Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Prevent oxidative combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid

InactiveCN104498164AImprove the lubrication effectImprove rust resistanceLubricant compositionWater basedCombustion

The invention discloses anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid. The anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is prepared from the following components in percentage by mass: 5 to 10 parts of base oil, 5 to 15 parts of an oiliness agent, 10 to 25 parts of organic amine, 5 to 15 parts of a synthetic rust inhibitor, 15 to 25 parts of a functional polyether surfactant, 0.2 to 3 parts of an extreme pressure additive, 3 to 8 parts of a solubilizer, 0.1 to 2 parts of a metal corrosion inhibitor, 0.1 to 2 parts of a magnesium alloy anti-fading agent, 0.1 to 2 parts of a bactericide, 0.1 to 1 part of an antifoaming agent, 0.1 to 10 parts of a pH regulator and 15 to 30 parts of water. The nticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is outstanding in ticorrosive and lubricating and has water resisting performances, and is high in cleaning and cooling effects, and effectively reduces the major technical problems such as corrosion, oxidative combustion, fading of magnesium alloy, demulsification and layering of the cutting fluid in the magnesium alloy processing process; the pH ranges from 9 to 11, and therefore, the demand of magnesium alloy cutting process can be met well.

Owner:苏州禾川化学技术服务有限公司

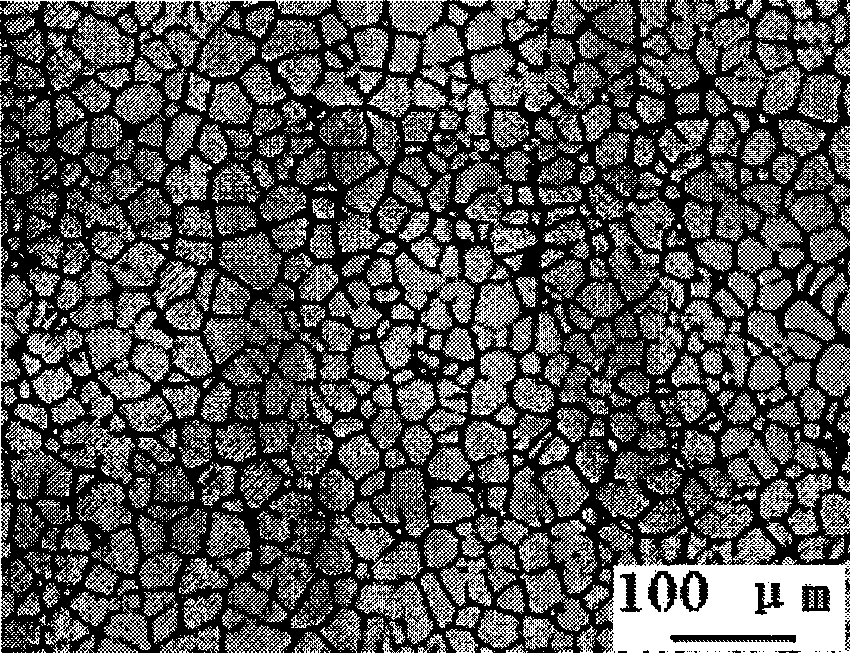

Preparation of nontoxic magnesium alloy material for biological implantation

The invention relates to a method for preparing a magnesium alloy material suitable for biological implantation, which comprises the following steps: preparing raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.5 to 1.9 percent of Mn, 0.6 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; or preparing the raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.3 to 0.9 percent of Zr, 0.5 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; preheating smelting equipment and adding the Mg into the raw materials; heating the mixture under the protection of argon gas with the flow rate of between 5 and 6 L / min and the pressure of 14 MPa; adding a fire retardant into the molten liquid when the temperature of the molten liquid reaches between 650 and 660 DEG C, raising the temperature of the molten liquid to between 700 and 720 DEG C, adding other alloy elements into the molten liquid respectively, and performing melting reaction; and stirring the mixture until the mixture is uniformly mixed after alloy is completely molten, keeping the mixture stand for 30 to 40 minutes, pressing a deslagging agent into the solution for deslagging, casting the alloy solution into a cast die after keeping the alloy solution for 10 to 20 minutes at the temperature of between 690 and 710 DEG C, and preparing a Mg-Mn series or Mg-Zr series biomedical magnesium alloy material ingot.

