Preparation of nontoxic magnesium alloy material for biological implantation

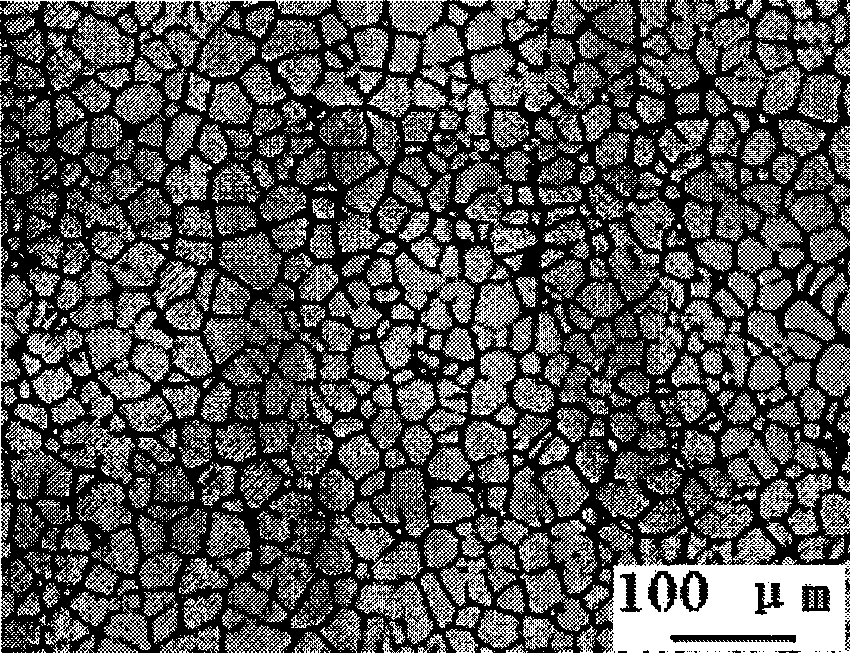

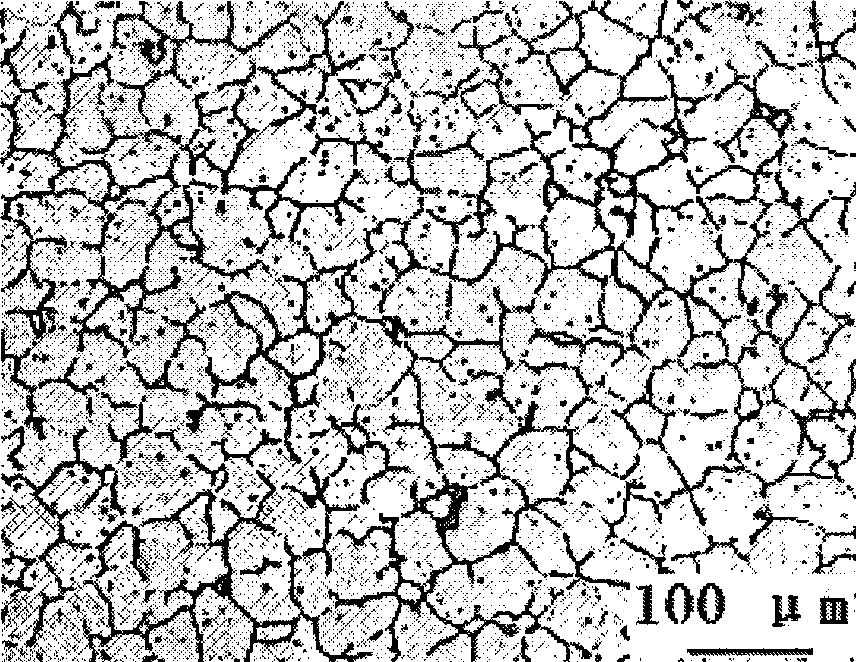

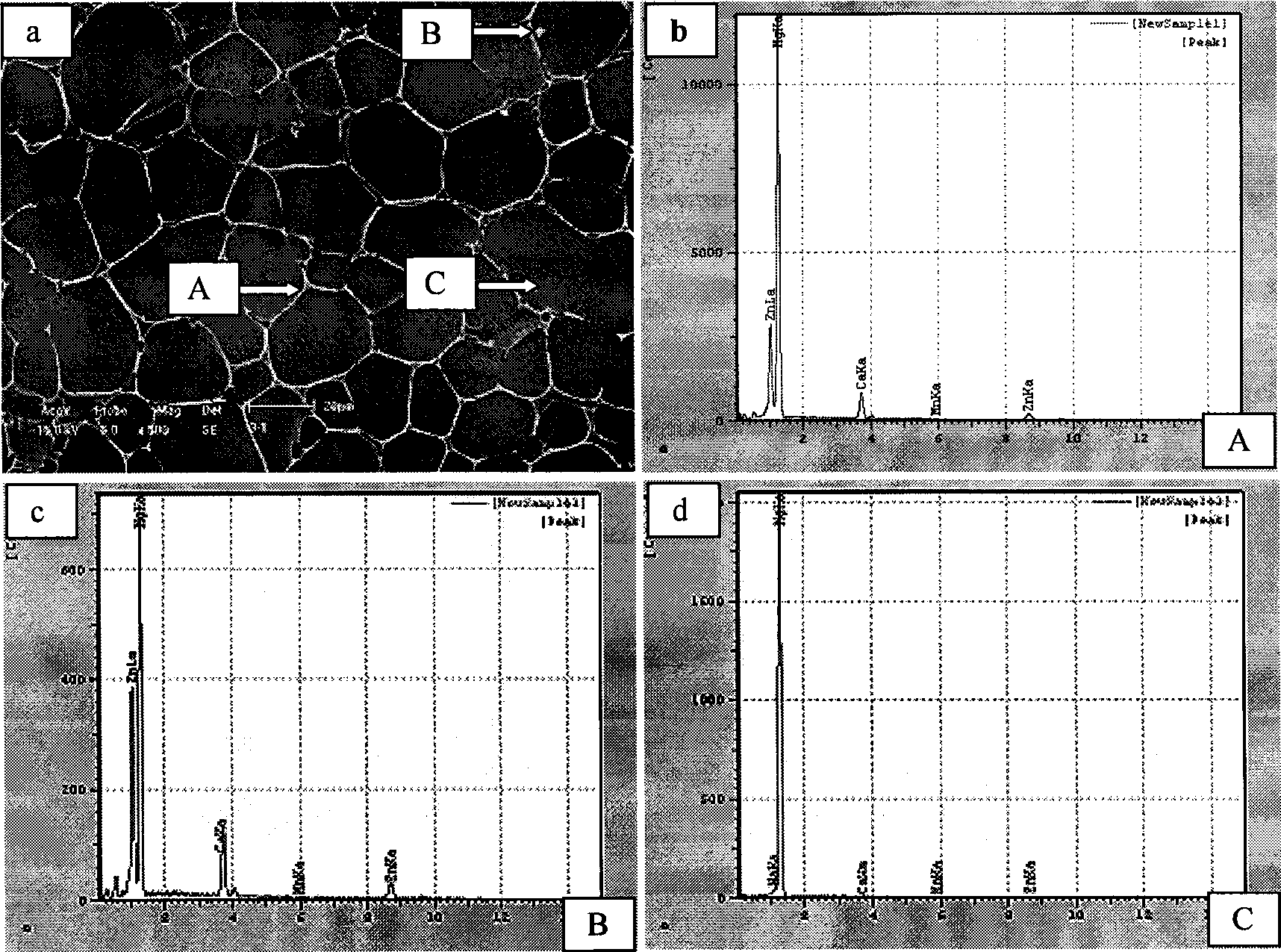

A magnesium alloy and biological technology, which is applied in the field of preparation of Mg-Mn and Mg-Zr series biomedical magnesium alloy materials, can solve the defects of single composition of magnesium alloy, plasticity, hardness, mechanical properties and corrosion resistance of castings, magnesium Problems such as insufficient uniformity and roundness of alloy ingot structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The smelting equipment is a thermal resistance furnace with a power of 2kw self-made in the laboratory. The structure is mainly composed of the built-in stainless steel crucible, the resistance wire surrounded by the crucible, as well as the insulation brick and the outer iron sheet.

[0028] The smelting equipment is used to heat and smelt the alloy. During the experiment, the temperature is measured with a thermocouple. When the set pouring temperature is reached, the molten magnesium alloy liquid is released at the furnace mouth for the pouring experiment.

[0029] Using this device to prepare Mg-Mn series biomedical materials, proceed as follows:

[0030] (1) The weight fractions of the chemical components are respectively: Zn2%, Mn0.5%, Ca5.0%, the sum of impurities≤0.1%, and the balance is Mg for raw material preparation;

[0031] (2) Preheat the smelting equipment to 550°C;

[0032] (3) Fill the preheated smelting equipment with argon gas, then ad...

Embodiment 2

[0035] Embodiment 2: the device of this example is identical with embodiment 1, carries out as follows:

[0036] (1) The weight fractions of the chemical components are respectively: Zn4%, Mn0.8%, Ca2.5%, the sum of impurities≤0.1%, and the balance is Mg for raw material preparation;

