Low-temperature halogen-free lead-free solder paste

A halogen-free lead-free solder paste and solder paste technology, applied in the field of surface mount technology low-temperature lead-free process welding, can solve the problems of poor mechanical properties and mechanical strength of solder paste, and achieve superior solubility, less residue, and guaranteed welding. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

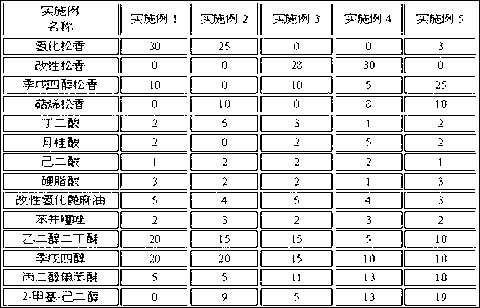

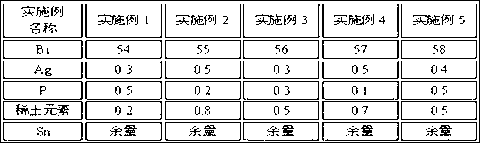

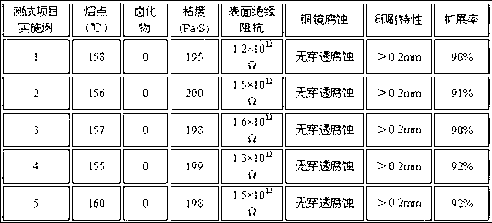

Embodiment 1

[0034] Preparation method: mix 20g ethylene glycol dibutyl ether, 20g pentaerythritol, 5g propylene glycol monophenyl ether, 30g hydrogenated rosin, 10g pentaerythritol rosin, 2g succinic acid, 2g lauric acid, 1g adipic acid and 3g stearic acid Heating to 120°C + 5°C until completely dissolved; while stirring, add 5g of modified hydrogenated castor oil and 2g of benzothiazole in sequence, and continue stirring to room temperature after dissolving. Take 10g of flux and 90g of solder powder and mix and stir under vacuum conditions to obtain a uniformly mixed low-temperature halogen-free lead-free solder paste.

Embodiment 2

[0036] Preparation method: 15g ethylene glycol dibutyl ether, 20g pentaerythritol, 5g propylene glycol monophenyl ether, 9g 2-methyl-hexanediol, 25g hydrogenated rosin, 10g terpene rosin, 5g succinic acid, 2g adipic acid, Mix 2g of stearic acid evenly and heat to 130°C + 5°C until completely dissolved; add 4g of modified hydrogenated castor oil and 3g of benzothiazole sequentially under stirring, and continue stirring to room temperature after dissolving. Take 12g of flux and 88g of solder powder and mix and stir under vacuum conditions to obtain a uniformly mixed low-temperature halogen-free lead-free solder paste.

Embodiment 3

[0038] Preparation method: 15g ethylene glycol dibutyl ether, 15g pentaerythritol, 11g propylene glycol monophenyl ether, 5g 2-methyl-hexanediol, 28g modified rosin, 10g pentaerythritol rosin, 3g succinic acid, 2g lauric acid, 2g Mix adipic acid and 2g stearic acid evenly and heat to 130°C + 5°C until completely dissolved; while stirring, add 5g of modified hydrogenated castor oil and 2g of benzothiazole in sequence, and continue stirring to room temperature after dissolving. 11g of flux and 89g of solder powder were mixed and stirred under vacuum conditions to obtain a uniformly mixed low-temperature halogen-free lead-free solder paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com