Preparation method of exciter beam for road crushing vehicle

A technology for exciting beams and beam bodies, which is applied in the field of preparing vibration beams for road crushing vehicles, can solve the problems of high processing difficulty and difficulty in fixing and connecting other components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

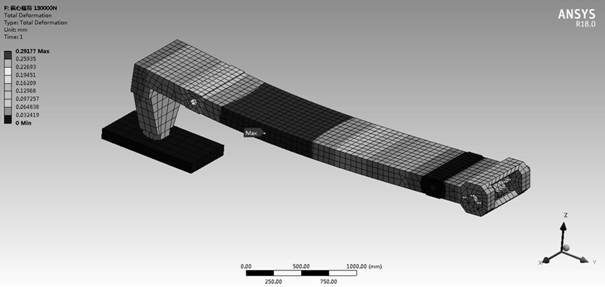

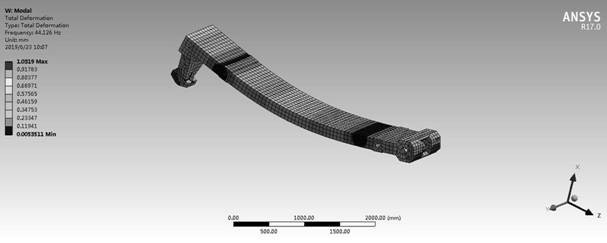

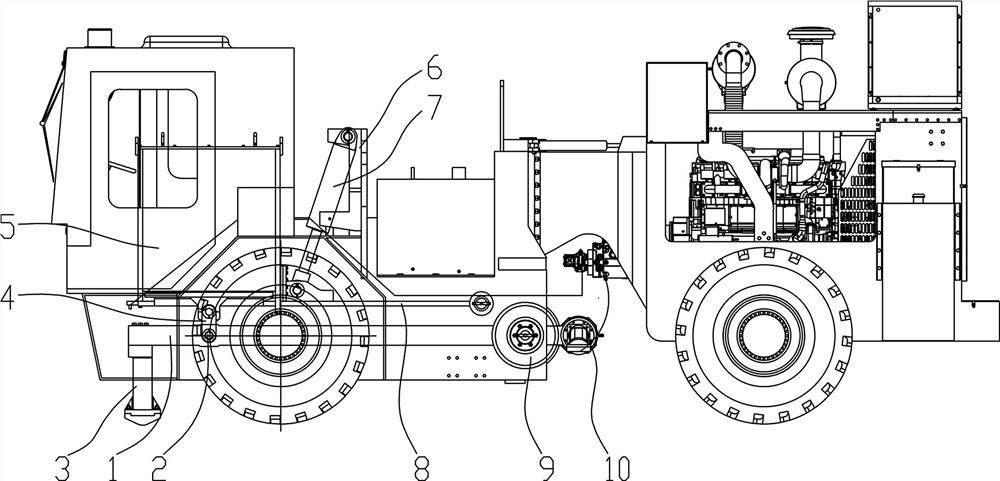

[0036] Such as Figure 1~3 Among them, the specific structure of the cement pavement crushing vehicle is: one end of the excitation beam 1 is connected to the breaking hammer 3, and the other end of the excitation beam 1 is connected to the excitation source 10;

[0037] The second hinge pin 11 close to the excitation source 10 is hinged with the car body 6 through the tire hinge 9;

[0038] The first hinge pin 2 close to the breaker 3 is hinged to the supporting plate 8 through the connecting rod 4, and the end of the supporting plate 8 away from the connecting rod 4 is hinged to the vehicle body 6;

[0039] The position in the middle of the supporting plate 8 is hinged with one end of the lifting cylinder 7, and the other end of the lifting cylinder 7 is hinged with the car body 6. The preferred solution is as figure 2 Among them, the supporting plate 8 is also provided with a counterweight 5, and the midline of the counterweight 5 is flush with the connecting rod 4. Thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com