Owner:NORTHEASTERN UNIV

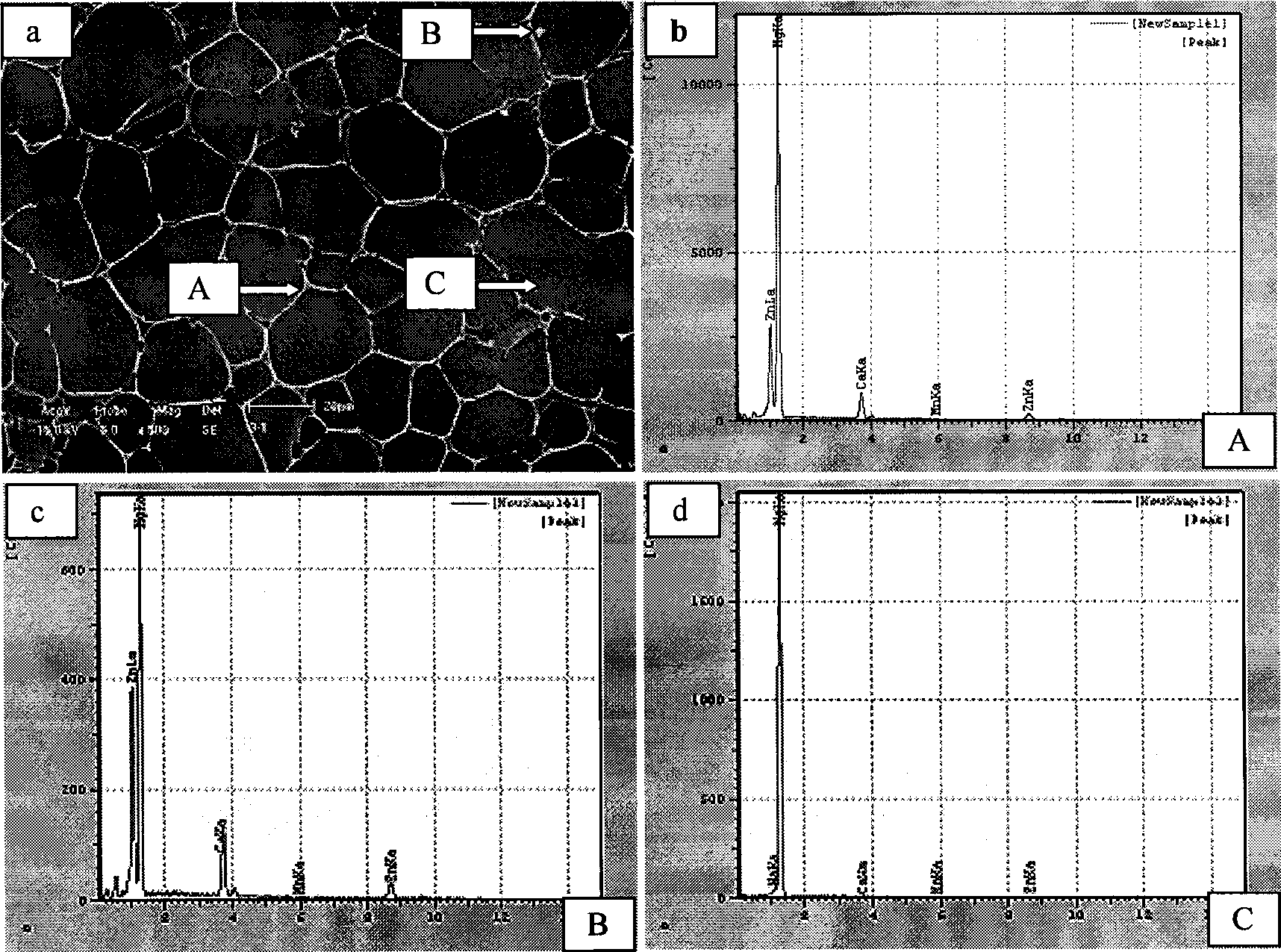

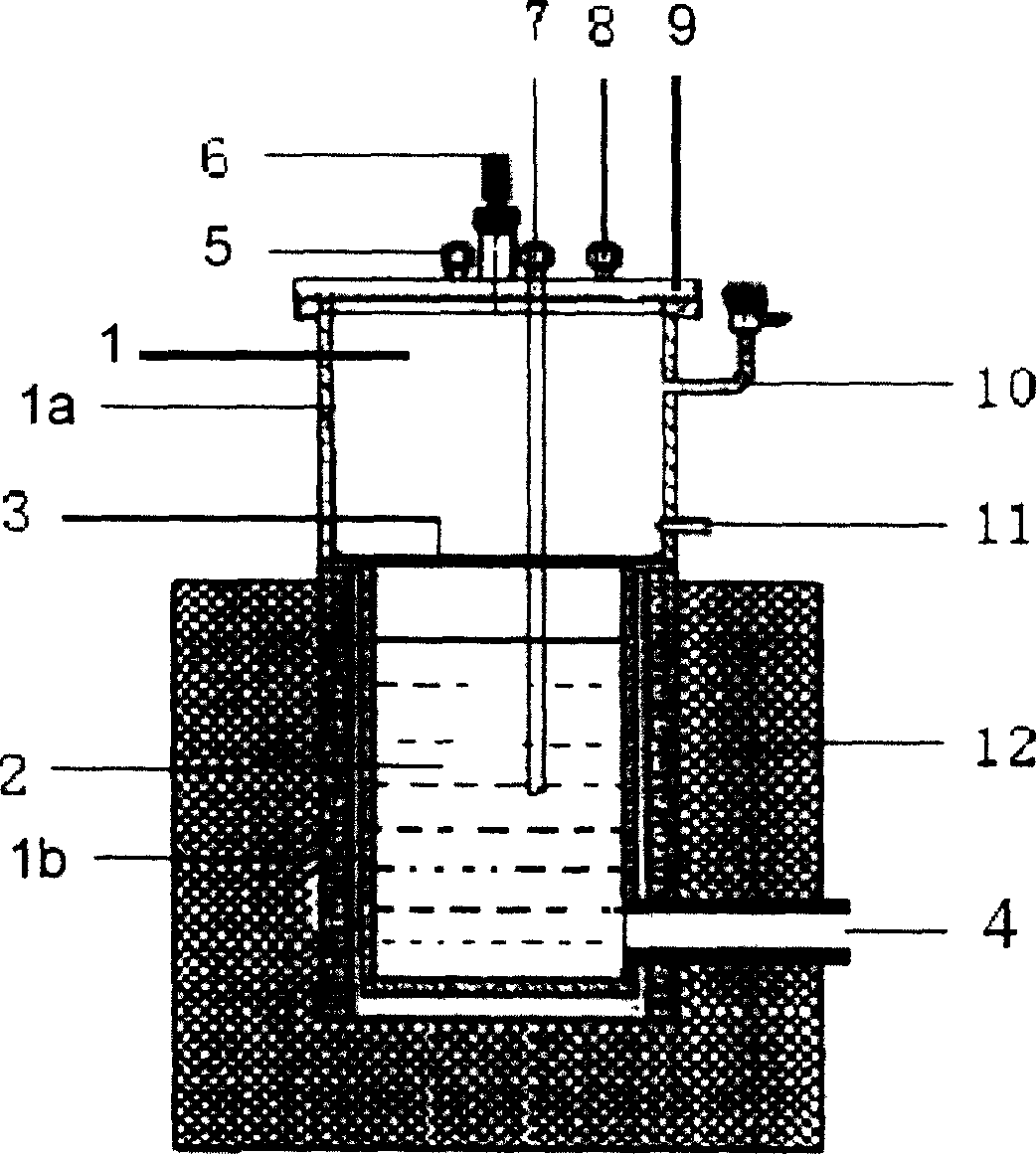

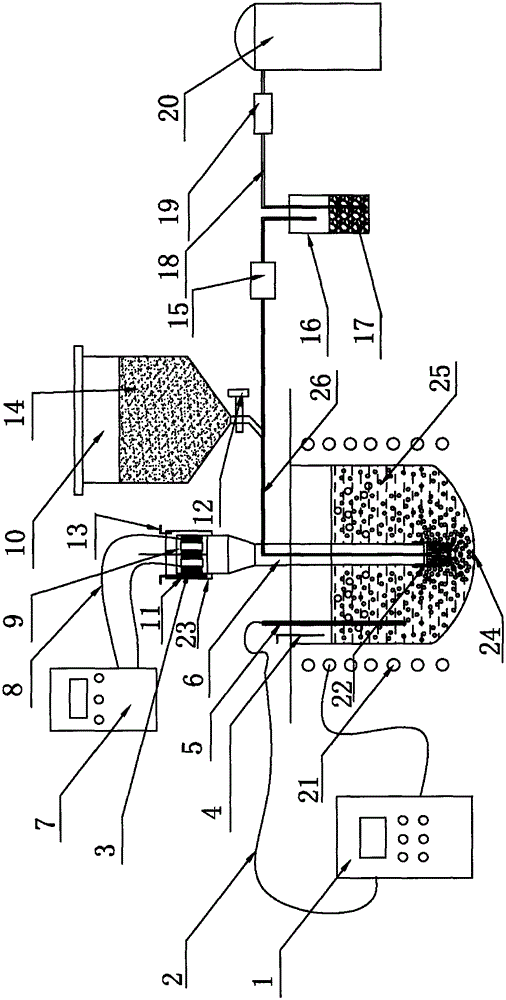

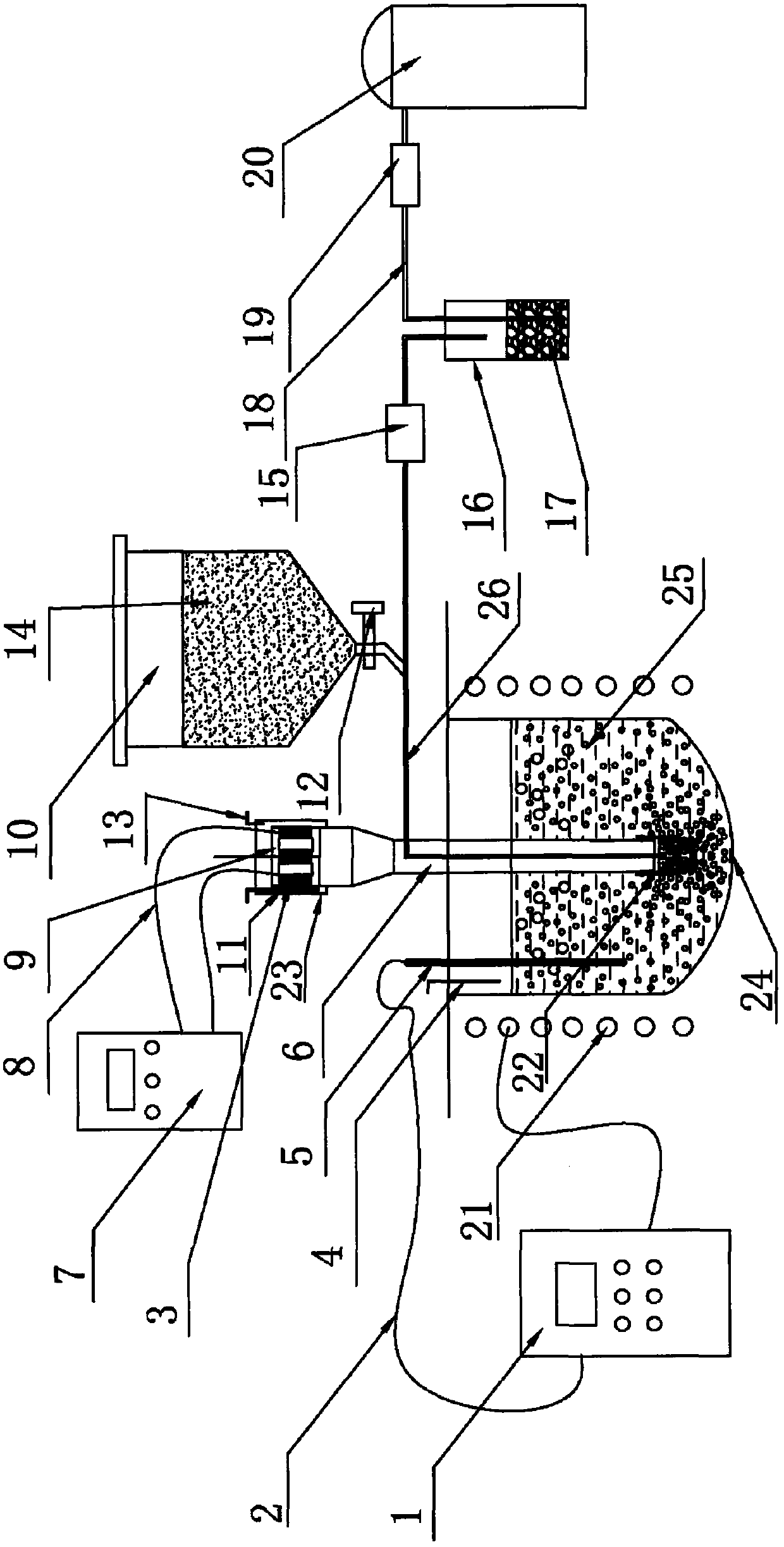

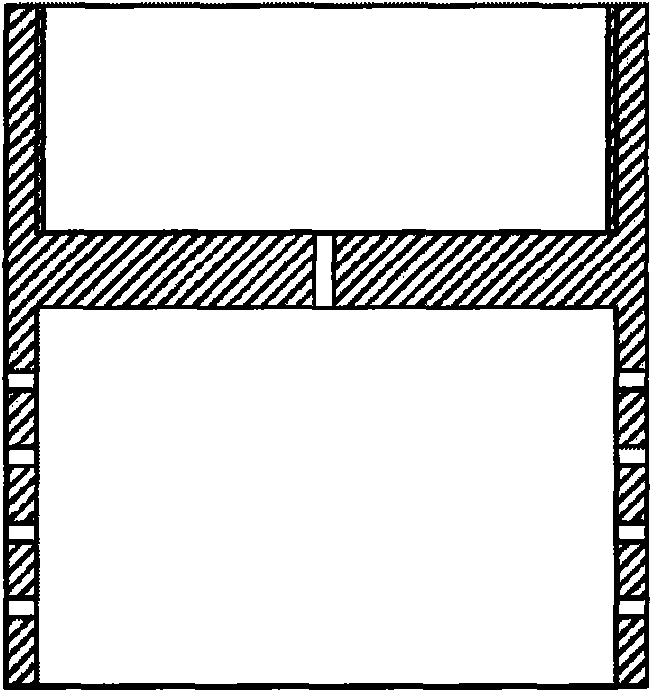

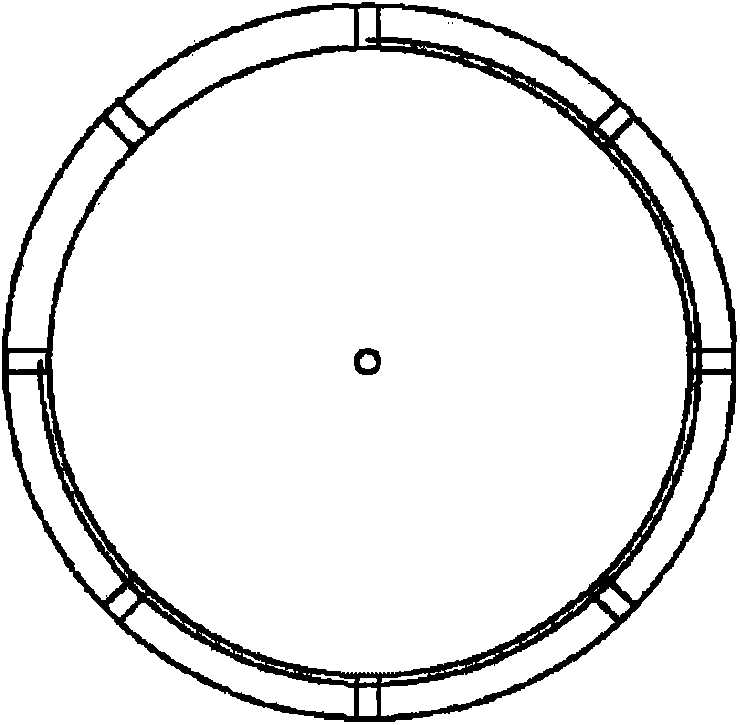

Device and method for producing integrated magnesium base composite material

InactiveCN101219471ADual control formingPrevent oxidative combustionMagnesium matrix compositeVacuum pump

The invention discloses a preparation device of integral magnesium matrix composite, which consists of a melting device and a squeezing device. The invention is characterized in that the concave mode barrel and the forming die bottom exit of the squeezing device are sealed in ejector pins; the upper end port of the concave barrel is sealed in cushion block to form a sealed cavity. The melting cavity of the melting device and the mould cavity of squeezing device are communicated through feed liquor of a three-way pipe; the third end of the three-way liquid inlet pipe is communicated with the vacuum pump through pipes; the liquid level sensor is inserted into the cavity of the melting cavity and connected with the cap of crucible lid by adopting self-sealing thread. By adopting the design of the preparation device of the integral magnesium matrix composite, the invention processes the required magnesium alloy for preparation magnesium matrix composite by the four steps melting, pouring, impregnating and extrusion forming in a totally closed integral device.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

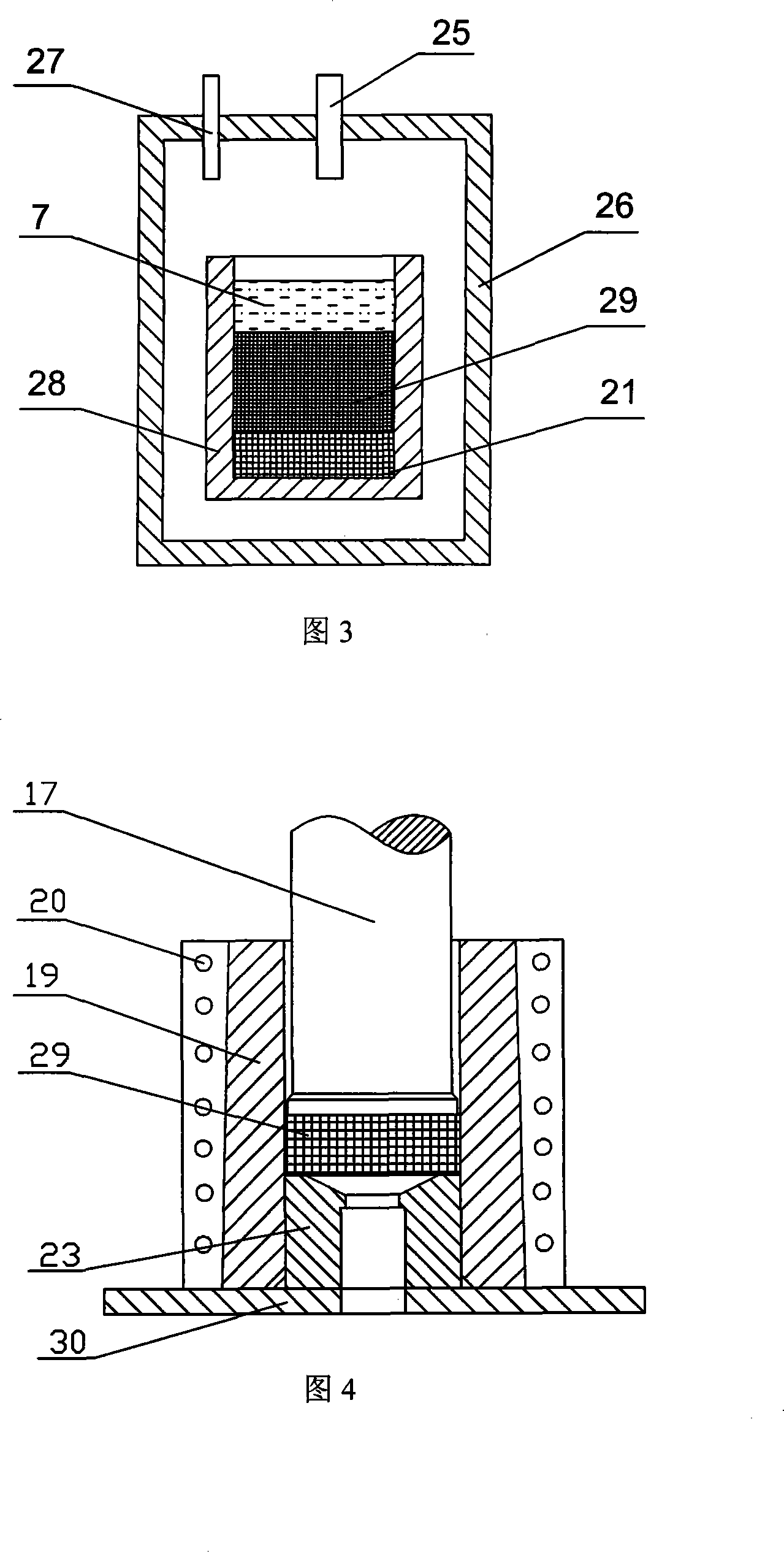

Mg alloy vacuum sealing smelter and method for preventing Mg alloy from oxidation burning

InactiveCN1651840AReduced sealing requirementsPrevent oxidative combustionCrucible furnacesMetallic materialsHeating furnace

The present invention relates to a magnesium alloy vacuum sealed smelting farnace and method for preventing magnesium alloy from being oxidated and burned. Said smelting furnace includes smelting crucible, heating furnace, protective gas input device, vacuum system and gas concentration analyzer. The described smelting crucible includes the crucible lower portion for smelting magnesium alloy and its upper portion for containing protective gas. Besides, said invention also provides the concrete steps of method for preventing magnesium alloy from being oxidated and burned.

Owner:TSINGHUA UNIV

Friction material, brake pad with friction material and method for manufacturing brake pad

ActiveCN106763364AImprove thermal stabilityHigh impact strengthOther chemical processesFriction liningVolumetric Mass DensityEngineering

The invention provides a friction material, a brake pad with the friction material and a method for manufacturing the brake pad. According to the friction material, through reasonable selection and matching of all raw material components, especially by controlling the proportion of inorganic matter and organic matter and adjusting the variety of the inorganic matter, a synergetic cooperation function is generated among all the components, and finally the brake pad made of the friction material has the beneficial effects of being good in heat stability, high in impact strength, large in hardness and resistant to wear; and besides, the density of the friction material is small, and the dead weight of the friction material under the same size condition is small, that is, the friction material is small in consumption when used for manufacturing the brake pad, so that the production cost of the brake pad can be lowered effectively on the premise of not sacrificing the performance of the brad pad; and accordingly, the friction material is suitable for braking of rail vehicles with the higher speed, the larger thermal load and the larger passenger capacity.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

