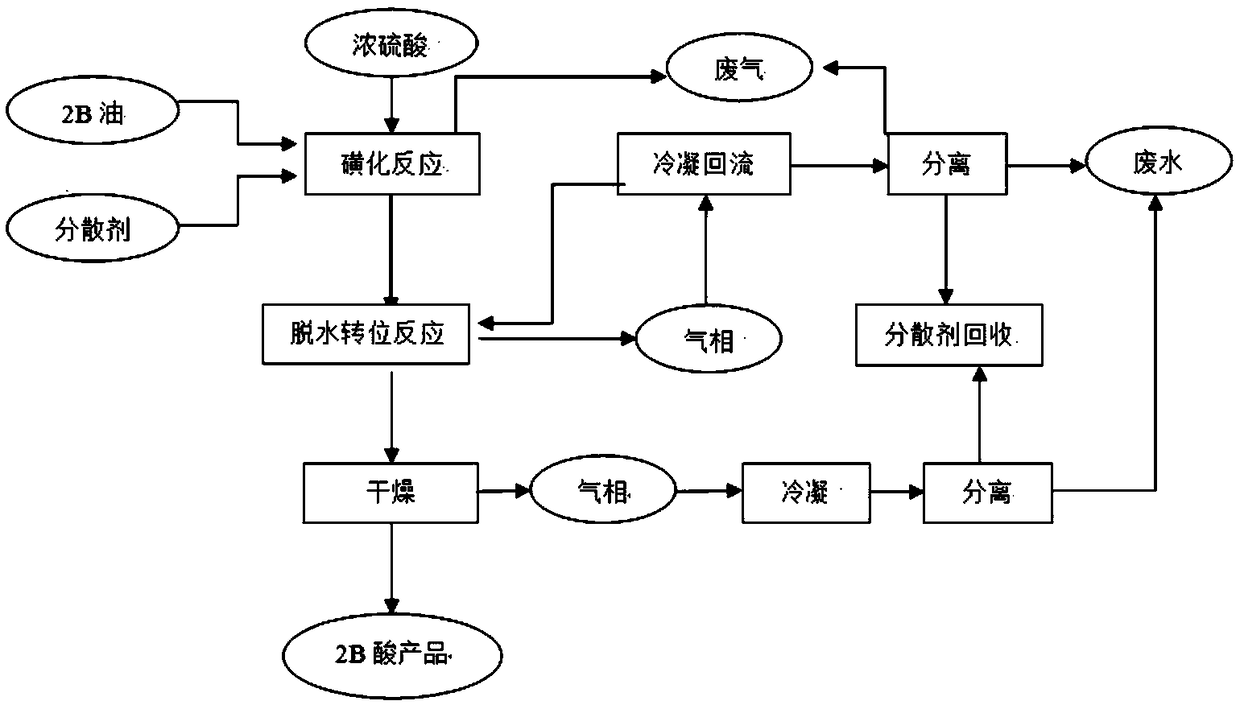

Method used

Image

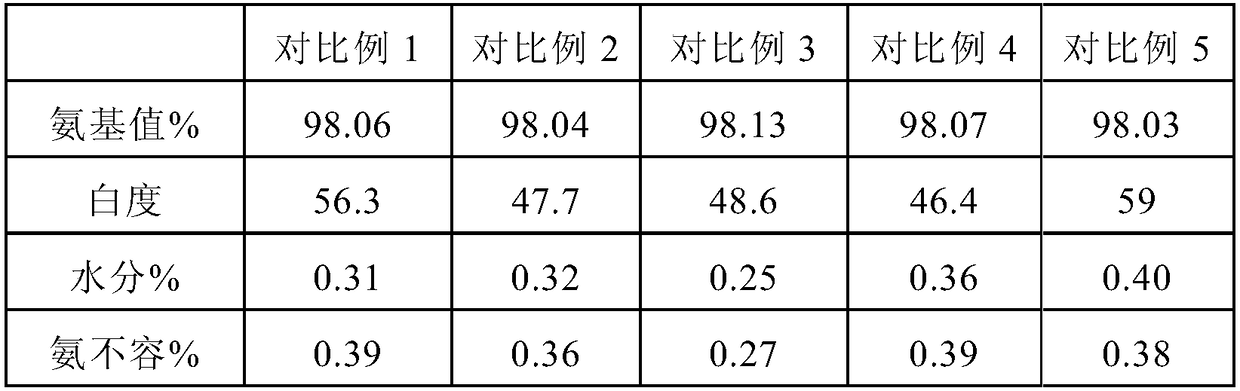

Examples

Embodiment 1

[0034] Content 99.7% 2B oil 700kg, dispersant (dichlorobenzene: D60 = 3:2, mass ratio) 1900kg, put into sulfonation reaction kettle; add 98% concentrated sulfuric acid 493kg after 50min, control the temperature of cooling circulating water at 100℃ Below; after the addition of sulfuric acid, start to heat up, keep the temperature at 126°C for 2 hours, transfer the material to the baking kettle to raise the temperature to 168°C, and carry out the dehydration and transposition reaction. The temperature of the heat transfer oil outlet of the baking kettle is controlled at about 190°C; Switch to the water separator after 30 minutes of solvent, control the gas phase temperature at the outlet of the water separator at 96°C, keep warm and dehydrate under normal pressure for 12 hours; after 12 hours, take a sample and test, the acid content of liquid chromatography 2B is 98.4%, start vacuum drying, Control the temperature of the heat transfer oil outlet of the baking kettle at 180°C, dr...

Embodiment 2

[0036] Content 99.7% 2B oil 695kg, dispersant (dichlorobenzene: D60 = 9: 1, mass ratio) 1900kg, put into sulfonation reaction kettle; add 98% concentrated sulfuric acid 487.65kg after 55min, control the temperature of cooling circulating water 100 Below ℃; start to heat up after adding sulfuric acid, keep the temperature at 130°C for 2 hours, transfer the material to the baking kettle to raise the temperature to 170℃, control the temperature of the heat transfer oil outlet of the baking kettle at about 190℃; switch to Water separator, control the gas phase temperature at the outlet of the water separator at 95°C, keep warm and dehydrate under normal pressure for 12 hours; after 12 hours, take a sample and test, the acid content of liquid chromatography 2B is 97.9%, start vacuum drying and drying, control the heat transfer oil of the baking kettle Oil outlet temperature 180°C, drying for 5.5 hours, sampling test: amino value 98.20%, whiteness 80.6, moisture 0.24%, ammonia insolu...

Embodiment 3

[0038] Content 99.7% 2B oil 694.8kg, dispersant (dichlorobenzene: D60 = 7:3, mass ratio) 1900kg, put into sulfonation reaction kettle; add 98% concentrated sulfuric acid 487.8kg after 60min, control the temperature of cooling circulating water Below 100°C; start to heat up after adding sulfuric acid, keep the temperature at 130°C for 2 hours, transfer the material to the baking kettle and raise the temperature to 168°C, and control the temperature of the heat transfer oil outlet of the baking kettle at about 190°C; switch after 30 minutes for heat preservation and water outlet. To the water separator, control the gas phase temperature at the outlet of the water separator at 96°C, keep warm and dehydrate under normal pressure for 13 hours; after 13 hours, take a sample and test, the acid content of liquid chromatography 2B is 98.5%, start vacuum drying, and control the heat conduction of the baking kettle Oil outlet temperature 180°C, dry for 5 hours, sampling test: amino value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com