[0037] (2) Preheat the smelting equipment to 560°C;

[0038] (3) Fill the preheated smelting equipment with argon gas, then add industrially pure magnesium with a purity of 99.99wt% into the smelting equipment, and under the protection of argon gas with a flow rate of 6L / min and a pressure of 14MPa heating to melt

[0039] (4) Use the JWK-702 precision temperature control cabinet to control the temperature of the melt. When the temperature of the molten magnesium reaches 650°C, add 2.0wt% of the total weight of the alloy to the flame-retardant metal calcium and raise the temperature to 710°C, and then add the alloying elements wherein, a melting reaction is carried out;

[0040] (5) After the...

Embodiment 3

[0041] Embodiment 3: the device of this example is identical with embodiment 1, carries out as follows:

[0042] (1) The weight fractions of the chemical components are: Zn 6.0%, Mn 1.9%, Ca 0.6%, the sum of impurities ≤ 0.1%, and the balance is Mg for raw material preparation;

[0043] (2) Preheat the smelting equipment to 580°C;

[0044] (3) Fill the preheated smelting equipment with argon gas, then add industrially pure magnesium with a purity of 99.99wt% into the smelting equipment, and under the protection of argon gas with a flow rate of 5L / min and a pressure of 14MPa heating to melt

[0045] (4) Use the JWK-702 precision temperature control cabinet to control the temperature of the melt. When the temperature of the molten magnesium reaches 660°C, add 5.0wt% of the total weight of the alloy to the flame-retardant metal calcium and raise the temperature to 720°C, and then add the alloying elements wherein, a melting reaction is carried out;

[0046] (5) After the alloy i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com