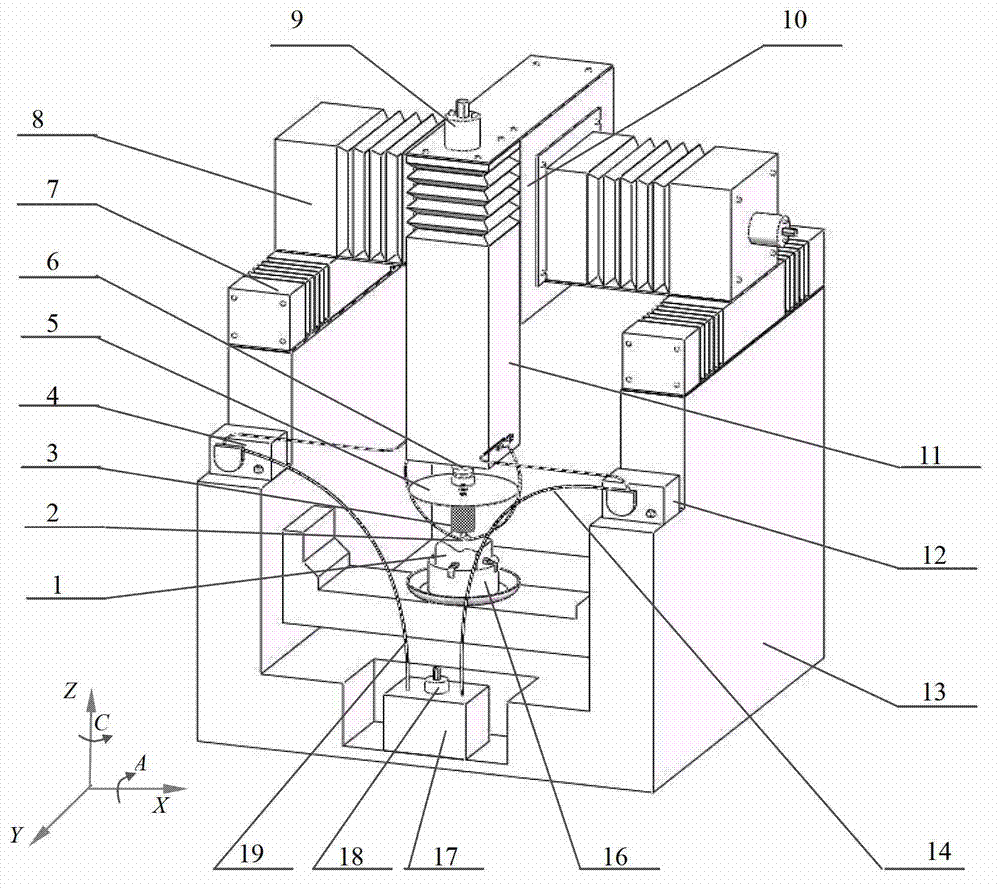

Constant pressure ultrasonic wave aiding magnetorheological finishing method and constant pressure ultrasonic wave aiding magnetorheological finishing device

An ultrasonic and constant pressure technology, applied in the field of intelligent constant pressure high-efficiency precision polishing, can solve the problems of unstable magnetorheological fluid, change of pressure in the processing area, single movement trajectory of the workpiece, etc., to achieve uniform removal, composition and The effect of uniform abrasive distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

