Hopper device used for material cooling, transferring and storing and material transferring method

The technology of a hopper device and a material receiving device is applied in the direction of packaging, transportation and packaging, and transporting passenger cars. It can solve the problems of keeping above the burning point, lower production efficiency, and fires in packaging bags, so as to prevent oxidative combustion, facilitate operation, and High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0027] The hopper device provided by the embodiment of the present invention is applied in the process of material cooling, transfer and storage, and can realize the integration of material cooling, transfer and storage.

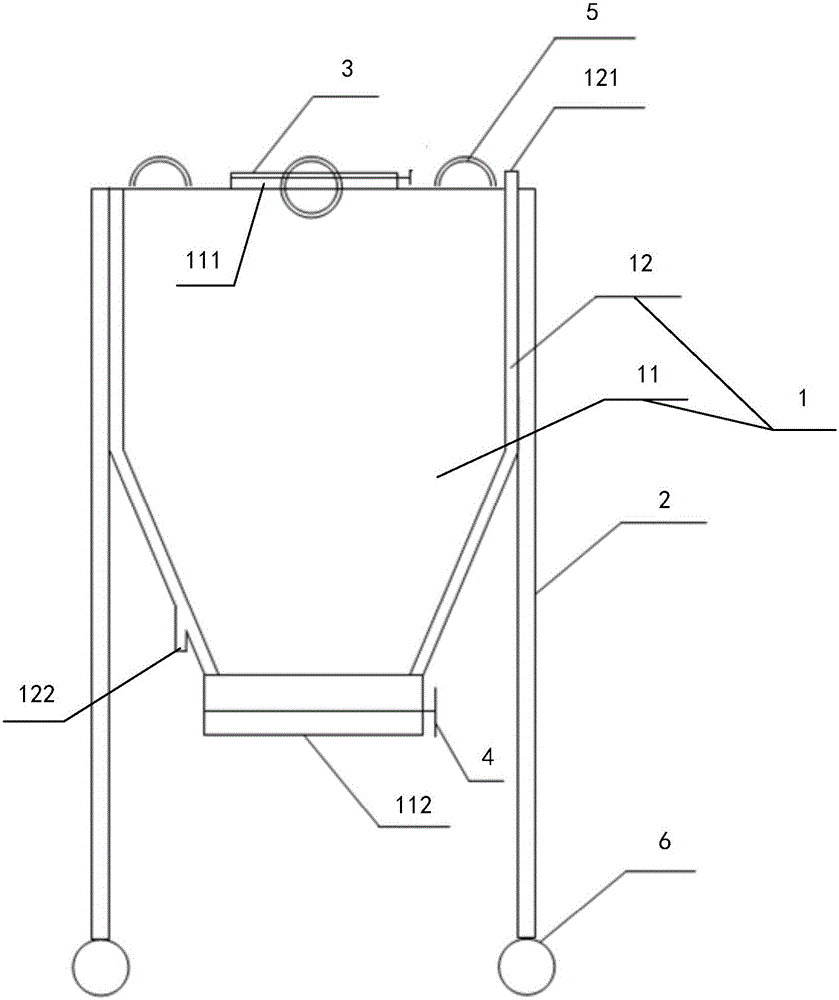

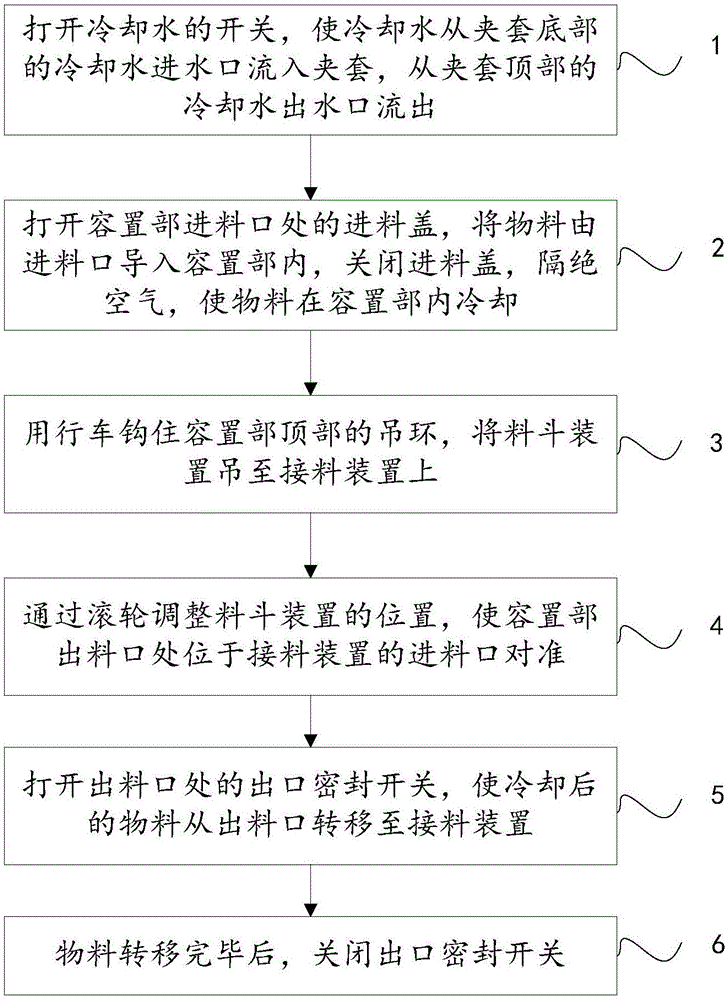

[0028] figure 1 A schematic structural diagram of a hopper device for material cooling, transfer, and storage provided by an embodiment of the present invention. Such as figure 1 As shown, the hopper device includes: a hopper body 1 and a plurality of supports 2 .

[0029] The hopper body 1 includes an accommodating part 11 and a jacket 12, and the function of the accommodating part 11 is to store materials.

[0030] Specifically, the accommodating part 11 can be divided into upper and lower parts, the upper part is cylindrical, and the lower part is inverted conical, and the upper and lower parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com