Graphene infrared heat radiation coating and preparation method thereof

A technology of heat-dissipating paint and graphene, applied in the field of paint, can solve the problems of narrow applicable temperature range, local hot spots, unsatisfactory heat dissipation effect of infrared radiation heat-dissipating paint, etc. The effect of thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] On the other hand, the embodiment of the present invention provides a preparation method of the graphene infrared heat dissipation coating in the above embodiment. In one embodiment, the preparation method of the graphene infrared heat dissipation coating comprises the following steps:

[0045] Step S01. Obtain the raw materials of the graphene infrared heat dissipation coating components: weigh the components contained in the graphene infrared heat dissipation coating according to the above-mentioned invention embodiment;

[0046] Step S02. Prepare composite infrared functional nanofillers: ball mill the weighed one-dimensional infrared functional nanomaterials, graphene, and hard functional auxiliary fillers to obtain composite infrared functional nanofillers;

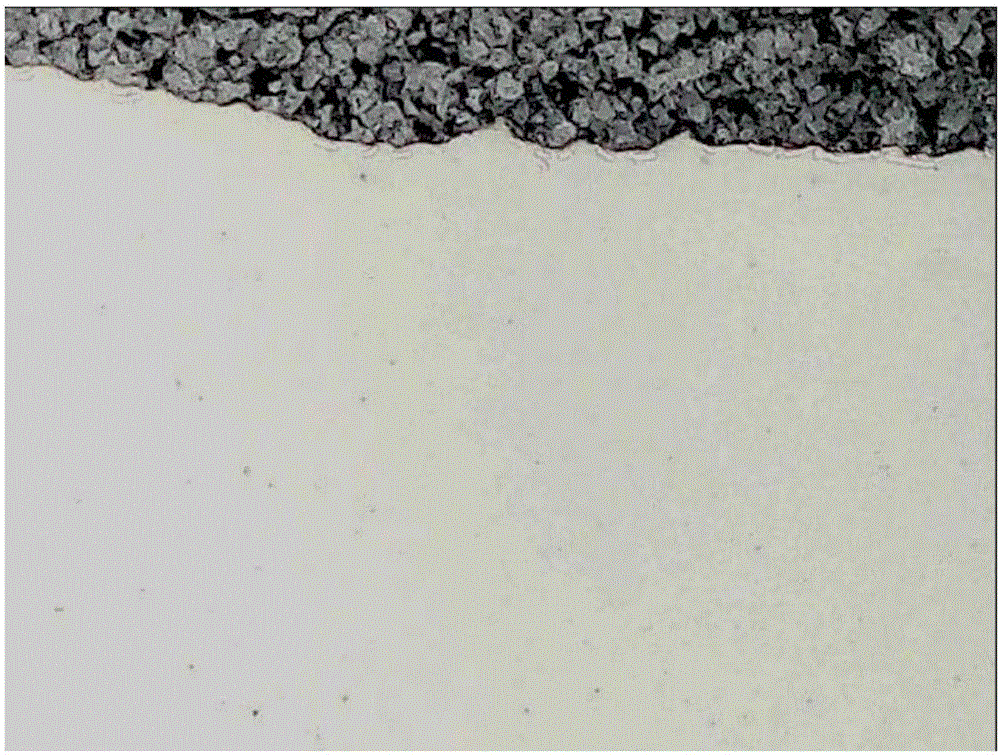

[0047] Step S03. Prepare heat-dissipating mixed slurry: dissolve the film-forming resin in a solvent and mix with the composite infrared functional nano-filler, then adjust the viscosity, pass through a gradin...

