A steam heating and setting device for cardboard forming

A heating and setting, steam technology, applied in the field of cardboard heating, can solve the problems such as the effect of heat drying cannot be effectively controlled, the surface temperature of the heating plate is unstable, and the fluidity of heat energy is poor, and achieves simple structure, good energy saving effect, and thermal conductivity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

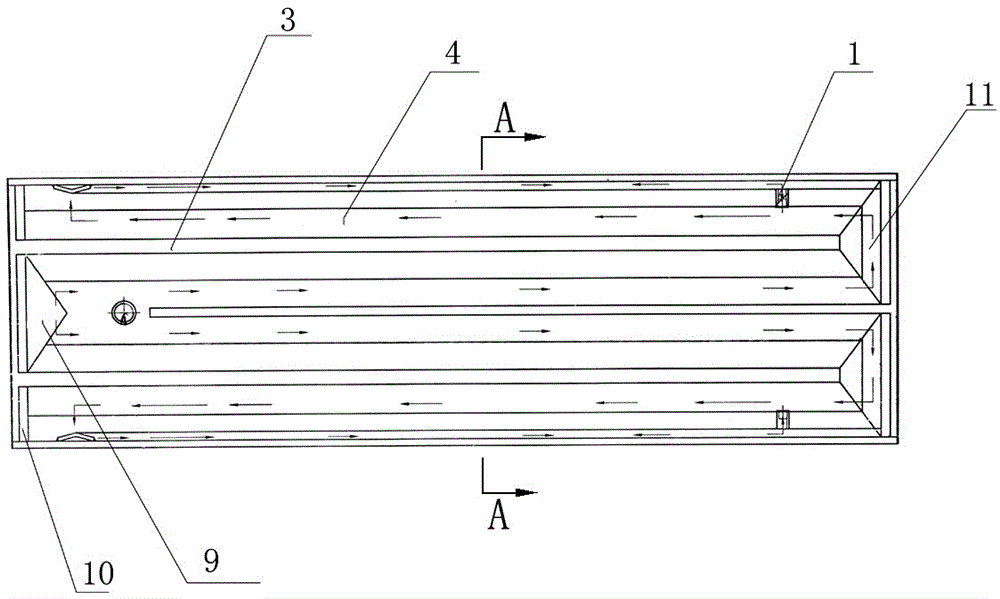

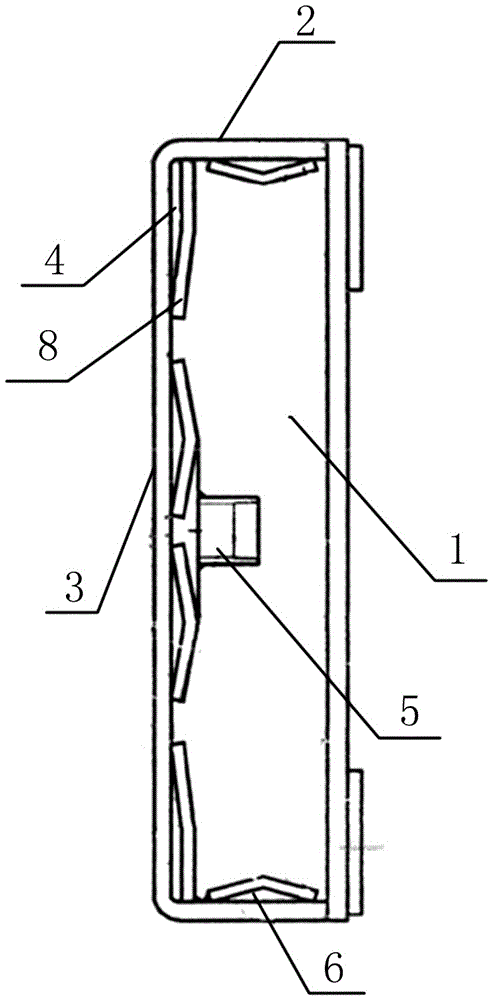

[0011] The present invention will be described in detail below in conjunction with the drawings: figure 1 , 2 As shown, the steam heating sizing device for cardboard molding according to the present invention includes a heating plate body 2 with a heating inner cavity 1. In the heating inner cavity 1 adjacent to the heating base plate 3, a back and forth coil is provided. The steam flow passage 4, wherein an air inlet 5 is provided on the middle steam flow passage on one end side, and the middle steam flow passage provided with the steam air inlet 5 is used as the starting point to be divided into two steam flow passages 4 arranged vertically opposite each other. The two steam flow passages 4 are finally connected with the side wall steam flow passages 6 on the two side walls respectively, and the end side walls of the side wall steam flow passages 6 are respectively provided with steam exhaust ports 7 and the heating cavity 1 The thickness is thinner, and the steam flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com