High-efficiency and energy-saving submerged arc furnace

A high-efficiency, energy-saving, submerged arc furnace technology, applied in the field of submerged arc furnaces, can solve the problems of low production efficiency and maintenance efficiency of submerged arc furnaces, and achieve the effect of improving production efficiency and maintenance efficiency and avoiding mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

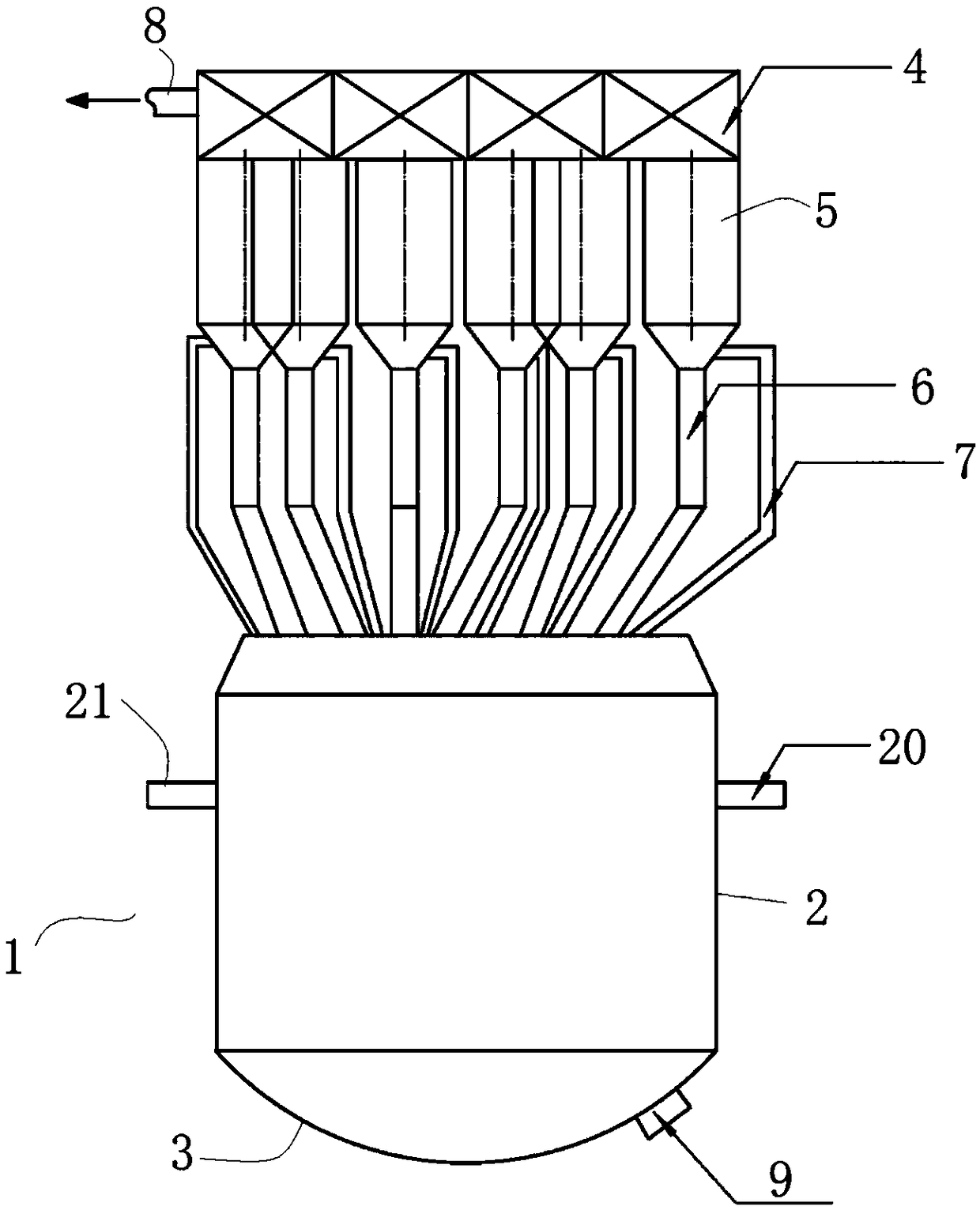

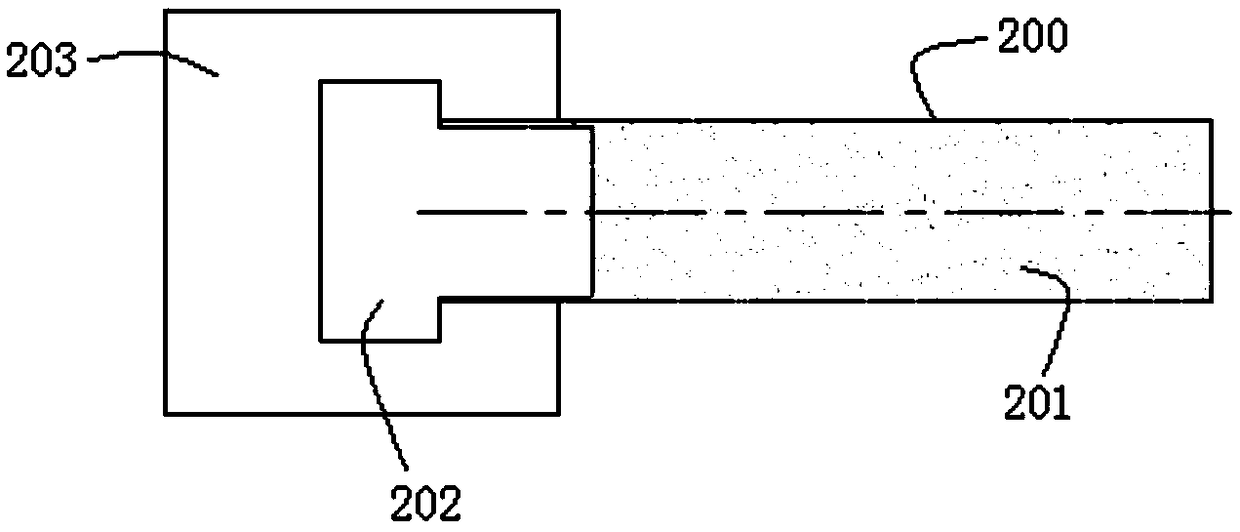

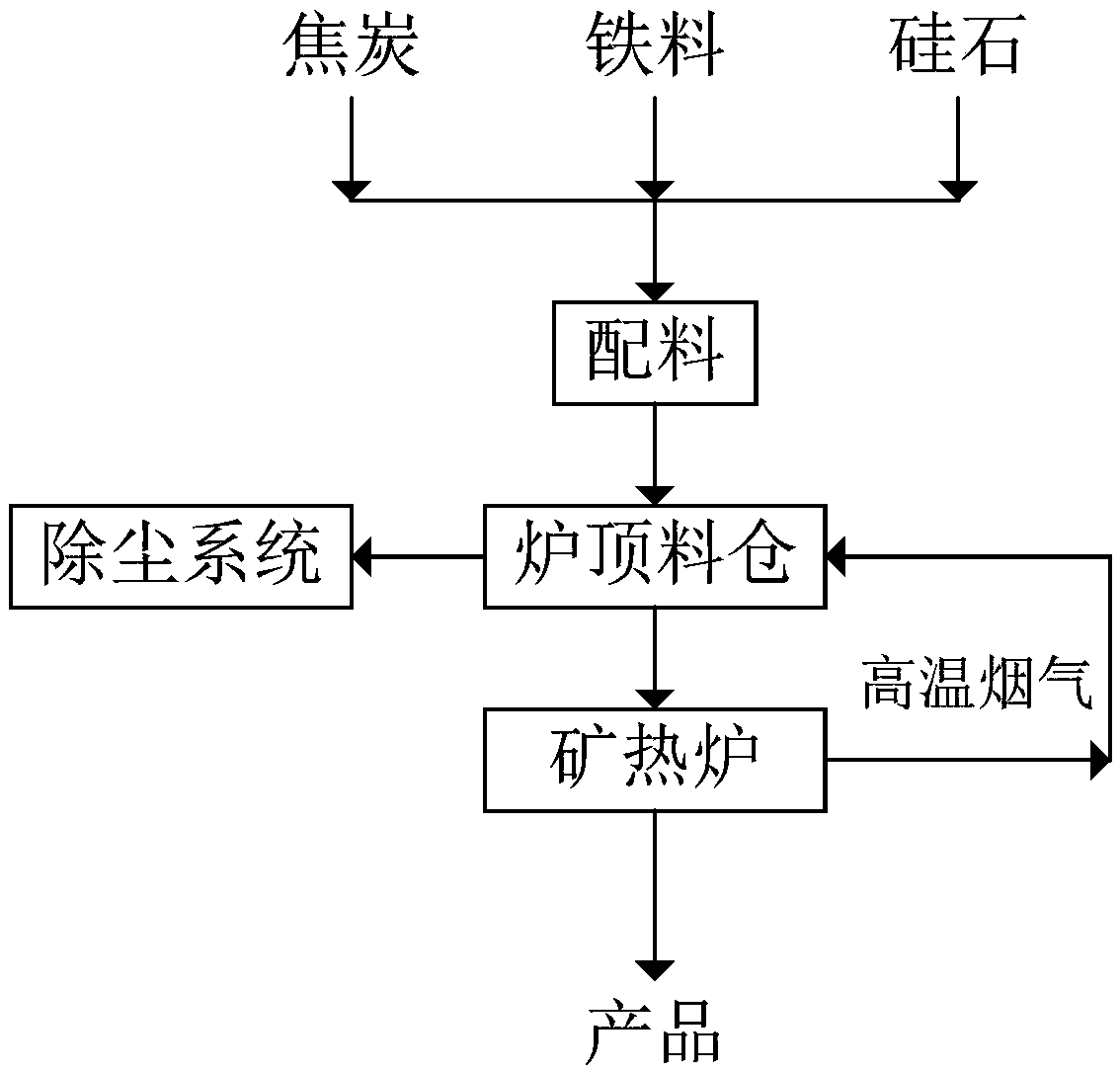

Embodiment 1

[0024] The working process of the high-efficiency and energy-saving submerged arc furnace of Example 1 is as follows image 3 Shown: silica, coke, iron and other raw materials are mixed and added to the distributor 4 for batching to obtain a mixture. The mixture enters the furnace body 1 through the feed pipe 6, and the electrode is energized to generate an electric arc and current to heat the furnace charge to achieve smelting In the process of energizing the electrode, the electrode paste 201 is gradually sintered and coked into shape. As the smelting process progresses, the end of the electrode in contact with the mixture is continuously