Protective agent for magnesium alloy melt pouring, magnesium alloy casting and preparation method thereof

A protective agent and magnesium alloy technology, applied in the field of magnesium alloys, can solve the problems of ineffective protection of magnesium alloys and performance degradation of formed magnesium alloy castings, and achieve the effects of good protection, performance improvement and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

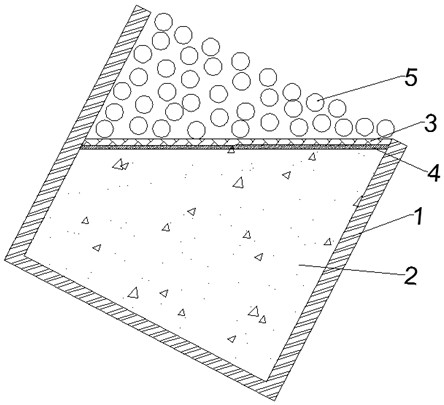

Image

Examples

preparation example Construction

[0039] In a second aspect, the present invention provides a method for preparing a magnesium alloy casting, comprising casting a magnesium alloy melt, and introducing the protective agent described in the first aspect before and / or during the casting.

[0040] The protective agent of the present invention can be introduced before and / or during the pouring according to actual needs, as long as it can protect the magnesium alloy melt, so as to ensure the quality of the magnesium alloy casting. Preferably, most of the protective agent is introduced before the casting, and an appropriate amount of protective agent is introduced during the casting process.

[0041] It can be understood that since the magnesium alloy melt has a relatively high temperature (generally around 700° C.), the protective agent will melt quickly after being introduced to form a protective layer.

[0042]The present invention does not have any limitation on the time of adding before the pouring, as long as i...

Embodiment 1

[0050] The protective agent of the invention is used to cast ZM5 alloy aviation bearings.

[0051] The material composition is ZM5 alloy, and its details are shown in Table 1.

[0052] Table 1

[0053]

[0054] Use the above materials to carry out the following smelting:

[0055] 1. Charge melting

[0056] Preheat the crucible to dark red, preheat the charge (namely the above materials) to above 200°C, and dry the flux (RJ-2) and modifier (hexachloroethane) at 140°C for 1.5h.

[0057] Sprinkle RJ-2 flux on the bottom of the crucible, add master alloy ingots, magnesium ingots, recycled materials, etc. in the preheated furnace materials, and heat up to melt.

[0058] After the charge is fully melted, adjust the temperature to 720°C, add the intermediate alloy and zinc ingot in the charge, and stir for 5 minutes after the charge is fully melted.

[0059] 2. Deterioration treatment

[0060] Adjust the temperature to 750°C, add 0.7wt% hexachloroethane for modification treat...

Embodiment 2

[0082] Carry out as in Example 1, the difference is that the proportions of the protective agents used are different, specifically, the mass ratio of sulfur and boric anhydride is 50:50, and the others are the same as in Example 1.

[0083] The surface of the obtained magnesium alloy casting is smooth and clean, and there is no oxidation and burning phenomenon in the melting process. After testing, the metallurgical quality meets the requirements of aviation standard HB7780-2005 Class I castings, and there is no inclusion (slag) in X-ray perspective.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com