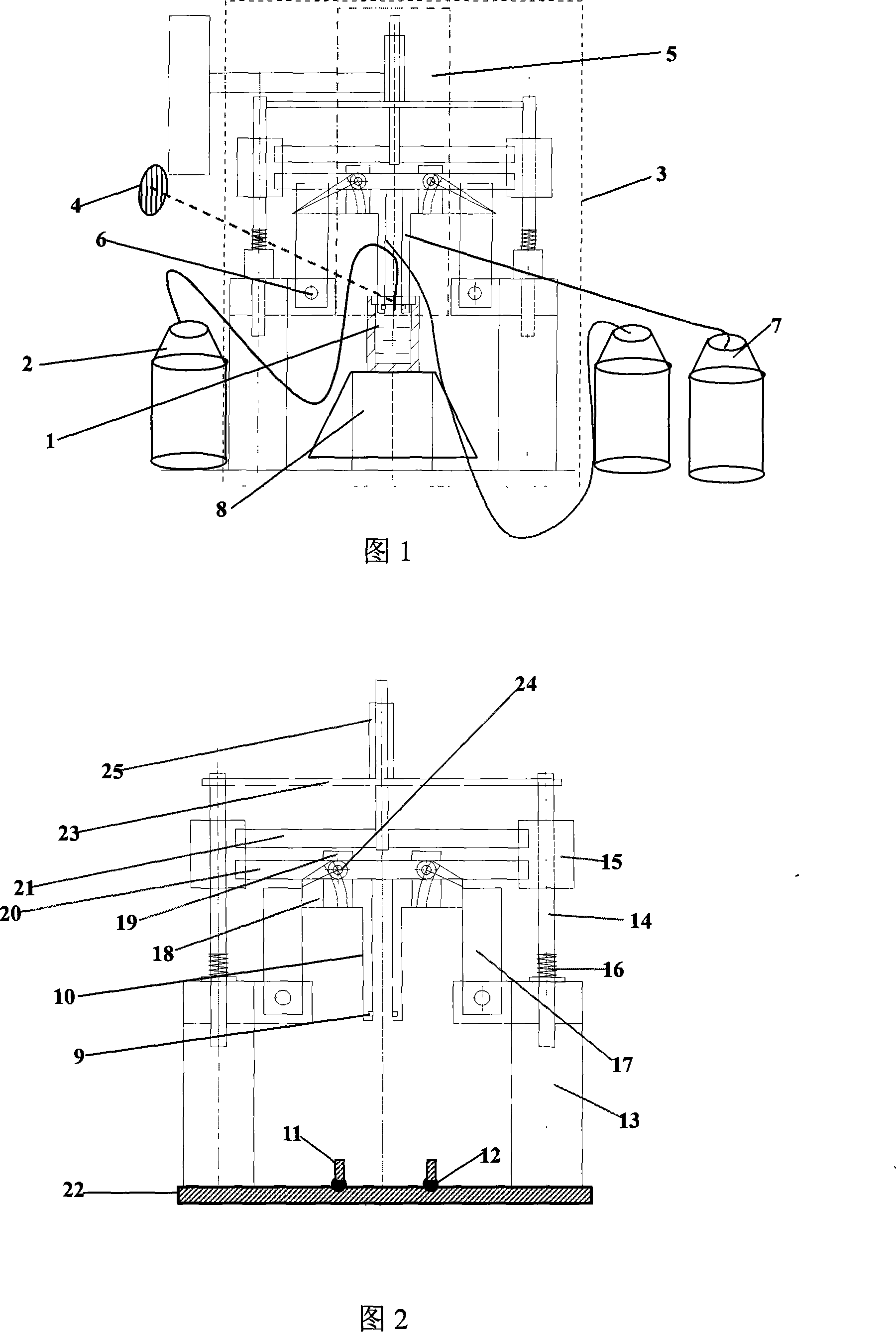

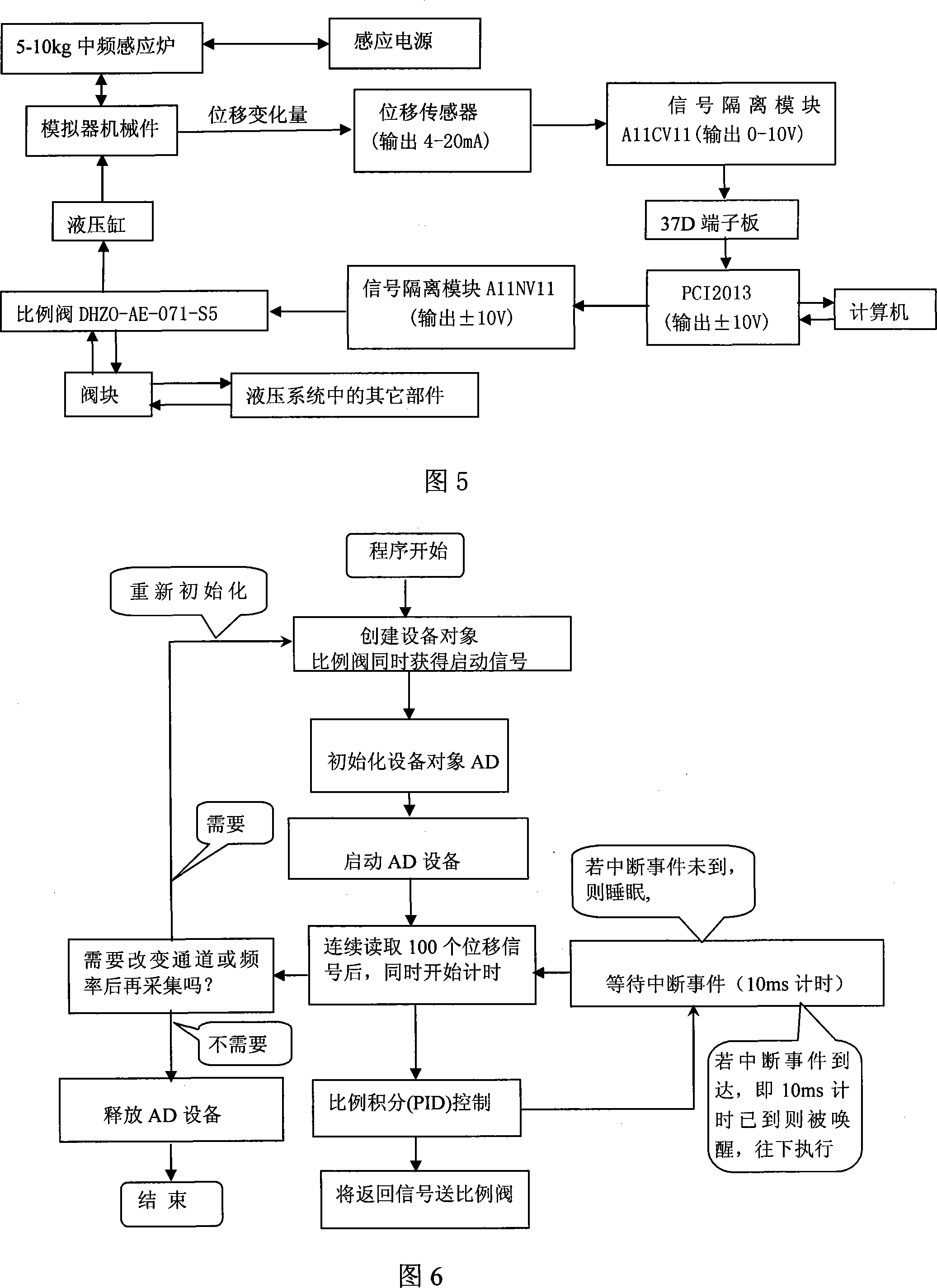

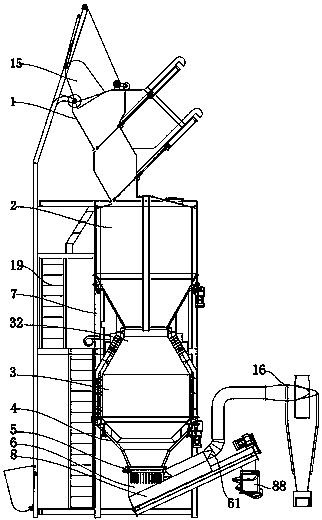

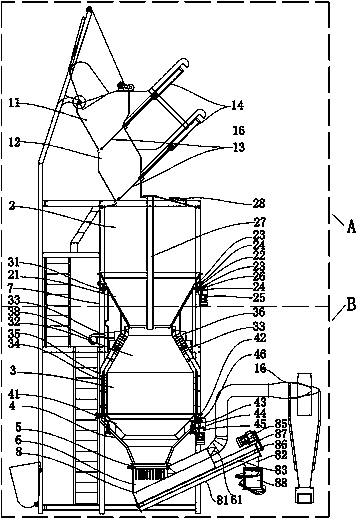

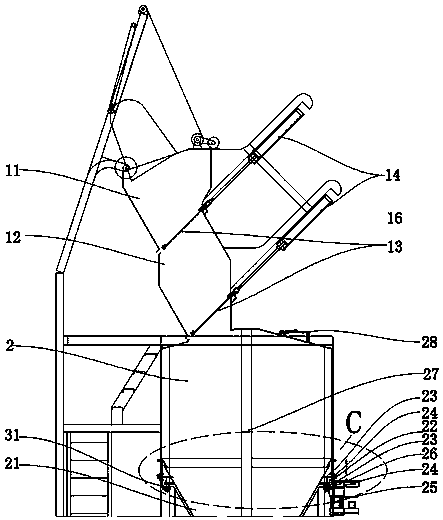

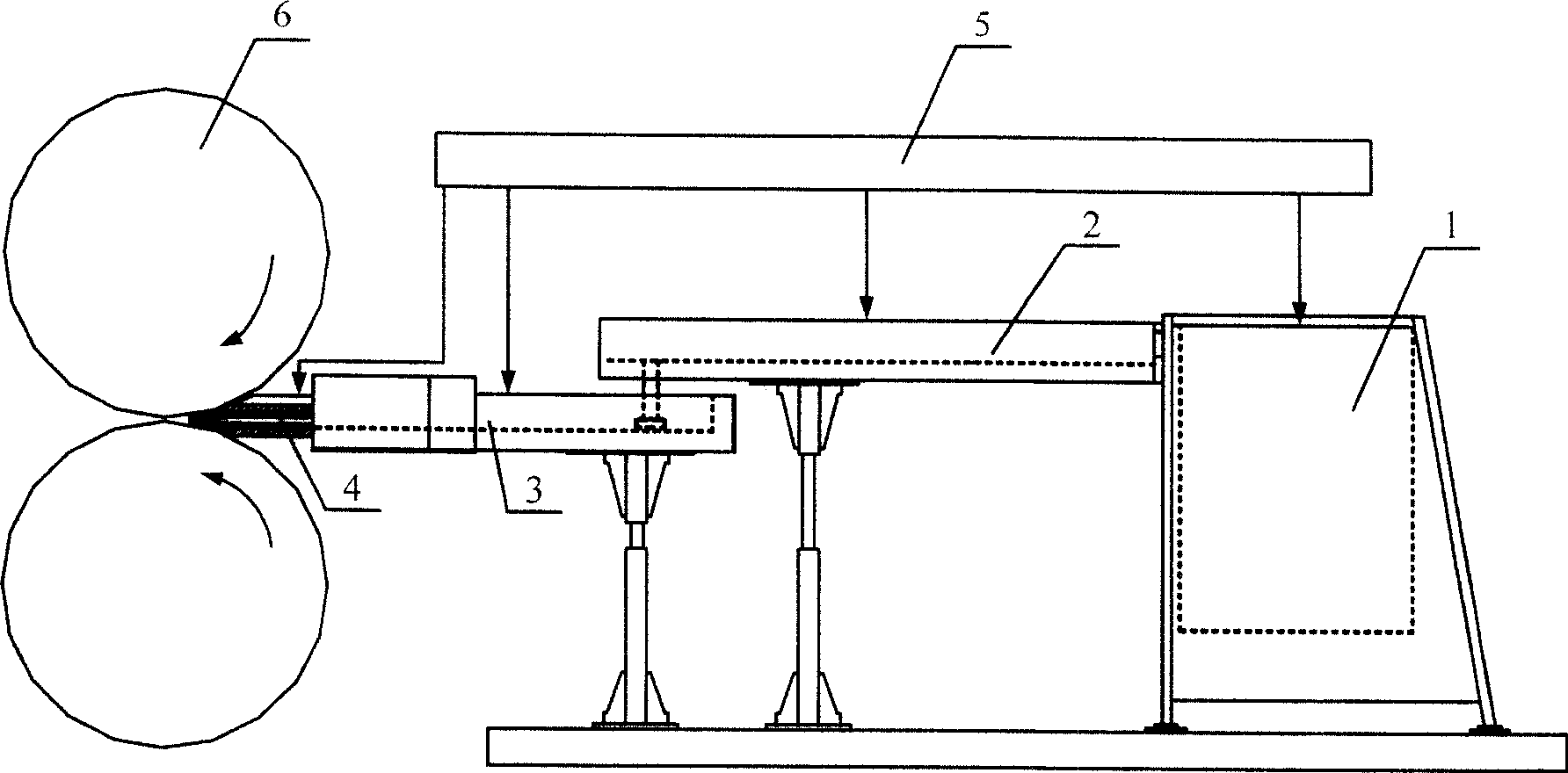

Dual-roller thin-belt casting rolling analog equipment as well as usage and control method thereof

InactiveCN101226701AThe simulation effect is realPrevent oxidative combustionEducational modelsNumerical controlMelting tankIntermediate frequency

The invention provides a simulation equipment of twin-roll strip roll casting, which comprises a medium-frequency induction furnace, an online gas supplying apparatus, a temperature field measuring device near the surface of an online crystallization surface and an online molten pool temperature measuring device. The structure of the simulator of the equipment is that a bottom support, a track of the medium-frequency induction furnace and a limiting stop are disposed on the base plate, two vertical sliding bars are arranged between the bottom support and an upper horizontal channel steel stage, each sliding bar is provided with a big sliding barrel capable of sliding along the bar, an upper cross beam and a lower cross beam are connected between two big sliding barrels, the channel steel stage is equipped with a hydraulic equipment, the hydraulic equipment and the lower cross beam are connected by screws, a casting mold is fixed on a small sliding block by a rapid expansion link, the small sliding block can slide on the lower cross beam, roller on the small sliding block can roll along a curved guide rail to drive the casting mold to move, the curved guide rail is fixed on a supporting board which is fixed in a groove on the inner side of the bottom support. By simulation experiments, matching relationship of each processing parameter in roll casting process can be obtained. The invention is used to direct actual commercial manufacture.

Owner:NORTHEASTERN UNIV

Downdraft carbon-gas co-production gasifier

The invention discloses a downdraft carbon-gas co-production gasifier. The main structure of the gasifier comprises a feed hopper, a stock bin, a gasification reaction chamber, a double-section bucket-shaped water cooling sleeve, a turnover grate and a settling chamber from top to bottom; a carbon discharging auger is arranged at the bottom of the settling chamber; a bucket-shaped conical materialdrawing disc is arranged inside the lower part of the stock bin; and a bucket-shaped conical disc is stacked inside the upper part of the double-section bucket-shaped water cooling sleeve. Biomass fuel is firstly subjected to a high-temperature cracking gasification reaction in the gasification reaction chamber to generate fuel gas, and the fuel gas is discharged downwards from a fuel gas outletin the side wall of a settling chamber; and biomass fuel which is not completely reacted in the gasification reaction chamber is carbonized, then falls into the settling chamber and is cooled to formbiomass carbon, so that simultaneous co-production of carbon and gas of the biomass fuel is realized. The gasifier has the following characteristics: the structure is scientific and ingenious and thefeeding hopper with a double-layer structure can prevent gas from escaping during feeding; the bucket-shaped conical material drawing disc prevents the material bin from material bridging and arching;a gas supply pipe is used as a middle air inlet channel, so that gas feeding is more uniform without dead angles; and the turnover grate has a function of spraying water mist at the same time.

