High-strength flame-retardant magnesium alloy and preparation method thereof

A magnesium alloy, high-strength technology, applied in the field of magnesium alloys, can solve the problems of poor mechanical properties and flame retardant properties, poor mechanical properties and flame retardant properties of magnesium alloys, and achieve good flame retardant properties, improved mechanical properties, and good room temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

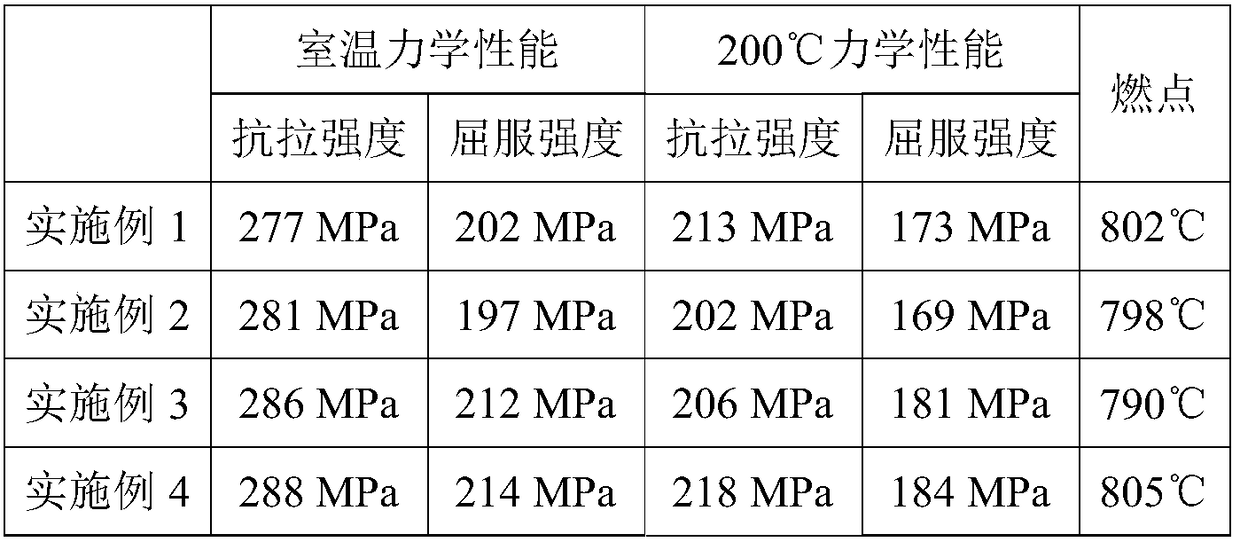

Embodiment 1

[0022] Example 1 of the high-strength flame-retardant magnesium alloy of the present invention consists of the following components in mass percentage: Nd 6.0%, Ce 3.5%, Al 2.2%, Si 0.8%, Ag 1.8%, Nb 0.8%, and the balance is Mg and unavoidable impurities, the total mass fraction of impurity elements Fe, Cu and Ni is less than 0.2%.

Embodiment 2

[0023] Example 2 of the high-strength flame-retardant magnesium alloy of the present invention consists of the following components in mass percentage: Nd 6.2%, Ce 3.2%, Al 2.5%, Si 0.5%, Ag 1.5%, Nb 0.9%, and the balance is Mg and unavoidable impurities, the total mass fraction of impurity elements Fe, Cu and Ni is less than 0.2%.

Embodiment 3

[0024] Example 3 of the high-strength flame-retardant magnesium alloy of the present invention consists of the following components in mass percentage: Nd 6.3%, Ce 3.2%, Al 2.0%, Si 0.6%, Ag 2.0%, Nb 0.9%, and the balance is Mg and unavoidable impurities, the total mass fraction of impurity elements Fe, Cu and Ni is less than 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com