Foamable resin particle and method for preparing foaming material from same

A technology for foaming resin and particles, which is applied in the fields of preparing foamed materials and thermoplastic elastomer foaming materials, can solve the problems of complex process, difficulty in obtaining foamed materials, and high difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

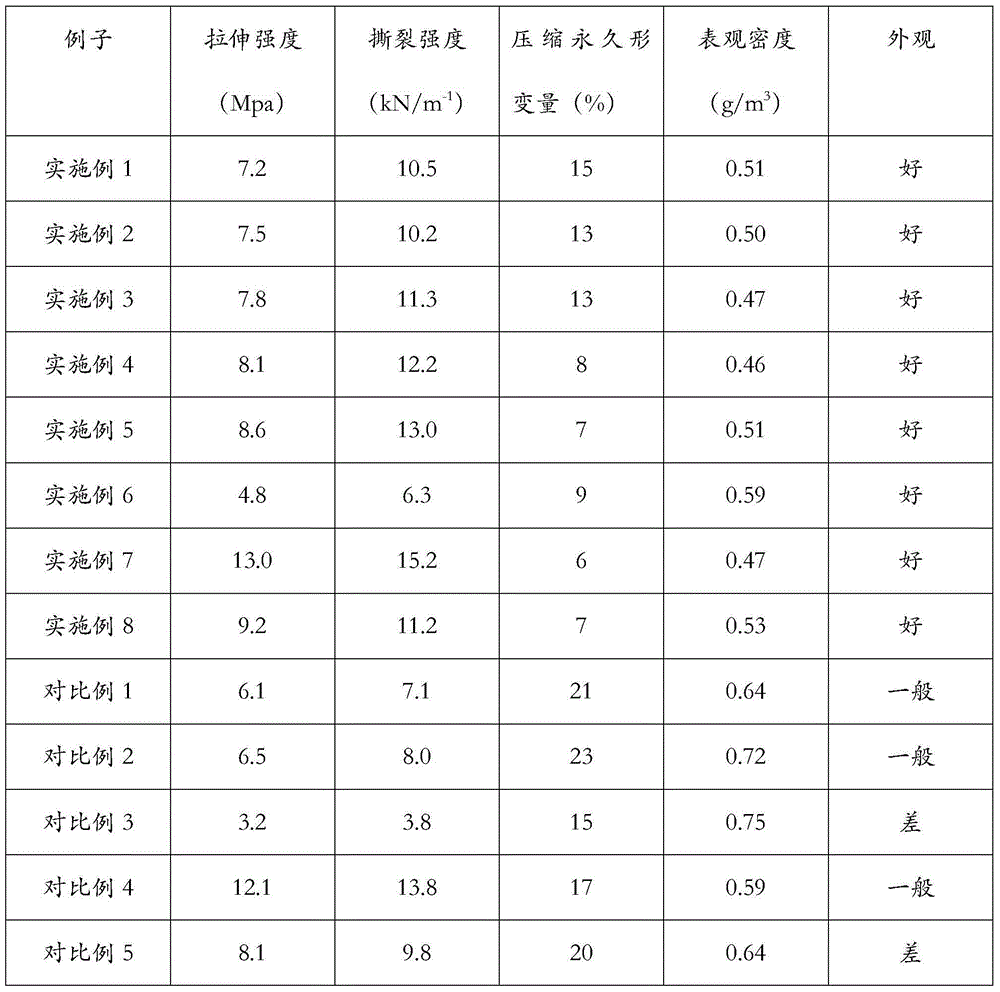

Examples

preparation example Construction

[0045] The raw material for the preparation of the EVA foam material of the present invention also includes cyclopentadiene organosilicon. The cyclopentadiene organosilicon in the present invention refers to an organosilicon compound having a cyclopentadiene group. Specifically, it can be trimethyl Silylcyclopentadiene, tridisilylcyclopentadiene, trimethyl(2,3,4,5-tetramethyl-2,4-cyclopentadien-1-yl)silane, trimethyl Silylpentamethylcyclopentadiene, 1-ethyl-5-(trimethylsilyl)-1,3-cyclopentadiene, trimethyl(1,2,3,4,5-penta Methylcyclopentadienyl)silane, bis(2,3,4,5-tetramethyl-2,4-cyclopentadien-1-yl)silane dimethyl ester, N-tert-butyl-1 , one or more of 1-dimethyl-1-(2,3,4,5-tetramethyl-2,4-cyclopentadien-1-yl)silylamine. The use of cyclopentadiene silicone can further reduce the permanent compression set rate of EVA foam material.

[0046] Another aspect of the present invention relates to a method for preparing the expandable resin particles, comprising: adding the EVA and...

Embodiment 1

[0069] Put 100 parts by weight of A1 and 60 parts by weight of B1 into a kneader for kneading at 70°C, and then use an extruder to extrude and granulate at 80°C to obtain expandable resin particles.

[0070] Weigh each raw material according to the following parts by weight: 100 parts by weight of C1100 parts by weight, 50 parts by weight of the above-mentioned expandable resin particles, after stirring the above-mentioned raw materials in a medium-speed mixer for 20 minutes, they are fed into the mixture with an aspect ratio of 32: 1. In the twin-screw extruder, the temperature of the twin-screw extruder is controlled at 195°C, the speed of the twin-screw extruder is 600rpm, and the pressure is 2MPa. The raw materials are melted and extruded, and cooled and formed in the mold to obtain lightweight hair bubble material.

Embodiment 2

[0072] Put 100 parts by weight of A1 and 60 parts by weight of B2 into a kneader for kneading at 70°C, and then use an extruder to extrude and granulate at 80°C to obtain expandable resin particles.

[0073] Weigh each raw material according to the following parts by weight: 100 parts by weight of C1100 parts by weight, 50 parts by weight of the above-mentioned expandable resin particles, after stirring the above-mentioned raw materials in a medium-speed mixer for 20 minutes, they are fed into the mixture with an aspect ratio of 32: 1. In the twin-screw extruder, the temperature of the twin-screw extruder is controlled at 195°C, the speed of the twin-screw extruder is 600rpm, and the pressure is 2MPa. The raw materials are melted and extruded, and cooled and formed in the mold to obtain lightweight hair bubble material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com