Method for repairing and polishing ceramic part through laser

A technology for ceramic parts, laser repair, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc. Completely eliminate problems such as deep pores and cracks, and achieve the effect of facilitating automated production, reducing impact, and repairing dimensional deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

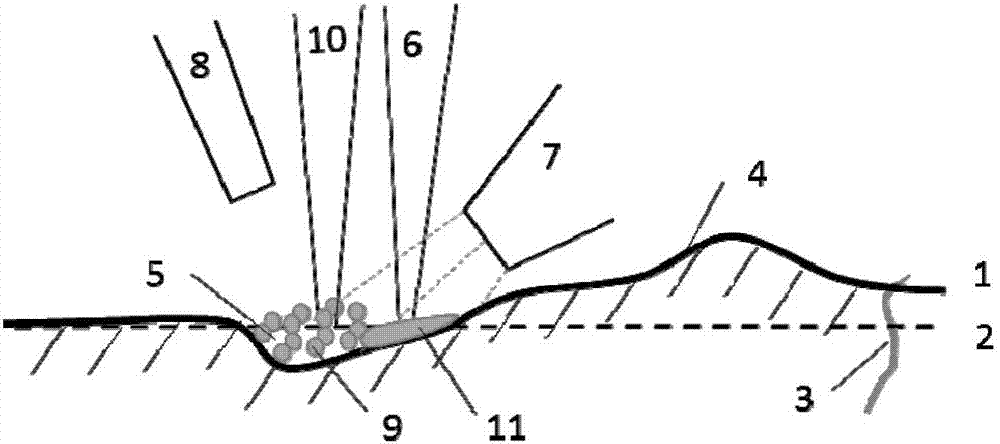

[0044] Such as figure 1 , a method for laser repairing and polishing ceramic parts, specifically comprising the following steps:

[0045] S1 cleans the ceramic parts and assembles the ceramic parts to the three-dimensional mobile platform;

[0046] S2 as figure 2 , scanning the surface profile (1) of the ceramic part, comparing the scanned profile model with the standard model (2), dividing the etching area (3), polishing area (4) and sintering area of the ceramic part surface District (5);

[0047] S3 processing the etched area with an excimer laser device;

[0048] S4 performs preset powder feeding on the sintering area, and uses the long-wavelength laser of excimer laser equipment to perform sintering repair;

[0049] S5 rough polishing the sintering area by using excimer laser equipment;

[0050] S6 uses excimer laser equipment for overall polishing of the processing area;

[0051] S7 scans the surface roughness of the ceramic part, if the roughness does not meet th...

Embodiment 2

[0053] The invention discloses a method for repairing and polishing SiC ceramic bearings with Nd:YAG laser and ArF excimer laser, which mainly includes scanning analysis, etching treatment, powder sintering treatment, rough polishing and overall fine polishing of SiC ceramic bearings. links. Specifically, as figure 2 shown, including the following steps:

[0054] ①Scan the three-dimensional mobile platform of the cleaned SiC ceramic bearing, use the microscopic detection unit to scan the surface profile of the bearing (1), compare the scanned model with the three-dimensional model of the bearing (2), and determine the etching area on the bearing surface (3) , Polishing zone (4) and sintering zone (5).

[0055] ②Set the parameters of the ArF excimer laser equipment (6), turn on the inert gas protection device (7), and remove the deep diffusion cracks by micro-etching for the deep cracks or deep pores on the material surface of the etching area (3) or pores, and then further...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com