Magnetorheological polishing device suitable for ultra-large aperture optical processing

A magnetorheological polishing and optical processing technology, applied in the field of precision optical polishing processing, can solve problems such as low material removal efficiency, and achieve the effects of improving material removal efficiency, reducing system complexity, and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

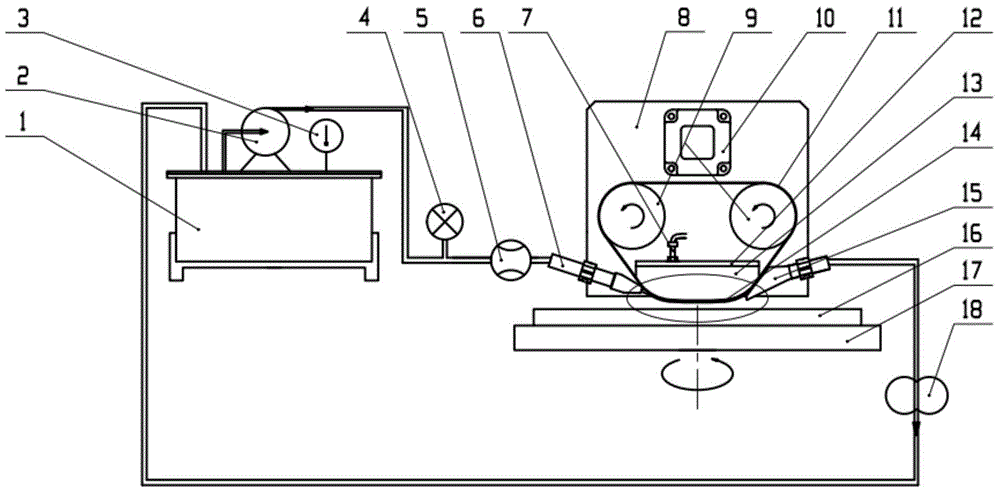

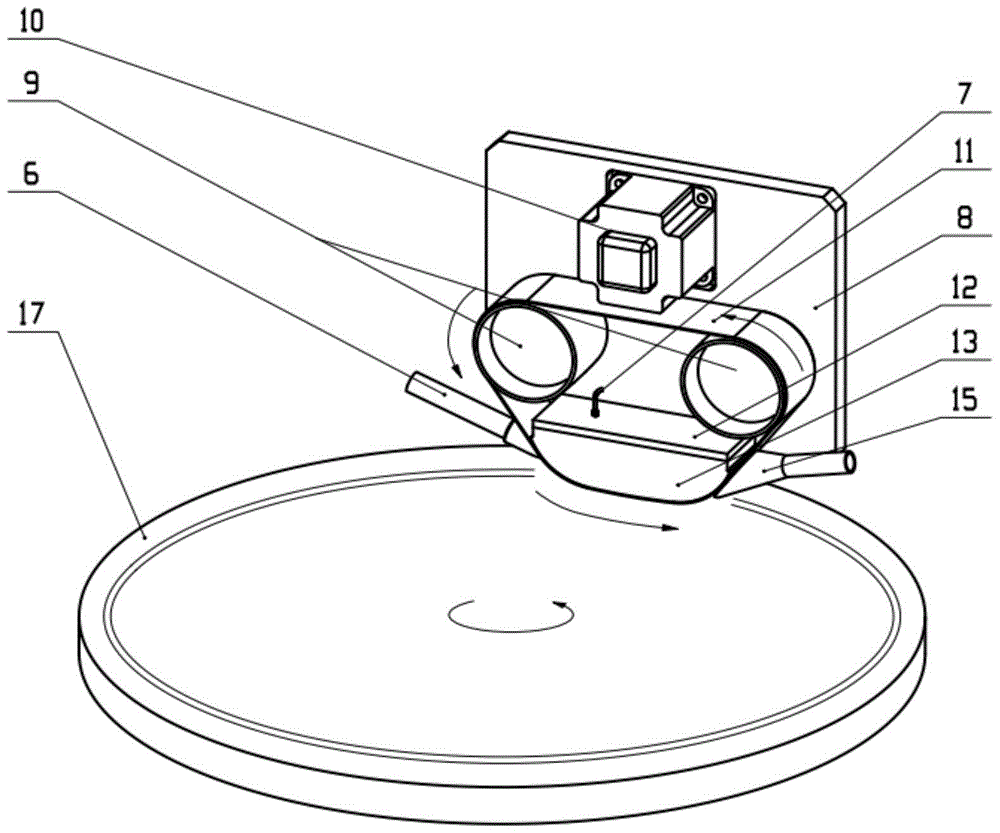

[0033] The inventive concept of the present invention is: for the approach of improving the polishing wheel linear velocity v, by the centrifugal force formula F=mv 2 / r (r=d / 2) It can be seen that under the condition of a certain magnetic field strength, that is, when F is limited, the larger the radius r, the larger the linear velocity allowed by the polishing wheel, and the higher the material removal efficiency. The magnetorheological polishing device of the present invention uses a novel magnetorheological fluid circulation method to improve the material removal efficiency of magnetorheological processing, so that the magnetorheological polishing technology can meet the processing requirements of large-diameter aspheric surface processing in the polishing stage.

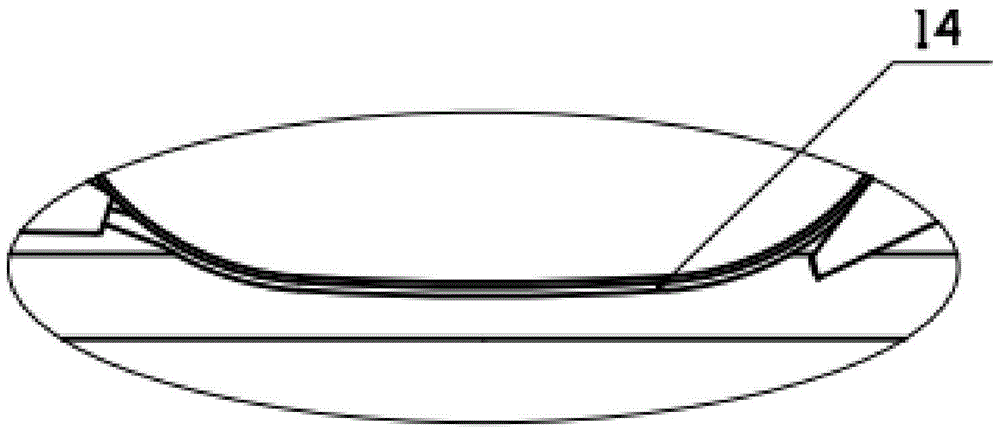

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] Figure 1-7 A specific embodiment of the magnetorheological polishing device of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com