consumed, and the electrode paste pressing and discharging device 202 continuously presses and discharges the electrode into the furnace body 1 , In order to realize the continuous use of the electrode, that is, to meet the characteristics of self-baking electrode while using, connecting to length, and sintering. The submerged arc furnace gas...

Embodiment 2

[0028] The working process of the high-efficiency and energy-saving submerged arc furnace of Example 2 is as follows: The related reaction of ferrosilicon smelting is: SiO 2 +2C=Si+2CO, Fe+Si=FeSi; submerged arc furnace gas contains CO and other flammable gas, the heat generated by the submerged arc furnace gas in the silica heating silo 10 and iron heating silo 11 after being burned by the burner Heat silica and iron materials. At the same time, the sensible heat of the submerged arc furnace gas is used in the carbon material preheating bin 12 to preheat the carbon material. In this way, different raw materials can be differentiated according to the nature of the raw materials, so that the preheating efficiency of different raw materials is higher, the consumption of electric energy is further reduced, the reaction time in the furnace body 1 is reduced, and the output of the furnace is increased. The preheated carbon material, the heated silica, and iron material are mixed in ...

Embodiment 3

[0030] The high-efficiency and energy-saving submerged arc furnace of Example 3 adopts a horizontal arrangement, which can expand the structure of the furnace body and increase the output; the number of electrodes can be set reasonably according to the output and design requirements.

[0031] In other embodiments of the high-efficiency and energy-saving submerged arc furnace of the present invention, the electrodes can be graphite electrodes; a single electrode can use the power supply mode of the patent related to the background art; when two electrodes are used, 380V three-phase electricity can be used, two of which The phases are connected to the electrodes separately, and the other phase is grounded; or the 220V voltage is used to connect, and the two phases are directly connected to the electrodes to form a current. When multiple electrodes are used at the same time, multiple three-phase transformers can be used, and every three electrodes are a set. If there is more than one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com