Lead-free high-quality clean aviation gasoline

A kind of aviation gasoline, high-quality technology, applied in the field of aviation gasoline, can solve problems such as lead environmental pollution, and achieve a good innovative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

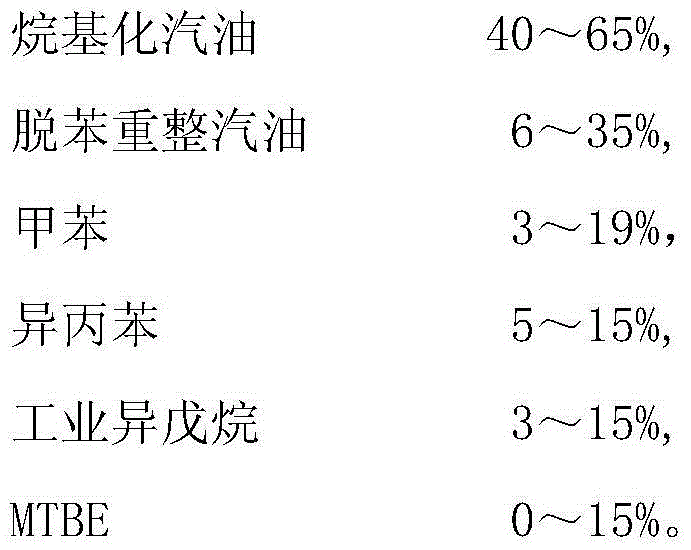

[0027] The components contained in the aviation gasoline of Examples 1-3 and their volume fractions are shown in Table 1, and each component is reconciled to form the aviation gasoline of Examples 1-3 respectively; the corresponding properties are shown in Table 2. It can be seen from Table 2 that the distillation range of aviation gasoline meets the requirements of GB1787-2008; the measured motor octane number, saturated vapor pressure, freezing point and water reaction volume change all meet the requirements of GB1787-2008.

[0028] Table 1 Blending scheme of aviation gasoline

[0029] Composition v%

Industrial isooctane

MTBE

Example 1

10

12

52

8

8

10

—

Example 2

17

10

52

8

13

—

—

Example 3

12

10

55

10

8

—

5

[0030] Table 2 Properties of Modulated Aviation Gasoline

[0031]

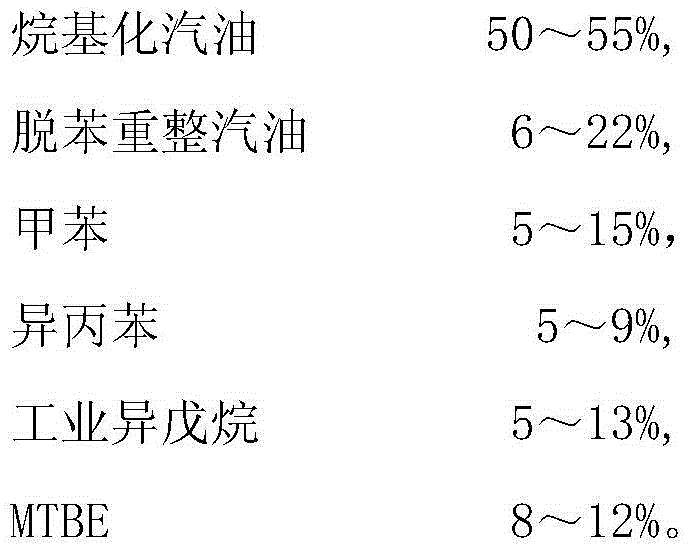

Embodiment 4、5

[0033] Embodiment 4,5 is that the raw material from the refinery is pretreated and used for blending components of aviation gasoline. The corresponding components and their contents are shown in Table 3, and each component is blended to form Examples 4 and 5 respectively. aviation gasoline; its corresponding properties are shown in Table 4. It can be seen from Table 4 that the distillation range of the blended aviation gasoline meets the requirements of GB1787-2008, and the measured motor octane number, saturated vapor pressure, freezing point and water reaction volume change also meet the requirements of GB1787-2008.

[0034] Table 3 Blending scheme of aviation gasoline

[0035]

[0036] Table 4 Oil properties of aviation gasoline

[0037] Distillation temperature / ℃

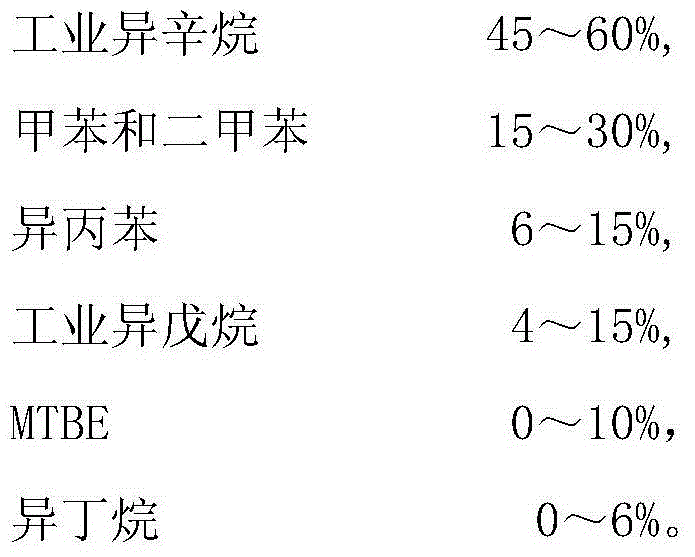

Embodiment 6~8

[0039] Embodiments 6-8 are the same as Embodiments 4 and 5. The raw materials from the refinery are processed and used for the blending components of aviation gasoline. The corresponding components and their contents are shown in Table 5. Each component is blended separately. Form the aviation gasoline of embodiment 6~8; Its corresponding property is as shown in table 6. It can be seen from Table 6 that the distillation range of the blended aviation gasoline meets the requirements of GB1787-2008, and the measured motor octane number, saturated vapor pressure, freezing point and water reaction volume change also meet the requirements of GB1787-2008.

[0040] Table 5 Blending scheme of aviation gasoline

[0041]

[0042] Table 6 Oil properties of aviation gasoline

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com