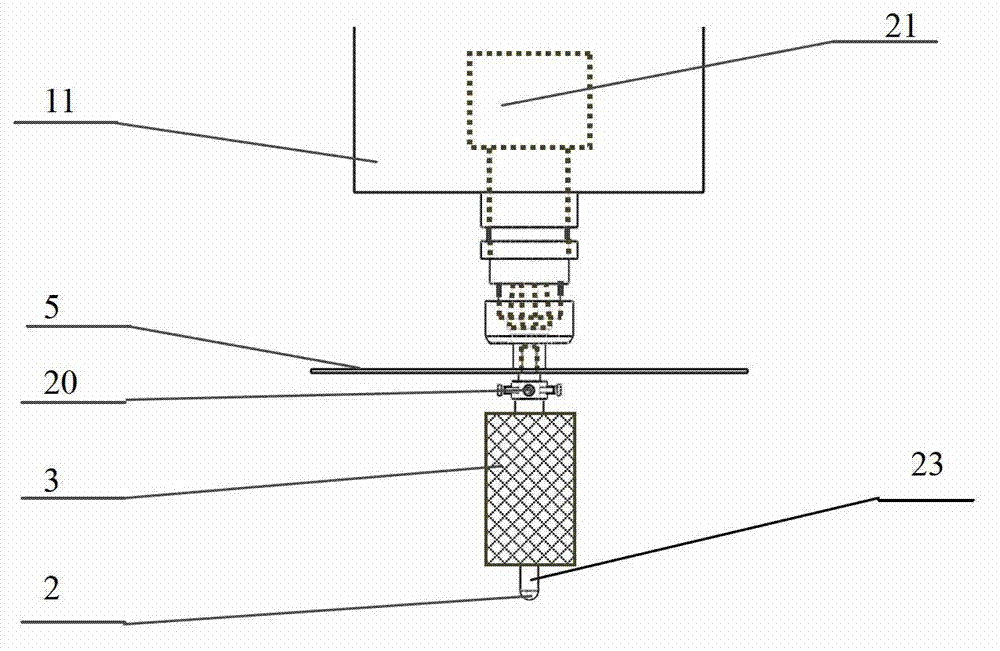

Method used

Image

Examples

Embodiment 1

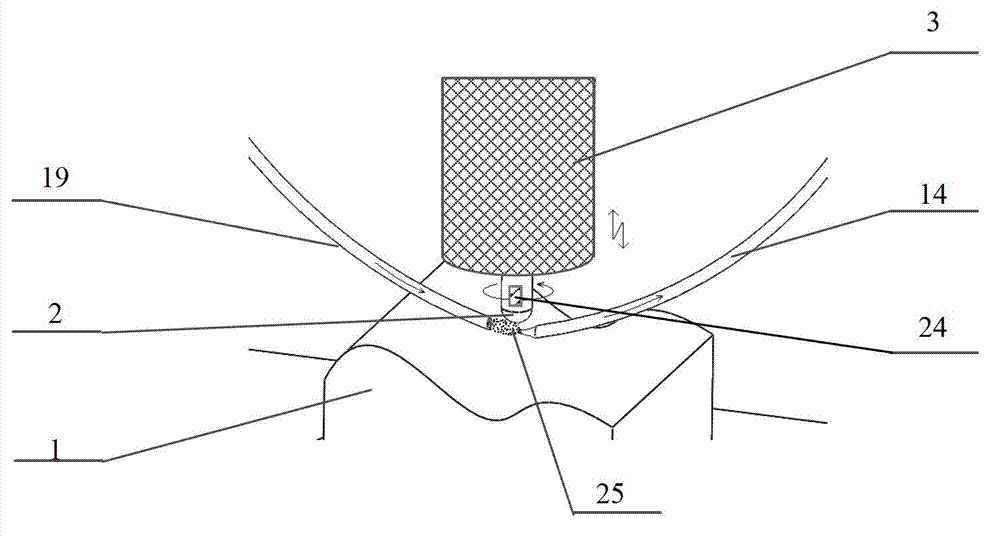

[0029] The ultra-precise magnetorheological polishing of the aspherical core (concave) with a caliber of φ8.4mm is completed by the method of the invention. The specific implementation process is as follows:

[0030] (1) Install the workpiece 1 after ultra-precision grinding on the rotary table 16, and the workpiece material is tungsten carbide cemented carbide;

[0031] (2) Drive the X, Y, Z-axis driving device to drive the main shaft to feed along the X, Y, Z guide rails, adjust the distance between the micro ball grinding head and the workpiece, so that a 5mm gap is formed between the two, and install it on the micro ball grinding head through the control system Threshold P of the load cell where the core of the electromagnetic coil protrudes above 1 and P 2 , P 1 =5N,P 2 =7N;

[0032] (3) Start the spindle to drive the micro ball grinding head to rotate, the speed of the micro ball grinding head is 12000rpm, and start the ultrasonic vibration device at the same time, ...

Embodiment 2

[0036] The ultra-precise magneto-rheological polishing of the glass-ceramic aspherical lens (convex surface) with a caliber of φ10mm is completed by the method of the invention. The specific implementation process is as follows:

[0037] (1) The workpiece 1 after ultra-precision grinding is installed on the turntable 16, and the workpiece material is glass ceramics;

[0038] (2) Drive the X, Y, Z-axis driving device to drive the main shaft to feed along the X, Y, Z guide rails, adjust the distance between the micro ball grinding head and the workpiece, so that a gap of 3mm is formed between the two, and install it on the micro ball grinding head through the control system Threshold P of the load cell where the core of the electromagnetic coil protrudes above 1 and P 2 , P 1 =2N,P 2 =2.5N;

[0039] (3) Start the spindle to drive the micro ball grinding head to rotate, the speed of the micro ball grinding head is 15000rpm, and start the ultrasonic vibration device at the sa...

Embodiment 3

[0043] The ultra-precise magnetorheological polishing of the aspherical prism (convex surface) with a caliber of φ2.6mm is completed by the method of the invention. The specific implementation process is as follows:

[0044] (1) The workpiece 1 after ultra-precision grinding is installed on the turntable 16, and the workpiece material is quartz glass;

[0045] (2) Drive the X, Y, Z axis driving device to drive the main shaft to feed along the X, Y, Z guide rails, adjust the distance between the micro ball grinding head and the workpiece, so that a 2mm gap is formed between the two, and install it on the micro ball grinding head through the control system Threshold P of the load cell where the core of the electromagnetic coil protrudes above 1 and P 2 , P 1 =1N,P 2 =1.2N;

[0046] (3) Start the spindle to drive the micro ball grinding head to rotate, the speed of the micro ball grinding head is 20000rpm, and start the ultrasonic vibration device at the same time, drive the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com