Owner:周勇

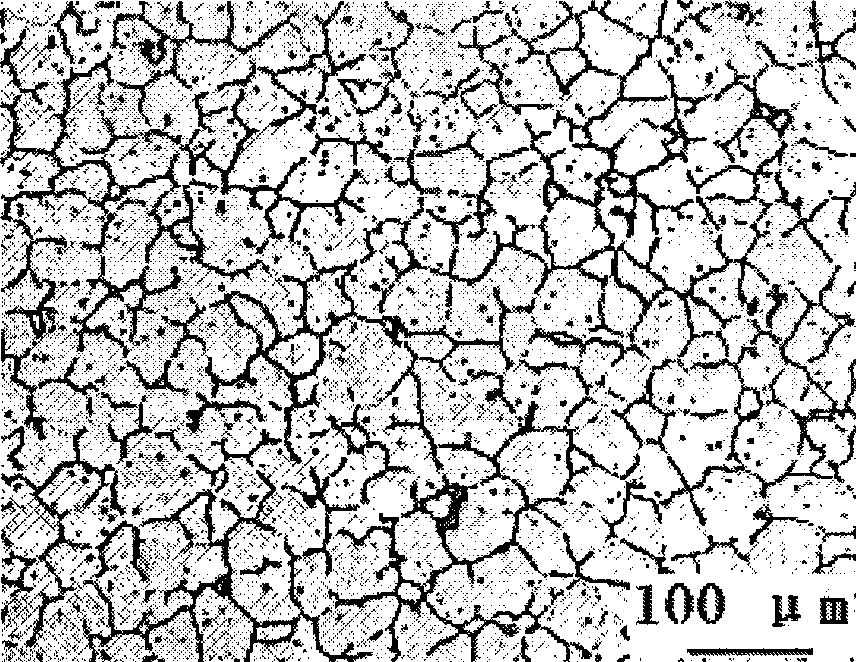

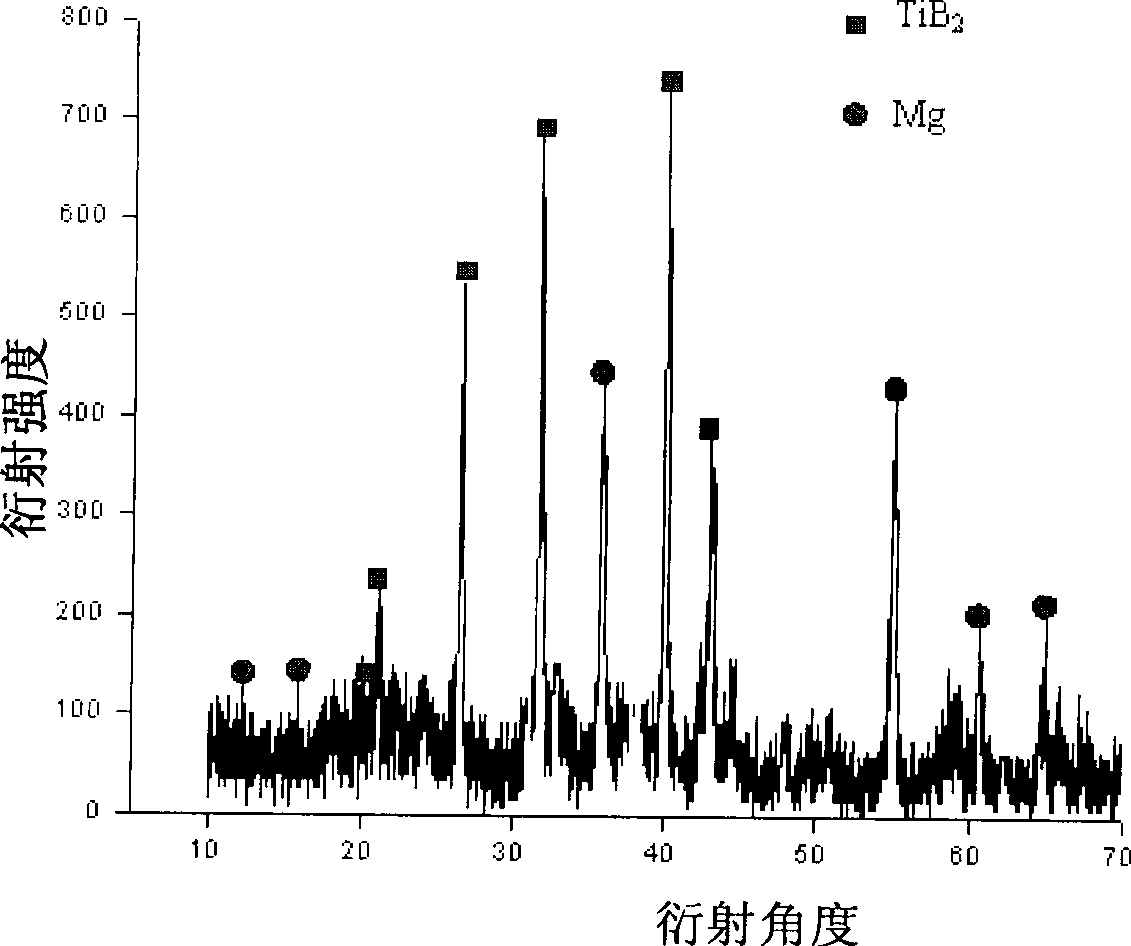

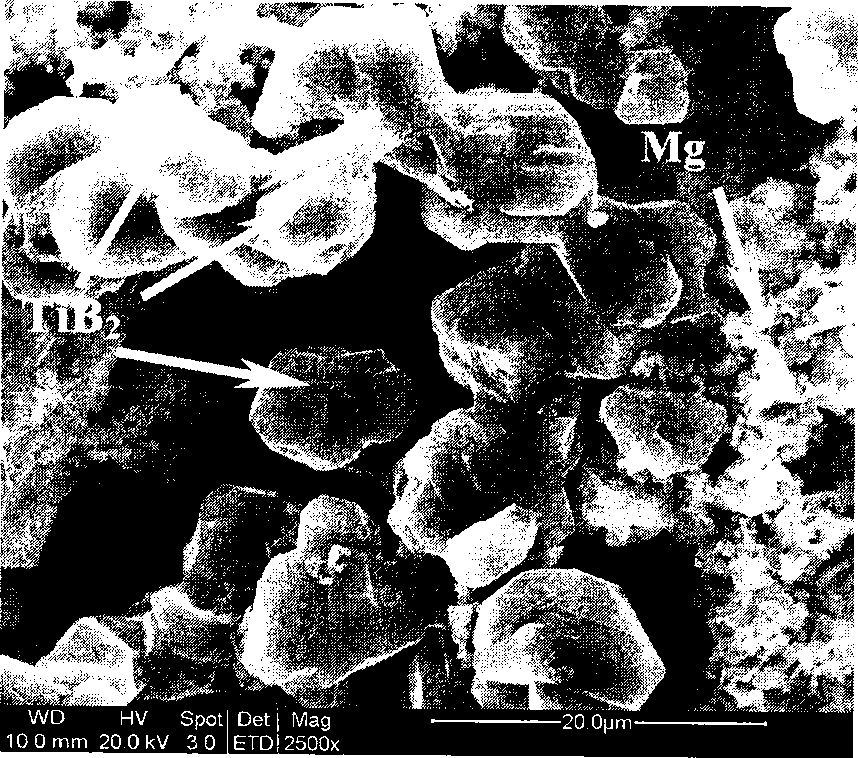

Method for preparing Mg-Ti-B grain refiner for magnesium and magnesium alloy

InactiveCN101457312APrevent oxidative combustionSimple preparation processChemical compositionCrucible

The invention provides a method for preparing a grain refiner for magnesium and magnesium alloy. The chemical compositions of the refiner are as follows (by weight percent): 13.78-55.10% of titanium, 6.22-24.90% of boron and the balance of magnesium. The preparation method comprises the following steps: titanium powder, boron powder and magnesium powders are mixed in a drying status, compacted and dried and then are arranged in a corundum crucible; the crucible is landfilled with fire-resisting powder; an isothermal treatment is carried out at the temperature of 700 to 1000 DEG C in a box-type resistance furnace for 60 to 180 min to prepare the Mg-TiB2 grain refiner. The method is simple in preparation procedure, easy in controlling the content of TiB2 and adding the TiB2, and capable of prominently refining the grain of the magnesium and magnesium alloy.

Owner:WUHAN UNIV OF TECH

Fusion agent for smelting of magnesium alloy containing rare earth yttrium and preparation method thereof

The invention relates to a fusion agent for the smelting of magnesium alloy containing rare earth yttrium and a preparation method thereof, belongs to the technical field of metal material metallurgy and aims to solve the technical problems of large ignition loss and poor purification effect of the rare earth yttrium when the fusion agent is used for smelting the magnesium alloy containing the rare earth yttrium. The invention provides the fusion agent for the smelting of the magnesium alloy containing the rare earth yttrium. The fusion agent contains the following components in percentage byweight: 25-35 percent of magnesium chloride, 30-40 percent of potassium chloride, 8-16 percent of sodium chloride, 10-15 percent of magnesium fluoride, 0.1-0.3 percent of beryllium oxide and 4-10 percent of carbonate. The invention also provides a preparation method of the fusion agent, which comprises the following steps of: mixing and drying the magnesium chloride, the potassium chloride, the sodium chloride, the magnesium fluoride and the beryllium oxide and adding the carbonate to prepare the fusion agent. The fusion agent has the advantages of reasonable composition, high rare earth yttrium yield and good refining effect. The method has the advantages of simple and convenient production process and low cost.

Owner:TAIZHOU VOCATIONAL & TECHN COLLEGE

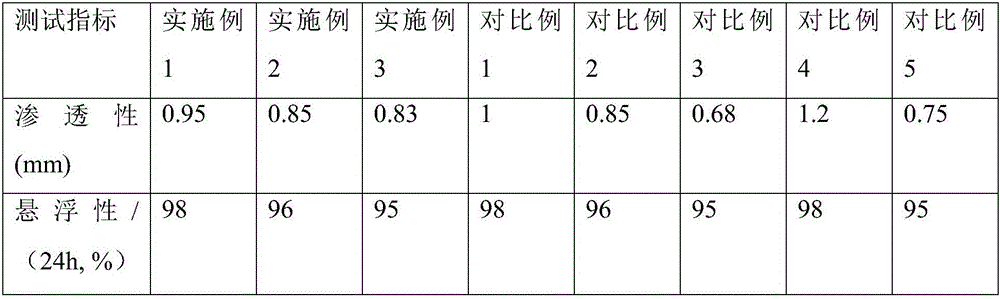

Self-hardening flame-retardant transfer coating for magnesium alloy sand casting and preparation method of self-hardening flame-retardant transfer coating

ActiveCN106270371AGood suspensionNot easy to precipitateFoundry mouldsFoundry coresPreservativeSuspending Agents

The invention relates to a self-hardening flame-retardant transfer coating for magnesium alloy sand casting and a preparation method of the self-hardening flame-retardant transfer coating. The self-hardening flame-retardant transfer coating is prepared from, by mass, 30-50 parts of heat-resisting aggregate, 0.5-2.5 parts of a suspending agent, 1-5 parts of a binder, 0.2-0.8 part of a coupling agent, 0.5-2.5 parts of a fire retardant agent, 0.1-1.5 parts of a defoaming agent, 0.01-0.03 part of preservative and 50-70 parts of water. The prepared coating has the good adhesion, coating performance and flame-retardant effect and is not prone to precipitating in the use process. In the casting process, a coating layer is not prone to cracking, the surface quality of a casting is good, dimensional precision is high, and the self-hardening flame-retardant transfer coating is suitable for the technical field of magnesium alloy casting.

Owner:SHANGHAI JIAO TONG UNIV

Water-based paint for metal casting

InactiveCN105710281AConducive to expulsionPrevent oxidative combustionFoundry mouldsFoundry coresWater basedBauxite

The invention discloses water-based paint for metal casting. The water-based paint comprises, by weight, 10-20 parts of zinc oxide, 2-5 parts of boric acid, 2-4 parts of alkyl sodium sulfonate, 5-10 parts of quartz powder, 5-10 parts of bauxite, 3-5 parts of sodium silicate and 30-50 parts of deionized water. The water-based paint for metal casting can resist a high temperature, improve a qualified rate and reduce a production cost.

