Dual-roller thin-belt casting rolling analog equipment as well as usage and control method thereof

A double-roller thin strip and simulation equipment technology, applied in the direction of digital control, electrical program control, teaching model, etc., can solve the problems of complex and different influencing factors, and achieve the effect of improving control accuracy, real simulation effect and improving surface quality.

Inactive Publication Date: 2010-11-10

NORTHEASTERN UNIV LIAONING

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The heat flux at the casting-rolling interface is not only different at different positions on the casting roll surface, but also its influencing factors are very complex

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

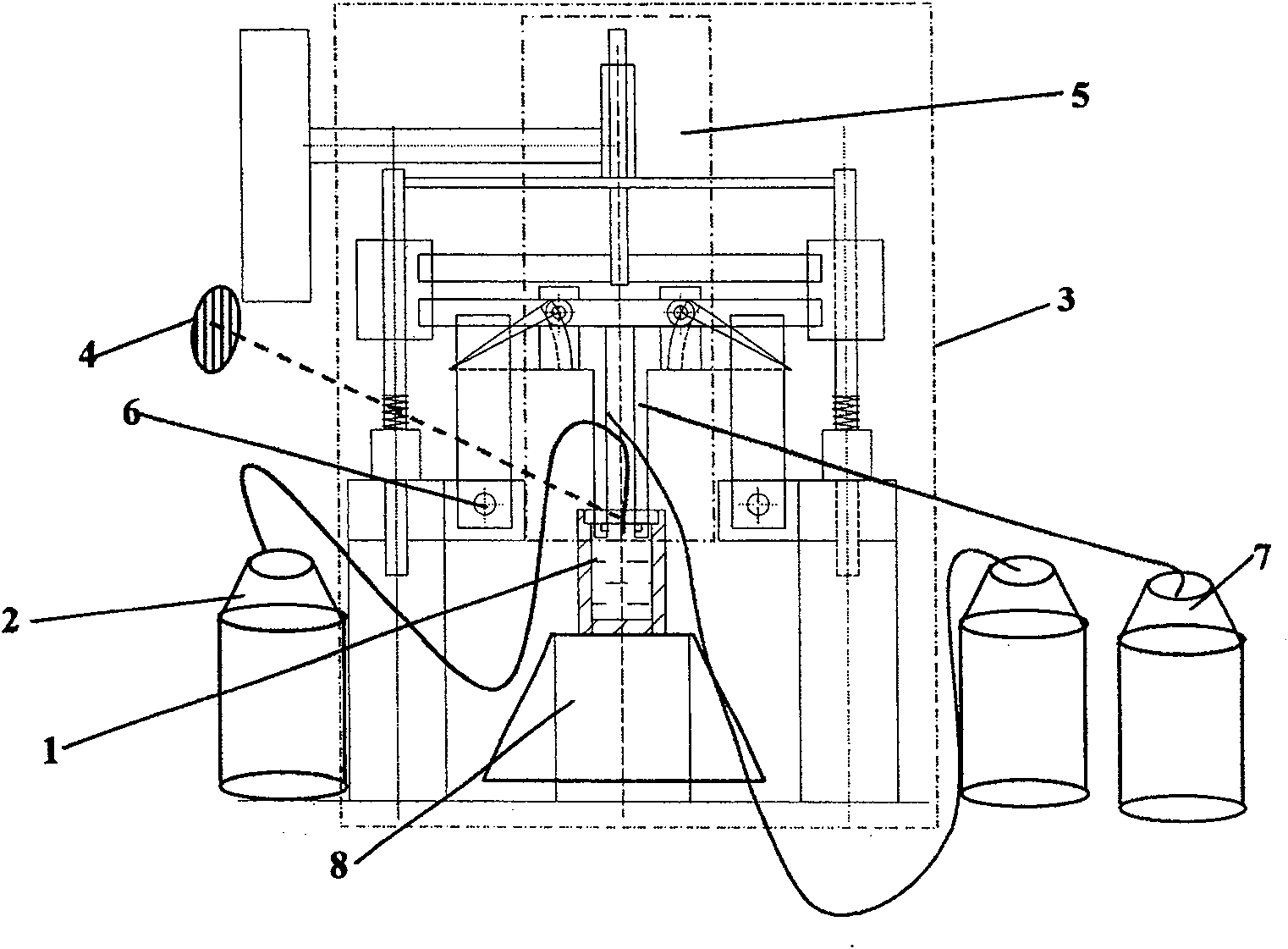

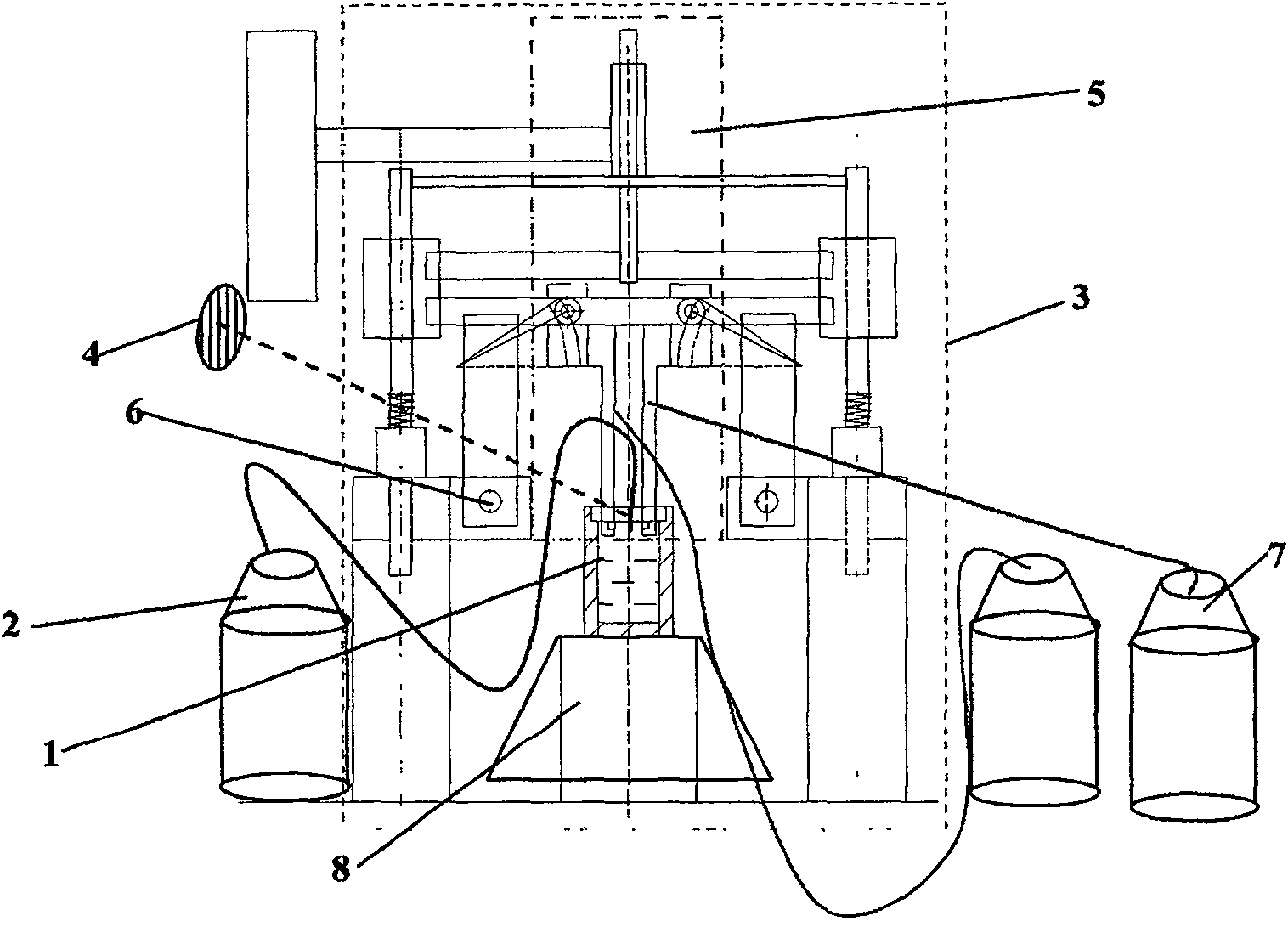

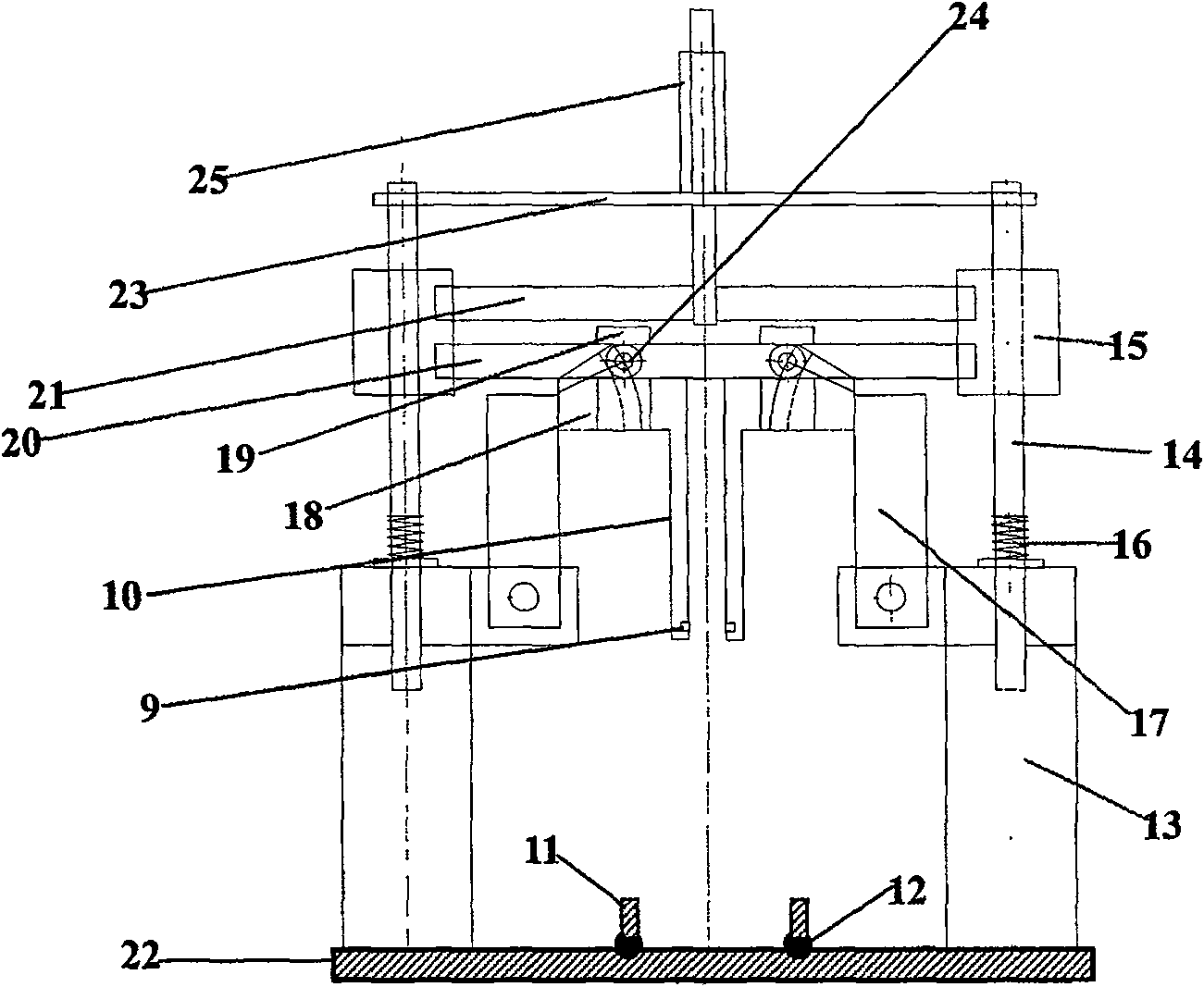

The invention provides a simulation equipment of twin-roll strip roll casting, which comprises a medium-frequency induction furnace, an online gas supplying apparatus, a temperature field measuring device near the surface of an online crystallization surface and an online molten