Device and method for producing integrated magnesium base composite material

A composite material and preparation device technology, which is applied in the field of integrated magnesium-based composite material preparation devices, can solve problems such as easy oxidation, reduced performance of parts, and difficult quantitative pouring of magnesium alloy liquid, so as to avoid oxidative combustion and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

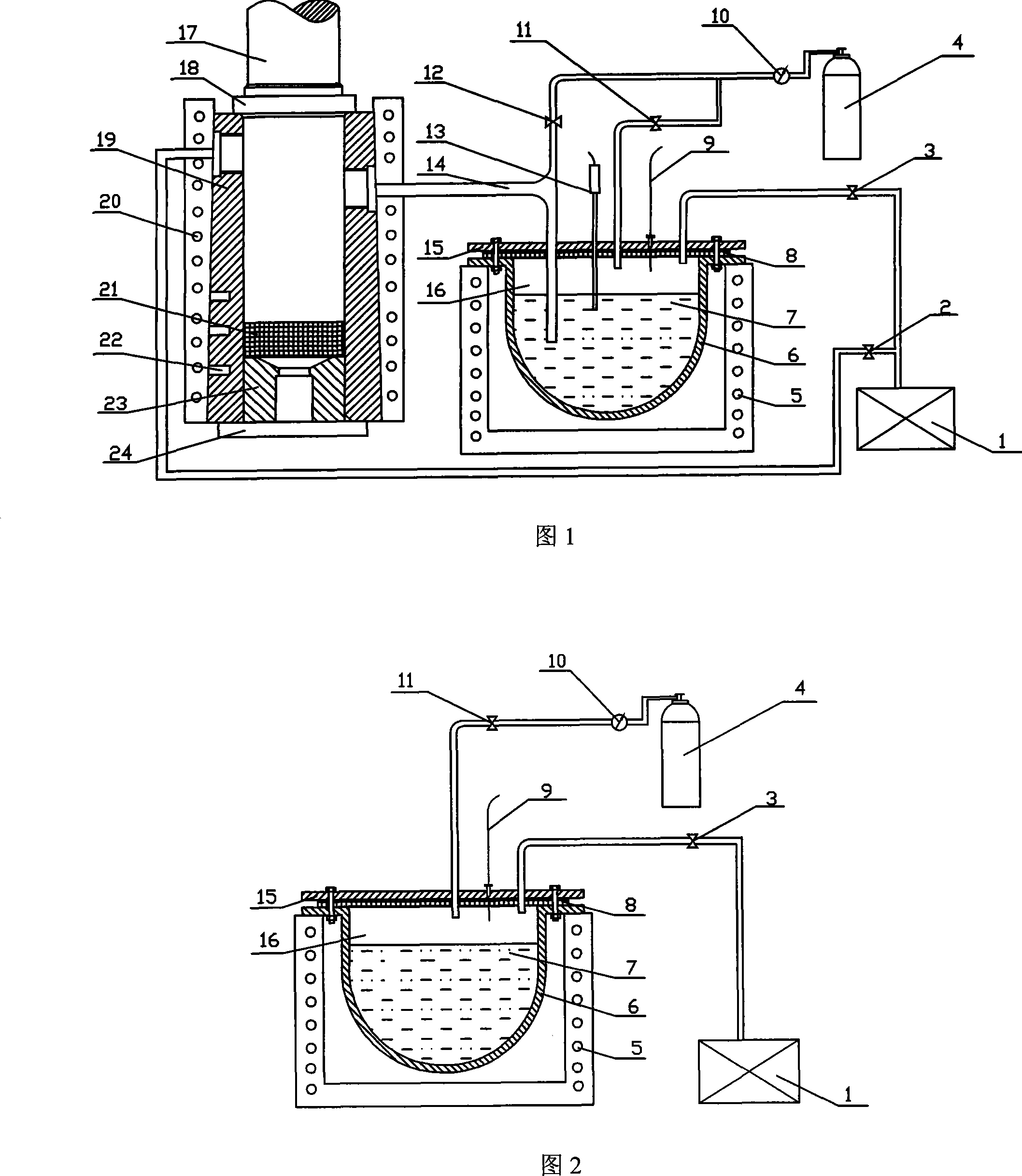

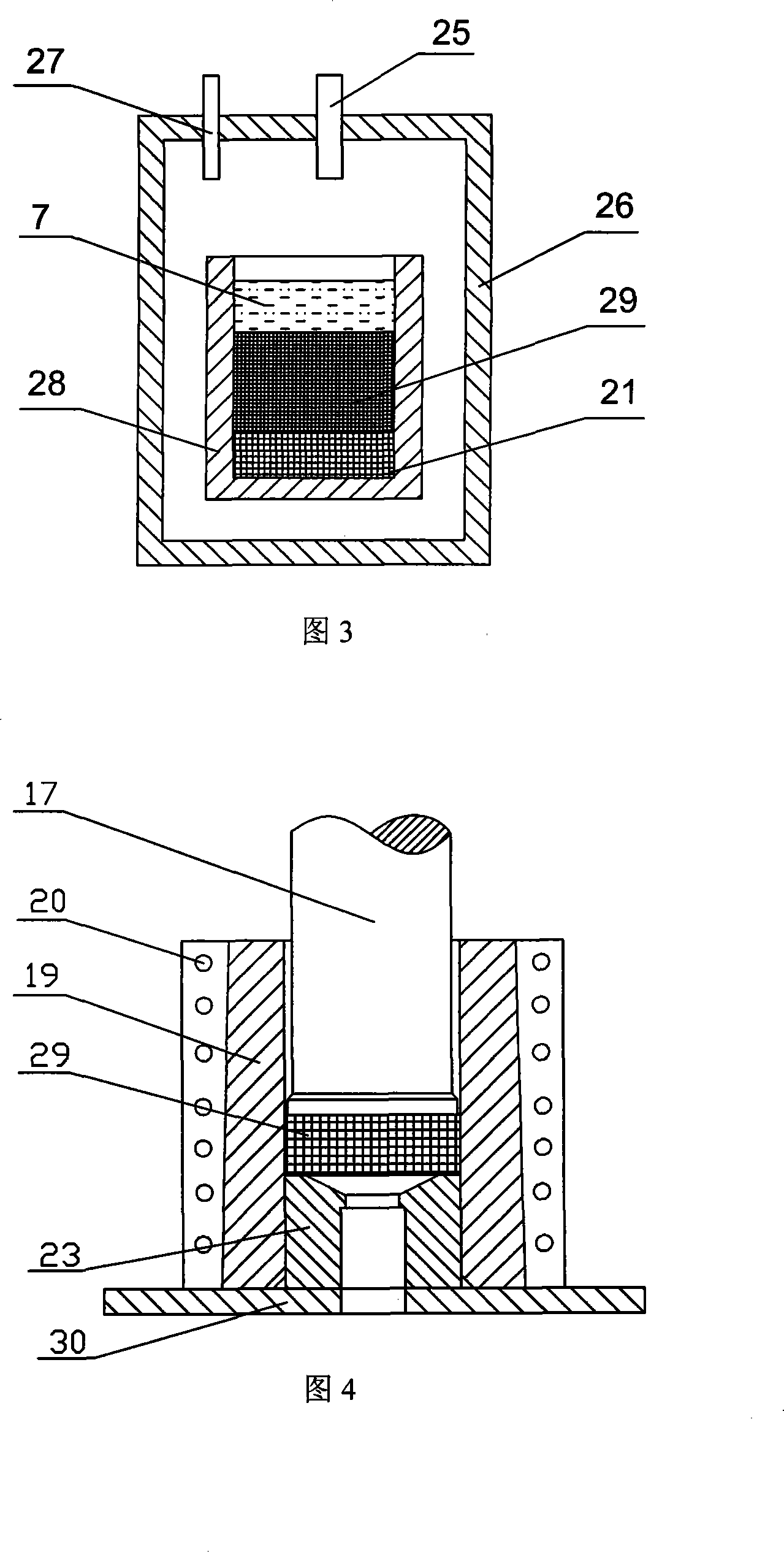

[0028] Example 1. Refer to Figure 1. The metal substrate used in this example is AZ91D magnesium alloy, and the preform is aluminum borate whisker produced by Luoyang Refractory Research Institute. The size of the preform is 45×30mm, and the aluminum borate whisker preform is prepared by wet method.

[0029] The device of the present invention comprises a smelting device and an extrusion molding device, the smelting device communicates with the die cavity of the die barrel 19 of the extrusion molding device through a three-way liquid inlet pipe 14, and the third end of the three-way liquid inlet pipe 14 passes through the D The valve 12 is connected with the pressure tank 4, the mold cavity of the die barrel 19 is communicated with the vacuum pump 1 through a pipeline, and the melting chamber 16 is also connected with the pressure tank 4 and the vacuum pump 1 through a pipeline respectively. The liquid level sensor 13 is connected with the crucible cover 15 by a self-sealing...

Embodiment 2

[0032] Example 2. The aluminum borate whisker prefabricated body is coated, and the aluminum oxide coating is prepared on the surface of the aluminum borate whisker by using the sol-gel method, so as to achieve the purpose of modifying the whisker surface.

[0033] Steps: (1) Place the prepared alumina-coated aluminum borate whisker prefabricated body in the die barrel 19, place the AZ91D magnesium alloy ingot in the crucible melting chamber 16, connect the device and the circuit, and place the The die barrel 19 and the crucible 6 are sealed;

[0034] (2) Close A valve 2 and B valve 3, close C valve 11, open D valve 12, feed Ar gas, and control the gas pressure at 0.2-0.9 MPa;

[0035] (3) Start the temperature control system, A resistance heater 5 is heated for 2 to 5 hours to keep the crucible temperature at 600 to 850°C, B resistance heater 20 is heated for 1 to 2 hours to control the temperature of the preform and the forming mold at The temperature is 400-700°C, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com