Owner:CHONGQING YONGLIN MACHINERY EQUIP

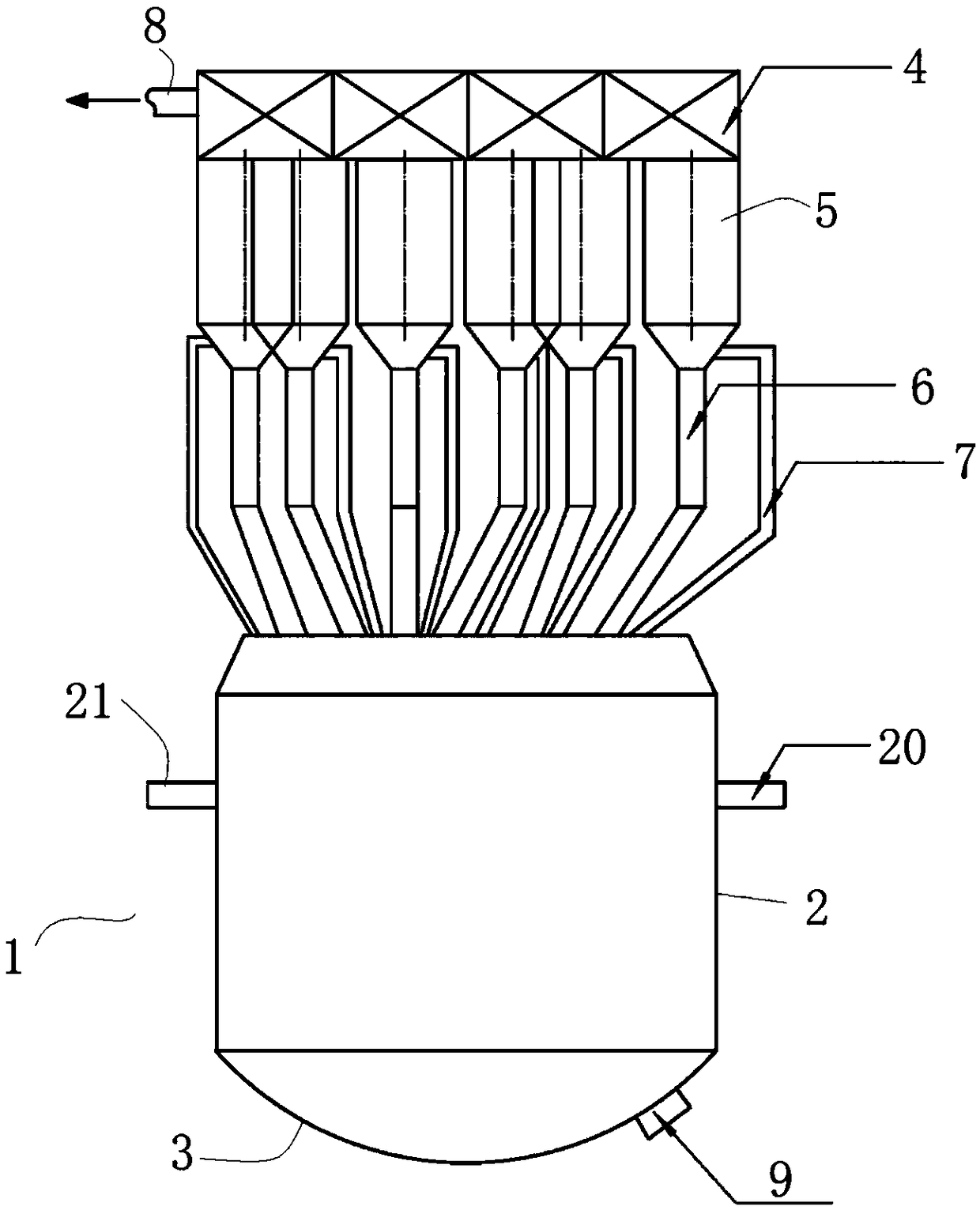

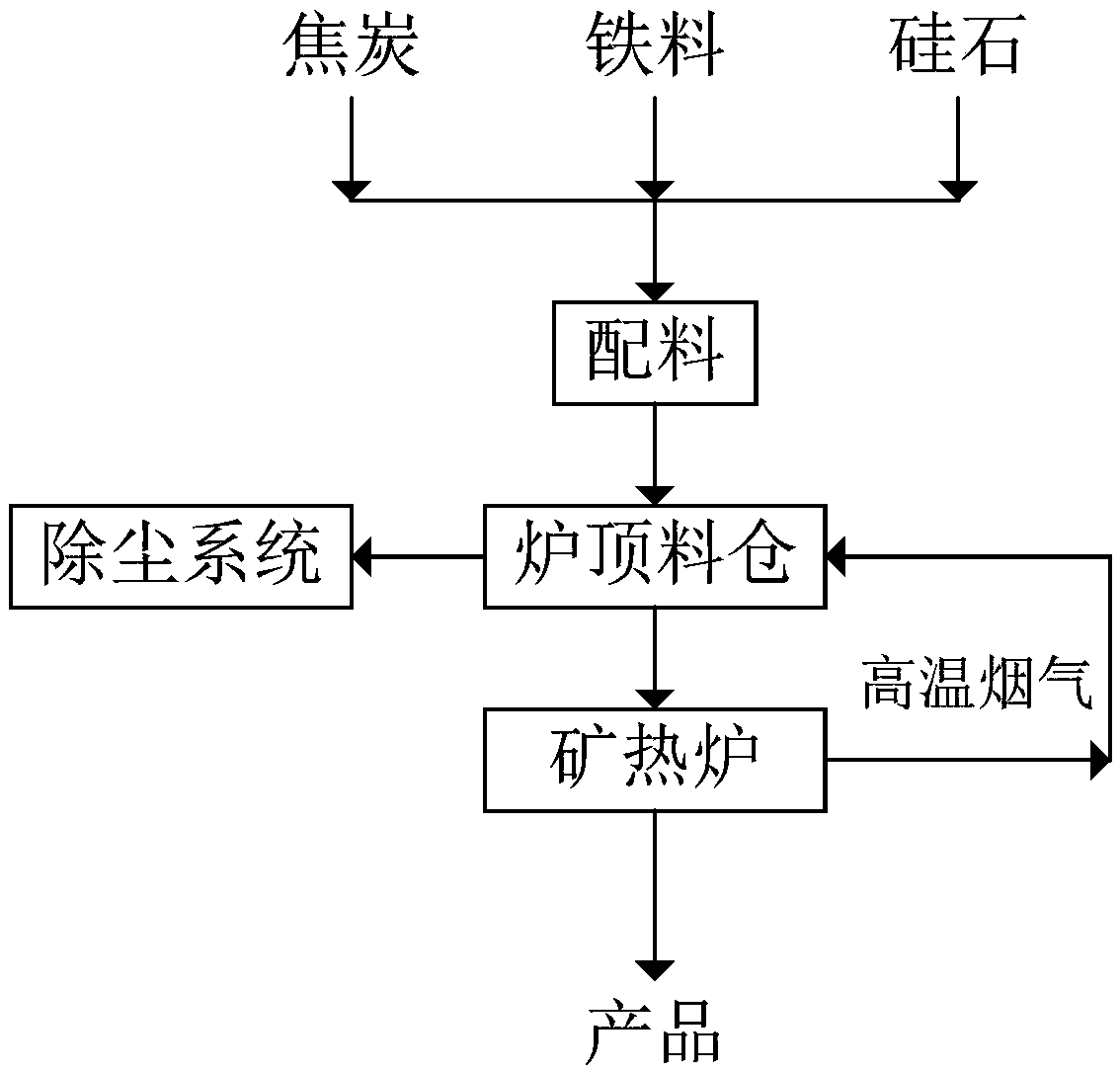

High-efficiency and energy-saving submerged arc furnace

PendingCN109114980AEasy to operateAvoid mutual interferenceFurnace typesPreheating chargesMetallurgyMaterials science

The invention relates to a high-efficiency and energy-saving submerged arc furnace which comprises a furnace body and at least one electrode arranged on the side wall of the furnace body. A charging hole is formed in the top part of the furnace body; the electrode is provided with a working end stretching into the furnace body; and the working end is horizontally arranged. According to the high-efficiency and energy-saving submerged arc furnace provided by the invention, the electrode is horizontally placed, and a space above the furnace body can be cleared, so that the charging operation canbe carried out conveniently; and the electrode adjustment operation and the charging operation are independent so as to be prevented from interfering mutually, so that the production efficiency and the maintenance efficiency are improved.

Owner:ZHEJIANG DEYAO ENERGY SAVING TECH CO LTD

Glass-powder-contained high-breathability water-base expendable pattern casting coating for magnesium alloy casting and preparing method for glass-powder-contained high-breathability water-base expendable pattern casting coating for magnesium alloy casting

The invention discloses a glass-powder-contained high-breathability water-base expendable pattern casting coating for magnesium alloy casting. According to the expendable pattern casting coating, kieselguhr subject to heat conduction modification serves as refractory aggregates; and meanwhile, raw materials such as magnesium hydrate and glass powder are added so that a coating layer can be heated in the pouring process to form a compact and even protection layer, molten metal can be effectively prevented from overflowing, meanwhile, the temperature in a cavity can be adjusted, and magnesium alloy oxidation burning can be prevented. The interior of the prepared coating is of an even fiber network structure, the coating performance is good, the water content is low, and the beneficial effects of being breathable, capable of achieving heat conduction, low in coefficient of thermal expansion and the like are achieved; and after the coating is used, a casting with high surface smoothness and low porosity can be obtained, and the magnesium alloy casting quality is effectively improved.

Owner:HUOQIU COUNTY XINRUI METAL PROD

Fire retardant

InactiveCN101445877APrevent oxidative combustionHas a tissue thinning effectFire retardantCobalt aluminate

The invention relates to a fire retardant. The fire retardant is characterized by comprising the following components by weight: 35-45% of cobalt aluminate, 25-36% of micanite, 8-16% of magnesium chloride and 14-20% of potassium chloride. A magnesium alloy to be processed is added with 2-5% of the fire retardant which covers the surface of alloy liquid so as to prevent magnesium liquid from contacting with air, thus achieving the effect of fire retardation and protection. The graininess of the cobalt aluminate, the micanite, the magnesium chloride and the potassium chloride adopted in the fire retardant is preferably and generally 100-200 meshes. The cobalt aluminate in the fire retardant has a surface activity effect, is enriched on the surface of the magnesium alloy liquid under the effect of the micanite, which can form a compact composite oxide film on the surface of the magnesium alloy liquid and refine grains of the magnesium alloy structure, thus improving the metallurgical quality of the magnesium alloy liquid and part performance.

Owner:大连核心铸造技术工程研究所

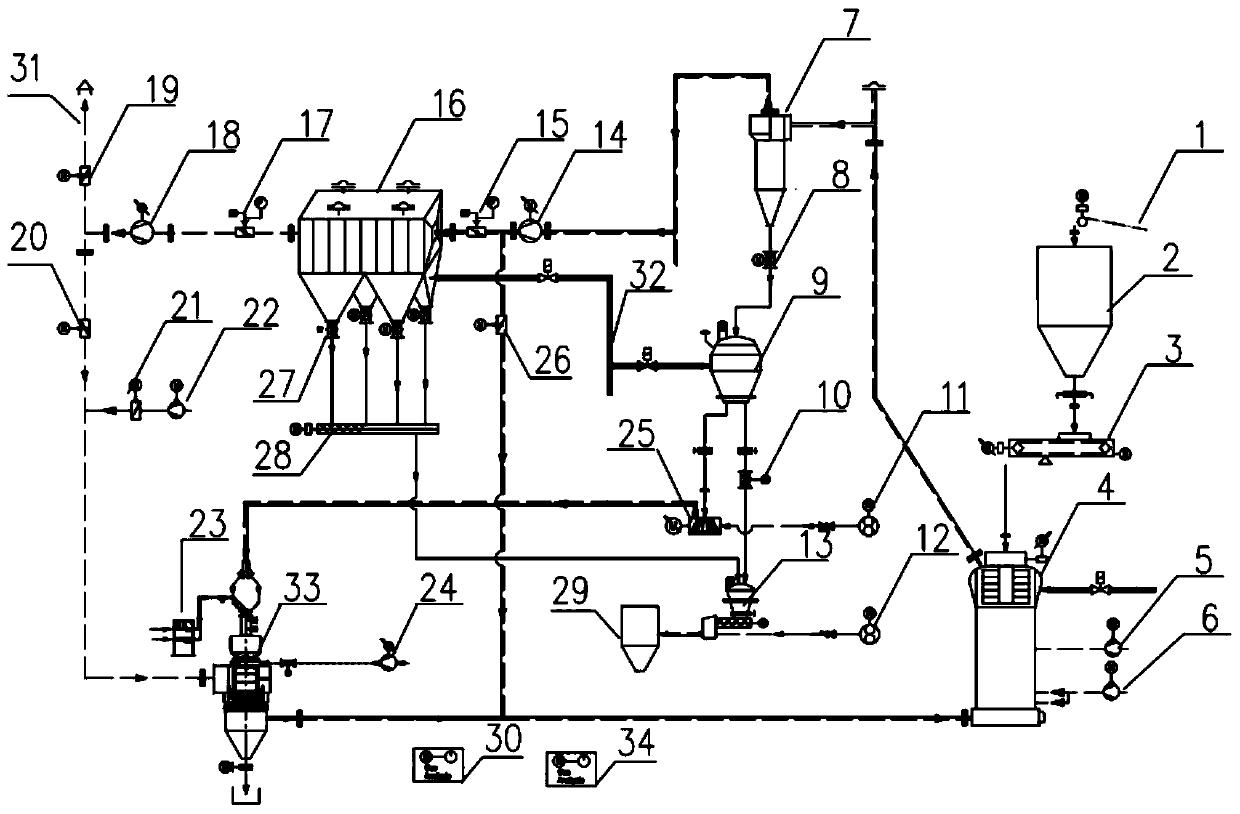

Coal grinding system and method for safely and efficiently preparing lignite

ActiveCN110404650AImprove collection effectReduce the amount of powderGrain treatmentsLump/pulverulent fuel preparationProcess engineeringMachining system

The invention discloses a coal grinding system and method for safely and efficiently preparing lignite. The coal grinding system comprises a raw coal feeding system, a hot blast stove system, a pneumatic conveying system, a finished product conveying system, a coal grinding machine system and a safety system, wherein the raw coal feeding system conveys the lignite to be ground to the coal grindingmachine system, and the pneumatic conveying system conveys qualified lignite powder to the finished product conveying system. Compared with the prior art, the coal grinding system and method for safely and efficiently preparing the lignite have the advantages that the preparation capability is high, the system drying capacity is large, the consumption of the hot blast stove is low, the safety guarantee is high, and the coal grinding system and method are suitable for preparing the coal powder of the lignite.

Owner:国能绿色能源股份有限公司

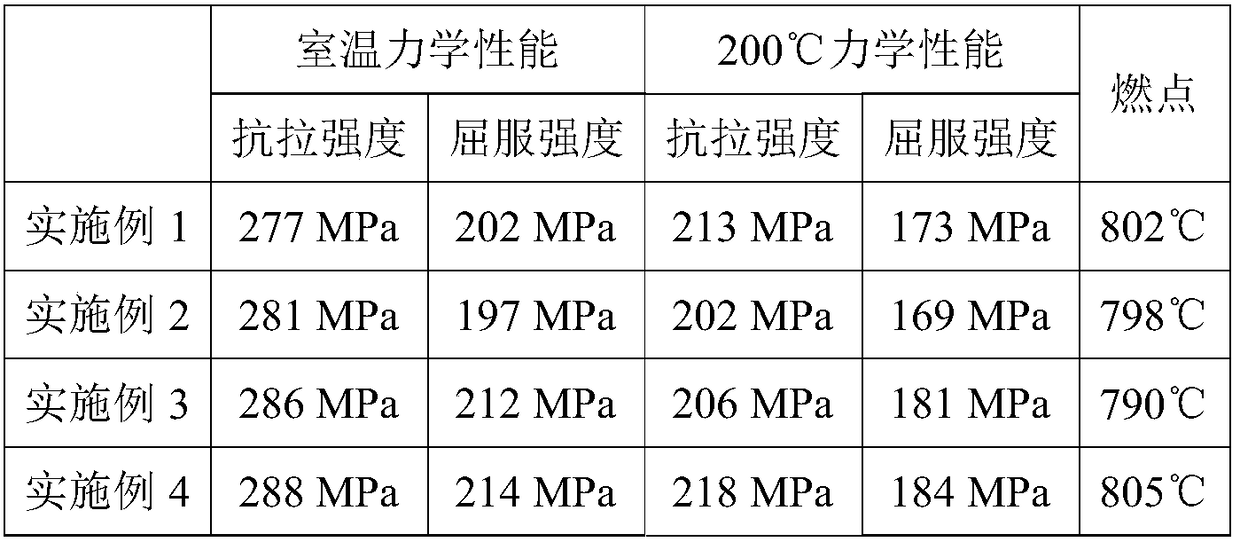

High-strength flame-retardant magnesium alloy and preparation method thereof

ActiveCN109280832AImprove flame retardant performanceGood room temperatureRoom temperatureUltimate tensile strength

The invention relates to a high-strength flame-retardant magnesium alloy and a preparation method thereof. The high-strength flame-retardant magnesium alloy is composed of the following components of,in percentage by mass, 5.0-7.0% of Nd, 3.0-3.5% of Ce, 2.0-2.5% of Al, 0.5-0.8% of Si, 1.5-2.0% of Ag, 0.8-1.0% of Nb and the balance Mg and inevitable impurities. According to the high-strength flame-retardant magnesium alloy, different components are reasonably matched, the Nd, Ce, Al, Si, Ag and Nb-containing flame-retardant magnesium alloy is prepared by an alloying method, the ignition pointof the magnesium alloy is about 800 DEG C, the flame retardant performance is good, meanwhile, the tensile strength of the magnesium alloy is about 280 Mpa, the yield strength at room temperature isabout 200 Mpa, the tensile strength of 200 DEG C is about 200 Mpa, the yield strength at 200 DEG C is about 170 Mpa, and good room temperature and high-temperature mechanical properties is showed.

