Light ageing resisting finishing method for aromatic polyamide fabric

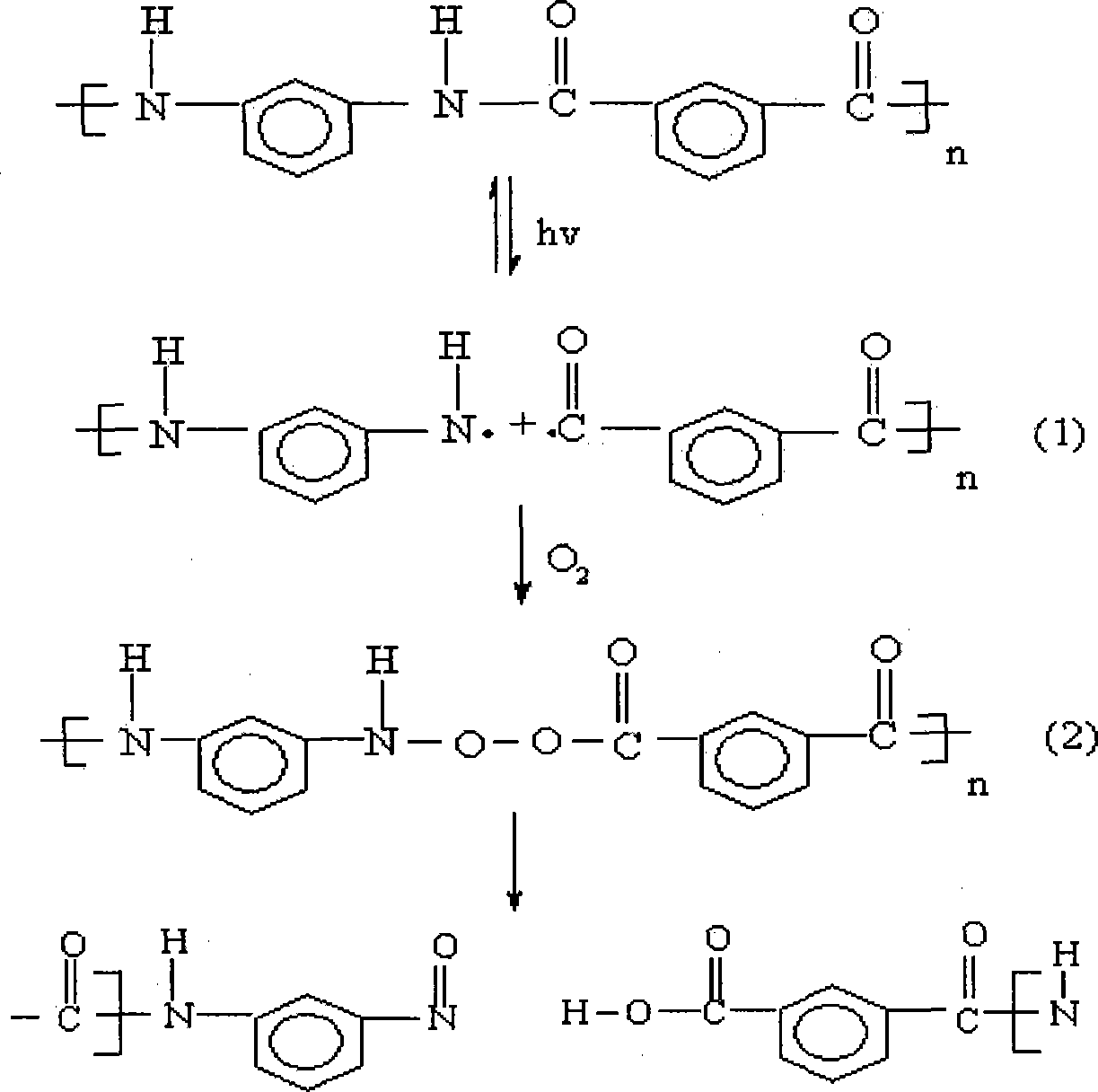

An aromatic polyamide, anti-photoaging technology, used in fiber processing, fiber types, textiles and papermaking, etc., can solve problems such as chemical bond damage, polymer aging, etc., to achieve safe industrial use, improved radiation resistance, UV resistance Performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment one: get U.S. DuPont company aramid fiber (commercial brand: M100) fabric 100KG, in the high-temperature high-pressure dyeing machine commonly used, clean the oil stain on the fabric surface with the nonionic surfactant of 0.5g / l (commonly referred to as pretreatment ), after the pretreatment, add 20KG anti-aging reagent emulsion to the dyeing solution, slowly raise the temperature to 120°C, and dye for 1.5h. After dyeing, it is washed with 0.1g / l surfactant, and after drying, a flame-retardant fabric with excellent anti-aging performance can be obtained. The comparison of the mechanical properties of the fabric before and after anti-aging treatment is shown in Table 1.

[0017] Table 1 Comparison of mechanical properties of aromatic polyamide fabrics before and after anti-aging treatment

[0018] Breaking strength (N)

[0019] Note: The aging conditions here are: 360W, 280~350nm wavelength ultraviolet light source, [UV irradiation intensity is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com