Energy-saving texture thermal insulation coating used for building external wall

A technology for building exterior walls and thermal insulation coatings, used in reflection/signal coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of low adhesion, weak alkali resistance, and high paint consumption. Unique spatial viewing angle, preventing discoloration and falling off, and overcoming the effect of external stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

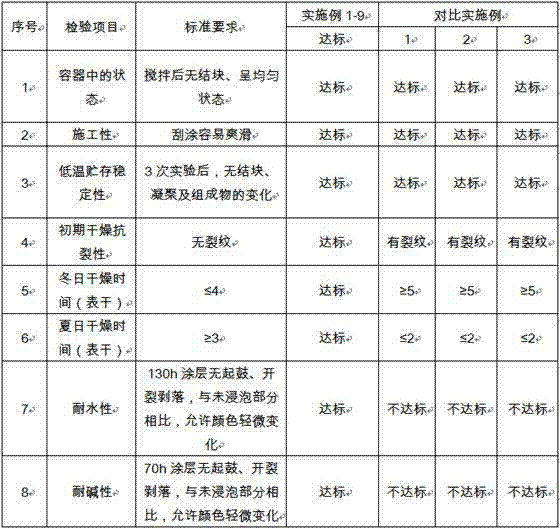

Examples

Embodiment 1

[0070] The heat-insulating coating with texture for energy-saving building exterior walls is composed of the following raw materials in parts by weight:

[0071] 10 parts of water, 40 parts of hand feeling filler, 15 parts of quartz sand, 8 parts of silicon-based active glue, 6 parts of putty, 12 parts of diphenylguanidine, 2 parts of zinc stearate, 1 part of organic zirconium complex, dimethyl 3 parts of aniline, 4 parts of pentaerythritol, 6 parts of modified floating beads, and 1 part of textured particles; the preparation of textured particles includes adding 6 parts of chlorinated paraffin, 3 parts of EPDM, and 4 parts of silane coupling agent by weight. With 1.2 parts of phenolic main antioxidant 1010 and auxiliary antioxidant 168 mixed with 1.2 parts by weight ratio 3: 7 mixture blending modified plasticization, extrusion granulation to obtain; wherein, feel filler is polyurethane fluff powder Mixture with elastic powder, acrylic fluff powder and elastic powder; putty f...

Embodiment 2

[0087] The heat-insulating coating with texture for energy-saving building exterior walls is composed of the following raw materials in parts by weight:

[0088] 15 parts of water, 50 parts of hand filler, 20 parts of quartz sand, 13 parts of silicon-based active glue, 9 parts of putty, 18 parts of diphenylguanidine, 4 parts of zinc stearate, 3 parts of organic zirconium complex, dimethyl 5 parts of aniline, 7 parts of pentaerythritol, 3 parts of modified floating beads, 3 parts of texture particles; the preparation of texture particles includes adding 10 parts of chlorinated paraffin, 7 parts of EPDM, 1 part of aluminate coupling A mixture of phenolic primary antioxidant 1010 and auxiliary antioxidant 168 mixed with 0.6 parts of phenolic antioxidant and 0.6 parts by weight ratio of 4:6 is obtained by blending, modifying, plasticizing, and extrusion granulation;

[0089] Wherein, the feel filler is a mixture of polyurethane fluff powder and elastic powder, acrylic fluff powder...

Embodiment 3

[0105] The heat-insulating coating with texture for energy-saving building exterior walls is composed of the following raw materials in parts by weight:

[0106] 12 parts of water, 45 parts of hand filler, 18 parts of quartz sand, 10 parts of silicon-based active glue, 7 parts of putty, 15 parts of diphenylguanidine, 3 parts of zinc stearate, 2 parts of organic zirconium complex, dimethyl 4 parts of aniline, 5 parts of pentaerythritol, 5 parts of modified floating beads, 2 parts of textured particles; the preparation of textured particles includes adding 8 parts of chlorinated paraffin, 5 parts of EPDM, 3 parts of aluminum-titanium composite couple by weight. Joint agent and 0.9 parts of phenolic primary antioxidant 1010 and auxiliary antioxidant 168 mixed in a weight ratio of 3:6 are obtained by blending, modifying, plasticizing, and extrusion granulation;

[0107]Wherein, the feel filler is a mixture of polyurethane fluff powder and elastic powder, acrylic fluff powder and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com