Owner:HENAN UNIV OF SCI & TECH

Rear-earth magnesium alloy smelting agent and preparation method thereof

The invention discloses rear-earth magnesium alloy smelting agent and a preparation method thereof. The rear-earth magnesium alloy smelting agent comprises the components in a molar ratio of chlorate to trifluoromethyl sulfonate to carbonate equal of (80-90):(1-3):15; the mixed solution is sprayed in to solution drops through a spraying device; the solution drops directly enters a decompression flashing device for evaporating and dehydrating; primary gas-solid separation is carried out by a gas-solid separating device; solid-phase materials are fed to a fluidization drying device, so that fluidization drying is carried out onto the solid-phase materials by the air which is pre-heated to 120 DEG C to 200 DEG C; secondary gas-solid separation is carried out by the gas-solid separating device to control the moisture content of the solid-phase materials to be within 0.2%; and the solid materials is filled in a sealed container for storage and used rear-earth magnesium alloy smelting agent for future use. The rear-earth magnesium alloy smelting agent is environment-friendly and energy-saving, low in treatment cost, good in treatment effect and high in utilization rate of valuable constituents.

Owner:YANGZHOU FENG MING METAL PROD

Flux used for recycling magnesium alloy cuttings, and preparation method and application method thereof

The invention discloses a flux used for recycling magnesium alloy cuttings, and a preparation method and application method of the flux, belonging to the technical field of magnesium alloy metallurgy. The flux mainly comprises anhydrous carnallite, magnesium chloride, potassium chloride, magnesium carbonate and calcium carbonate, the mass percentages of the components are respectively 10-80%, 0-40%, 5-40%, 0.5-3% and 0-2%, and not more than 40% of other components such as sodium chorlode, calcium chloride and the like can be added according to thickness of magnesium cuttings and a heating condition. According to the invention, before the magnesium cuttings enter into a furnace, the magnesium cuttings and the flux are fully mixed, and then are added into a smelting furnace, the flux is smelted and attached on the surface of the magnesium cuttings along with a temperature rise of the furnace, the contact of the surface of the magnesium with gas and oxidization of the surface can be blocked, meanwhile, oxidization and combustion of the magnesium cuttings can be effectively prevented by inflaming retarding gas generated by the flux, and the recovery rate and the production safety of the magnesium cuttings are improved.

Owner:有研金属复材技术有限公司

Casting-rolling process and equipment for magnesium alloy slab

InactiveCN100463732COmit flaw detectionFoundry Organic UnityMetal rolling stand detailsRollsShielding gasIngot

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Durable crucible and molding method thereof

The invention discloses a durable crucible and a molding method thereof, and relates to the technical field of crucible molding. The durable crucible is prepared from the following raw materials in percentage by total weight: 10 to 20 percent of alumina, 2 to 8 percent of cerium oxide, 3 to 7 percent of yttrium oxide, 25 to 35 percent of fused silica, 10 to 40 percent of zirconia and 10 to 30 percent of chromium oxide. The molding method comprises the following steps: weighing the above raw materials, then uniformly mixing the alumina, the cerium oxide and the cerium oxide, adding the mixtureto an electric melting furnace for electric melting, and then performing refining; then uniformly mixing the fused silica, the zirconia and the chrome oxide, and adding the mixture into the electric melting furnace, and continuing electric melting to form a melt; pouring an appropriate amount of the melt into a casting cavity of a mold, cooling the melt after the pouring is completed, and demolding the melt to form the crucible. The crucible cast by the molding method is uniform in texture, and has the advantages of high heat resistance, high toughness, high stability and durability.

Owner:贵州大东风机械有限公司

A kind of magnesium alloy melt refining method

ActiveCN104004930BImprove fullyWell mixed contactProcess efficiency improvementCavitationMagnesium alloy

The invention relates to a magnesium alloy melt refining method and belongs to the technical field of alloy melt processing. The method includes the following steps: melting a magnesium alloy billet; inserting a hollow tool head filled with inert gas into the magnesium alloy melt in a heat preservation container; starting a high-intensity acoustic cavitation system to process the alloy melt.

Owner:中天时代镁业有限公司

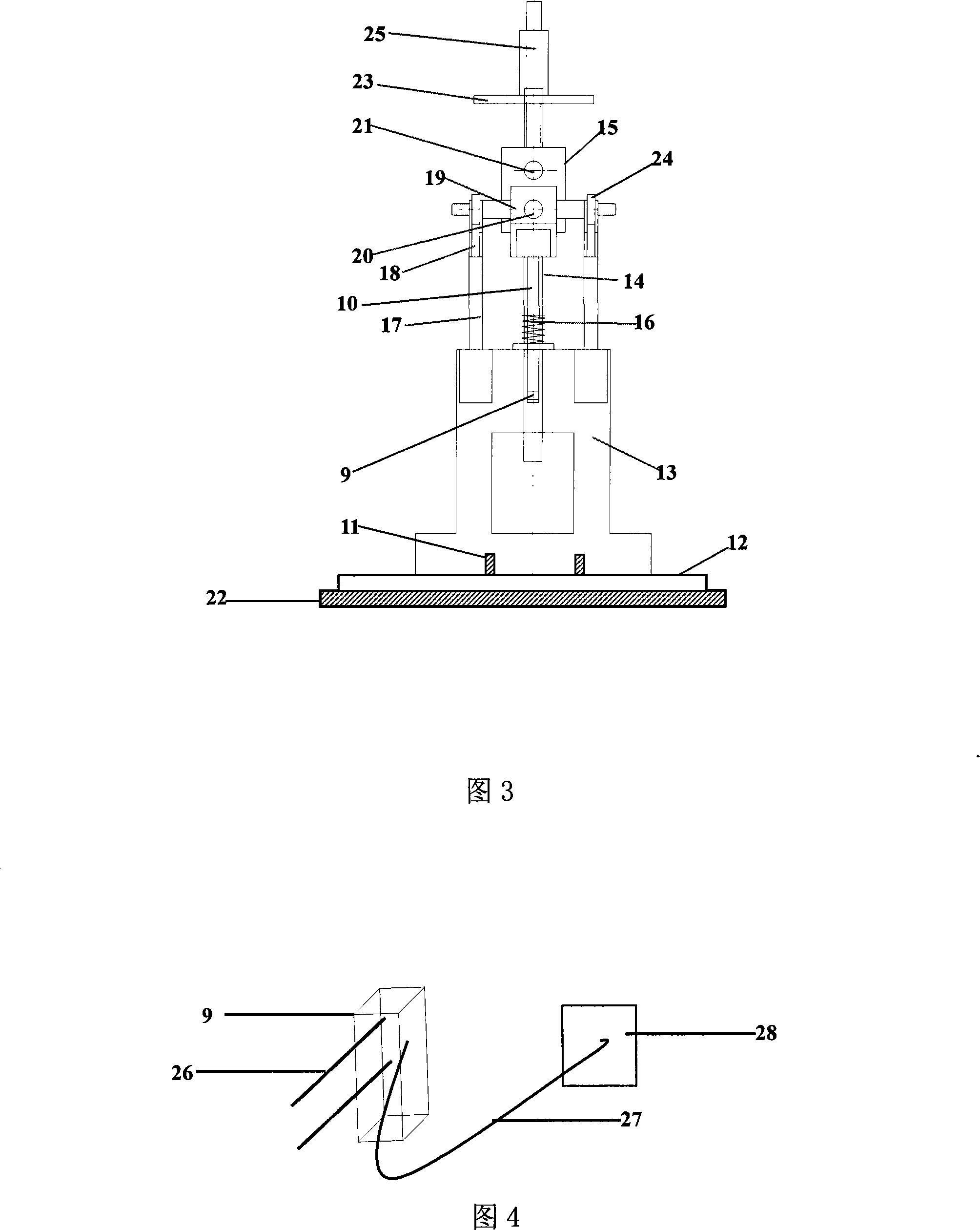

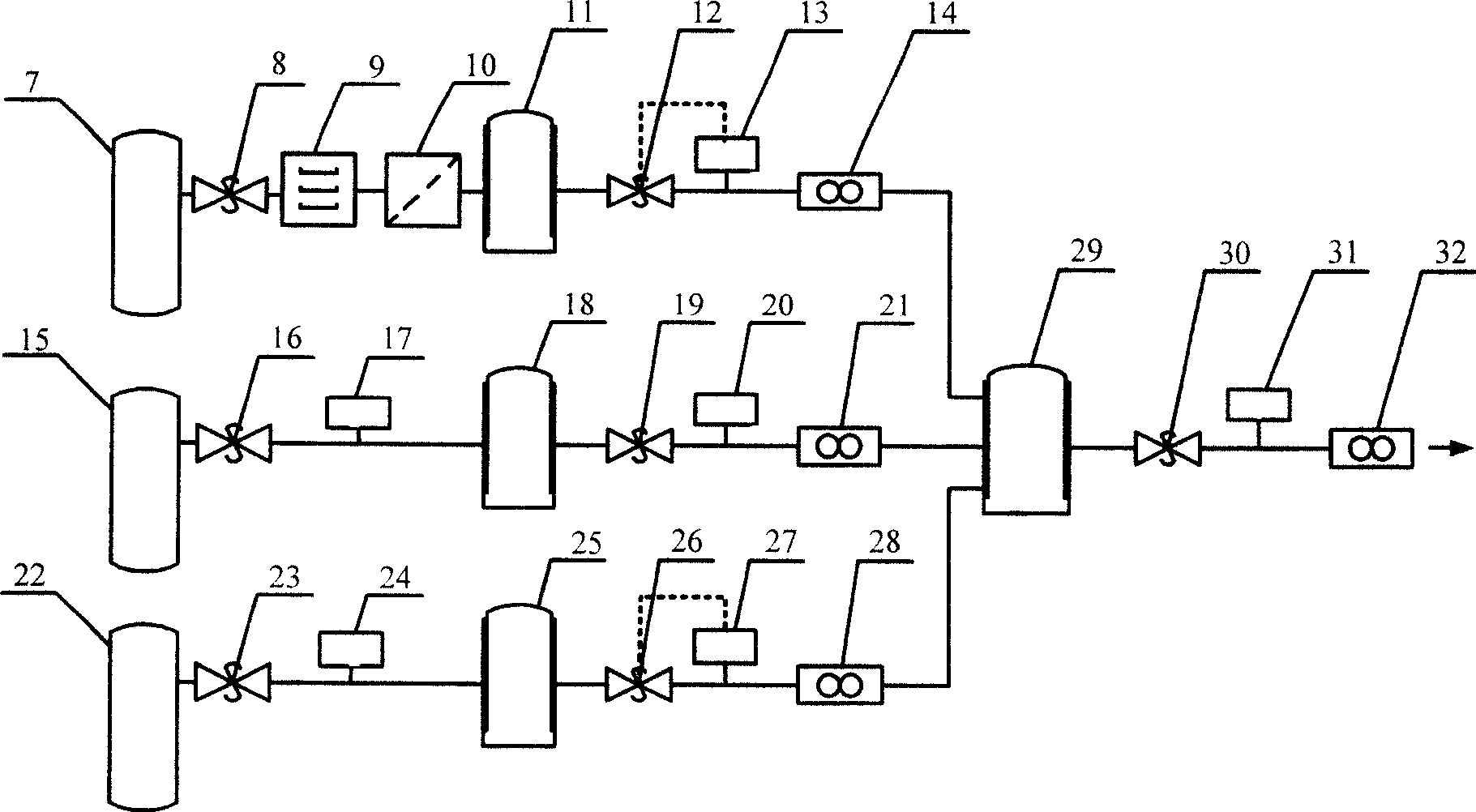

Magnesium alloy melt refining device

The invention relates to a magnesium alloy melt refining device mainly comprising four parts, namely a high-strength acoustic cavitation system, a quantitative flux supply system, an inert gas supply system and a melt heat preservation system.

Owner:NORTHEASTERN UNIV LIAONING

Smelting flame-proof protection method for magnesium alloy

The invention provides a flame retarding protective method used in magnesium alloy smelting, which comprises the steps of introducing a mixed gas comprising 1, 1, 1, 2, 3, 3, 3-heptafluoropropane (HFC-228ea) gas and diluting gas into a magnesium alloy smelting furnace at the same time of smelting magnesium alloy to conduct flame retarding protection of magnesium alloy until the smelting and casting are finished. The used HFC-228ea gas has the advantages of low greenhouse effect, extremely low toxicity under working concentration, nearly no influence to human body, high quality, high efficiency, and environmental friendliness. The inventive method solves the environmental, equipment and human body damage problems when protecting magnesium alloy smelting with high-greenhouse effect SF6 and toxic SO2 used in the current international magnesium industrial community; and has the advantages of simple process, distinct environment and economic benefits, and applicability to industrial application.

Owner:FUZHOU UNIV

Method preventing magnesium alloy from oxidative combustion

The invention provides a method for preventing magnesium alloy from oxidizing and combusting while the magnesium alloy is smelted. The method comprises the following steps: leading mixed gases comprising HFC-245fa gas and diluent gas to a magnesium alloy smelting furnace so as to protect the smelting of the magnesium alloy; and when the magnesium alloy is smelted, drying and mixing the gases, and conveying the gases to the magnesium alloy surface to be protected to provide the protection. The HFC-245fa (1,1,1,3,3-Pentafluoropropane with the structural formula of C3F5H3) gas adopted by the invention has low greenhouse effect with extremely low toxicity in the working concentration, thereby hardly affecting the human body; the method has the advantages of high quality, high efficiency, environmental protection, low cost and easy and feasible operation, solves the problems in the aspects of environment, equipment, harm to human health and the like caused by the SF6 gas having high greenhouse effect and the toxic SO2 gas for preventing the smelting of the magnesium alloy in the current international magnesium industrial community, and has remarkable value of environmental protection and economic benefit, therefore, the method is suitable for large-scale industrialized popularization.

