High-fluidity lubricant for metal drawing and application thereof

A lubricant, fluid technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

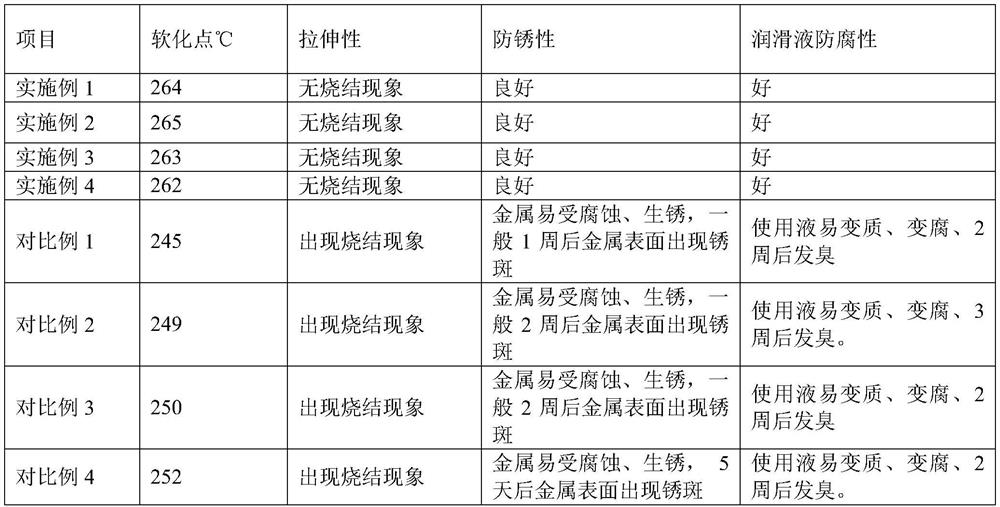

Examples

Embodiment 1

[0039] One, the preparation film-forming agent is acrylic acid-polyurethane emulsion, and its preparation process is:

[0040] A. Synthesis of core-shell hydroxyacrylic acid emulsion by seed method: Add core raw materials methyl methacrylate, butyl acrylate, and acrylic acid in sequence in the container, with a mass ratio of 1:1.1:2.3, heat up to 80°C, and add the first core layer The monomer was kept warm for 35 minutes to obtain the seed emulsion of the core layer. The duration of dropping the second core layer monomer was 1.2 hours. The mixed solution of toluene diisocyanate trimer, polyethylene glycol monomethyl ether and polyether, its mass ratio is 1:1.2:1.7:1.8, keep warm for 1.9h after the dropwise addition, and adjust the pH value of the emulsion after cooling down to room temperature Between 7.5, filter to obtain a core-shell type hydroxyacrylic acid emulsion; the mass ratio of the core material, the first core layer monomer, the second core layer monomer and the she...

Embodiment 2

[0053] One, the preparation film-forming agent is acrylic acid-polyurethane emulsion, and its preparation process is:

[0054] A. Synthesis of core-shell hydroxyacrylic acid emulsion by seed method: Add core raw materials methyl methacrylate, butyl acrylate, and acrylic acid in sequence in the container, with a mass ratio of 1:1:2.5, raise the temperature to 78°C, and add the first core layer The monomer was kept warm for 40 minutes to obtain the seed emulsion of the core layer. The duration of dropping the second core layer monomer was 1 hour. The mixed solution of isocyanate trimer, polyethylene glycol monomethyl ether and polyether has a mass ratio of 1:1:1.8:1.5. After the dropwise addition, keep it warm for 1.8 hours. After cooling down to room temperature, adjust the pH value of the emulsion to 8.0 or less. Between, filter to obtain the core-shell type hydroxyacrylic acid emulsion; the mass ratio of the core raw material, the first core layer monomer, the second core lay...

Embodiment 3

[0067] One, the preparation film-forming agent is acrylic acid-polyurethane emulsion, and its preparation process is:

[0068] A. Synthesis of core-shell hydroxyacrylic acid emulsion by seed method: add core raw materials methyl methacrylate, butyl acrylate, and acrylic acid in sequence in the container, with a mass ratio of 1:1.2:2, heat up to 82°C, and add the first core layer The monomer was kept warm for 40 minutes to obtain the seed emulsion of the core layer. The duration of dropping the second core layer monomer was 1.5 hours. The mixed solution of toluene diisocyanate trimer, polyethylene glycol monomethyl ether and polyether, the mass ratio is 1:1.4:1.5:2, keep warm for 2 hours after the dropwise addition, and adjust the pH value of the emulsion to 7.0 after cooling down to room temperature In between, filter to obtain a core-shell type hydroxyacrylic acid emulsion; the mass ratio of the core material, the first core layer monomer, the second core layer monomer and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com