Capillary core performance testing device for heat pipe and testing method thereof

A testing device and capillary core technology, applied in the field of heat pipes, can solve problems such as the unfavorable actual performance of the capillary core, and achieve the effects of good capillary suction performance and penetration performance, wide adaptability, and simple testing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

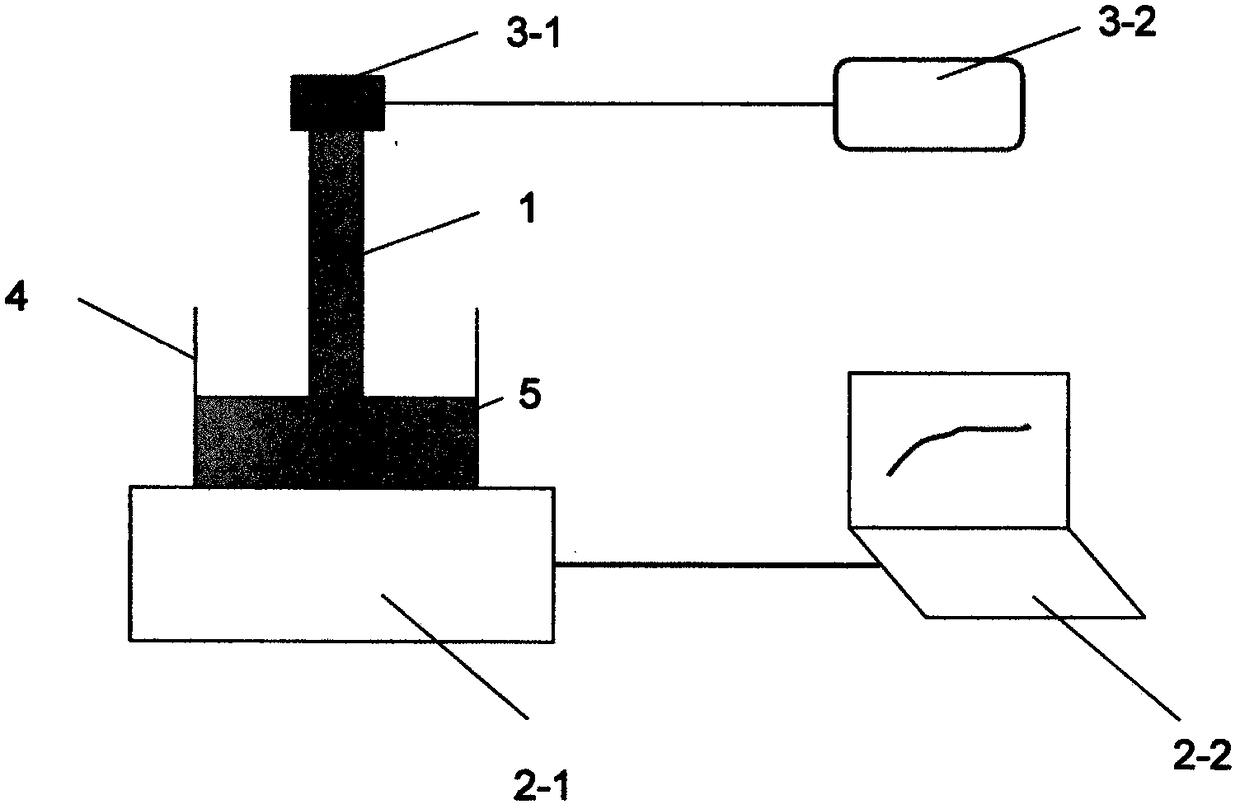

[0025] Such as figure 1 As shown, the present invention provides a novel heat pipe capillary wick performance testing device, comprising a capillary core to be tested 1, a weight testing system 2, a heating system 3, a working medium container 4 and a working medium 5, and the capillary core to be tested 1 One end extends into the working medium container 4 and contacts with the working medium 5 (the contact condition can be similar to that of the capillary wick in the heat pipe), and the other end of the capillary wick 1 to be tested is heated by the heating system 3 (the heating condition can be similar to that of the capillary wick in the heat pipe). The situation of the capillary wick in the heat pipe is similar), when heated to the phase transition point of the working fluid, the working fluid at the heating place undergoes a phase change, becomes steam and is emitted to the outside world, and the capillary wick 1 continuously flows from the working medium container throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com