Owner:FUZHOU UNIV

Method for preventing oxidizing fire of magnesium alloy

InactiveCN101220420APrevent oxidative combustionEnvironmentally friendlySulfur hexafluorideVentilation mode

The invention relates to a method for preventing the oxidation and burning of magnesium alloy and belongs to the field of metallurgy technology of magnesium alloy. The method comprises the following steps: the melting protection of the magnesium alloy is made by pumping the mixed gas of trifluoroiodomethane gas and dilute gas into a melting furnace of magnesium alloy; when the magnesium alloy is melted, the gas is dried, mixed and transported to a magnesium alloy surface which is needed to be protected with conventional methods; wherein, the purity of the trifluoroiodomethane and the dilute gas in the mixed gas is the industrial purity, and the dilute gas is one or a plurality of the gases of dry N2, CO2, Ar and compressed air; mixed gas of different proportions and ventilation modes are adopted according to the sealing conditions of the melting furnace of the magnesium alloy; the mixed gas comprising the trifluoroiodomathane is adopted for the melting protection when the magnesium alloy is melted in unsealed melting furnaces or sealed melting furnaces, which has good protecting effect and the advantage of environment-friendliness compared with the protection of sulfur hexafluoride, and the invention is simple in technique of melting protection and has good industrial application prospect.

Owner:TSINGHUA UNIV +1

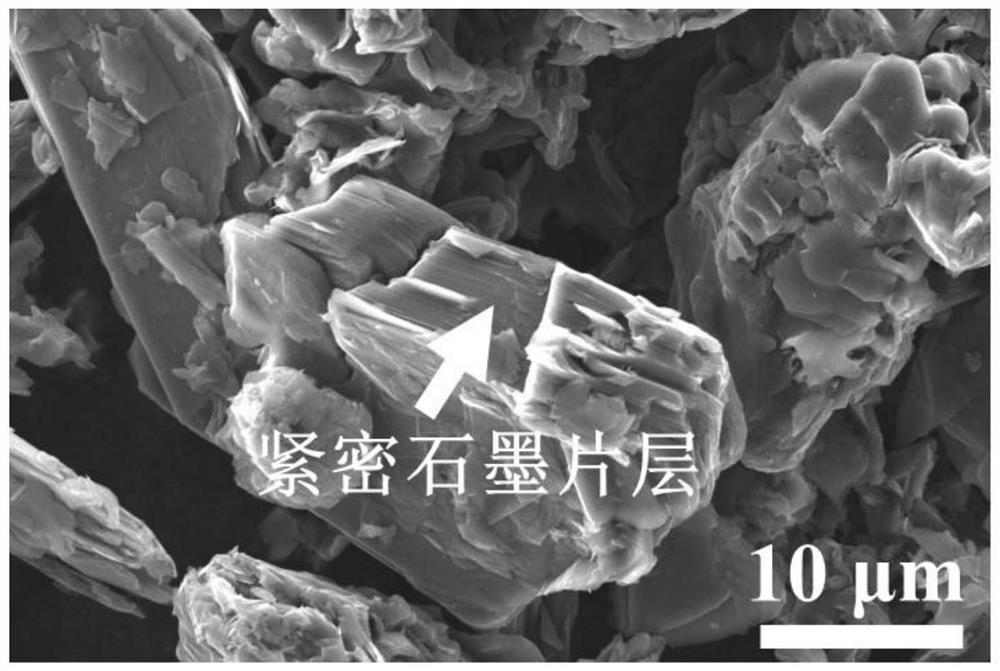

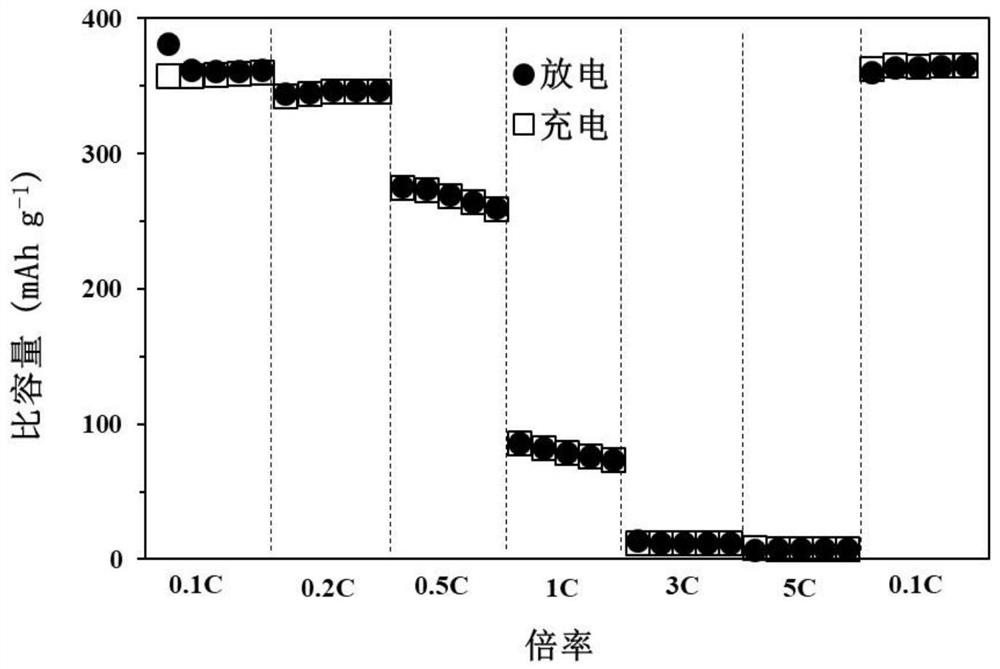

Composite modified graphite negative electrode material and preparation method thereof

ActiveCN112374552AFast preparationWide variety of sourcesGraphiteFinal product manufactureNanoholeGraphite

The invention discloses a composite modified graphite negative electrode material and a preparation method thereof. The preparation method comprises the following steps: 1) mixing graphite, an oxidantand an intercalator according to a certain mass ratio to obtain a mixed solution; 2) carrying out stirring reaction on the mixed solution under a constant temperature condition to obtain an intercalation product; and 3) repeatedly washing the intercalation product with deionized water until the pH value of the filtrate is 57, drying the washed intercalation product, heating to a target temperature in an inert atmosphere, and keeping the temperature for a specific time to obtain the target object. The composite modified graphite negative electrode material prepared by the method disclosed by the invention is manganese oxide loaded sulfur-free micro-expanded graphite, and has nanopores and properly enlarged graphite lamellar spacing. The method has the advantages of being high in operability, easy to produce, low in equipment requirement and good in repeatability, and the prepared composite modified graphite negative electrode material has high specific capacity, excellent rate capability and long cycling stability and is easier to use in the field of commercial lithium ion batteries.

