Mg alloy vacuum sealing smelter and method for preventing Mg alloy from oxidation burning

A vacuum sealing, magnesium alloy technology, applied in the fields of metal materials and metallurgy, can solve the problems of equipment and human harm, increase the environment, short life and other problems, achieve the effect of friendly operation interface, economical and environmental protection, and prevention of oxidative combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

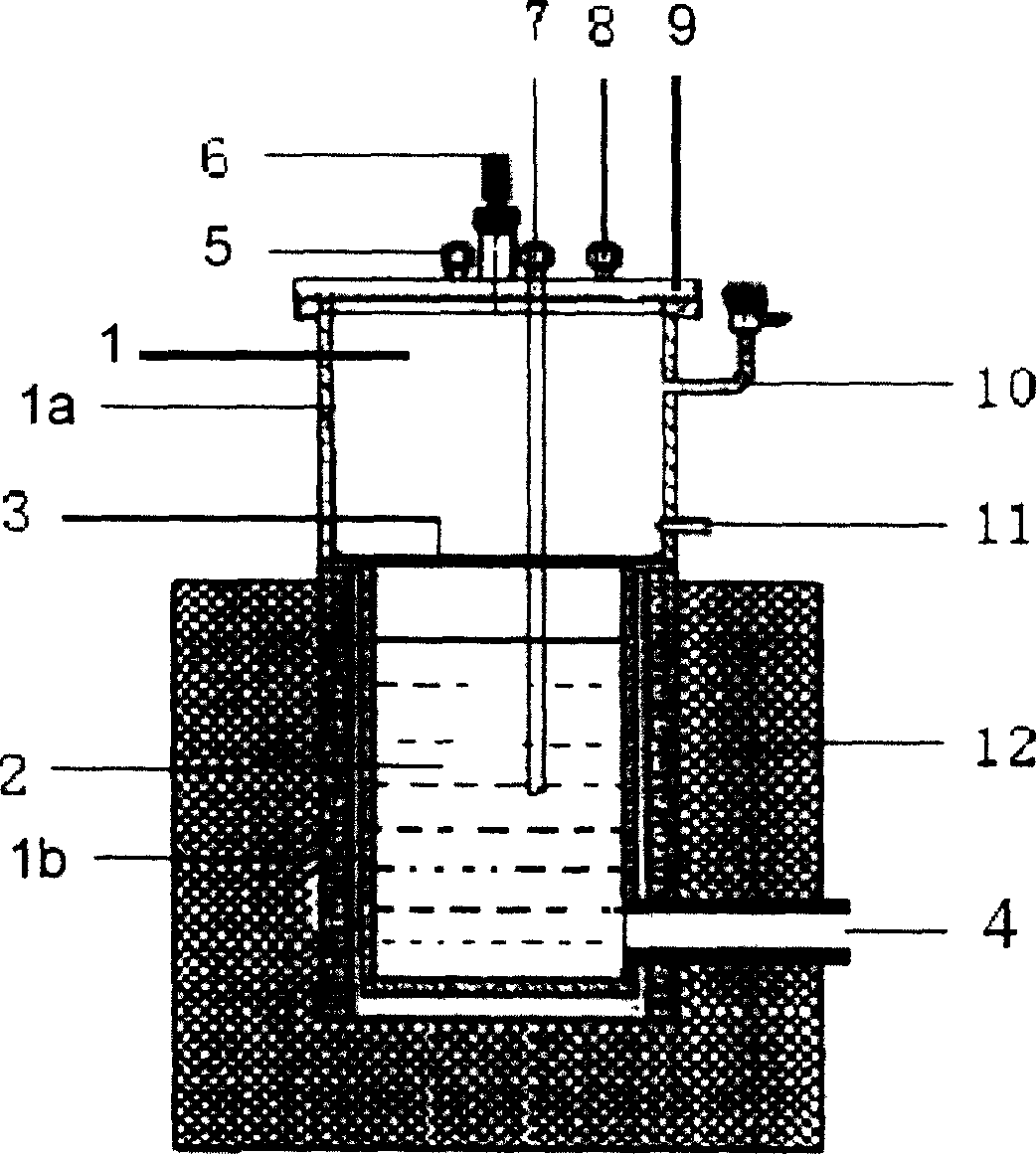

[0028] Example 1. Melting magnesium alloy AZ91D, the melting temperature is 720°C, the melting crucible pressure rise rate is 20000Pa / hour, and the protective gas input pipeline is connected for the first time

[0029] Remove the crucible cover 9, put the dried magnesium alloy AZ91D into the lower part 1b of the crucible, and then cover the heat shield 3 and the melting crucible cover 9. Then open the vacuum system to remove the air in the smelting crucible 1; when the pressure in the crucible 1 is less than 1Pa, open the gas charging port and continue pumping for 3 minutes, while using the protective gas input device to fill the melting crucible 1 through the gas charging port 10. Gas, 99.9% N 2 +0.1% SF 6 , to prevent evaporation, oxidation, and combustion during the smelting process of molten magnesium. When the pressure in the melting crucible is 1 atmosphere, close the gas filling port, turn on the power supply of the heating furnace, and start smelting magnesium alloy. ...

example 2

[0031] Example 2. Melting magnesium alloy AZ91D, melting temperature is 720°C, melting crucible pressure rise rate is 200Pa / hour, and there is no air in the protective gas input pipeline

[0032] Remove the crucible cover 9, put the dried magnesium alloy AZ91D into the lower part 1b of the crucible, and then cover the heat shield 3 and the melting crucible cover 9. Then open the vacuum system to remove the air in the melting crucible 1; when the pressure in the crucible 1 is less than 1Pa, close the isolation valve of the vacuum system connected with the melting crucible 1. Open the gas charging port, and use the protective gas input device to fill the melting crucible 1 with protective gas through the gas charging port 10, 99.9% N 2 +0.1% SF 6 , to prevent evaporation, oxidation, and combustion during the smelting process of molten magnesium. When the pressure in the smelting crucible is 80,000Pa, close the gas inlet, turn on the power of the heating furnace, and start smelt...

example 3

[0034] Example 3. Melting magnesium alloy AZ91D, melting temperature is 720°C, melting crucible pressure rise rate is 0.2Pa / hour, and there is no air in the protective gas input pipeline

[0035] Remove the crucible cover 9, put the dried magnesium alloy AZ91D into the lower part 1b of the crucible, and then cover the heat shield 3 and the melting crucible cover 9. Then open the vacuum system to remove the air in the melting crucible 1; when the pressure in the crucible 1 is less than 1Pa, close the isolation valve of the vacuum system connected with the melting crucible 1. Open the gas charging port, and use the protective gas input device to fill the melting crucible 1 with protective gas through the gas charging port 10, 99.5% N 2 +0.5% SF 6 , to prevent evaporation, oxidation, and combustion during the melting of molten magnesium. When the pressure in the melting crucible is 20,000 Pa, close the gas inlet, turn on the power of the heating furnace, and start melting magnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com