Quantum dot interlayer CSP backlight with luminescence of five surfaces and manufacturing method thereof

A quantum dot and backlight technology, applied in the field of backlight, can solve problems such as quantum dot powder performance attenuation, achieve high yield, high light extraction efficiency, and improve light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

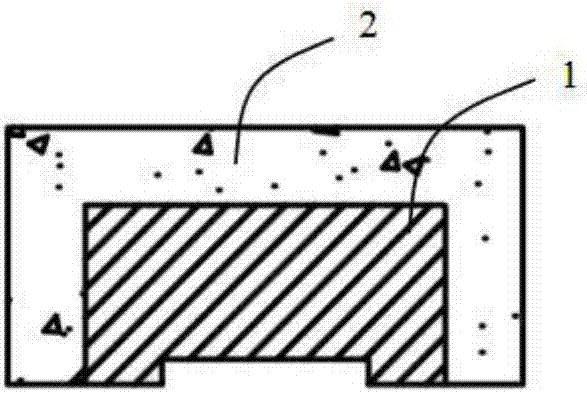

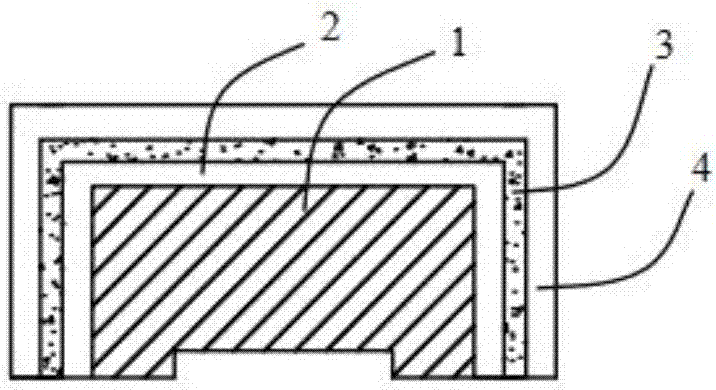

[0031] Such as image 3 As shown, the embodiment of the present invention provides a five-sided luminous quantum dot interlayer CSP backlight, including a luminous flip chip 1, which also includes an inner transparent glue layer 2 wrapped around the upper end and surroundings of the flip chip 1, so The inner transparent glue layer 2 is wrapped with a quantum dot glue layer, and the quantum dot glue layer 3 is wrapped with an outer transparent glue layer 4; the quantum dot glue layer 3 is formed by curing encapsulation glue dissolved with quantum dot fluorescent powder.

[0032] The CSP backlight provided by this embodiment emits light outward through the upper end and the surrounding area.

[0033] The inner transparent glue layer 2 is a high-refractive-index transparent glue layer; the high-refractive-index transparent glue has a refractive index of 1.50-1.55 and is made of epoxy resin or organic silica gel.

[0034] The outer transparent glue layer 4 has glue with a strong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com