Process for preparing liquefied natural gas (LNG) by low concentration coal bed methane oxygen bearing copious cooling liquefaction

A low-concentration technology of coalbed methane, applied in refrigeration and liquefaction, liquefaction, gas fuel, etc., can solve the problems of refrigerant channel blockage, large fluctuations in methane content, waste of energy, etc., and achieve the effect of saving money and not cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] First, a device for producing natural gas suitable for the process of producing LNG by oxygen-containing cryogenic liquefaction of low-concentration coalbed methane of the present invention will be described.

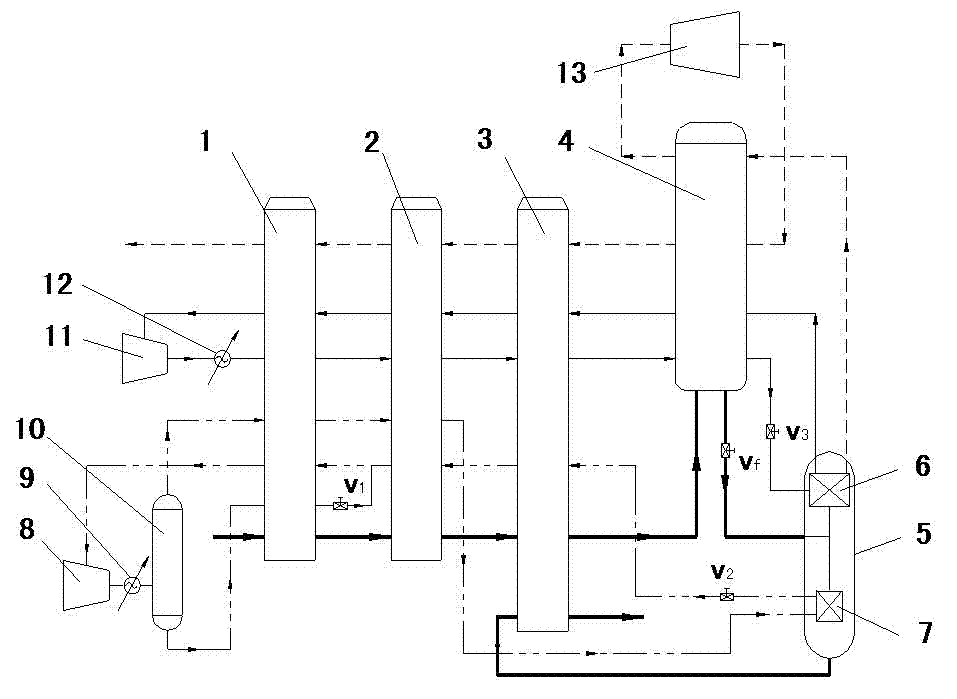

[0034] Such as figure 1 As shown, the low-concentration coalbed methane oxygen-containing cryogenic liquefaction device for producing natural gas includes a main process system and a refrigeration system.

[0035] The main flow system includes the primary heat exchanger 1, the secondary heat exchanger 2, the tertiary heat exchanger 3, the subcooler 4 and the rectification tower 5 along the flow direction of the purified CBM, and the top of the rectification tower 5 is A tower top condenser 6 is set, and a reboiler 7 positioned at the bottom of the tower is arranged in the rectification tower 5 tower, and the nitrogen and oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com