pool temperature measuring device. The structure of the simulator of the equipment is that a bottom support, a track ofthe medium-frequency induction furnace and a limiting stop are disposed on the base plate, two vertical sliding bars are arranged between the bottom support and an upper horizontal channel steel stage, each sliding bar is provided with a big sliding barrel capable of sliding along the bar, an upper cross beam and a lower cross beam are connected between two big sliding barrels, the channel steel stage is equipped with a hydraulic equipment, the hydraulic equipment and the lower cross beam are connected by screws, a casting mold is fixed on a small sliding block by a rapid expansion link, the small sliding block can slide on the lower cross beam, roller on the small sliding block can roll along a curved guide rail to drive the casting mold to move, the curved guide rail is fixed on a supporting board which is fixed in a groove on the inner side of the bottom support. By simulation experiments, matching relationship of each processing parameter in roll casting process can be obtained. The invention is used to direct actual commercial manufacture.

Description

Twin-roll thin strip casting and rolling simulation equipment and its use and control method technical field The invention relates to a simulation device, in particular to a casting-rolling simulation device and its use method and control method. Background technique With the introduction of concepts such as reduction, conservation and circular economy, the iron and steel industry has paid more and more attention to the issue of scrap steel reuse. Scrap steel generally contains a large amount of impurity elements such as P, Cu, Sn, Pb, Zn, etc., and it is often very difficult to remove them from scrap steel. In the national key basic research, it is proposed that when scrap steel is processed for reuse, rapid solidification technology such as twin-roll strip casting and rolling can be used to suppress or even eliminate the macro-segregation of impurity elements in scrap steel, so that the impurity elements can be evenly distributed In the steel, it can save a lot of scrap...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G09B25/02B22D11/16G05B19/18

Inventor 刘振宇周国平曹光明李成刚邱以清刘相华王国栋

Owner NORTHEASTERN UNIV LIAONING

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com