Owner:昆明云大新能源有限公司

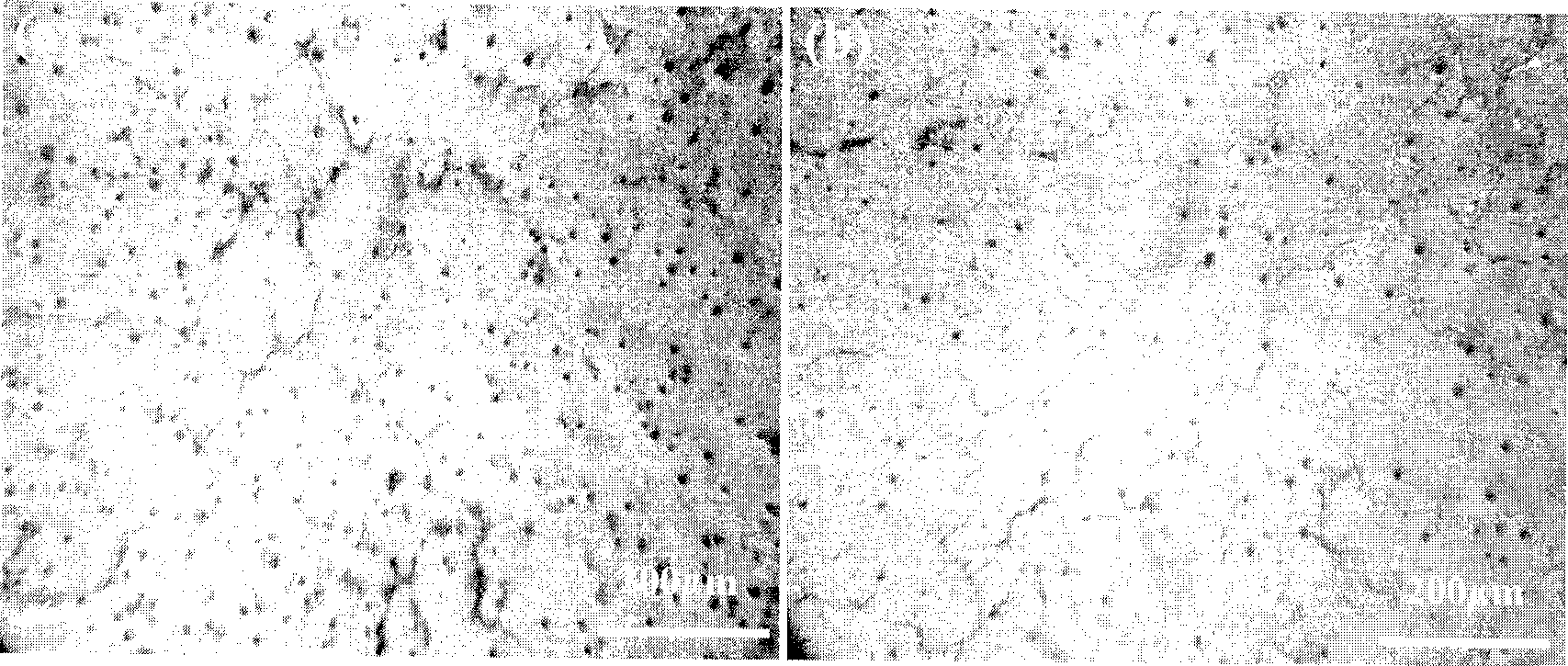

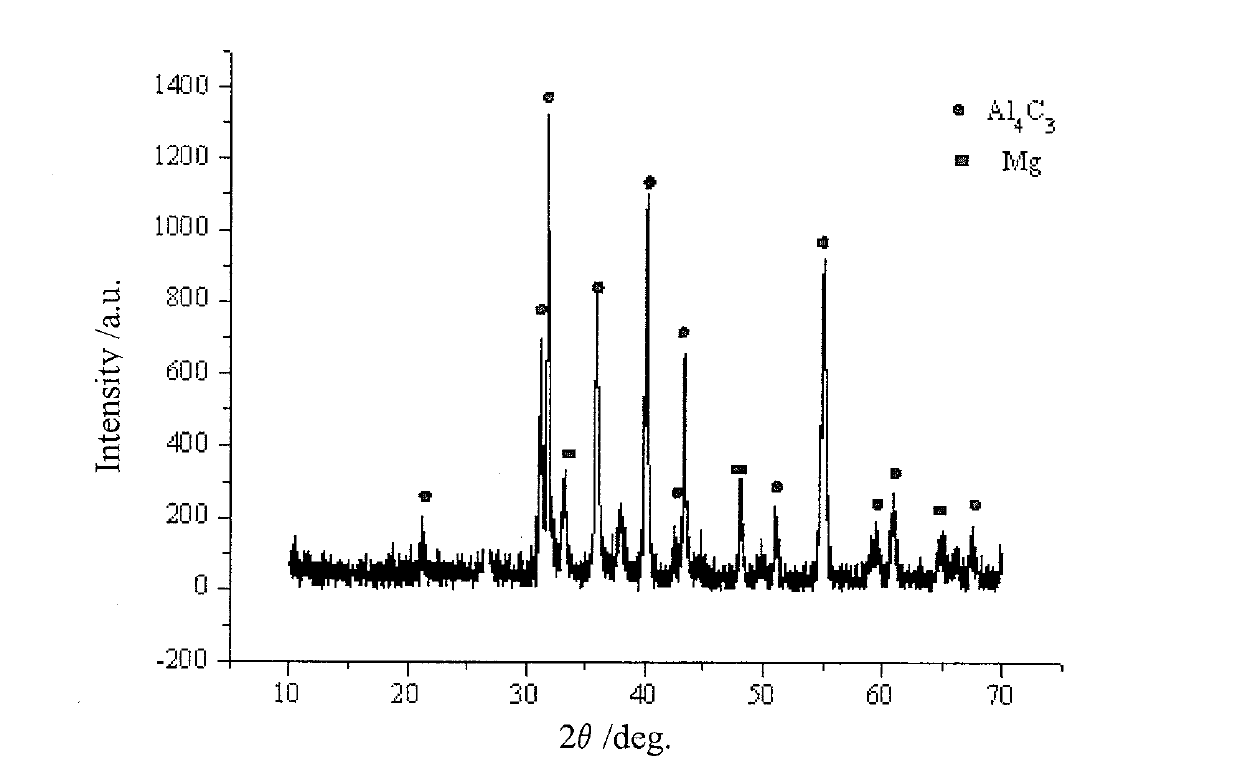

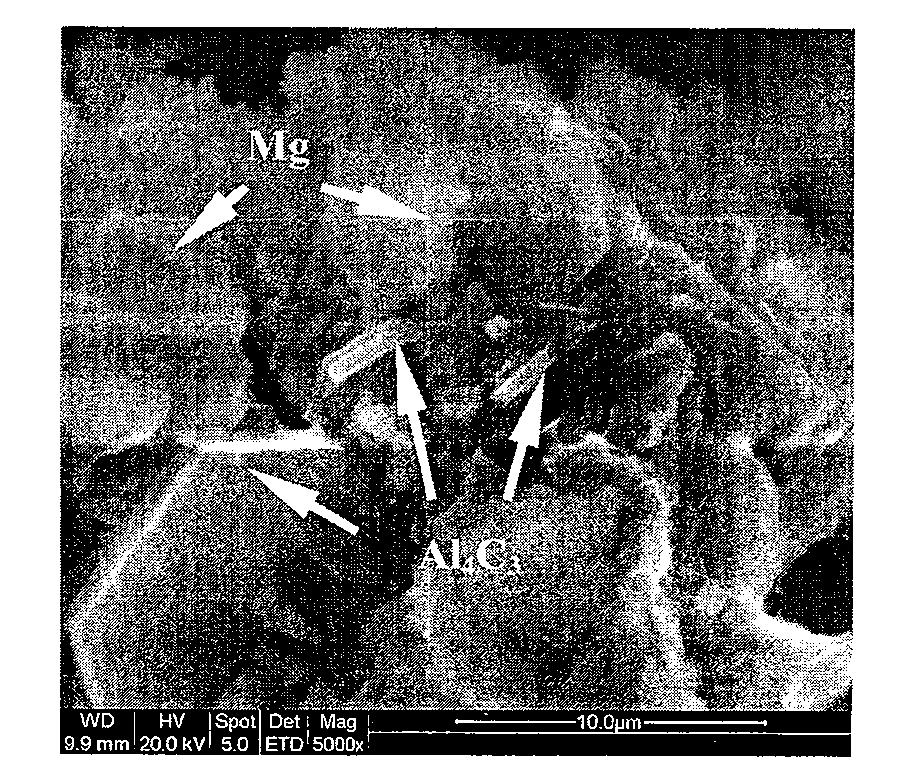

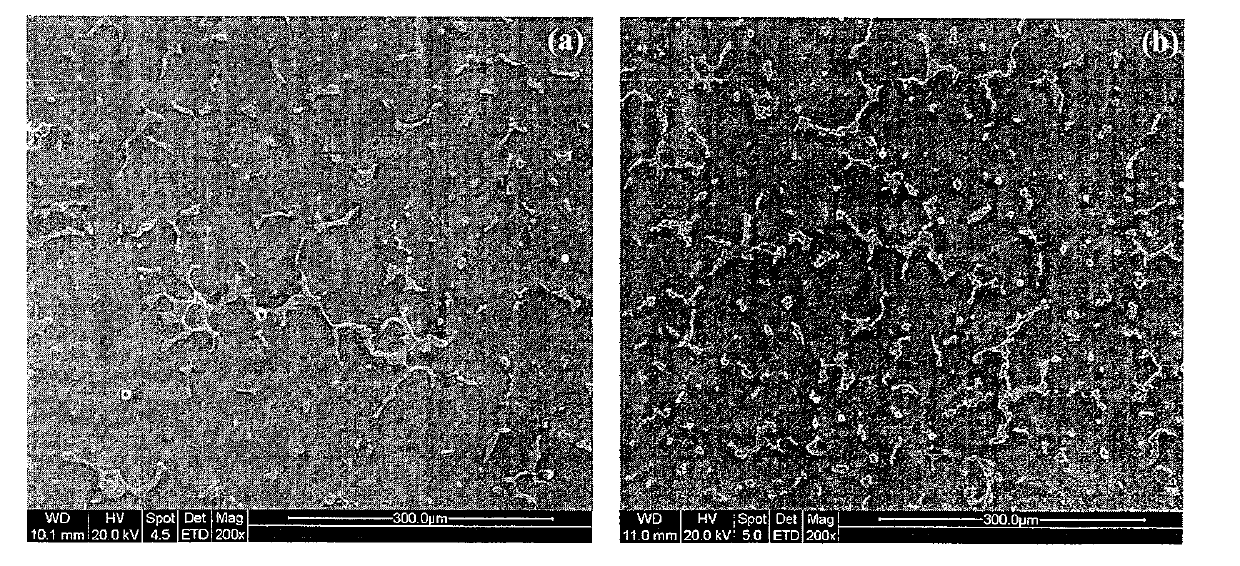

Method for preparing magnesium and magnesium alloy composite grain refiner

The invention provides a magnesium and magnesium alloy composite grain refiner and a preparation method thereof. The chemical composition of the refiner is (percentage by weight): 15-37.5% aluminum, 5-12.5% carbon, 5-20% cerium, and the balance is magnesium. The preparation method of the refiner is as follows: dry-mix aluminum powder, carbon powder and magnesium powder, briquette and dry them, place them in a corundum crucible and fill them with refractory powder, and heat them in a box-type resistance furnace at 700-900°C Mg-Al4C3 is obtained by isothermal treatment for 30-120 minutes, and then remelted with magnesium ingot and Mg-25%Ce master alloy to finally prepare Mg-Al4C3-Ce composite grain refiner. The method is easy to operate and easy to industrialized production, and the prepared compound refiner is easy to control the content and easy to add, and can obviously refine the crystal grains of magnesium and magnesium alloys.

Owner:WUHAN UNIV OF TECH

Protective agent for magnesium alloy melt pouring, magnesium alloy casting and preparation method thereof

The invention belongs to the technical field of magnesium alloy, and particularly relates to a protective agent for magnesium alloy melt pouring, a magnesium alloy casting and a preparation method thereof. The protective agent for magnesium alloy melt pouring comprises boric anhydride and sulfur; the mass content of the boric anhydride accounts for 30-60% of the total amount of the protective agent, and the mass content of the sulfur accounts for 40-70% of the total amount of the protective agent. According to the protective agent, the thickness of a multi-layer protective layer formed during pouring is increased, and the compactness of a single protective layer is also improved, so that a magnesium alloy melt is well protected, the purity of a magnesium alloy casting prepared from the magnesium alloy melt is guaranteed, the performance of the magnesium alloy casting is improved, and the metallurgical quality is excellent; and oxidation combustion of magnesium alloy can be avoided.

Owner:HEBEI GANGYAN DEKAI TECH CO LTD

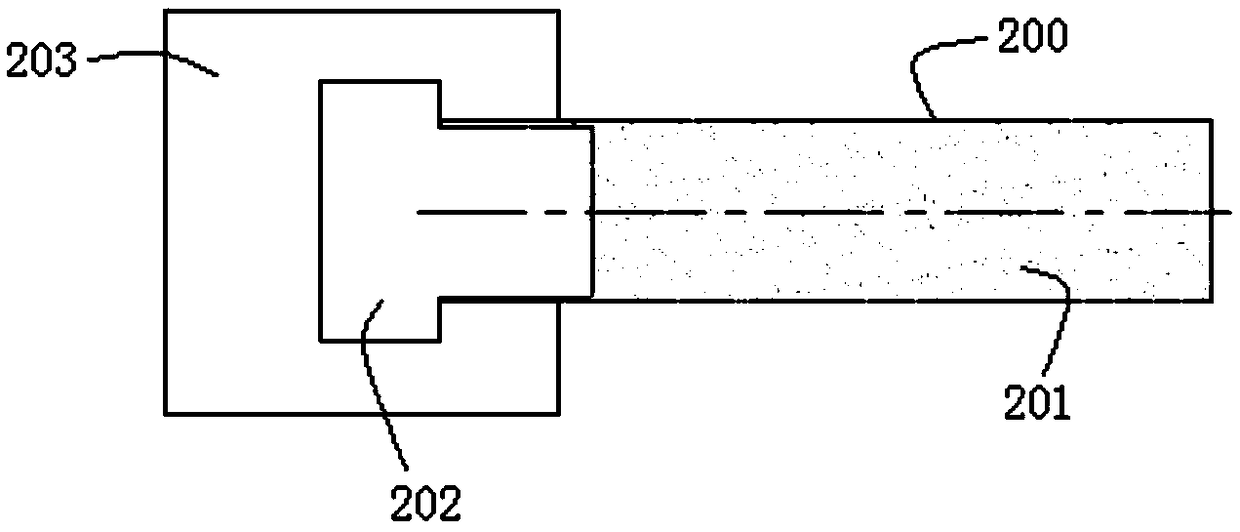

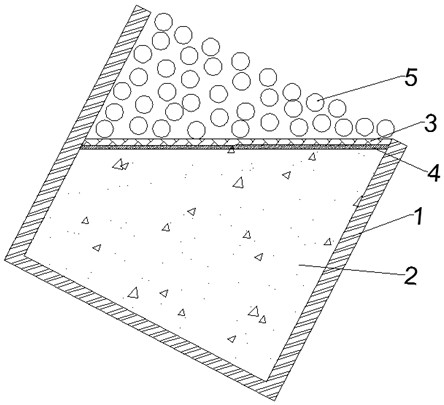

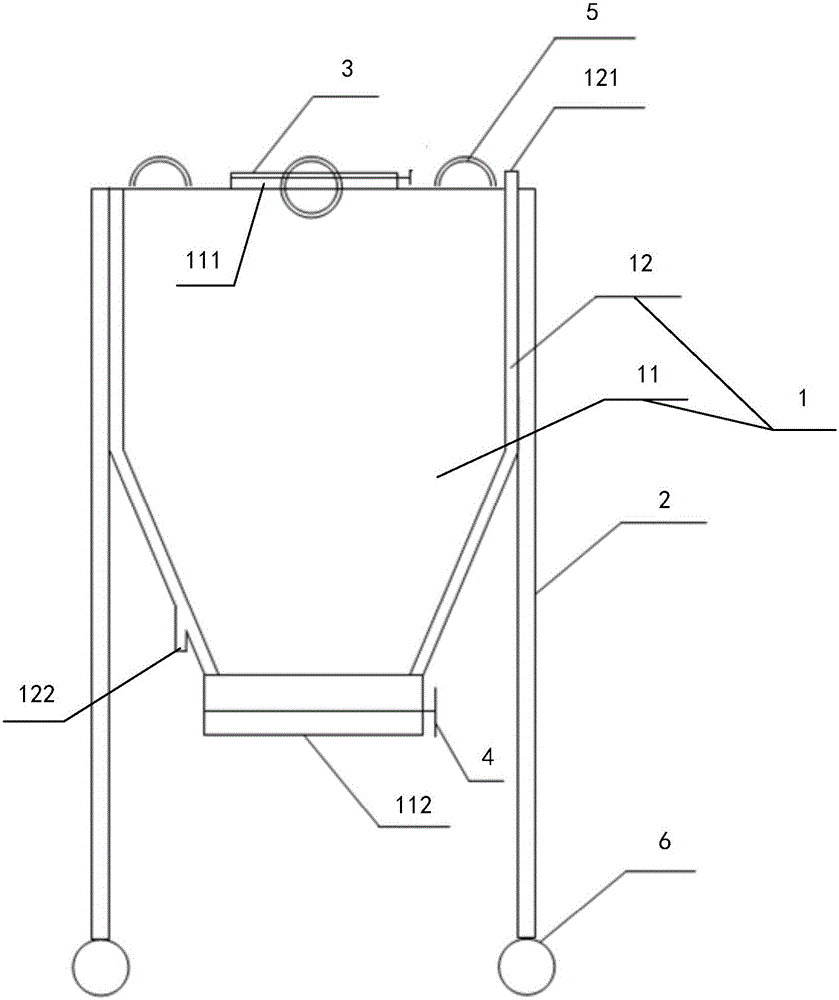

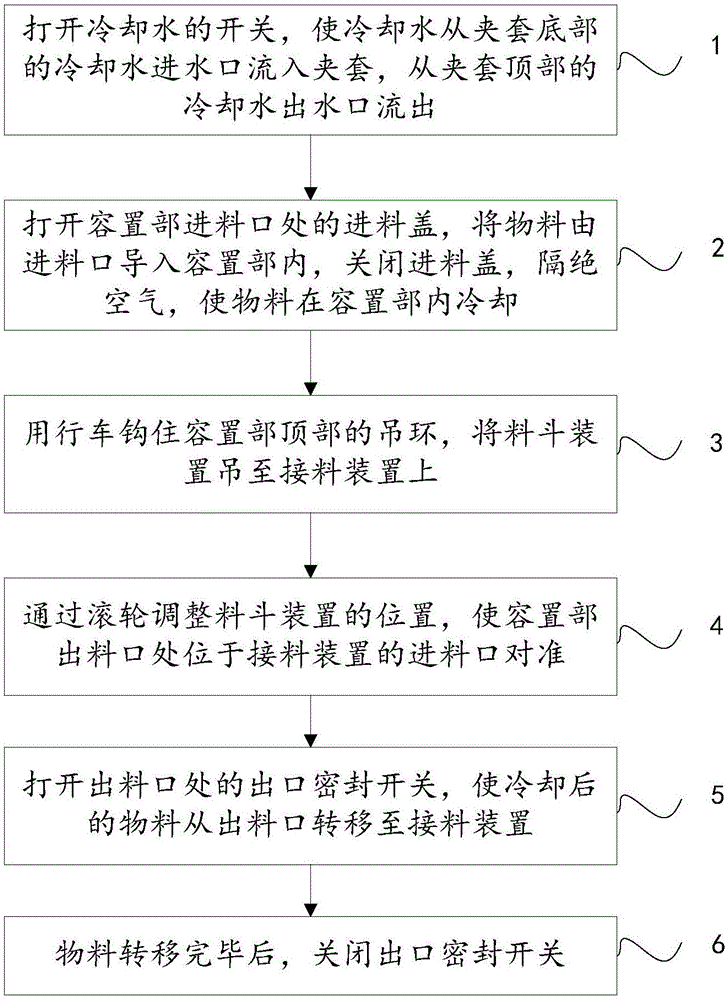

Hopper device used for material cooling, transferring and storing and material transferring method

InactiveCN106742854AInsulate the airPrevent oxidative combustionLarge containersTank wagonsEngineeringMechanical engineering

The embodiment of the invention relates to a hopper device used for material cooling, transferring and storing and a material transferring method. The hopper device comprises a hopper body. The hopper body comprises a containing part used for storing materials, a jacket and multiple supports. The upper portion of the containing part is in a cylinder shape, and the lower portion of the containing part is in an inverted cone shape. A feeding port is formed in the top of the containing part, and a discharging port is formed in the bottom of the containing part. The discharging port is provided with an outlet sealing switch. The containing part further comprises a feeding cover which is buckled on the feeding port, and the feeding port and the feeding cover are sealed through rubber and are used for isolating air. Materials enter the containing part from the feeding port and are discharged out of the containing part through the discharging port. The jacket is arranged at the outer portion of the containing part, surrounds the containing part and is used for cooling the materials in the containing part. A cooling water outlet is formed in the top of the jacket, and a cooling water inlet is formed in the bottom of the jacket, wherein cooling water flows into the jacket from the cooling water inlet and flows out of the jacket from the cooling water outlet. The multiple supports are arranged on the peripheral edge of the hopper body. The upper portion of the support is connected with the hopper body and is used for supporting the hopper body.

Owner:江西紫宸科技有限公司 +1

Water-based lost foam casting coating with porous zeolite modified by titania film for magnesium alloy casting and preparation method thereof

InactiveCN105750485AImprove adsorption capacityImprove thermal stabilityFoundry mouldsFoundry coresWater basedCombustion

The invention discloses a water-based lost foam casting coating with porous zeolite modified by a titania film for magnesium alloy casting.According to the lost foam casting coating, kieselguhr and quartz sand which are subjected to heat conductive modification are used as refractory aggregate, and meanwhile the porous zeolite modified by the titania film is added, so that the coating has the good adsorbability and heat stability, foam liquid can be effectively adsorbed in the casting process, the problem that sand adheres to a casting can be effectively prevented, the temperature inside a cavity can be adjusted, and magnesium alloy oxidative combustion is avoided.The prepared coating has the advantages of being good in suspension property, breathable, resistant to heat, good in heat conductivity and heat insulation and the like.A casting with the high surface smoothness can be obtained after the coating is adopted, and the quality of the magnesium alloy casting is effectively improved.

Owner:HUOQIU COUNTY XINRUI METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com