Embodiment 1

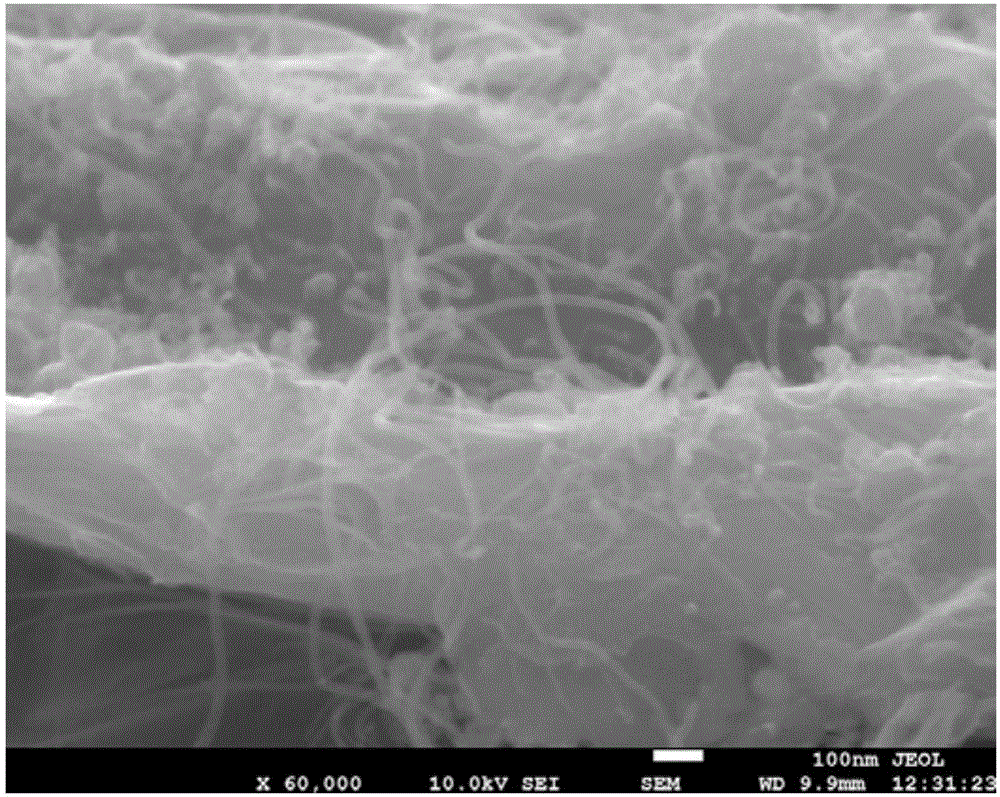

[0058] This embodiment provides a graphene infrared heat dissipation coating and a preparation method thereof. The graphene infrared heat dissipation coating includes: 1g graphene (3 layers on average, sheet diameter 0.1-2μm), 50g silicon carbide nanowires (nanowire diameter 20-100nm), 1.5g single-walled boron nitride nanotubes (tube diameter 1.5-5nm, average tube length 25 μm), 3g of WC-Co hard functional auxiliary filler, 45 parts of epoxy resin E-44 resin, 3% curing agent ethylenediamine.

[0059] Its preparation method comprises the following steps:

[0060] S11: Weigh 1g graphene (average number of layers 3 layers, sheet diameter 0.1-2μm), 50g silicon carbide nanowires (nanowire diameter 20-100nm), 1.5g single-walled boron nitride nanotubes (diameter 1.5 -5nm, the average tube length is 25 μm), 3g of WC-Co hard functional auxiliary fillers are placed in the ball milling tank of the planetary ball mill;

[0061] S12: Select balls with diameters of 0.5, 3, and 5 mm, where...

Embodiment 2

[0070] This embodiment provides a graphene infrared heat dissipation coating and a preparation method thereof. The graphene infrared heat dissipation coating includes: 5g of graphene (2 layers on average, sheet diameter 0.05-1 μm), 25g of infrared functional radiation nanotube silicon carbide nanowire (nanowire diameter 150-200nm), 2g of multi-walled nitrogen Boron nanotubes (diameter 10-15nm, average tube length 60μm), 2.5g of WC-Co: NbC-Co 1:2 hard functional auxiliary filler, 10g of polyvinylidene fluoride (PVDF).

[0071] Its preparation method comprises the following steps:

[0072] S21: Weigh 5g of graphene (average number of layers 2 layers, sheet diameter 0.05-1μm), 25g infrared functional radiation nanotube silicon carbide nanowire (nanowire diameter 150-200nm), 2g multi-walled boron nitride nanotube (tube diameter 10-15nm, average tube length 60μm), 2.5g of WC-Co:NbC-Co 1:2 hard functional auxiliary filler is placed in the ball mill tank of the planetary ball mill; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com