Composite modified graphite negative electrode material and preparation method thereof

A graphite negative electrode and composite modification technology, which is applied in the direction of graphite, chemical instruments and methods, nickel compounds, etc., can solve the problems of reducing ion conductivity, high equipment requirements, and difficulty in expanding production, and achieve volume specific capacity. Large-scale production, avoiding the effect of poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A kind of preparation method of composite modified graphite negative electrode material of the present invention comprises the following steps:

[0040] 1) Mix graphite with oxidant and intercalant according to a certain mass ratio to obtain a mixed solution;

[0041] 2) stirring the mixed solution under constant temperature conditions to obtain intercalation products;

[0042] 3) Repeatedly washing the intercalation product with deionized water until the pH of the filtrate is between 5-7, then drying the washed intercalation product, and then calcining in an inert atmosphere to raise the temperature to the target temperature and keep it warm for a specific time After that, the target object is obtained.

[0043] In the step 1, the mass ratio of graphite to oxidant and intercalant is 1:1-10:1-10.

[0044] The graphite is a mixture of one or more of natural graphite, artificial graphite, spherical graphite, graphite mesophase, the particle size of the graphite is 1-60 ...

Embodiment 1

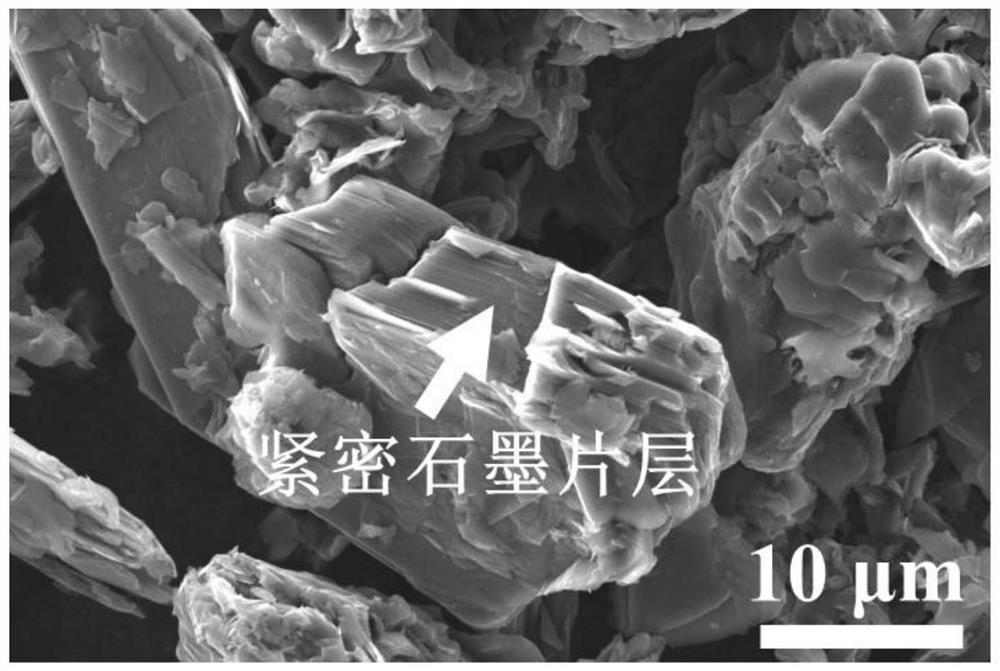

[0054] Artificial graphite anode materials with a particle size of 20 μm and a purity of 99wt% were mixed with 99.99% potassium permanganate and 50% nitric acid at a ratio of 1 g: 0.4 g: 4 mL, and stirred at 40 °C at a speed of 1000 rpm for 12 h, then use deionized water to wash and filter the product solid at room temperature until the pH of the filtrate is 5, and dry the product solid at 30 °C for 24 h, then heat up to 1 °C / min in a tube furnace under a nitrogen atmosphere. Calcined at 650 °C for 2 h to obtain a composite modified graphite anode material, that is, manganese oxide-loaded sulfur-free micro-expanded graphite for lithium-ion battery anode materials.

Embodiment 2

[0056] Artificial graphite anode material with a particle size of 20 μm and a purity of 89wt% was mixed with 99% potassium permanganate and 70% concentrated nitric acid at a ratio of 1 g: 1.46 g: 4 mL, and stirred at 40 °C at a speed of 1000 rpm for 12 h, then use deionized water to wash and filter the product solid at room temperature until the pH of the filtrate is 6, dry the product solid at 60°C for 12 h, then heat up at 10°C / min in a tube furnace under an argon atmosphere Calcined at 650 °C for 12 h to obtain composite modified graphite anode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com